- Home

- Collections

- JUNE LI

- Harvest 03 - March 1958

Harvest 03 – March 1958

Harvest

VOL. 1 NO. 3

PUBLISHED BY J. WATTIE CANNERIES LTD.

HASTINGS & GISBORNE

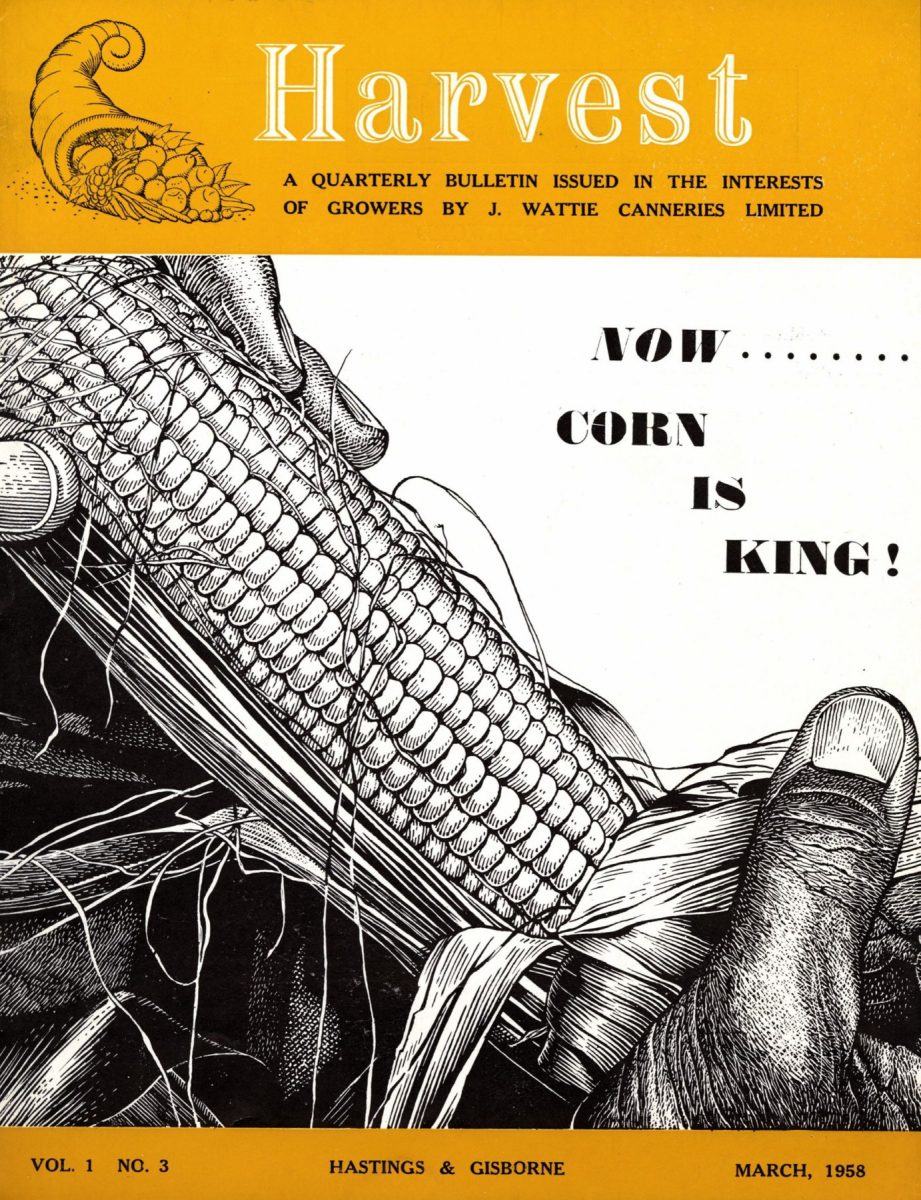

OUR COVER

Gisborne sweet corn, Poverty Bay’s largest crop.

