- Home

- Collections

- JUNE LI

- Harvest 01 - October 1957

Harvest 01 – October 1957

HARVEST

VOL. 1 NO. 1

PUBLISHED BY J. WATTIE CANNERIES LTD.

HASTINGS & GISBORNE

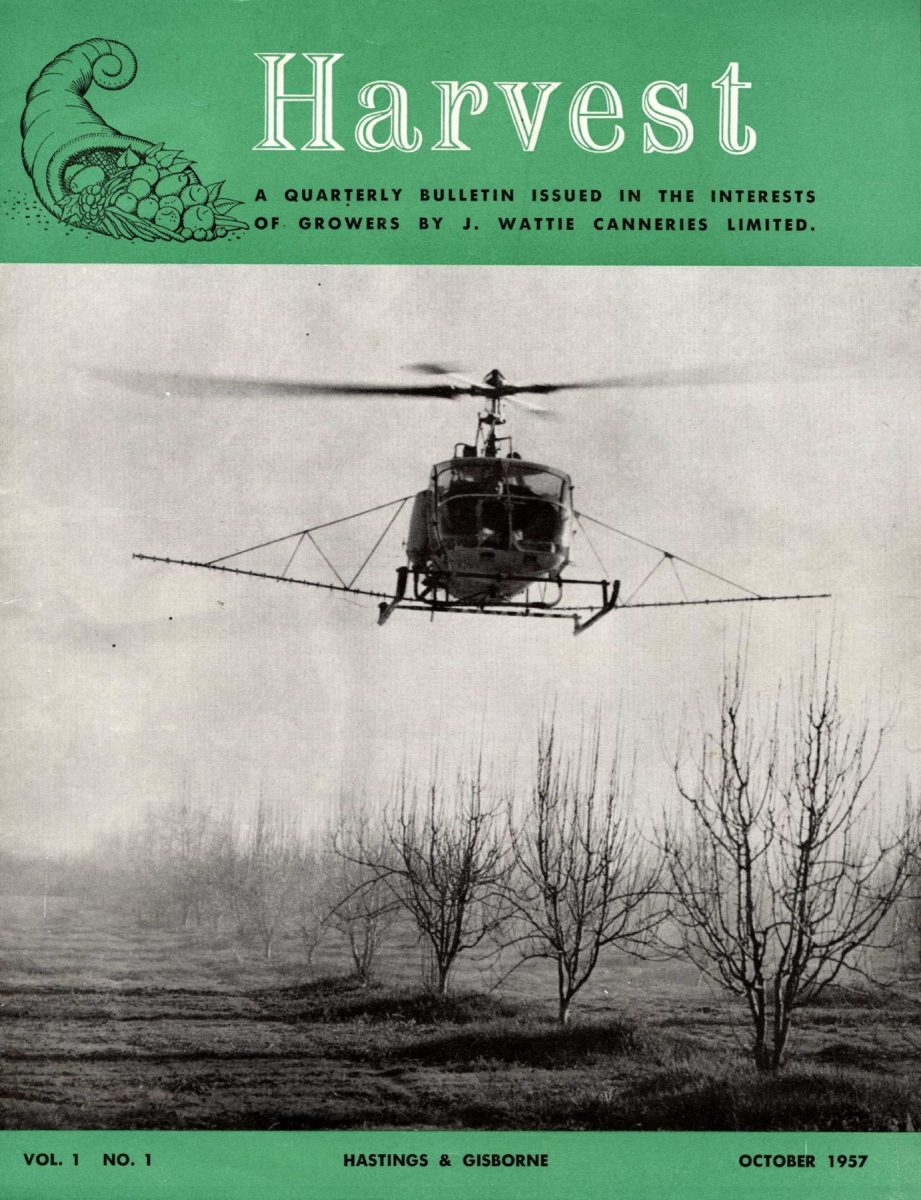

OUR COVER

Shows a helicopter, for the first time in New Zealand, spraying a J. Wattie Cannery orchard during September, 1957.

FOREWORD

BY THE CHAIRMAN OF DIRECTORS

I am pleased to write this foreword for the first issue of our Growers’ Bulletin.

A publication of this kind, by relaying to growers news and helpful information about the food processing industry, will provide a very important service.

