- Home

- Collections

- SANDERS MJ

- Weddel's World

- Weddel's World 1977 - October

Weddel’s World 1977 – October

Weddel’s World

WESTFIELD

TOMOANA

PATEA

KAITI – in conjunction with Gisborne Sheepfarmers Freezing Co. Ltd.

QUARTERLY NEWSLETTER

ISSUED BY

W. & R. FLETCHER (N.Z.) LTD

October 1977

Kaiti upgrading on the move

The Gisborne Refrigeration Company’s new palletised cold store, being built on the wharf front of Gisborne harbour, is expected to be commissioned by January.

Work is well advanced on the project, which is being constructed in steel framed, polystyrene aluminium sandwich panels with a storage area of nearly 600,000 cubic feet.

The cold store complements the present cold store facilities and will allow the Kaiti works, run in conjunction with the Gisborne Sheepfarmers Freezing Company, to maintain the kill during the peak of the season.

It is being built on land leased from the Gisborne Harbour Board. Positioned a mere one hundred metres from the wharf loading area, this accessibility for loading out is ideal in the active port area.

One feature of the new cold store is an underfloor ventilation system which provides a natural air flow to prevent frost heave under the building

Air is allowed to flow under the insulated cold store floor through a series of hollow concrete building blocks set about a metre apart running across the 30 metre width of the 83 metre long building.

The store is being built by McMillan and Lockwood with the refrigeration equipment being supplied and installed by Ellis Hardie Syminton. The store was designed by Marks Stiles and Sedcole, Hamilton.

Other progress in the large scale upgrading of the Kaiti Works to meet the new hygiene regulations includes commissioning a two-bay truck wash.

All other requirements for the introduction of these regulations, including humane stunning and head inspection, were operating before their official introduction at the beginning of this month.

The erection of the new pump station for the works’ new effluent disposal system has been delayed by the extreme weather which caused serious rain damage in the city of Gisborne. However it is expected to be in use by the beginning of the new season.

Building tenders closed on October 17 for Kaiti’s new three-chain mutton slaughterhouse which will replace the existing building and form the next major stage in the construction programme.

Training Course

A highly successful conference for 28 training officers from the Meat Industry was held in Wellington in July.

Westfield’s staff and training manager, Owen Wood was a member of the working party responsible for planning and running the conference. Also included on the working party was the training officer from Kaiti, Don Johnston.

Other Fletchers training personnel who took part and contributed in no small measure to the conference were Bill Mischefski of Patea, Ken Hutchinson of Tomoana and John Graham, also from Kaiti.

The objective of the seminar was to assist training officers in their own development and in the planning of effective on-works training programmes.

Photo captions –

Looking down from Kaiti Hill on the new cold store.

The framework takes shape.

Laying the underfloor ventilation which will prevent frost heave under the building.

PROGRESS ON NEW TOMOANA CHAINS

Despite consistent bad weather during the winter good progress is being made on the extensive upgrading of Nelson’s (N.Z.) Ltd’s Tomoana works at Hastings, featuring the construction of a new six-chain mutton slaughterhouse.

Progress on the erection of the columns for the three storey building is well underway with already some 3,500 tonnes of concrete having been poured, and 250 tonnes of reinforcing steel used so far.

The next stage of construction involves the filling in of the ceiling of the new road access tunnel which will pass through the start of the slaughterhouse building, about under the legging table area.

The new roadway into the works has been started and to accommodate the greatly increased work force of contractors, Tomoana has been using another section of the paddock at the front of the works.

Another major change on the skyline is the steelwork for the new freezer block. The new unit, which features a blast freezing tunnel, will greatly improve the efficiency of this process with a capacity of handling the total daily kill in less than 24 hours, as opposed to the former system which at times stretched to two or three days.

Work on the construction of the new mutton unloading ramp is also progressing well, with the former ramps being taken out of service to allow for the new development of that area. As a temporary measure until the construction is complete, stock will be unloaded in the present pig unloading bay.