FOREWORD

One hears a great deal, these days, of how food production for processing is developing in Hawke’s Bay. J. Wattie Canneries Ltd. have certainly increased output year by year and, in consequence other processors have been attracted to the district. Peach production in both Hastings and Gisborne is increasing rapidly: asparagus production on the Heretaunga Plains is booming: we have just completed the harvesting of 3,000 acres of peas, between the two factories, while the total area of peas for processing in our two districts would be in the vicinity of 5,500 acres for the 1957-58 season. It is a remarkable development.

In consequence one also hears how “sheep and cattle are disappearing from the plains,” yielding place to crops, and that “grass seed is a thing of the past.” This is taking too much for granted. It is agreed that areas for cropping are increasing, and rotations between food crops and grass are becoming more frequent. But it is difficult to think that sheep and cattle, and the grass associated with them, will disappear from the plains.

There are few crops that can be grown to good advantage for more than two years in succession in the same soil. Even rotating crops other than grass soon comes to an end if the level of organic matter and humus cannot be maintained in other ways. Grass, and the stock that go with it, are still the best method of rejuvenating soil and maintaining its fertility. Short-term cover crops such as cereals cannot do what grass will do. Mulches and compost have their limitations.

Continuous cropping with peas, beans, tomatoes, potatoes, etc. tend to build up diseases such as wilt, foot rot, collar rot, sclerotinia and others These diseases live for many years in the soil and are difficult, if not impossible, to eradicate. Already there are areas where it is unwise to grow peas because of the presence of fusarium wilt in the soil. Weeds as well as crops can be hosts to these diseases.

(Continued on next page)

FOREWORD (Continued)

If stock should disappear from our flat land then our whole system of cropping must change completely. Other means of maintaining soil fertility would have to be employed. The natural thought would turn to the retention and use of city wastes. In Hastings, Humic Composters Ltd. have done a great deal to show the way, but until the sewage waste problem is tackled officially and systematically, our present system of crop rotation could not change greatly. Sewage utilisation is a long-term project, but it must come in time. Another big issue which, if resolved, could improve production to a great extent, is drainage. High water-table and floodable areas are holding back production on otherwise good land.

Our factories are strategically placed in these most highly productive areas in New Zealand and we are proud to have been the means of establishing and developing this important production of fruit and vegetables for processing. It is a development of the utmost consequence for the man on the land. But it should not be assumed that cropping for processing spells the doom of stock and pasture on the plains. The traditional Hawke’s Bay farming and the new cropping are complementary, and should, for a long time, be co-existent.

Yours sincerely,

Bob June

Hastings Field Supervisor.

FACTORY FIRSTS: 1

J. Wattie Canneries Ltd. were the first canning factory to become established in Hawke‘s Bay and in Poverty Bay, canning fruit for the first time in 1934. Since then Wattie’s have been the first in the field with a great many major processing developments. Many of these innovations have been of great importance to the industry.

Periodically in “Harvest” there will be brief notes on some of these “firsts.” Since the factory first started operations on fruit, it is fitting to mention that the first automatic pear peeling and coring machines were introduced into New Zealand by our Hastings factory. These machines peel, halve and core the pear at the one operation, leaving a smooth, uniform pear ready for processing.

Another introduction for the first time in this country were the automatic peach- pitting machines. Peaches are halved and the pit or stone removed, again in one operation. The number of these machines has been increased from time to time. Four new ones have only just been installed. It is anticipated that with the firm’s own peach orchard coming into bearing-the largest in New Zealand-and other growers’ plantings steadily increasing, our present annual production of over 2,000 tons of canned peaches will be doubled within the next three years.

This sort of sustained output cannot be created by the short route: it takes years of detailed planning from the orchard through the factory equipment to the distribution and sales organisation. But it all begins on somebody’s faith and vision, since every major achievement is the lengthened shadow of one man.

