- Home

- Collections

- JUNE LI

- Harvest 06 - March 1959

Harvest 06 – March 1959

Harvest

VOL. 1 No. 6

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

We must apologise to readers for omitting the December issue of Harvest. It was just physically impossible to do all the field work as well as write about it. We trust that you will forgive our default, journalistically, and accept this as a combined December-March issue.

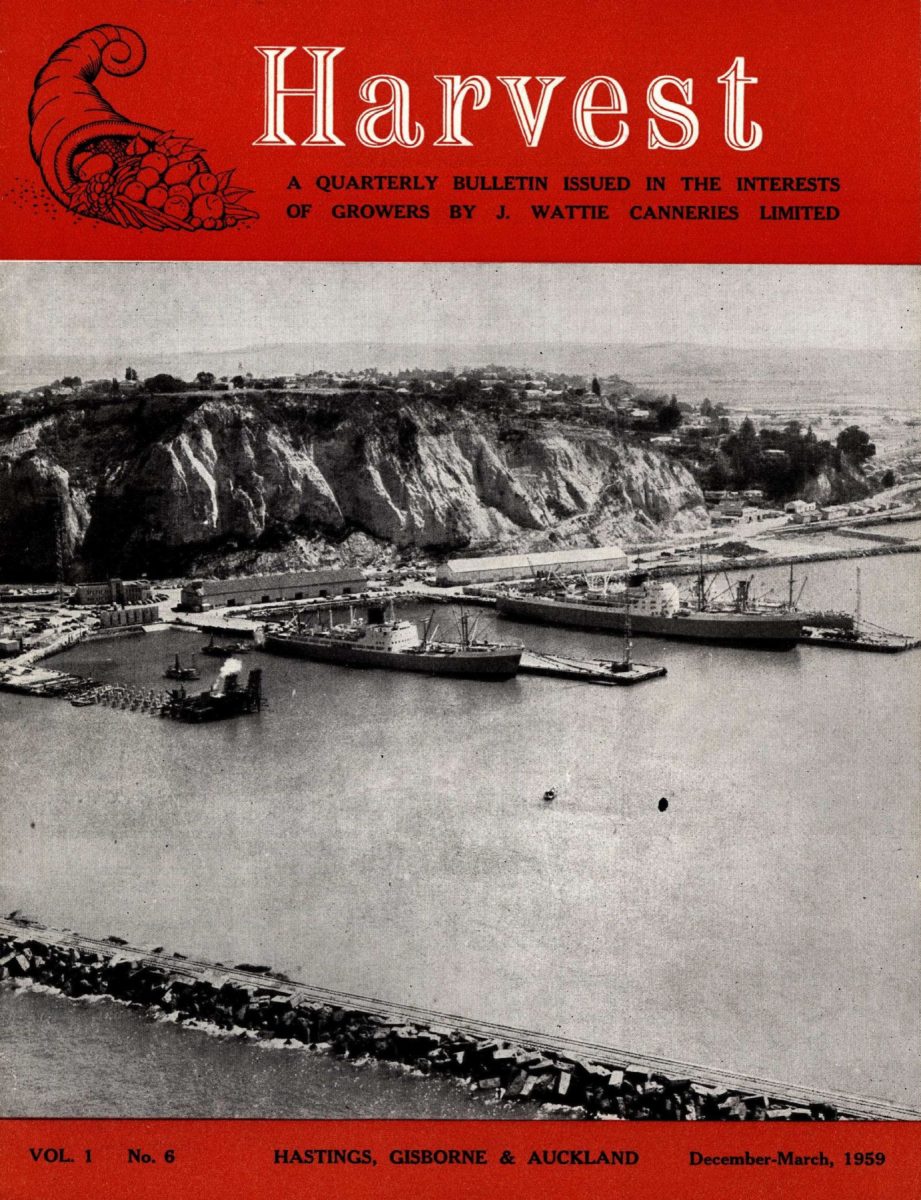

OUR COVER

NAPIER: Third port in NZ in export volume; J Wattie canneries are the largest single users of the port

FOREWORD

THIS year we celebrate our Twenty-fifth Anniversary. From a small beginning has grown an industry worthy of its place as the leading food-processing firm in New Zealand. Development has been constant, and as the years go by it has tended to gain momentum. Our Managing Director, Mr. J. Wattie, has written a short article in this issue on the future prospects.