The first of the modified mutton chains to be operated until the commissioning of the new slaughterhouse for the beginning of the 1978/79 season has been trial run on mutton and lamb and has been temporarily used for the bobby calf operation.

The restraining conveyer [conveyor] on the chain is also operating as is the electrical stunning of stock as required by the new Hygiene regulations. All other chains and sticking facilities are to be altered before the start of the new season.

Other new facilities now in use include a new effluent recovery system, a transformer station and work on the main new saveall at the northern end of the works is progressing on target. The bar screen machine is to be relocated on the works side of the new saveall to remove large solids before entering the new system, which is basically a two scraper system, the lower bar removing solids while the top bar will skim off fat for reprocessing into tallow.

Photo caption – A rainbow hangs over the new mutton slaughterhouse complex as work continues during a recent break in the weather.

NEW WEDDEL MIDDLE EAST MANAGER

W. Weddel and Co’s manager for the Middle East, Mr J. S. (Stuart) Sharpe inspecting lamb carcasses at Tomoana with Nelsons (NA) Ltd.’s general manager, Mr Michael Sanders during a recent familiarisation tour of Australasia.

During his visit to New Zealand Mr Sharpe also toured the Westfield works and had talks in Wellington with W. & R. Fletcher management, shipping interests and other parties covering trade with the Middle East.

He also toured William Angliss works in Australia and met some of the group’s key personnel there.

In addition to the growing Gulf market, Mr Sharpe’s responsibilities extend to Egypt, Iran, Iraq, Saudi Arabia and Jordan, all markets growing yearly in importance for New Zealand meat exporters.

Brazilian Manager studies Australasian methods

The general manager of the Vestey Organisation’s Goiania freezing works in Brazil, Roger Beasley (right), inspecting some New Zealand cuts at the Westfield works with Neil Bridgland of the Production Department.

Mr Beasley had spent a month in Australia visiting the group’s William Angliss works, and other companies, comparing management controls and equipment in use in Australia before flying on to New Zealand.

After seeing the British Lions win the second test against New Zealand in Christchurch, Mr Beasley had talks in Wellington with senior Fletcher management, and also visited Westfield and Patea.

In Auckland he also saw Mr A. G. Brebner who was in charge of the construction of the Goiania works. While in Patea Mr Beasley renewed acquaintances with the works second engineer, John Weatherley, with whom he worked for a number of years in Brazil.

Mr Beasley joined Vesteys in London in 1958 and after one year in Britain was transferred to Brazil where he has worked ever since.

Vesteys operate three works in Brazil, killing mainly beef.