The J. Wattie Canneries have enriched the entire Hawke’s Bay economy, and given to the man on the land a new concept of security and prosperity. To the nation as a whole they have contributed a volume of foodstuffs second to none in the world as to quality; and with every passing year our canneries bring New Zealand nearer to self- sufficiency in the staple lines of fruit and vegetables. What is more, with the steady development of the export trade with the United Kingdom, foresight is laying the basis of continuing expansion far beyond our own consumer capacity.

It means much to us at Wattie’s to be first in building a major industry such as this.

How is Hybrid Sweet Corn Produced?

Sweet corn consumption in New Zealand is increasing rapidly. Only a few years ago many New Zealanders had never tasted it, and even today there are some who have not considered it as a useful item in their diet. It seems a case of liking the flavour very much or not at all. Most people are very fond of it, and to the housewife it is a vegetable that can be used in so many ways. To most people there is nothing to surpass fresh corn on the cob, but it retains its full flavour well both frozen and canned.

Since J. Wattie Canneries Ltd. first started to process sweet corn on a large scale, consumption in New Zealand has steadily risen and an export market has also been established. The production of corn has been confined to Gisborne, partly because the district has long been noted for its high production of maize, and partly to balance production between the two factories. The Hastings factory at that time of the year is fully employed on fruit.

One of the most interesting aspects of corn growing, whether it be maize, sweet corn or pop corn, is the great advancement in the production of seed over the past few years. In the past there were only open pollinated varieties and yields were variable and unreliable. Plant breeders introduced hybrid seed a few years ago which has put the production up as much as 50 per cent. Other advantages are stronger stalks, improving harvesting operations and greater disease resistance, more uniform maturity, height of cob, and many others. Many growers will remember the old open pollinated varieties where some plants did not even produce a cob at all.

FLOWERING UNIQUE.

Corn flowers and produces its seed in a very interesting and unique way. At the top of the plant is the tassel: this is a collection of hundreds of male flowers. The female part of the flower is actually present, but it is very minute and non-functional. There are three anthers on each flower which each produce thousands of pollen grains. This pollen is released into the wind and is thoroughly mixed and settles slowly to the ground.

Lower down on the plant one or more ear-shoots also develop. This ear is a collection of hundreds of female flowers arranged along a central core. This becomes the cob when developed and is protected by leaves which we call the husk. From the tip of the husk the stigmas are extruded: these we know as the silk. Each of these silks is connected to an ovary containing the unfertilised egg cell.

The mixture of pollen blowing through the air from the tassel makes contact with the stigma and pollination is effected. It has been found that bees play no part in the pollination of maize, but they may often be seen working on the tassel. Investigation has also shown that rarely is pollination effected from the silk and tassel of the same plant.

After pollination, every grain of pollen sends out a tube which grows down through the silk and eventually the male part from only one of the pollen tubes in each silk combines with the female part of the egg cell. Fertilisation then takes place with every separate egg cell and this goes to make up a complete ear of maize. It is this fact which makes the production of the seed so difficult. The egg cells on each ear could be fertilised by hundreds of different male flowers, giving each one a different parentage. To obtain the uniform seed production of hybrid maize, this parentage has to be controlled.

OLD AND NEW METHODS.

In the past an effort to maintain the best plants was done by mass selection. The best cobs were selected from the best plants, but as we have seen, the parentage was not known and the results from this seed could be most varied. Another method was known as the ear-to-row breeding. The most desirable ears were selected and the grain from each was sown in a separate row. Ears from only the best rows were then saved for seed. Here again results could not be much improved.

Sweet corn harvesting at Gisborne.

CONTROL EASILY DONE.

The production of controlled parentage is called inbreeding and is the substitution of artificial self-pollination for natural cross- pollination, controlling the parentage of every grain on the cob. It is a simple process. The best plants in a crop are selected for self-pollination. A bag is placed over the ear before there is any sign of silk development. Another bag is placed over the tassel. Pollen collected in the tassel bag is shaken over the silks which have been produced meantime. The tassel bag is then tied securely over the ear and the operation is complete. Every egg cell on the particular ear will have the same male parent. All this is clear sailing; but where do we go from here?

