- Home

- Collections

- EDLIN LA

- Canning By Wattie's

Canning By Wattie’s

Page 1

ACKNOWLEDGEMENTS

Our thanks are due to Mr T. Conway (Hastings) and Mr. R. Viney (Gisborne), each of the Horticultural Division, Department of Agriculture (N.Z.), for reports and statistics of the two areas.

Also, as industry does not grow to full maturity without co-operation, we take this opportunity of expressing thanks to the wholesale distributors:

Harrisons & Crosfield Ltd., England,

Harrisons Ramsay Pty. Ltd., N.Z.,

and our many customers within and beyond New Zealand.

Since the Company’s commencement we have received the greatest courtesy and assistance which has resulted in an association of mutual respect and confidence.

Written and Compiled by K. W. H. ELLICOTT, F.R.G.S.

Page 3

Food for the People

The whole world has been warned. The press, radio, and even the screen, have been used to indicate the rapid growth of population in excess of production. Throughout the world, organisations such as the United Nations and others, are designed to encourage science in the conduct of research that will help to solve the problem. Further, it is not only production, but distribution, that is equally important if distress and disaster are not to overwhelm the people. Such foresight is imperative, and a logical need wherewith to face the facts; the need to provide the world’s increasing millions with enough to eat. That part of distribution which concerns the preparation, packing and despatch of foods to anywhere in the world is largely confined to canning and freezing. These processes are an absolute necessity where consumption is gaining on productivity. From areas most favoured and suitable for particular foods, through processing, to the less favoured areas and peoples, there is a market demanding supply and variety which may never be satisfied. Therefore we have sound reasons for presenting the story of an industry which has a rightful place among the contributors of that essential need of man everywhere – good food.

Page 4

NEW ZEALAND

The Food Store

This Dominion has the largest productive capacity per head in the world. With nearly 90 per cent. of all production exported, it is the world’s second principal wool exporting country. Apart from wool, meat, dairy produce, etc, New Zealand has the climate and soil which enables it to be acknowledged as one of the world’s ideal food producing countries.

J. WATTIE CANNERIES

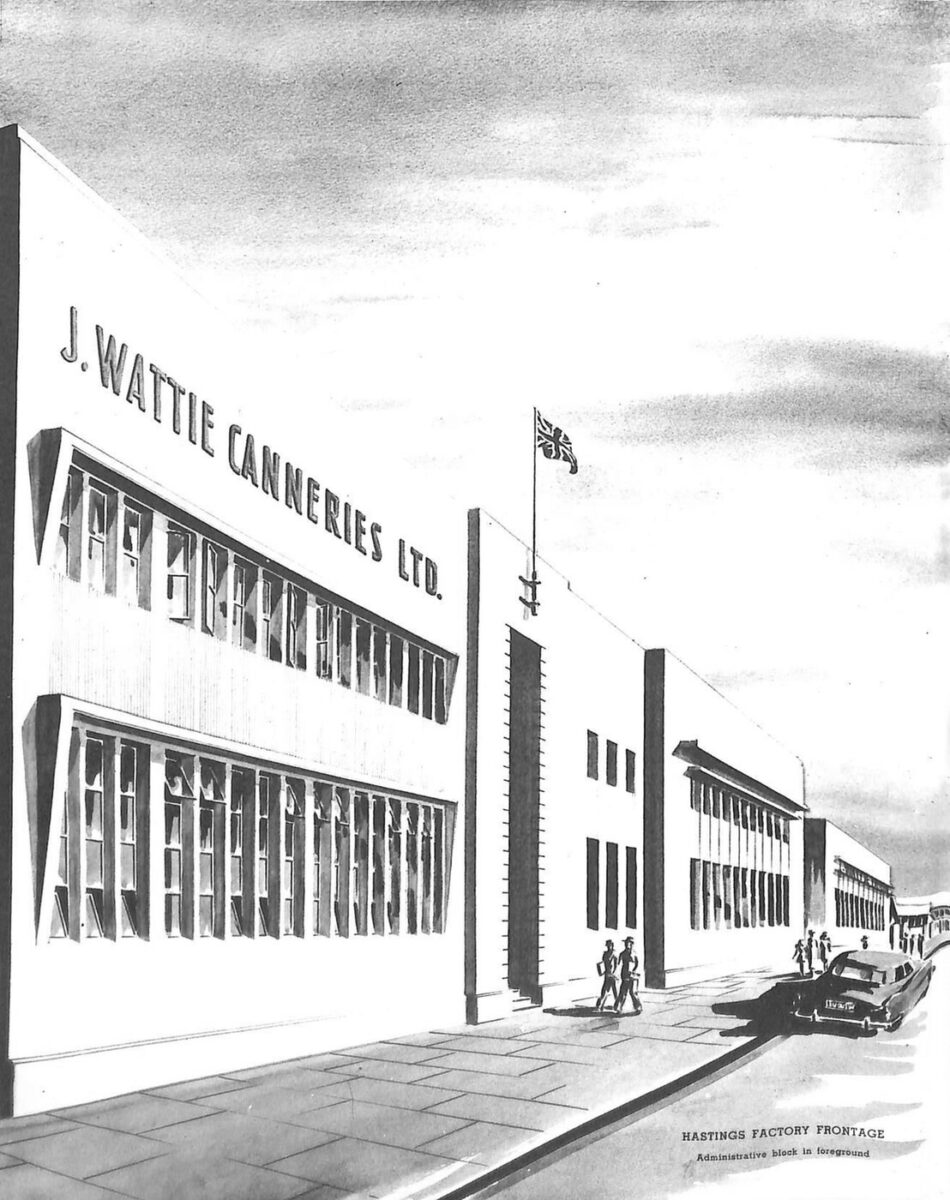

New Zealand’s export capacity includes a rapidly increasing volume of canned foods, grown under ideal conditions in regions of high fertility. The impact of canning and freezing processes on the national income is now immensely important to the country, and the prosperity of thousands of producers and workers depends upon our factories at Hastings and Gisborne.