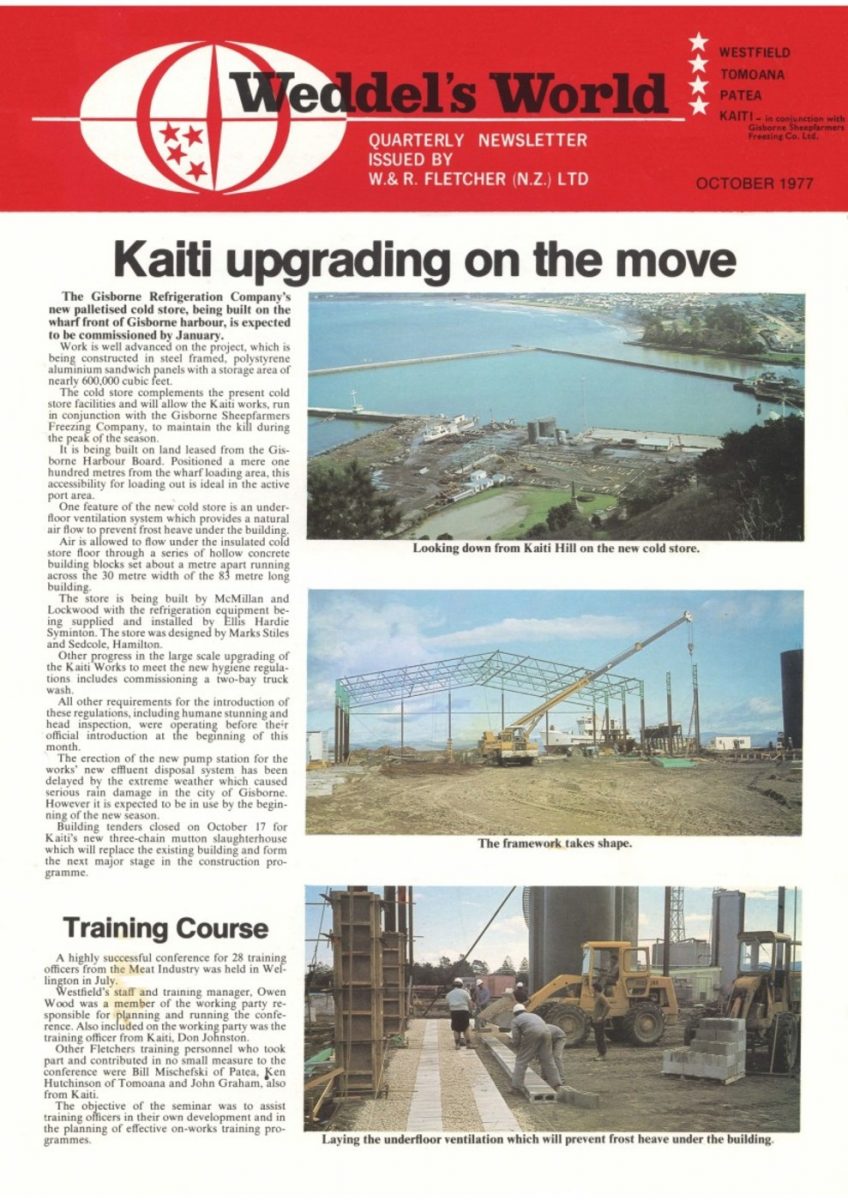

SUPPORT FOR NEW TOWN HALL

The Mayor of Wellington, Mr Michael Fowler, sees a major project come closer to fruition as he inspects a cheque for $4,000, the first contribution of a five year $20,000 commitment for the new Wellington Town Hall from W. & R. Fletcher (N.Z.) Ltd and Blue Star Lines.

The cheque was handed over jointly by Fletcher’s general manager, Mr Mark Hinchliff right and Mr Bob Whyte, New Zealand manager of Blue Port-ACT, acting on behalf of Blue Star.

Mr Fowler praised the two international companies for their involvement in the project to give Wellington a new Town Hall, and said he hoped the pledge would set the trend for involvement by many other companies operating in Wellington.

He said the fund raising was progressing on target and he expected the first stage of physical construction on the new complex to begin next year.

Mr Fowler said that he had seen Mr Edmund Vestey at the Union International Offices in London during his fund-raising tour earlier this year and had been impressed by Mr Vestey’s knowledge of the project.

Mr Hinchliff pointed out that Fletcher’s had had a long association with the economic growth of New Zealand and was pleased to be able to participate in a project that would be of great benefit to the country’s capital.