Science and invention are continually bringing about changes and improvements in all departments, including horticulture, which directly concerns you as growers and us as processors. Better varieties of seeds, fertilisers, cultivating methods and labour saving machinery are constantly being discovered. It is essential, therefore, that we all keep abreast of the times; and really this is not so difficult because today knowledge is freely available. In fact, those who possess the latest information are happy to pass it on. This small bulletin can well be a suitable medium for reporting to our growers such advice and information. If it achieves that much it will be making a valuable contribution to all sections of our industry and to the nation we jointly serve.

Those responsible for its compilation could receive not greater reward.

J Wattie

CHAIRMAN OF DIRECTORS

Introducing Our First Issue

The idea of a newsletter or bulletin to growers has been considered for some time. With the tremendous and interesting expansion being experienced by this company at the present time, we would like our growers to feel closely identified with our successes. After all, if we as food processors expand, we can do it only if growers are willing to produce the necessary material. We are and must always be closely associated.

It says much for the close co-operation of grower and the factory, when after more than twenty-three years, we are still able to continue without the necessity of written contracts of any kind. Growers know they are free and welcome at all times to talk over any problem. We have few changes among our growers, and most of you are not only growers but friends, and our business with you is carried out on a friendly basis.

Growers’ meetings are always of great value, and we will continue to have one each year. These meetings give the grower and processor an opportunity for discussion.

We hope these bulletins will keep us in closer contact throughout the year. If you have any points of interest you think worthy of passing on to your fellow grower – let us know; we will be happy to feature it.

It is hoped to keep these notes topical and of interest to both fruit and vegetable growers, and we trust they will be appreciated.

Yours sincerely,

Bob June

Aerial view of the factory of J. Wattie Canneries Ltd., Hastings.

J. Wattie Canneries Ltd., Introduce

Something NEW in Spraying….

A few weeks ago, for the first time in New Zealand, fruit trees were sprayed from the air by helicopter here in Hastings. Since then further trials on fruit trees and vegetable crops have been undertaken. The conclusions are that spraying by this method can be carried out successfully and economically.

The first trial on peach and pear trees was carried out on our No. 1 Farm at Mangateretere. Winter oil was applied at fifty gallons to the acre. The strength used was a 4% mixture of red oil at 3X concentrate – in other words, 12 gallons of oil in 100 gallons of water. Seventy two jets were used of varying sizes to give a fairly fine droplet size, and 12% gallons were applied in each of four runs over a given area.

Three rows at a time can be covered comfortably and an acre can be covered in four minutes, including mixing and filling.

Magenta dyed cardboard squares were used to record spray pattern in all parts of the tree. We were pleased to find the pattern very even and at least comparable to conventional concentrate sprayers by ground application.

Very little information on helicopter spraying could be gleaned from any source. Applications by conventional concentrate sprayers were used as a basis. Ideas from our own experience, from Helicopter Services Ltd., who did the spraying, and from officers of the Horticultural Division, were pooled. The rest was a case of trial and error.

CONCLUSIONS:

The first trial showed that coverage on the upper part of the tree was satisfactory, but the base and underside of the larger limbs were not sufficiently covered to give good red mite control. Further trials with a change in technique will be necessary.

Much useful information was gleaned, however, and in this respect the trial was well worth while.

Photograph, showing the helicopter which was used in the spraying of fruit trees on No. 1 Farm at Mangateretere.

Left to Right: P. Marshall, pilot, E. Shakespeare, Farm Manager, R. J. June, Field Supervisor and J. Wattie, Chairman of Directors.

Spraying with a Turbomist Concentrate sprayer, now used extensively in NZ.

SECOND TRIAL:

The second trial, using copper sprays was tried on twelve acres of our own farm again. A three times concentrate was again used and coverage this time was more satisfactory, as it was not so necessary to cover the underneath portion of the tree. The aim was to cover the buds for leaf curl control. Although it is too early to see if perfect control was obtained, we feel very confident that it will be entirely satisfactory.

OTHER CROPS SPRAYED:

Several crops of broad beans have recently been sprayed by the same helicopter. A fungicide and an insecticide were applied to the broad bean crop to prevent the development of rust and aphis.

Two different application rates were tried and it is felt the one with finer nozzles and a greater output of liquid per acre was the most satisfactory, with up to 24 gallons of liquid per acre.

THE FUTURE OF HELICOPTER SPRAYING:

We have great confidence in the future of this method of spray application. It has many features to commend it.