Page 5

J. WATTIE CANNERIES LTD.

GROWERS AND PACKERS OF QUALITY FOODS

FACTORIES

King Street

HASTINGS

Mataroa St.

GISBORNE

NEW ZEALAND

Head Office: King Street, Hastings, Hawke’s Bay, N.Z.

MANAGING DIRECTOR

J. WATTIE

DIRECTORS

Chairman: J. Wattie

Deputy Chairman: A. I. Rainbow, O.B.E.

H. G. Carr A. F. Redgrave G. J. Wattie

Secretary: J. E. Clapcott

Managers: R. K. Wattie, Hastings; G. J. Wattie, Gisborne

Bankers: Bank of New South Wales, Hastings, N.Z.

N.Z. Auditors: McCulloch, Butler & Spence, Hastings, N.Z.

N.Z. Solicitors: Scannell & Bramwell, Hastings. N.Z.

Page 6

FROM THE MINISTER OF INDUSTRIES & COMMERCE

The canning of the products of the land, being a combination of both primary and secondary industry, is a logical activity for a country with a fundamentally agricultural economy. Twenty years ago the canning industry in New Zealand was mainly concerned with meat products, although some fruit canning was also undertaken. Today, a modern and well-equipped industry is engaged in canning not only the traditional items but also an ever-growing variety of vegetables and fruits for the home and export markets.

The great change which has taken place in the industry over this period is exemplified in this brochure, a story of enterprise, initiative and industrial and scientific development. The brightly labelled products of J. Wattie Canneries Limited are a familiar sight not only in the shops and homes of New Zealand but also overseas, particularly in the United Kingdom, where the Company has been successful in building up a steadily expanding market against world competition.

The Company is to be congratulated on its enterprise and it is with pleasure that I commend this brochure to all interested in New Zealand’s development.

Jack T. Watts

PARLIAMENT BUILDINGS, WELLINGTON

Page 7

INTRODUCTION

The following pages contain the outline of an industry which has its origin in the abundant production of two of New Zealand’s most highly favoured horticultural areas. As a food industry, it claims to fulfil an important role in the service of the country, and to maintain a high reputation for products of outstanding quality which this countryside grows.

For some time my fellow directors have expressed a desire to have a graphic account of the Company’s achievements, and now I hope that not only their wishes are satisfied. but that it will be of interest to many here and abroad who would like to know what can be done in a comparatively new but richly productive country.

My grateful thanks are due to all who have co-operated so well, the directors, shareholders, staff. growers and distributors. whose practical support it has been my privilege to enjoy throughout the years.

J Wattie

HASTINGS

Page 8

Nicholas Appert

1750-1841

The Pioneer of Canning

The method of food preservation by heat in a hermetically sealed container was one of the most dramatic events in industrial history. In 1795 the French Government offered a prize for an improved method of conserving food. The condition of loads and their distribution, especially to the army and navy of Napoleon, demanded urgent remedy. Nicolas Appert, born in 1750, had worked and experimented with food all his life, so he naturally gave attention to the offer. With no science to help him as a background, it was not until 1810 that M. Appert established a formula that food substances placed in tight containers, hermetically sealed, and subjected to a due amount of heat, would keep. This simple discovery depended on the use of only strictly fresh and sound materials, observing scrupulous cleanliness in preparation, and exercising the utmost care in closing the container, as well as in the application of heat. Methods then were extremely crude, and though he won the Napoleonic award, the full import of his discovery could not be grasped at the time.

Appert published his results from research on several occasions, and in 1814 demonstrated his methods in London, though the question of manufacturing satisfactory containers for widespread distribution was still unanswered. In time, an English company was formed with the aim of designing tin containers to take the place of bottles of the kind used by Appert. After much difficulty and loss, the makers were eventually successful, though for many years it continued to remain a small industry, even in Britain.

From this humble beginning the development of the canning industry became a leading influence in nineteenth century industrial expansion. In France, the United States, and Britain, the mere acceptance of a universally adopted method was only a lead to later experiments and discoveries. It is now that we find ourselves appraising not only the pioneer M. Appert, but all those salutory [salutary] effects which result from safer and better handled foods, as well as adding to the pleasures of the table.

Page 9

The Age of Knowledge and Progress

We are nearly 150 years ahead of M. Appert’s experimental adventures. The elaborate care given to processing and canning food today results from the advancing knowledge of scientists and engineers, from the time of Appert to the exacting demands of our ever changing world.

Photo caption –

THE HASTINGS LABORATORY, WHERE ALL PRODUCTS ARE TESTED FOR THE MAINTENANCE OF QUALITY AND FOOD VALUES.

Page 10

THE

Heretaunga

Plains

“A paradise of earth for one sweet sake” -Shelley

Hawke’s Bay province is situated on the east coast of the North Island, and its most closely settled and flourishing district is the flat Country on which Hastings is the natural centre. These are the Heretaunga Plains, the production per acre of which makes it New Zealand’s most important horticultural district. Indeed, the geographical advantages of this area are reflected in the climate, productivity and position of the Plains as to assume, without exaggeration, that this is one of the most favoured districts in the world. That part of the Plains associated with the growth of fruit and vegetables covers approximately 7000 acres, with an undefined but immense area for further expansion.

Soil and Climate

The rivers have contributed the rich alluvials, of which varied soil types favour the growth of particular fruits and vegetables, and much of the great success achieved by growers is due to early perception in selecting suitable varieties that thrive on these soils.