LIVESTOCK CORNER

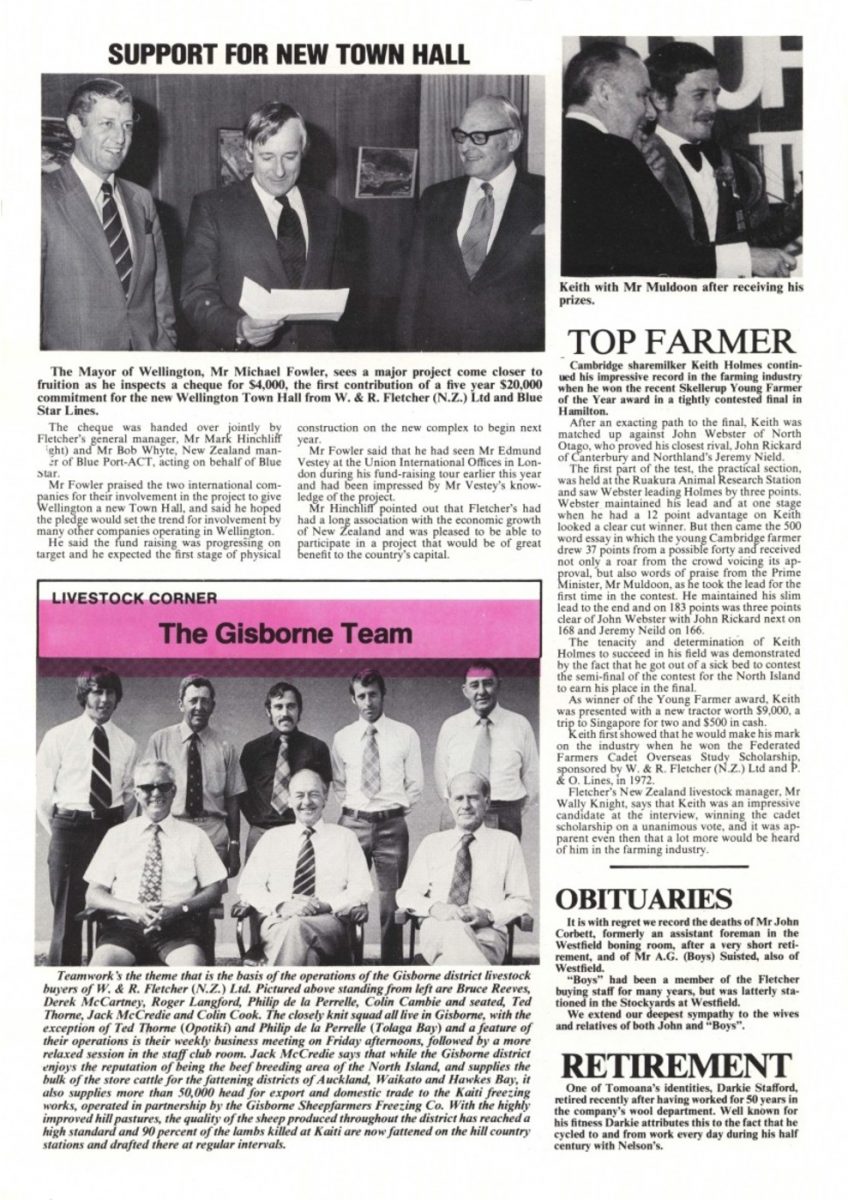

The Gisborne Team

Teamwork’s the theme that is the basis of the operations of the Gisborne district livestock buyers of W. & R. Fletcher (NZ) Ltd. Pictured above standing from left are Bruce Reeves, Derek McCartney, Roger Langford, Philip de la Perrelle, Colin Cambie and seated, Ted Thorne, Jack McCredie and Colin Cook. The closely knit squad all live in Gisborne, with the exception of Ted Thorne (Opotiki) and Philip de la Perrelle (Tolaga Bay) and a feature of their operations is their weekly business meeting on Friday afternoons, followed by a more relaxed session in the staff club room. Jack McCredie says that while the Gisborne district enjoys the reputation of being the beef breeding area of the North Island, and supplies the bulk of the store cattle for the fattening districts of Auckland, Waikato and Hawkes Bay, it also supplies more than 50,000 head for export and domestic trade to the Kaiti freezing works, operated in partnership by the Gisborne Sheepfarmers Freezing Co. With the highly improved hill pastures, the quality of the sheep produced throughout the district has reached a high standard and 90 percent of the lambs killed at Kaiti are now fattened on the hill country stations and drafted there at regular intervals.

TOP FARMER

Cambridge sharemilker Keith Holmes continued his impressive record in the farming industry when he won the recent Skellerup Young Farmer of the Year award in a tightly contested final in Hamilton.

After an exacting path to the final, Keith was matched up against John Webster of North Otago, who proved his closest rival, John Rickard of Canterbury and Northland’s Jeremy Nield.