Space does not permit enlarging on this at the moment. We are fortunate to have this machine based in Hawkes Bay. It is owned and operated by Helicopter Services Ltd., and we wish to thank them for their co-operation in these trials.

In the coming season many of our canning and freezing crops will be sprayed by this means. They will include more work on broad beans and fruit trees, and also trials on tomatoes, potatoes and for weed control in peas.

Weed Control in Pea Crops

Hit-or miss methods in weed control among pea crops – common until a few years ago – have changed to something approaching a fine art. Today, there need be very few failures.

For the past few years D.N.B.P. sprays have been used almost exclusively in the District, with a few trials of M.C.P.A. But during the past season large scale trials of a new material, M.C.P.B., have given very heartening results.

THE NEW MATERIAL:

M.C.P.B. was developed in England and very closely resembled M.C.P.A. It is a hormone spray requiring care where drift on to susceptible plants such as grapes and tomatoes might be encountered. From the operator’s point of view, it is much safer and quite pleasant to use, compared with the old “yellow peril” of D.N.B.P. It is also cheaper.

In the sap stream of certain plants are found enzymes which can break down M.C.P.B. into M.C.P.A. It is actually the broken down form which causes the typical twisting hormone effect, eventually killing the plant. Most weeds contain this enzyme while peas do not; bringing about the selectivity.

USES:

Crops other than peas which are tolerant to M.C.P.B. include potatoes, cereals, grasses, red and white clovers, carrots, celery, parsnips and lucerne. In our trials on peas, we found it gave good control of fat hen, nettle, shepherd’s purse and cornbind. Californian thistles were knocked back so that they were no trouble in the crop. Nightshade, or berry weed as we frequently call it, where sprayed early, was controlled fairly well in most cases. Similarly, wild turnip was controlled only when sprayed before any stem started to form. Docks were well and truly checked and seedlings were killed altogether.

Good weed control of wild turnip (Sinapis Arvensis) with D.N.B.P. Unsprayed portion on the right shows the density of the weeds before spraying.

Spraying peas with a 30 ft. boom. Note the outrigger wheel and spray marker on the extreme left. The boom projects only 8 ft. from the truck on the driver’s side. Booms fold along side of truck when not in use.

THE ANSWER TO PRINCE OF WALES:

Up to the present time the worst weed to control has been Prince of Wales Feather (Amaranthus Retroflexus). Provided the spray can be applied at an early stage of the weed growth (say up to two inches high), control can be obtained very economically and completely. This now makes possible the production of peas in many areas where contracts would not be accepted before because of the known presence of this weed.

More experimentation, however, will be required on the control of nightshade. No crops for processing in Hawkes [Hawke’s] Bay were lost because of the presence of nightshade last year. The M.C.P.B. gave sufficient check to prevent the formation of berries at harvest time. However, in seed crops and in other districts this was not the case. As we have only had one season’s trial it is too early to make definite recommendations. Each crop will have to be assessed at spraying time. Where there is an abundance of nightshade and no prince of wales feather, D.N.B.P. will undoubtedly be recommended. If prince of wales is predominant we will recommend M.C.P.B. and if necessary follow up with D.N.B.P. where the nightshade is not controlled.

Many growers will no doubt be wanting to use the new material themselves, because it can be applied at lower water rates, and also because there is no health hazard.

There are some very efficient contractors available in Hawkes Bay at the present time and application costs are reasonable.

Rates below 15 gallons of water per acre are not recommended; 20 gallons will be used by contractors. The material can be used from 2¼ to 3 pints per acre according to type of weed and time of application.

Different brands of M.C.P.B. have different concentrations, so growers should watch this point. They vary from 3 to 4 lbs. acid equivalent per gallon, so allowance will have to be made for this. Because the amount of water is reduced by about half compared to D.N.B.P., application costs by contract will be less.

A minimum of 14 rows in the headlands is required to allow room for the turning of trucks. When 4-row planters are used, 16 – row headlands should be planted.

On the outside 4 rows of the headlands the corners should be gradually rounded to allow the pickers to harvest the crop while turning, and the remaining rows of the headlands should be squared at the corners. By these means damage in harvesting is reduced to a minimum.

WEED CONTROL:

Spraying for weed control should be carried out in all crops unless they are entirely free from weed. This is not only to afford the crop complete freedom from competition from weeds, but also to assure reasonably clear paddocks for future cropping.