The Plains centred on Hastings occupy about 77,500 acres, and are formed on the site of an old sea-basin that was progressively infilled with sediments from the three rivers. These deposits now form mainly silt loams and sandy loams derived from sandstones, mudstones, and limestones of the foothills. Another source is the volcanic ash showers covering the headwaters of the rivers. It will be realised that silt and sandy lomes are characteristics of the area, and that pip and stone fruits, berry fruits and vegetables, are best adapted to the fertile Recent soils of these alluvial flats.

The latitude of the area is comparable with that of Central Spain or Southern Italy in the Northern Hemisphere, and as temperature and rainfall determine the living conditions of a country or district, the following averages over a period of years 1928-1950, supplied by the N Z. Government

Meteorological Service, are included. It should be noted that the recording centre is Hastings, the commercial centre of the Heretaunga Plains, which is only six miles from the Coast.

Average annual rainfall 31.25 ins.

Average No. of rain-days 126

Average bright sunshine 2,406 hrs (approx.)

Temperature in shade (deg. F’ht.):

Average annual mean daily maximum 66.8

Average annual mean daily minimum 44.9

Frost risk is limited compared with some other areas of similar production. Frosts at the right period are always welcome, and these are by far a general tendency. The rate of loss over long periods is relatively moderate, and the orchardist, apart from his necessary vigilance and preventative efforts, feels comfortably secure from the results of extremes. Only two frosts of exceptional severity have affected the whole area with loss, in 1910 and 1936.

But high fertility is not restricted to the Plains surrounding Hastings. There are valuable areas in the surrounding country, including central Hawke’s Bay, which offer sheltered valleys and good well drained soil depths to prospective growers. Indeed, the potential for expansion is sufficient to warrant a large influx of settlement that will share in the promise of production to growers and our canning industry in the years to follow.

Popularly known to New Zealanders as “Sunny Hawke’s Bay”, the province derives its main source of income from sheep farming, but so benevolent are the attributes of soil and climate on the Plains that the food producing industry is now vitally important to the national revenue. Our factory in Hastings, therefore, has all this line area of production at its “back door” offering an enormous potential for food supply and distribution – mankind‘s most urgent problem in the world today.

Page 12

The Triumph of Orchards

In 1909 apple growing was showing a promising return, though in the past many people had expressed the opinion that the district was unsuitable. Since then, orchards have been put down or expanded to such an extent that 1350 acres of apple orchard have produced almost 950,000 bushels. Another fruit grown in the district, of immense value to the canning industry, is the William Bon Cretien pear. There are 9600 trees of this variety in bearing, and 7900, at present non-bearing, are planted. A production of 70,000 bushels can result from a good season, yet the demand is such as to warrant a considerable increase of this commodity.

It soon became evident to orchardists that the district was second to none for apples; the premier district for pears and peaches in the Dominion, as well as being suitable for nectarines, plums and berry fruits. Nearly half a century ago an orchard of peaches, 60 rows of one mile long, was planted successfully by a pioneer of orcharding, Mr. J. N. Williams, and was known as Kaipo [Kaiapo] Orchard. He also founded the Frimley Canning Factory which ceased to operate in the year 1911 [1913]. Steady progress over the years has firmly established the fruit industry in this district, which now produces over 40 per cent. of the pip fruit of the country.

Pip Fruit and Stone Fruit Production

The following figures indicate the pip-fruit orchard capacity for the past four years of bushel cases delivered to the Marketing Department:

1949 1950 1951 1952

Apples 617,271 518,629 470,242 831,000

Pears 163,737 118,099 189,222 146,800

Total 781,008 636,728 659,464 977,800

Total quantities of stone fruit to all sources during seven years is as follows:

1945-46 437,000 ½-cases

1946-47 227,000 ½-cases

1947-48 635,000 ½-cases

1948-49 478,000 ½-cases

1949-50 228,000 ½-cases

1950-51 500,000 ½-cases

1951-52 560,000 ½-cases

Taking all fruits into consideration, it is the largest fruit producing district in the Dominion. This development has made a leading contribution to closer settlement, the economic importance of which is shown in the high degree of prosperity attained in less than fifty years. There are now more than approximately 700 registered commercial growers cultivating an area of over 6000 acres in fruits and vegetables as follows:

3450 acres in apple, pear and stone fruits; 3398 acres in commercial vegetables; 93 acres in berry fruits, and 500 acres in vineyards. But with young orchards in the making, and the factories expanding markets, these areas will be greatly increased in the near future.

To the observer from a height, say the Havelock Hills, the orchard country presents a magnificent view of fruit and sheltered trees. Clearly defined are the neat homes of orchardists surrounded by all on which they depend, as we, the canners, depend on them.

Photo captions –

DRIVEWAY TO THE CANNERIES FARM

A SECTION OF THE CANNERIES PEACH ORCHARD [next page]

Page 14

Canning the Answer

THE YEARS BEFORE WATTIE’S

Here was the fruit growing under ideal conditions, in such abundance that it was far in excess of demand. Quality and quantity had gone beyond the testing point of production value. The orchardist was gaining reward for his efforts, but grew dangerously complacent about the colossal waste which results from over-production and limitation of markets. For many years the grower suffered the effects of low prices, and there were some who were slow to respond to the advisory services and research offered by a progressive and efficiently conducted Department of Agriculture. But time and experience are very persistent instructors, and competitive growing forced the orchardist to meet the crisis which confronts all producers when deciding to “get on or get out”. It was then that difficulties strengthened the growers’ own organisation, the Hawke’s Bay Fruitgrowers’ Association, which has performed an important service in promoting fruitgrowing knowledge and in the protection of the industry.