The first part of the test, the practical section, was held at the Ruakura Animal Research Station and saw Webster leading Holmes by three points. Webster maintained his lead and at one stage when he had a 12 point advantage on Keith looked a clear cut winner. But then came the 500 word essay in which the young Cambridge farmer drew 37 points from a possible forty and received not only a roar from the crowd voicing its approval, but also words of raise from the Prime Minister, Mr Muldoon, as he took the lead for the first time in the contest. He maintained his slim lead to the end and on 183 points was three points clear of John Webster with John Rickard next on 168 and Jeremy Neild on 166.

The tenacity and determination of Keith Holmes to succeed in his field was demonstrated by the fact that he got out of a sick bed to contest the semi-final of the contest for the North Island to earn his place in the final.

As winner of the Young Farmer award, Keith was presented with a new tractor worth $9,000, a trip to Singapore for two and $500 in cash.

Keith first showed that he would make his mark on the industry when he won the Federated Farmers Cadet Overseas Study Scholarship, sponsored by W. & R. Fletcher (NZ) Ltd and P. & O. Lines, in 1972.

Fletcher’s New Zealand livestock manager, Mr Wally Knight, says that Keith was an impressive candidate at the interview, winning the cadet scholarship on a unanimous vote, and it was apparent even then that a lot more would be heard of him in the farming industry.

Photo caption – Keith with Mr Muldoon after receiving his prizes.

OBITUARIES

It is with regret we record the deaths of Mr John Corbett, formerly an assistant foreman in the Westfield boning room, after a very short retirement, and of Mr A. G. (Boys) Suisted, also of Westfield.

“Boys” had been a member of the Fletcher buying staff for many years, but was latterly stationed in the Stockyards at Westfield.

We extend our deepest sympathy to the wives and relatives of both John and “Boys”.

RETIREMENT

One of Tomoana’s identities, Darkie Stafford, retired recently after having worked for 50 years in the company’s wool department. Well known for his fitness Darkie attributes this to the fact that he cycled to and from work every day during his half century with Nelson’s.

WESTFIELD FIRE

Quick work by the Westfield Freezing Company staff and the Auckland Metropolitan Fire Brigade was instrumental in limiting the damage caused to the works, following the outbreak of a major fire in the engine room in July.

The fire was triggered off by what appears to have been a short circuit in the electrical switchboard and it spread quickly throughout the engine room putting all seven compressors and five boosters out of action.

The main electrical transformer supplying power to the plant was also affected resulting in a complete loss of power to most sections for two days until connections were restored.

Seventeen Auckland fire appliances and seven St John Ambulances together with their mobile cafeteria were on the scene soon after the fire broke out at about 8 pm. and at least half of the fire appliances were still at the works at daybreak the following morning.

Company tradesmen and outside contractors put in a “goliath” effort in working continuous shifts round the clock to restore refrigeration within 70 hours of the outbreak of the fire.

It was a great relief that, after a quick inspection of the thousands of tonnes of meat in store, it was found that temperatures had held and there was no damage to the product in store.

Through the tremendous effort of all those involved the plant was killing again within a week of the outbreak but it will be between six and nine months before the engine room is fully restored.