THE HISTORY OF HYBRID MAIZE.

The first extensive experiments in inbreeding of maize was carried out quite independently by two Americans about fifty years ago. They found that inbreeding caused some peculiar results. First, it caused considerable reduction in vigour; the plants were smaller and weaker, with small ears. Secondly, it brought about distinct types, some desirable and others most undesirable. Thirdly, it was found the various types bred true, giving a fixed inbred line of seed.

The next step was the amazing one which gave the first hybrid maize. Again quite independently, these two men found that by crossing some of these weak inbred lines, they gave a product of superior vigour with high yielding uniformity. The cost of this seed production was high, but in 1917 Donald F. Jones, of the Connecticut Agricultural Experimental Station, crossed two of the single cross varieties, giving a double cross hybrid. This reduced costs and did a great deal to make the production of hybrid seed an economic proposition. The development of hybrid sweet corn and pop corn soon followed, and to-day many new hybrid varieties are constantly being produced. It is interesting to note that the first hybrid sweet corn was the Golden Cross Bantam. This variety is still grown in New Zealand and is of fine quality, having good flavour, colour and cropping ability.

As stated in our last “Harvest” issue there are nine varieties being grown on a commercial scale this year, and ten new varieties under trial. At the time of writing it is too early to say what the results are going to be, but every effort is being made to find the best variety possible to suit the district, both for the benefit of the growers and factory alike.

Maturity and Harvesting of Sweet Corn

Sweet corn is a crop that responds to fairly high temperatures and ample moisture in the soil, and reasonable humidity in the atmosphere. Any variance from the ideal conditions – such as excessively high or less than normal temperatures or insufficient moisture means a variance in the maturity period.

In Gisborne, over a four-year period, the time from planting to maturity has varied from 110 to 117 days for early plantings down to 100 days for later plantings on the general soil types of the district; but on two occasions crops have matured at 93 days. These were grown on soil types that are of very limited areas in the district.

American sowers state that, for every 18° F. rise in temperature the maturity rate of sweet corn doubles, but our experience in Gisborne has been that, while with ample moisture there is a very rapid increase, in very dry conditions maturity is comparatively slower even with very high temperatures.

At times it has been necessary to harvest up to double the amount planted for short periods, but each year the general comparisons between the planting period and harvesting period have been similar i.e., harvesting has to be carried out in approximately four-fifths of the time of the planting period.

With ample moisture there has not been any pronounced difference in maturity periods on different soil types, but in dry seasons differences have been very marked.

In judging the maturity of sweet corn, a general guide can be taken from the formation of the silks on cobs, which appear from four to six weeks from maturity; but the final summing up can only be done by inspections of crops. In seasons with ample moisture when crops grow evenly, judging maturity is simple; but in dry years it has been found that the majority of crops are uneven. In cases of marked variation, to obtain the maximum production it is necessary to leave the most forward cobs to reach the fullest maturity that can be taken for processing before harvesting the crop.

The final judgment of a crop is by running the thumb-nail along the rows of kernel to test the milk or cream stage. In moderate temperatures sweet corn will hold the ideal stage for four to five days, but with high temperatures and humid conditions, will pass through this stage in one to two days.

In Gisborne our harvesting is carried out with three two-row pickers, each capable of harvesting, if necessary, up to one acre per hour in reasonably sized paddocks, and on occasions these three pickers have harvested areas exceeding 30 acres in one day in daylight hours.

When starting harvesting of a paddock of sweet corn, the first four rows around the outside of the paddock are taken out with the pickers, having the elevators facing directly behind, with trucks following up to and below the elevators. The removal of these four rows allows room for the elevators to be swung to the right and the trucks to operate alongside the pickers, as shown in the illustration. In wide paddocks, crops are cut into lands after the headland rows have been taken out, by taking four rows out at intervals across the paddock again with the elevators of the pickers facing directly behind. This reduces dead running for the pickers.