MAN WITH A VISION

None was more conscious of the waste of excellent fruit than Mr. Wattie, who for some considerable time had realised the loss and prospective loss of surplus fruit. In his capacity as manager of Hawke’s Bay Fruitgrowers’ Ltd., a packing industry, Mr. Wattie had given considerable thought to the means of creating a market for processed fruits. He discussed with friends the prospects of pulping fruit for jam making. Soon he was able to attract the practical assistance of a few small investors, and it was from this small beginning that the prospect of canning was seriously considered. The original Company was registered in 1934 with a capital of ₤1250, subscribed by 28 members. The premises were leased from the Hawke’s Bay Fruitgrowers Ltd. for a period of five years, and the purpose of the Company was the pulping of fruit for jam makers, the first order being 81 tons of fruit pulp. During this momentous year in the Company’s history, some experimental canning operations were carried out with improvised plant, which was replaced in the fruit season of 1935 by what was then standard canning equipment purchased in Australia by Mr Wattie. Originally designed for the handling of peaches and pears, this machinery did not preclude the hand peeling and coring of fruit, as well as the hand halving and stoning of peaches, and not the least laborious method, the hand packing of each can. After processing the cans were hand stacked, and at a later stage each was again handled for labelling and casing. Cases were then hand nailed and stencilled. Despite these almost primitive methods the undoubted quality of the product was acknowledged by the extent of the demand, and considered to be the foundation of the company’s success.

In that first season there were 25 on the payroll, and the factory was a modest little establishment in a building which has been remodelled, part of which is now the First Aid centre. The variety of canned peaches was Golden Queen which to this day has proved outstanding in quality. As a result, subscribers were found with sufficient support to increase the capital to ₤10,000 by June 1935. Coincident with this increase the leased premises were purchased, and a policy of expansion with a basis of increased efficiency and high quality, was established.

Photo caption – THE FIRST FACTORY, 1934

Page 15

TESTING TIME

In 1936 there developed a crisis which strained the Company’s resources to the limit. The gale in February and the frost in October of that year had the most devastating effect on production. It was 26 years since the area had experienced such a frost. The peach crop was wiped out and only 10 per cent. of the pear crop remained. The Directors actually faced the question of closing down. By approaching the Company’s distributors, however, on the market for canned tomatoes, they in turn contacted the merchants and assured the Company it was well worth attempting. Contracts were let for 250 tons, and the whole pack was sold. Our thanks are due to the Distributors, Messrs. Harrisons Ramsay Pty. Ltd., for their cooperation.

In his report to shareholders at the third annual meeting of the Company in September 1937, Mr. Wattie went on to say that the Company possessed as up-to-date a plant as any in Australasia, with a capacity of 26,000 cans per 8-hour day. He was undaunted by the last season’s catastrophy [catastrophe], as the whole pack of peaches, pears, tomatoes and peas for the coming season was tentatively sold. He was convinced that though production was in the hands of the elements, the supplies that would be available in a few years, given reasonable weather conditions, would make the factory the premier canning concern in the Dominion. This Prophecy was to be completely fulfilled.

Still another prophetic development had its dramatic results. Work of a pioneering nature had produced small packs of peas and asparagus which had been enthusiastically received. Peas would necessitate the installation of special machinery and this plant was soon obtained. As opposed to the imported bleached type of canned asparagus, the Company processed this commodity green, and though nervous about its reception at first, it was soon evident that the market for this variety would be one of the most successful on the Company’s record. Extensive plantings were undertaken that year by Asparagus Ltd. and together with other contractors, production followed which established this commodity as a major line.

The crisis was passed, and out of it grew the vitality and initiative on which all progress is fed. It has rendered a service to the wills of men who were willing and able to shoulder the responsibility of trust, while the brighter prospects of the future were assured.

PLANNING BRINGS RESULTS

The story of our contribution to the canning industry would be incomplete without mention of the meticulous care required in planning to manufacture and market our products. Before the war, eighty per cent. of our canned goods were imported. This trade was considerably upset during hostilities, since after depending on our own resources we found ourselves with an expanded and prolific orchard and vegetable production together with a factory of unexcelled promise, geared and built to meet almost any demand from large scale commitments.

Until 1939 developments had been providentially timely, for by then the Company had already built progressively towards a large scale capacity, and was thus well prepared to offer its services when the conflict started. From the outset it was planned to ensure continuity of raw materials by entering into long term contracts which encouraged the planting of pears, peaches, asparagus and other products on an exceptionally larger scale. Growers are remembered by their industry and enterprise in a risk which resulted in so much mutual success and profit.

Again, it is the Company’s practice to call meetings of particular growers of products as well as combined meetings of all suppliers, when the Managing Director outlines the results of the past season and the needs and plans of the coming season. Every opportunity is also given to discussing problems with the Field Supervisor, who advises on methods of obtaining the desired standards of quantity and quality.

Photo caption – DIRECTORS: (Left to right) A. I. RAINBOW, H. G. CARR, J. WATTIE, J. E. CLAPCOTT (Secretary), A. F. REDGRAVE, G. J. WATTIE

Page 16

Service in Wartime

PRODUCTS ESSENTIAL TO VICTORY

The Second World War

Food for the people or food for the forces? Food at all times is a first thought, but conditions of wartime production demand supreme effort in field and factory. The Directors were prompt in appreciating the situation, realising that it was a duty to the country to give war production first consideration. New problems were faced and in every way met. New installations included the establishment of a Government dehydration plant – later to be purchased by the Company – and together with other new machinery, the factory quickly reached the production stage for the armed services which exceeded that of any other cannery in the country.

Dehydration of foods was a decision of the NZ. Government after experiments had been carried out by the Department of Scientific and Industrial Research. Our Hastings factory was the first to have a plant for this process installed, and a considerable variety of fruits and vegetables were thus made available for widespread distribution to the forces. The entire output of the factory during the war years was under the direction of the Food Controller, and the whole output until 1942 was disposed of by him to the British Authorities and thereafter to the United States Joint Purchasing Board. Our capacity even allowed for substantial quantities of canned goods for the home market. Long hours were worked, night and day shifts carrying on for seven days a week, while staff co-operation was acknowledged by every practical means, including a first class cafeteria service, first aid and welfare department, and generous bonus payments. Labour supply had become extremely difficult, so it is fitting to record grateful thanks to many women and girls from all quarters who counted their work as their contribution to the war effort.