FAMILY TIES

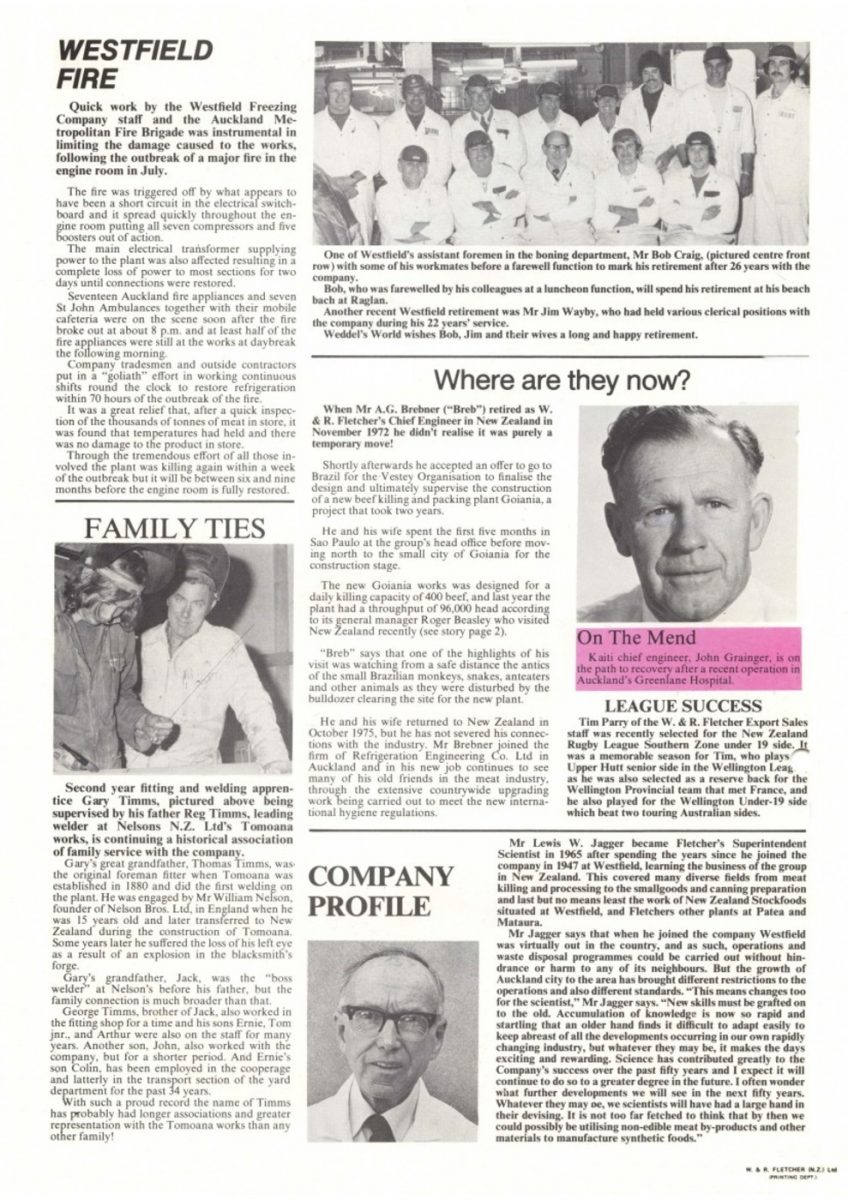

Second year fitting and welding apprentice Gary Timms, pictured above being supervised by his father Reg Timms, leading welder at Nelsons N.Z. Ltd’s Tomoana works, is continuing a historical association of family service with the company.

Gary’s great grandfather, Thomas Timms, was the original foreman fitter when Tomoana was established in 1880 and did the first welding on the plant. He was engaged by Mr William Nelson, founder of Nelson Bros. Ltd, in England when he was 15 years old and later transferred to New Zealand during the construction of Tomoana. Some years later he suffered the loss of his left eye as a result of an explosion in the blacksmith’s forge.

Gary’s grandfather, Jack, was the “boss welder” at Nelson’s before his father, but the family connection is much broader than that.

George Timms, brother of Jack, also worked in the fitting shop for a time and his sons Ernie, Tom jnr., and Arthur were also on the staff for many years. Another son, John, also worked with the company, but for a shorter period. And Ernie’s son Colin, has been employed in the cooperage and latterly in the transport section of the yard department for the past 34 years.

With such a proud record the name of Timms has probably had longer associations and greater representation with the Tomoana works than any other family!

One of Westfield’s assistant foremen in the boning department, Mr Bob Craig, (pictured centre front row) with some of his workmates before a farewell function to mark his retirement after 26 years with the company.

Bob, who was farewelled by his colleagues at a luncheon function, will spend his retirement at his beach bach at Raglan.

Another recent Westfield retirement was Mr Jim Wayby, who had held various clerical positions with the company during his 22 years’ service.

Weddel’s World wishes Bob, Jim and their wives a long and happy retirement.

Where are they now?

When Mr A. G. Brebner (“Breb”) retired as W. & R. Fletcher’s Chief Engineer in New Zealand in November 1972 he didn’t realise it was purely a temporary move!