Spraying of corn crops should be carried out before cultivation and when the plants are from 4” to 6” high. Later spraying not only definitely retards crop development and greatly reduces production, but also causes malformed cobs that give excessive waste when processing. These effects become progressively worse with the lateness of sprays.

Corn at the early stages mentioned will not be affected by the application of up to 1½ pints 24D of 4 lbs. a.e. per acre, and in general not less than 1 pint per acre should be applied.

CULTIVATION:

Every endeavour should be made to carry out 2 cultivations before the corn gets too high: the first at a stage when the hormone sprays have had a chance to be effective and the second when the corn is from 12” to 15″ high. Under general conditions these will benefit the crop and assure weed control. Moulding of rows should be avoided as it is unnecessary and causes difficulty in harvesting, in that the hmoulds are inclined to control the run of the tractor.

CONTROL OF PESTS:

Cutworm, Wire – worm and wheat – stem borer are prevalent in most parts of the district and although as yet no set course has bheen followed in prevention of damage from these pests it is fast becoming obvious that some action is vital.

Methods of prevention suggested are: -(A) Overall ground treatment with 2 lbs. 50% wettable D.D.T. powder mixed in 1 cwt. superphosphate; or (B) Applying 1 lb. 50% D.D.T. powder mixed with ¼ to ½ cwt. superphosphate – through the manure boxes of the planter at sowing; or (C) Spraying into and along 6” each side of the furrow made by the planter before covering in takes place with 1 lb. 50% D.D.T. to acre.

VARIETIES:

Up to 1956 practically all corn grown was Golden Cross hybrids, and while good production was obtained from these it was considered that improved varieties could give higher production, make for easier harvesting, and also be of greater value for processing.

In 1956 some 12 varieties were planted in trial areas and from these, 4 varieties were selected for further trials on a commercial scale. A fairly large area of Golden Cross will be grown this year, but also 6 other varieties will be grown commercially, and 8 varieties in row trials. It is hoped to select 2 or 3 varieties that will give high production, be readily harvested mechanically and be equally suitable for processing as whole kernel cream style and corn on the cob. Indications are that some of the new hybrids will supersede the Golden Cross.

OVERHANGING TREES:

Overhanging trees reduce yields and affect maturity. They may also interfere with harvesting operations. The clearance required is 14 ft. Growers would assist harvesting and also help themselves if boundary trees are trimmed where required.

ASPARAGUS

The Most Certain Horticultural Crop

The developing production of this crop for canning and freezing is going ahead in leaps and bounds. Perhaps this is because it is the least hazardous of any horticultural crop. Overhead costs are low, since no spraying is necessary. There is no outlay for cases or packing material. A working period of only six months of the year affords the crop every care.

We would like to remind growers that establishing costs can be greatly reduced by growing your own plants. We have seed of the best variety available. Should you be interested, give us a call, and we will be happy to give you any advice and assistance you need.

If you have suitable soil conditions, you can plan to grow this vegetable with confidence. There is a large unsatisfied demand for Wattie’s Canned Asparagus throughout New Zealand and overseas markets. Our canned asparagus is as keenly sought in the United Kingdom as in New Zealand. You will find it displayed in the high class stores in London, and in fact it has become renowned throughout England.

Because supplies are insufficient we are embarrassed by the demand. Wattie’s are thus able to guarantee asparagus growers long term contracts backed by assured world markets.

We require upwards of 10,000 acres of asparagus where to date the acreage does not exceed 7,000. Our Field Supervisors will gladly discuss with you on the spot, the suitability and profitability of any land you may have available for this dramatic new cropping potential.

TELEPHONE NUMBER ALTERATIONS

It will be some time before the next telephone directory will be distributed, so would growers please note the following which may not appear in the current directory:-

HASTINGS:

Field Supervisor R. I. June, residence, 7513

No. 1 Farm Manager. E. Shakespeare, residence, 2335

No. 2 Farm Manager W. G. McMillan, residence, 6960

No. 3 Farm Manager T. Cotterill, residence, 99-831M

GISBORNE:

Field Supervisor L. R. Renouf, residence, 5829

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

October 1957Publisher

J Wattie Canneries LtdPeople

- T Cotterill

- R (Bob) I June

- P Marshall

- W G McMillan

- L R Renouf

- E Shakespeare

- James Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.