THE CANNERIES FARM

In 1945 the Company undertook to farm 132½ acres of land at Mangateretere, four miles from the factory. This property now yields peaches, tomatoes and boysenberries of excellent canning varieties. There are over 2500 peach trees and 2300 pear trees, with nearly all the peach trees in full bearing, but the pear trees have not yet reached the bearing stage. There are also 18 acres of boysenberries which yield prolific crops.

Experimental Work

Besides being an important feeder to the factory, the farm is used for experimenting with new crops. Already much valuable research has been accomplished, and at present under test are a number of prune and apricot trees which were imported from California a few years ago. These trees are very promising and making good growth. Six years ago experiments were conducted with the growing of haricot beans for processing. The beans were formerly imported, but in the past two years enough have been grown locally to meet the factory‘s requirements, while the quality of these beans has now proved to be superior to the imported variety. In the season just ended 140,000 tomato plants were cropped. The farm staff consists of eight regular members, but during the harvesting season fifty pickers are employed.

Page 18

A process described – from field to can.

As numerous requests for a description of processing reach the office from various sources, we offer an outline of what happens to peas from cropping to canning.

HARVESTING

When our field supervisor decides that peas are in the correct stage of maturity for canning, the harvesting team with mobile harvesters moves on to the field. These machines gather the growing vines as they travel along, threshing the peas and delivering them into boxes for transport to the cannery, spreading the vines on the ground for ploughing in, thus enriching the soil by returning nitrogen.

In the 1953-54 pea season, the Company will own and operate the largest fleet of these mobile pea harvesters in the world.

CLEANING

The peas are led through a winnower and then through a water floatation [flotation] machine to remove extraneous material and over-ripe peas. Rod reel washers then apply high pressure water sprays while the reels rotate. The peas are then automatically pumped to the factory canning lines, at the head of which are the first inspection belts where members of the staff are skilled in discarding peas not up to standard as they pass along.

BLANCHING

Peas then pass through the blancher, where they are carried through in hot water at a controlled temperature. Among the reasons for blanching is shrinkage by the expulsion of gases contained in the plant cells.

This helps to obtain a high vacuum in the finished product, together with the proper fill of the cans. Alter blanching, the peas pass over another inspection belt and are then elevated to the hoppers on the filling machines. These machines fill a predetermined weight of peas and boiling brine to each can, thus ensuring the exclusion of air.

The cans are then mechanically conveyed to the closing machine, which double seams the tops. They are now ready for heat processing, which involves exposure of the sealed container to steam under pressure for a correct period of time. The aim is to ensure complete sterilisation which is carried out in large automatic pressure cookers. In these the cans are conveyed through a steam pressure chamber for a set period of time, and then on into a cooling section where they are subjected to cold water sprays. The cans leave the pressure cooker cooled down to 90 degrees F., and as they are still wet with cooling water they automatically pass through an air blast drier, leaving them in a suitable condition for labelling. The labelling machine is connected behind the can drier so that cans run continuously on through the labeller and into the automatic case packing machines. All that remains now is the lidding and wiring of cases or the glueing of cartons, which is carried out by the latest mechanical operations.

From the time that peas are harvested in the field, right through to labelling and casing, is a matter of only one and a-half hours. Such a short period is due to careful planning and the use of up-to-date machinery. The quality of the product is assured by this rapid process, as it is well known that once the peas are harvested they begin to lose their sweetness and food value. Thus only the best food in the best condition is good enough for canning.

Page 19

Harvesting the Crop

The combination of time, power, and skill, is the key to successful harvesting. The teams are assembled at an appointed time, and their operational speed enables quick supply of the product to the factory in its freshest and best condition.

Pea Harvesting

One of the outstanding contributions to farm economics on the Plains has been the cropping of peas. Hawke’s Bay farmers have come to realise the exceptional benefits to the soil of this rotational crop by the increase of nitrogenous content. Tomatoes and beans are also contributive by this rotational practice. In quality and quantity, the grasses, particularly the renowned Hawke’s Bay Rye Grass, thrive to an exceptional degree, thus completing the rotational cycle.

Photo captions –

SHOWING FORMER METHOD OF LOADING PEA VINES WHICH WERE TRANSPORTED TO THE FACTORY FOR THRESHING

THE MOST MODERN MOBILE HARVESTERS ARE NOW OPERATED BY THE COMPANY – COMBINING HARVESTING AND THRESHING IN ONE COMPLETE OPERATION

LOADING PEA HODDERS FOR IMMEDIATE TRANSPORT TO FACTORY

Page 20

GOLDEN QUEEN

peach of quality

Canned peaches have universal appeal, and are extensively produced in the U.S.A., Australia, and South Africa, as well as in New Zealand. There are a number of acceptable varieties, but this did not prevent the introduction of another which has become an outstanding contribution to the delights of the table anywhere – the Golden Queen. Its origin appears to have been in Tauranga, in the Bay of Plenty fruit growing area on the east coast of the North Island, and was either raised or located in 1909 by Mr. Berridge, who was in charge of a Government experimental station. Mr. Berridge interested the late Mr. D. Hay, a nurseryman of Auckland, who sent his foreman to Tauranga to get all the buds from the tree, and to dig it out. The budding wood was cut off and packed in a box, well watered, and received in Auckland the following day. The leaves were cut off and budded without delay, which could be considered exceptionally quick work for those days. The demand at first was limited, as it was treated as just another new peach. It was apparently introduced to the Hawke’s Bay district about the year 1918, thus making the approximate supply date 1923. In 1934 several orchards in this area had a number of trees, grown as a bottling peach of great popularity. The attention of Mr. Wattie was drawn to the possibility of canning this late season variety of the yellow clingstone. An immediate and agreeably surprising demand led to a marked change in orchard development, which was stimulated by the Company’s contract growing system. This season, 1952-53, 82 per cent. of all late varieties planted are Golden Queen, while 90 per cent. of all late varieties processed are of this variety. There are 20,000 Golden Queen trees bearing which produce 120,000 bushels, and a further 12,000 non-bearing are planted. Yet the success of this delicious fruit does not preclude the possibility of other attractive canning varieties, for the Company is ever mindful of the necessity to keep abreast with the food “fashions” of tomorrow. At the same time, other suitable varieties could profitably extend the period of peach canning to lighten the load on availability of space and equipment.