Shortly afterwards he accepted an offer to go to Brazil for the Vestey Organisation to finalise the design and ultimately supervise the construction of a new beef killing and packing plant Goiania, a project that took two years.

He and his wife spent the first five months in Sao Paulo at the group’s head office before moving north to the small city of Goiania for the construction stage.

The new Goiania works was designed for a daily killing capacity of 400 beef, and last year the plant had a throughput of 96,000 head according to its general manager Roger Beasley who visited New Zealand recently (see story page 2).

“Breb” says that one of the highlights of his visit was watching from a safe distance the antics of the small Brazilian monkeys, snakes, anteaters and other animals as they were disturbed by the bulldozer clearing the site for the new plant.

He and his wife returned to New Zealand in October 1975, but he has not severed his connections with the industry. Mr Brebner joined the firm of Refrigeration Engineering Co. Ltd in Auckland and in his new job continues to see many of his old friends in the meat industry, through the extensive countrywide upgrading work being carried out to meet the new international hygiene regulations.

On the mend

Kaiti chief engineer, John Grainger, is on the path to recovery after a recent operation in Auckland’s Greenlane Hospital.

LEAGUE SUCCESS

Tim Parry of the W. & R. Fletcher Export Sales staff was recently selected for the New Zealand Rugby League Southern Zone under 19 side. It was a memorable season for Tim, who plays Upper Hutt senior side in the Wellington League, as he was also selected as a reserve back for the Wellington Provincial team that met France, and he also played for the Wellington Under-19 side which beat two touring Australian sides.

COMPANY PROFILE

Mr Lewis W. Jagger became Fletcher’s Superintendent Scientist in 1965 after spending the years since he joined the company in 1947 at Westfield, learning the business of the group in New Zealand. This covered many diverse fields from meat killing and processing to the smallgoods and canning preparation and last but no means least the work of New Zealand Stockfoods situated at Westfield, and Fletchers other plants at Patea and Mataura.

Mr Jagger says that when he joined the company Westfield was virtually out in the country, and as such, operations and waste disposal programmes could be carried out without hindrance or harm to any of its neighbours. But the growth of Auckland city to the area has brought different restrictions to the operations and also different standards. “This means changes too for the scientist,” Mr Jagger says. “New skills must be grafted on to the old. Accumulation of knowledge is now so rapid and startling that an older hand finds it difficult to adapt easily to keep abreast of all the developments occurring in our own rapidly changing industry, but whatever they may be, it makes the days exciting and rewarding. Science has contributed greatly to the Company’s success over the past fifty years and I expect it will continue to do so to a greater degree in the future. I often wonder what further developments we will see in the next fifty years. Whatever they may be, we scientists will have had a large hand in their devising. It is not too far fetched to think that by then we could possibly be utilising non-edible meat by-products and other materials to manufacture synthetic foods.”

W. &. R. FLETCHER (N.Z.) Ltd.

(PRINTING DEPT.)

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Business / Organisation

W & R Fletcher (NZ) LtdFormat of the original

LeafletDate published

October 1977People

- Roger Beasley

- A G Brebner

- Neil Bridgland

- Colin Cambie

- Colin Cook

- John Corbett

- Bob Craig

- Philip de la Perrelle

- Michael Fowler

- John Graham

- John Grainger

- Mark Hinchliff

- Keith Holmes

- Ken Hutchinson

- Lewis W Jagger

- Don Johnston

- Wally Knight

- Roger Langford

- Derek McCartney

- Bill Mischefski

- Prime Minister Muldoon

- William Nelson

- Jeremy Nield

- Tim Parry

- John Rickard

- Bruce Reeves

- Michael Sanders

- J S (Stuart) Sharpe

- Darkie Stafford

- A (Boys) G Suisted

- Ted Thorne

- Arthur Timms

- Colin Timms

- Ernie Timms

- Gary Timms

- George Timms

- Jack Timms

- Reg Timms

- Thomas Timms

- Tom Junior Timms

- Edmund Vestey

- Jim Wayby

- John Weatherley

- John Webster

- Bob Whyte

- Owen Wood

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.