One cannot help but think that this future is dependent on production by our growers and our own farms. Over a long period this is reasonably secure, but one bad season can set us back considerably. It is a comforting thought to know that we have a man at the helm who has grown with the business. Through his knowledge and forethought we have consolidated and made future production as secure as is humanly possible.

With factories in two different districts, risks have been spread. This has been amply illustrated to be sound this year, when one district experienced a disappointing pea crop, while the other produced a record crop. While our own farms, now amounting to nearly 500 acres, also give us security, we must always rely on our growers, however, for the bulk of our supplies. Many growers think that they will not be required to grow certain crops such as peaches and pears because we are producing large quantities ourselves. This is a mistaken idea. No grower willing to produce peaches, pears and asparagus has ever been turned away.

No one knows what the future holds in store. The next twenty-five years will no doubt bring many changes. But processed food must always be required. We feel we have the solid support of growers behind us. It is pleasing to note that in spite of poor returns by many of our growers this year, they are already planning to carry on as usual next season. The man on the land must be tenacious, strong of heart and full of faith for the future. That is why it is a pleasure to be so closely associated in this big business together.

Yours sincerely,

Bob June

Field Supervisor, Hastings.

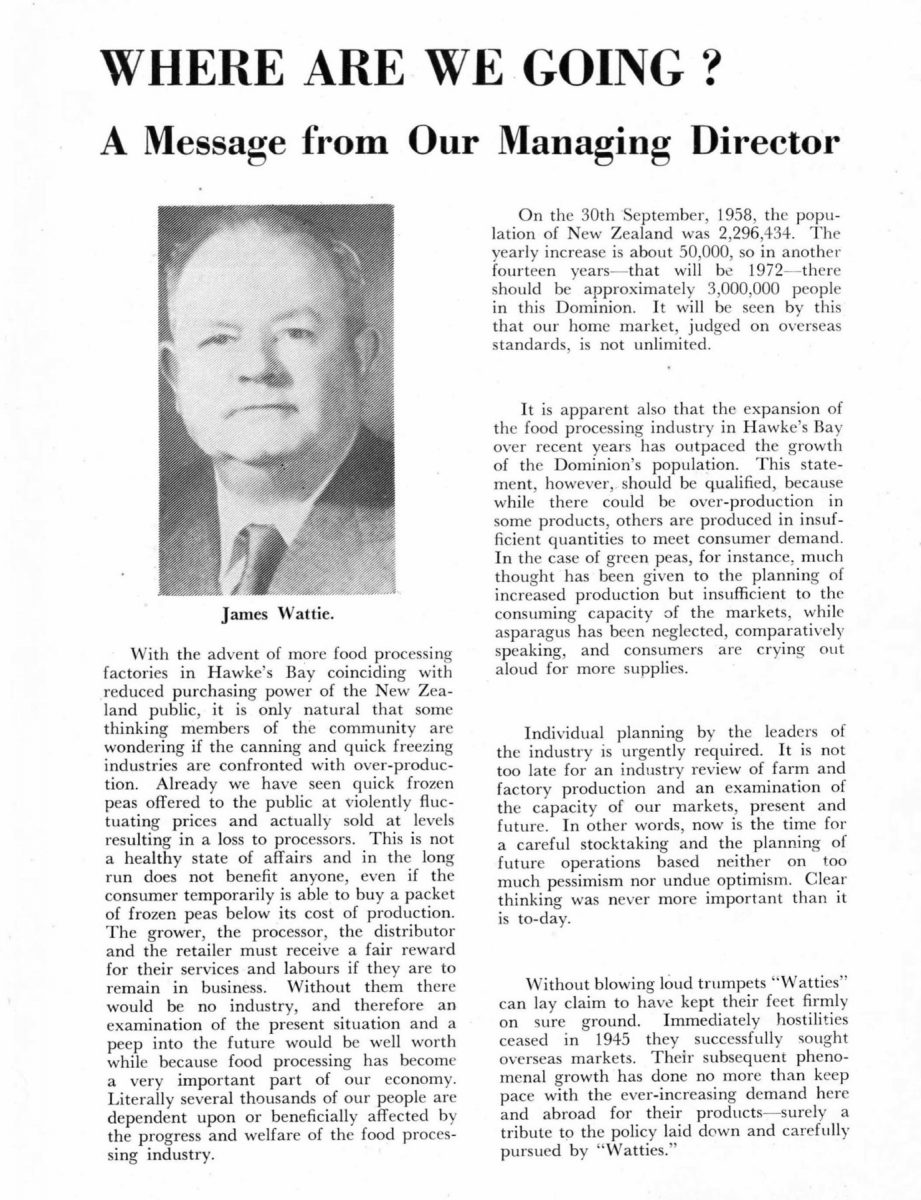

WHERE ARE WE GOING?