Page 22

PROCESSING PEACHES

Maturity is closely watched at picking time. Prompt delivery to the factory is then absolutely essential to canning the product at its best. The machines pit about 90 peaches per minute, or approximately 35 lbs. per minute through each machine. One man can keep two automatic feed machines supplied.

TIPPING PEACHES INTO HOPPER OF AUTOMATIC FEEDER

PACIFIC

PEACH PITTING MACHINES WITH LATEST AUTOMATIC PEACH FEEDING ATTACHMENT

PACIFIC ROTARY PEACH PITTING MACHINE

Page 24

The TOMATO CROP

Tomato growing is one of the most exacting operations in the industry, due to dependence on good climatic conditions. It is a product which demands the closest attention to spraying and careful cultivation. It is also an extremely popular item as Tomato Puree, Tomato Soup, Tomato Sauce, etc.

Photo captions –

TOMATO PICKING ON THE COMPANY’S ESTATE

CARE IS TAKEN TO HARVEST THE CROP AT THE RIGHT TIME, ENSURING QUALITY IN THE FINISHED PACK

Page 25

James Wattie

Like so many New Zealanders, his adaptability was acquired from early association with the soil. His father was a farmer in North Canterbury, where he was born in 1902. The family then settled in Hawke’s Bay in 1915, where his school career was followed by a position with the Fruit, Produce and Cool Store Co. Ltd., then on ground now included in the Hastings factory site. In 1917 he joined the clerical staff of the H.B. Farmers’ Meat Co. Ltd., remaining 8 years, during which time he studied accountancy. In 1925 he was appointed Secretary of the H.B. Fruitgrowers Ltd., and soon became Manager, holding that position until 1934, when he began his first canning venture.

Since then, he has devoted all his energy and initiative to the origin, development and achievement of the Company. Extensive travel, an aptitude for making friends, and his keen observation, have done much to establish the Company’s success in the Dominion and overseas. Indeed, his contribution to commerce has provided a link in the chain of New Zealand’s enterprise.

– K.W.H.E.

Page 26

Our Gisborne Factory

The Company Expands

In 1951 the Company decided to establish a factory in Gisborne, the centre of a district particularly well suited for the production of sweet corn and peas, with additional prospects by way of exceptionally good soil and climatic conditions for extensive production at fruits and vegetables similarly grown on the Heretaunga Plains. Indeed, some authorities predict a production value as great or even greater than that of Hawke’s Bay. There are many geographical features common to both districts, such as hills protecting flats to the coast, sheep country, and comparative river formations.

CLIMATE

The warm temperature climate of Gisborne is well suited for the production of horticulture crops. Official statistics for 13 years (1937-50) give the average annual temperature at 57 degrees, while the average annual sunshine recorded is 2284 hours. The average annual rainfall for the district is 39.75 inches, but this is of varying distribution. There are 35 annual average number of days of ground frost, and an average annual number of 147 rain days. Wainui district, situated on the coast about 4 miles south of Gisborne, is entirely free of frosts, while the Ormond district has only very light frosts.

Page 27

SOILS

Soils of the Gisborne flats vary considerably in type but the majority have a high fertility. Most types are alkaline to slightly acid, but do not require lime, and have a very high potash and high phosphate content. Most of the soil in and around Gisborne itself is of a pumice and sandy nature, but with green manuring and the use of fertilisers some excellent crops are produced. Owing to its free draining structure it is particularly suitable for winter and spring vegetables, and comprises about 5000 acres. The Gisborne flats, built up from the Waipoa [Waipaoa] River, cover an area of 52,000 acres.

POTENTIAL DEVELOPMENT

Horticultural practice is in its infancy in this district, but in a few years thousands of acres will be devoted to these crops. One of the main factors restricting full land utilisation is the danger of serious flooding which occurs in some seasons from the Waipoa River. With the Flood Control scheme now approved and to be carried out as a priority, the high promise and potential production of this district is assured. A more specialised and intensive type of farming will be expected, while climate and soil make it possible for the successful growth of fruit and vegetables equal to, and sometimes surpassing, those grown elsewhere in the Dominion. At least half of the area which is liable to flood damage is suitable for horticultural crops, and although an increase in land values may be expected with successful flood control, this will be offset by larger per acre earnings. At least 10,000 acres of first class land, previously subject to flooding, are likely to be made available.

MARKET GARDENING

In 1920 the area devoted to market garden crops was 60 acres, and by 1948 this area had been increased to 439 acres. By 1952 this area was further increased to 1500 acres, mainly due to the establishment of our Gisborne factory. In the first year the cannery processed about 1000 acres of sweet corn, from which an average yield of 4 tons per acre was harvested. In more favourable areas yields of up to 7½ tons per acre were obtained. In 1953 approximately 2500 acres were producing market garden crops, and of these 1000 acres of peas, 550 acres of sweet corn and 80 acres of tomatoes, were grown for canning purposes. It is confidently expected that market garden crops will continue to increase considerably, and that other crops, such as asparagus and beans, will be grown more extensively.