The sweet corn season is generally a very busy one, both in the field and in the factory, but it is an excellent line to handle, in that all operations are completely mechanised from the paddock to the final stage of processing, making it a most interesting operation to observe.

Photo caption – Our Gisborne factory.

CROP TOPICS

A report – without prejudice! on our harvest hopes this current season.

PEAS.

As anticipated in the last issue of “Harvest,” the pea crop just completed has been exceptionally good. Not only was the crop above average in weight, but quality was of a high standard also. Harvesting conditions were the best ever known, as only a few hours in the whole season were lost due to rain. Crops were also more uniform than usual. This helped make a uniformly good quality product with the minimum of cutting out parts of paddocks, and therefore a minimum of shifting from one crop to another.

As a result of good harvesting conditions very few crops had to be by-passed. Parts of one or two were lost following a howling wind with 90° temperatures just after Christmas, and again with very hot weather late in January, when maturity dates closed in very rapidly from 75 to 60 days. Only one grower’s entire crop was by-passed, and even then the price we paid him for the harvested seed showed a satisfactory result.

The crop was well above budget figures, and it is a great satisfaction to growers and field men alike to think that our harvesting and processing capacity is now so great that we could cope with such a tremendous quantity at short notice.

GREEN BEANS.

In spite of the long dry spell, the bean pack should exceed considerably the expected yield. Most of our growers have irrigation of some sort, and it is in seasons such as this that an irrigation plant is a sound investment. Bean planting has to be controlled so that it won’t clash with peas at harvest time. As a result some of the crops were planted as late as December. However, these late crops have had irrigation and are doing as well as the early ones which had to go through periods of cold nights and even light frosts.

Some of the new varieties are showing promise, and next season will see some new ones grown on a commercial scale. The cost of stringing pole beans has been greatly reduced with the use of finer string, and we want a big increase in these next year. Areas of dwarf beans will be reduced and will be confined mostly to growers with crops such as peaches and asparagus, where they can be grown between the rows to help pay off the cost of establishment.

Pole or climbing beans are more desirable because of their fuller flavour. Plant breeders have made a wonderful job of producing a completely stringless dwarf bean, but unfortunately flavour has been impaired. The white-seeded Blue Lake variety grown this year has proved a fine cropper and an improvement over the old Blue Lake varieties grown previously in the Hastings district.

PEACHES.

The peach harvest is drawing close at the time of writing, and crops are still looking remarkably well. Growers will be on the alert for a change in weather and should be applying close-ratio sprays. This, of course, is most important for two reasons. One, to obtain a build-up of protective spray on the fruit; and secondly, keeping in mind that the surface area of the individual fruits is increasing very rapidly as maturity approaches. Foliage for the most part is excellent, and we only hope that there will be sufficient moisture to produce reasonably sized fruit. It is only now that previous remarks on thinning can really be appreciated. There is no doubt that some growers did not thin severely enough.

Many growers have been able to irrigate their peaches, and there is no doubt they will be well repaid in a dry season such as this. A new low-cost perforated hose system of irrigation, although not highly efficient, has allowed more growers to at least get some water on their crops. Too many growers, when considering irrigation, are inclined to consider their crop only. They should look beyond their present crop and consider the tree itself. A tree that grows well this year with ample moisture is more likely to crop consistently thereafter.

We still require more peaches. With a crop expected this year to exceed 2,500 tons, we have installed more equipment to cope with it in both the Hastings and Gisborne factories. We have also obtained an extra 25,000 dump cases should they be required. As many growers know, J. Wattie Canneries will have the largest peach orchard in New Zealand coming into bearing next year. Our own plantings now exceed 130 acres, but we are happy to assist anyone wishing to plant further areas. We can give assistance in many ways. One practical way is to make a green bean contract available. This crop grown between the trees for the first two years can pay the complete cost of establishment.

