“The Brewery has all the latest appliances for the manufacture of beers and cordials. Water is obtained through a four-inch well 251 feet in depth. The analysis of the water shows its chemical qualities to be specially adapted for the manufacture of beverages. Six men are employed in the brewery, which is a fine three-storey building and all its plant is arranged on the gravitation principle. The cellar is large and cool, and the bottling department is constructed of brick, ensuring an even temperature. The ales produced at this brewery are of a high character, delicate to the palate and for brilliancy and flavour leave nothing to be desired. They have been awarded several prizes and the leading hotels have them on tap.”

Some years later, Edward Newbigin changed his company’s name, this time to Leopard Brewery, to avoid confusion with the Burton Brewery in Palmerston North.

In 1956, Leopard Brewery was sold to Malaysian Breweries Limited, Singapore, who put substantial investment into expanding and modernising the plant and building.

1n 1966 New Zealand Breweries Limited bought a 50 percent interest in Leopard and in 1982, exactly a century after the brewery was founded, purchased the remaining 50 percent shareholding.

The Hastings Brewery is part of the New Zealand Brewing Group of Lion Nathan. It is one of four breweries Lion Nathan operates in New Zealand. Today the Hastings Brewery combines the traditional brewing process with high tech brewing and packaging equipment. Since 1988 over $14 million has been spent redeveloping the brewery site to keep pace with increased production.

The modern plant, together with technical expertise and the highest quality ingredients have resulted in beers produced by the brewery being recognised internationally with a number of awards. Most recently the brewery was awarded three gold medals at the Monde Selection in Brussels for Lion Brown, Rheineck and Leopard.

In September 1990 the Hastings Brewery became the first brewery in the world to achieve registration under the International Standards Organisation 9000 series, which establishes the strictest standards for quality systems. This was appropriate recognition for a brewery which for more than a century, has strived to maintain the highest quality standards.

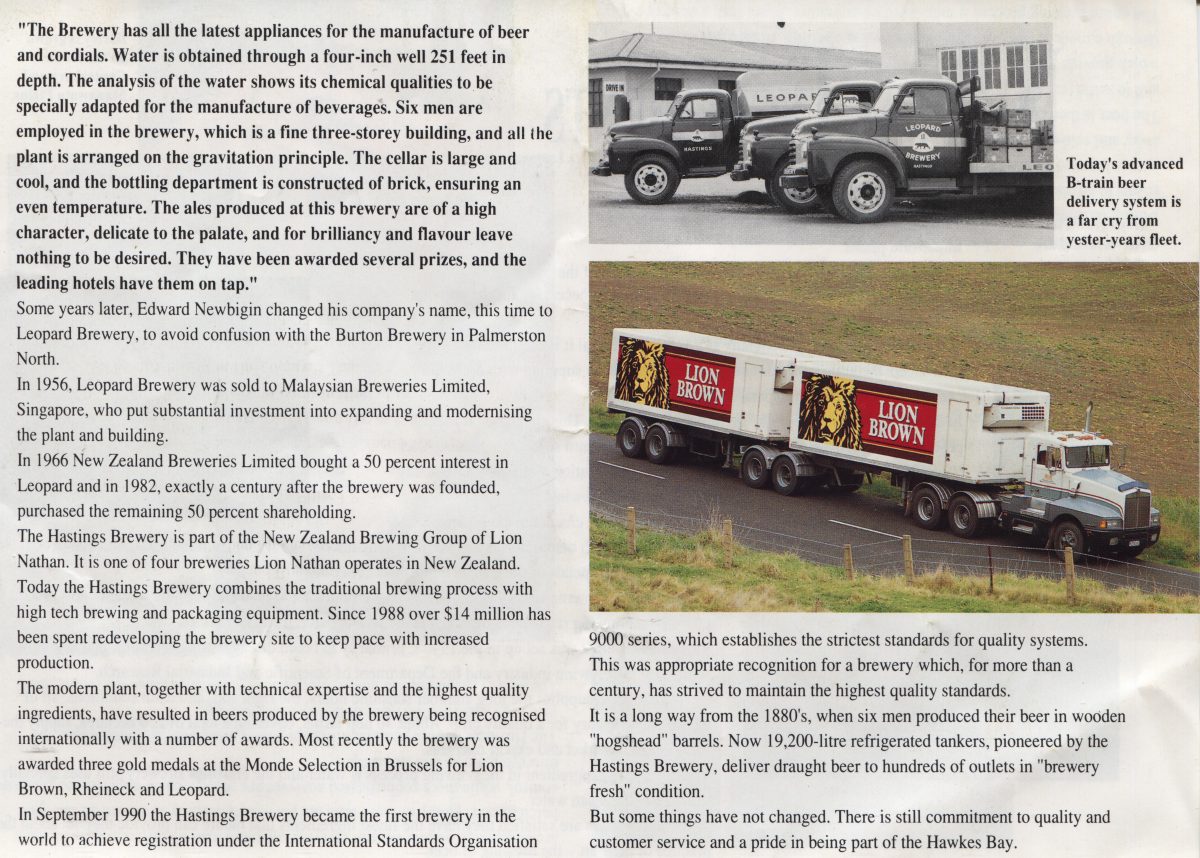

It is a long way from the 1880s when six men produced their beer in wooden “hogshead” barrels. Now 19,200-litre refrigerated tankers, pioneered by the Hastings Brewery, deliver draught beer to hundreds of outlets in “brewery fresh” condition.

But some things have not changed. There is still commitment to quality and customer service and a pride in being part of the Hawke’s Bay.

Photo caption – Today’s advanced B-train beer delivery system is a far cry from yester-years fleet.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.