Photo captions –

SWEET CORN AT ITS BEST

HARVESTING SWEET CORN

Page 28

PIP FRUIT

The average production in 1953, taken over a period of 6 years, was 37,237 bushels of apples and 4356 of pears. There are several new orchards planted under the Rehabilitation Scheme which have not yet commenced production. The district is well suited for pip fruits, quality and yields being comparable to Hawke’s Bay, where up to 1000 bushels per acre are produced in favourable seasons. Production is by no means sufficient to meet the demand, and increased plantings of suitable varieties would be well worthwhile.

STONE FRUIT

In 1953 the estimated production of stone fruit was 9700 bushels of peaches, 1200 bushels of nectarines, and 1150 bushels of plums. Again, demand far exceeds supply even for local requirements. Peaches and plums mature 7 to 10 days earlier than in other districts, and although increased plantings of early varieties appear to be worthwhile, other varieties should be planted with caution due to the possibility of over supply at some periods. Growth of trees, quality, and yields of stone fruit are comparable with Hawke’s Bay, and increased plantings suitable for canning should be considered. Plantings of Golden Queen peaches for the factory are expected to yield highly promising results.

Establishment of the Factory

GISBORNE 1951

A valuable site was acquired from the Gisborne Sheepfarmers’ Frozen Meat and Mercantile Co. Ltd., together with a leasehold property from the Gisborne Harbour Board. A short time later the property of Clare and Clare, adjacent to the main factory building, was purchased. The complete area covers approximately 6½ acres, and is situated by the waterfront, with its own rail siding adjoining the coastal harbour facilities. Though in the commercial area, this exceptionally valuable site is only a matter of five minutes’ walk from the centre of Gisborne. All buildings are new and well lighted, equipped with the latest labour saving machinery, an up-to-date analytical laboratory, staff cafeteria, and modern administration offices. There is ample room for expansion to meet future needs, and the modern water conservation plant assures all demands by the erection of 8 storage tanks with a total capacity of 80,000 gallons.

The factory was officially opened on Saturday, 2nd February, 1952. The staff were brought from our Hastings factory by special train. A large and representative gathering including the Mayor of Gisborne and the local Member of Parliament together with representatives from all local bodies, was also present, as well as local shareholders and members of the wholesale and retail trades. The factory went into full production immediately, and the season’s operations resulted in a total of 4,172,000 eleven-ounce cans of sweet corn. This was followed by the canning of minced beef loaf, which reached an output of 3,321,000 cans. This season, 1952-53, this factory has produced new varieties, including boysenberries and asparagus. Pea production this year has reached 3,309,458 cans of ll ounces, sweet corn 2,763,332 cans, as

Page 29

well as additional lines of tomato products. The maximum number of employees has reached 240 over each of the past two seasons.

At present there are 80 growers supplying the factory, many of whom are now planning to increase their areas for the coming years. The encouragement derived from the establishment of the factory has introduced a new conception of land use, a new economic factor to the district, and has already added new wealth and more prosperity to another of New Zealand‘s most favoured areas.

It should be realised that the factory began with all the advantages of experience and administration that were contributed by the parent establishment in Hastings. The factory site is ideal and the producing area outstanding. Growers are encouraged to expand and prosper with the facilities offered by the Company, which spares no effort in assisting development in every possible way. Also, it is grateful for the help and ready co-operation extended by the farmers’ own organisations, together with those public bodies and their officers immediately concerned with the development of an industry which has brought to Gisborne a new asset in keeping with its natural and material progress.

Photo caption – GISBORNE FACTORY NEAR HARBOUR ENTRANCE

Page 30

GISBORNE FACTORY SCENES

1. Corn elevators speed delivery to the Factory’s husking machines.

2. Harvested corn arrives at receiving yard by Company’s fleet of trucks.

3. Corn passes through automatic husking machines before processing.

4. Laboratory tests are conducted by using the latest equipment.

This superbly built factory offers ideal working conditions. It has a large cafeteria with excellent food service.

Page 31

LOADING WATTIE’S PRODUCTS FOR THE UNITED KINGDOM

TRANSPORT

By road, rail and sea, and even by aeroplane, the Company depends on every means of carriage for its incoming and outgoing goods and services. Imports include machinery, thousands of tons of tin plate, installation material, and a host of other items necessary to canning and packing. In 1953 no less than 9474 tons of canned fruit, meat and vegetables were exported to the United Kingdom or distributed throughout New Zealand by rail or coastal vessels. Dressed boards for cases and cartons are other important and large items for transport. Milled timber for cases arrives in planed parts, which are assembled at the factory. The value of these goods alone, purchased during 1953, amounted to ₤77,465, involving transport services to an exceptional extent for New Zealand factory demands. The Company owns and maintains a fleet of 20 motor vehicles, as well as harvesting and other machinery for the field.

Page 32

Overseas Markets

At the conclusion of the war production period, every opportunity had to be taken to use the highly developed plant now available for large scale commercial use. The home market was assured, but the remaining plant, formerly required in field and factory for military production, was in excess of requirements. With the addition of further equipment, plans for re-organisation were made with the aim of trading overseas. In April, 1946, Mr. Wattie left on his first visit to the United States and Great Britain, which was more in the nature of a survey. It will be understood that the post-war reconstruction period had barely begun, and that any assessment of the market was extraordinarily difficult under conditions governed by controls. Another visit in 1948 resulted in substantial orders being obtained in Britain, though a dramatic check to prospects occurred when the exchange rate between New Zealand and the United Kingdom was cancelled. In due time the situation was rectified by satisfactory adjustments, the value of products exported to Britain that financial year amounting to £154,799. In 1949, Mr. Wattie again visited these countries accompanied by the Deputy-Chairman, Mr. A. I. Rainbow, a visit which did much to increase the goodwill of overseas associations already made. A further visit by Mr. Wattie in 1952 included Australia, where he travelled considerable distances to observe orchard and canning developments. It is gratifying to note that the Company’s 1953 financial accounts record £626,884 worth of overseas sales. Mr. Wattie visited the United Kingdom again this year, 1953, and large orders for the coming season have been obtained.