APPLES AND PEARS.

Our Sturmer apple pack will exceed last year’s, but unfortunately we will not be packing Ballarats. The pear pack too will exceed last year’s. It is pleasing to see the pears so free from black spot and limb rub.

All fruit looks extremely well. Out of the years of experimentation with sprays and spray technique has come something really worth while. No doubt the answer to red mite, mealy bug and woolly aphis is at hand and they will be overcome as codling moth has been. One has only to picture one variety, Sturmer, to see what new sprays, pruning and manuring have done in a matter of seven or eight years. Growth has become re-established and large dark green leaves have replaced the curled and discoloured ones. The crop of this variety must have increased tremendously.

If rain is not forthcoming soon, this will be a year of trial for grassed areas, especially in stone fruit. If competition for moisture has no serious results this season, another doubt in favour of grassing down will be cast aside. This practice has been going long enough now to say it has been successful.

TOMATOES.

At this stage the crop is looking well, but the size of the plants is smaller than usual, due to dry and fluctuating temperatures. Green back is prevalent in early picks. This trouble can always be associated with fluctuating temperatures. With frosts in mid-December and again in mid-January one must expect their effect to be felt. Tomatoes seemed to escape any actual “cutting” by frost, but crops of beans, sweet corn, pumpkins and marrows have been affected in isolated places near Hastings. A reasonable average can be expected, but will be below the last three years.

SWEET CORN.

Gisborne rainfall has been very low. Most crops of sweet corn have had no rain since planting. Growth is short and crops must be below average. Harvesting will also be difficult due to low growth.

BROAD BEANS.

Since J. Wattie Canneries Ltd. introduced frozen broad beans to the New Zealand public two years ago, this vegetable has become very popular. Last season for the first time it was produced in quantity. Other processors followed our lead, and as a result this pack is readily available. As sales of this commodity are slow during the summer, it is difficult to know how many to plant at this time of the year, yet growers would wish to know as planting time is nearly upon us.

There will be an increase in area over last year, so those who grew last season are assured of an area again. We will be recommending a wider distance between rows, as picking was difficult in the three-foot rows last season.

Left: Barnyard Grass.

Flower stalks grow from 1ft. to 5ft. high. Seed heads somewhat like paspalum.

Right: Foxtail Grass.

Flower stalks grow from 1ft. to 5ft. high; seed heads from 2in. to 4in. long, with clinging bristles.

The Problem of Barnyard and Foxtail Grasses in cropping areas of Poverty Bay.

Barnyard grass (Echinocloa Crusgalli) and Foxtail grass (Setaria Viridis and Setaria Glauca) are strong growing prolific seeding annual grasses, prevalent in several parts of the Poverty Bay flats and causing considerable losses in cropping.

Although they have been present in the district over a long period, a noticeable increase in their spread in cultivated areas has been evident during the past few years. Some paddocks have become so affected as to be useless in their present state for late cropping.

It is apparent that many growers do not recognise these grasses or realise what a menace they can become, and it is hoped that this article will give a better understanding of the problem.

These grasses are often found together, and the Foxtails have often been referred to as the companions of Barnyard grass, which is present in New Zealand from South Canterbury northward. They are common in waste areas, drains, etc., as well as in cultivated areas. Both grasses are problems in corn growing in U.S.A., and are prevalent in other parts of the world.

Barnyard and Foxtail grasses are fairly late in developing, and as far as processing crops are concerned, it is mainly sweet corn that has been seriously affected; but losses on late planted pea crops have also occurred. Wet seasons favour their development and plants of each can grow to five feet and more, with ample moisture; and under such conditions instances have been noted of crops being completely smothered. While plant growth is not so great in dry conditions, these grasses have seriously depleted production due to their gross feeding habits on moisture and nutrients.