The results from these visits are incalculable. Orders in terms of money may reflect success, yet personal experiences, associations, and friendships made, do much to strengthen the bonds of Commonwealth. Moreover, they are the only means of establishing confidence and understanding of the marketing conditions overseas.

EXPERIENCE TEACHES

In 1950, Messrs. Gordon Wattie and Ray Wattie, sons of the Managing Director, travelled extensively in the United Kingdom and U.S.A., in order to study production methods. Their experiences included several months of practical work under the normal conditions of employment in similar factories. Mr. Gordon is now Managing Director at Gisborne, and Mr Ray is Manager of the Hastings factory.

Page 34

Figures that Count

The following amounts indicate the rapid expansion realised by the Company over a period of seventeen years.

1936 1953

Turnover £13,447 £1,404,411

Plant £4,684 £297,799

Buildings £7,932 £164,305

Wages and Salaries £1,835 £235,199

There were 766 employees during the peak period of last season.

SEASON 1939-40 1940-41 1941-42 1942-43 1943-44 1944-45 1945-46 1946-47 1947-48 1948-49 1949-50 1950-51 1951-52 1952-53

UNITS IN MILLIONS 1.65 2.05 4.85 4.91 7.09 10.21 6.95 10.0 14.15 15.9 15.54 14.34 25.9 24 .7

SEASON 1935-36 1936-37 1937-38 1938-39 1939-40 1940-41 1941-42 1942-43 1943-44 1944-45 1945-46 1946-47 1947-48 1948-49 1949-50 1950-51 1951-52 1952-53

TONS 159.1 116.3 422.0 493.1 1034.2 1433.4 2538.7 3205.7 5057.5 8148.0 4048.6 6489.7 7786.5 7464.0 6497.4 5813.2 9828.1 9782.2

The whole production during the 1939-45 war period was governed by the Food Controller.

Australia, our strongest competitor, which has the advantage of 25% since exchange alterations were made, has not affected the increase in demand for our products.

BIRDS EYE FOODS (N.Z.) LTD.

Before commencing operations in Hawke’s Bay, the proprietors of this deep freezing process made a survey of other districts in New Zealand, where canning factories were operating. Hastings was chosen as being the most suitable centre from a production point of view. The plant was installed on the premises of J. Wattie Canneries Ltd., and the first pack was produced in December 1946, on the co-packer principle as practised in the U.S.A., which includes the joint staff arrangement.

Page 35

CANNING by Wattie’s

By the assembly of facts and photographs, we have tried to present a record of our achievement in the canning industry, and we have not refrained from telling of difficulties and seasonal problems, which were surmounted by an energy and determination no less vigorous or effective than that expressed by many of the Elizabethan adventurers of another expansive age. As with them, our existence depends on the resources and initiative of our natural endowments, and though the same tests of justification and endurance are common to most industries in all parts of the Empire, we venture the opinion that New Zealand is now primarily and geographically important to world markets, and that our own factories have not been the least impressive contributors.

That the Company was justified and rewarded for its enterprise is now beyond question. The quality of its products is the measure of its success. There is now no limit to our exportable capacity. The Company has at its disposal the railway and shipping facilities which a large industry needs, while production is planned years ahead to satisfy future markets.

The Company’s policy is clear. The application of the most modern machinery and methods, the promotion of good conditions and welfare safeguards for employees, and the maintenance of the highest quality in all products. As Mr. Wattie so aptly expressed it, “You cannot get anything better out of a can than you put into it.” Again, without stressing any claims to distinction, our two large establishments are firmly rooted in the national economy. They directly influence and encourage the growing of high grade fruits and vegetables returning to growers an attractive reward for their industry. They are leading customers of transport services, as well as employers of hundreds of full and part time workers. Also, they preserve and distribute the excellent products of a richly fertile countryside for the health and pleasure of the consumer in peace, or for the forces of the nation in war. Though in a position to render the country vital national service in a time of crisis, we trust that such a need will never occur again. On the contrary, our industry will flourish by the extension of local and overseas markets, the demands of which are founded on assurances by those who are highly expert in food marketing.

Page 36

The Staff Responds

The Company has been exceptionally fortunate in engaging staff throughout the years which appears to realise the immense promise of these growing and canning districts. The rapid development of these regions has attracted a large number of skilled and seasonal workers who not only appreciate the conditions of the industry, but soon adapt themselves in the varied occupations it offers. Some members have been with the Company from the beginning, while others continue to add their years of association in increasing numbers.

Both factories are well equipped with modern cafeterias which offer meals and services at the lower cost. Excellent social clubs are organised by the staff, and provide a wide range of activities which include film evenings, dancing, picnics, sports, such as basketball, cricket, and indoor games. Particular consideration is given to hospital patients who are sent flowers, tobacco, and other gifts through club committees. The Company, apart from providing facilities to assist, contributes in various ways to the success of the clubs. Staff co-operation has been a consistent feature at all times, and the Company appreciates the fine working spirit which has always accompanied that strenuous period – the peak of the season. That the staff in turn has been mindful of its happy association has been expressed on several occasions, one of which gives a practical example as illustrated. We look forward with every confidence to that continuous goodwill which is founded on the sincere loyalty and accord of past relationships.

CAFETERIA

FIRST AID ROOMS

Produced by Pictorial Publications Ltd., Hastings Printed by Swailes Printing Co., Ltd.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Business / Organisation

J Wattie Canneries LimitedFormat of the original

Book hardbackCreator / Author

- K W H Ellicott

People

- Nicholas Appert

- Mr Berridge

- H G Carr

- J E Clapcott

- T Conway

- K W H Ellicott

- D Hay

- A I Rainbow

- A F Redgrave

- R Viney

- Gordon J Wattie

- James Wattie

- Ray Wattie

- J N Williams

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.