SPREAD.

Being annual grasses, their spread is only by distribution of seed. Transfer of stock, tractors and farm equipment from infested paddocks is probably the major means of spread, not only by carrying seed on their surfaces, but also by transferring soil containing seeds. Other means are by birds, in water backing up from drains or draining off affected paddocks at seed maturity stage.

Generally the initial spread is around gateways, and unless prompt action is taken to eradicate the grasses at this stage, cultivating and harvesting equipment will readily spread them throughout the paddocks.

CONSIDERATIONS REGARDING CONTROL.

Much work has been carried out, both in New Zealand and overseas, with chemical sprays for control of these grasses, but to date none has been found that will not also affect growing crops. TCA at 10 to 15lbs. per acre or I.P.C. or C.I.P.C. at 2 to 4lbs. per acre have been recommended, and soil sterilents such as Atlacide or Polyborchlorate will readily kill the grasses. These treatments would mean loss of crop until the materials have been leached out of the soil.

When either Barnyard or Foxtail grass is found in patches in a paddock and eradication by cultivation either by hand or machine is not practicable, the use of the above treatments would be well warranted, as after one seeding, widespread infestation will occur and eradication would then be extremely difficult and costly. These grasses will not compete with good pasture and in the event of paddocks becoming seriously affected, grassing down is recommended. As the viability of Barnyard grass seed in the soil is considered to be only five years, eradication is not such a problem as that of Foxtail grass, the seed of which is reckoned to live for twenty years in the soil.

Evidence from two paddocks sown in barley for seed production has shown that this crop subdues these grasses.

The cleaning-down of cultivating and harvesting equipment coming from infested paddocks is advisable and would appear to be the only practicable action that can be taken to prevent initial spread. The cleaning of corn harvesters with the aid of a compressor over the past three years after coming out of affected paddocks has been very effective in most cases.

Although there are many weeds to contend with in growing crops, it is considered that Barnyard and Foxtail grasses are major problems, and their presence in many paddocks in Poverty Bay is ample evidence of their effects, showing the necessity for action as early as possible. Only thus can we hope to eradicate or control the grasses and prevent further losses of land for general cropping.

Dump Cases

“Now is the time…”

With the bulk of the produce now supplied to the factory, the annual chore has been commenced of sorting, repairing and stacking our dump cases.

Will you please gather and return to us any cases still on your property. They are provided for your convenience and to save you cost: they are an expensive item in our operating costs, and our accountants are forever insisting that cases not returned should be charged out to the grower concerned Well, we do have a detailed record of case distribution: we could easily make a tally and a charge. But we prefer to keep our relations with you on a fair-play, rather than a penalty basis.

So will you support us against the accountants – and send back all our dump cases?

WHAT IS “ENOUGH”?

No matter how many dump cases we had – and they run to scores of thousands – we’d never have enough, or so it seems. Why? Because instead of a sensible day-to-day draw-off from our stocks as boxes are needed, so many good fellows can’t sleep at night unless they know they’ve accumulated enough cases to handle their entire crop for weeks ahead. Couldn’t we try the sensible way next year and keep cases circulating as needed, instead of accumulated in great heaps all over the district?

Our Fred Tierney is a remarkable compound of Christian charity and dark distrust: the former he tries to extend to all, but the latter he reserves for growers who give him needless repair work by careless and damaging handling of his cases. He tells us, too, that our dump cases can be seen around the countryside in various and sundry unauthorised uses: picnic boxes, dog houses, milk boxes, children’s carts, playhouses, shed linings, fowl nests, shed shelves. It appears that growers consider a damaged dump case not worth returning, and so to be sent to Rotten Row or used ignobly around the farm.

Fred devotes the best years of his life to rebuilding and restoring these old masters: so send ’em back, whole or damaged.

You wouldn’t want him to have a permanently soured disposition, would you now?

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

March 1958People

- R (Bob) I June

- Fred Tierney

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.