A Message from Our Managing Director

With the advent of more food processing factories in Hawke’s Bay coinciding with reduced purchasing power of the New Zealand public, it is only natural that some thinking members of the community are wondering if the canning and quick freezing industries are confronted with over-production. Already we have seen quick frozen peas offered to the public at violently fluctuating prices and actually sold at levels resulting in a loss to processors. This is not a healthy state of affairs and in the long run does not benefit anyone, even if the consumer temporarily is able to buy a packet of frozen peas below its cost of production. The grower, the processor, the distributor and the retailer must receive a fair reward for their services and labours if they are to remain in business. Without them there would be no industry, and therefore an examination of the present situation and a peep into the future would be well worth while because food processing has become a very important part of our economy. Literally several thousands of our people are dependent upon or beneficially affected by the progress and welfare of the food processing industry.

On the 30th September, 1958, the population of New Zealand was 2,296,434. The yearly increase is about 50,000, so in another fourteen years – that will be 1972 – there should be approximately 3,000,000 people in this Dominion. It will be seen by this that our home market, judged on overseas standards, is not unlimited.

It is apparent also that the expansion of the food processing industry in Hawke’s Bay over recent years has outpaced the growth of the Dominion’s population. This statement, however, should be qualified, because while there could be over-production in some products, others are produced in insufficient quantities to meet consumer demand. In the case of green peas, for instance, much thought has been given to the planning of increased production but insufficient to the consuming capacity of the markets, while asparagus has been neglected, comparatively speaking, and consumers are crying out aloud for more supplies.

Individual planning by the leaders of the industry is urgently required. It is not too late for an industry review of farm and factory production and an examination of the capacity of our markets, present and future. In other words, now is the time for a careful stocktaking and the planning of future operations based neither on too much pessimism nor undue optimism. Clear thinking was never more important than it is to-day.

Without blowing loud trumpets “Watties” can lay claim to have kept their feet firmly on sure ground. Immediately hostilities ceased in 1945 they successfully sought overseas markets. Their subsequent phenomenal growth has done no more than keep pace with the ever-increasing demand here and abroad for their products – surely a tribute to the policy laid down and carefully pursued by “Watties.”

Photo caption – James Wattie.

Under present conditions a canning and quick freezing factory must have large-scale production before it becomes efficient and economic. A number of small units could never give the satisfaction to farmers, the trade, or to the consumers that one or two large, well-equipped factories would provide.

Yes, “Watties” face the future with confidence. In twenty-five years of successful processing they have acquired a fund of knowledge and experience which is invaluable. They have gathered a staff of executives, all competent in their respective departments and conscientious in their desire to serve the industry well and truly.

I conclude this brief message to our suppliers by saying that the future is bright and that with careful planning you and we will go a long way together. By careful planning I mean producing those foods most suitable to Hawke’s Bay conditions and which in the processed form are wanted by millions of consumers here and abroad. There will always be a good market for our products, but we must never forget that good quality and the right price are vital factors. You and we realise that simple fact, and therefore buyers have confidence in us.

There have always been many matters of great interest to discuss at our suppliers meetings, and I am sure the next one will not be an exception in this respect. In the meantime, I extend to you all best wishes for a prosperous 1959.

J Wattie

FACTORY FIRSTS

Although mobile pea harvesters are a common sight to anyone living in a pea-growing district, they still hold an interest for the onlooker. For those who have not seen them before, they are fascinating to watch at work in the field.

J. Wattie Canneries were the first to introduce this type of machine into New Zealand. In 1952 the first one was given a trial in the Hastings district. It proved fairly satisfactory after a few modifications. The following year ten more were imported. Two private growers, Messrs. D. Webb and T. Ryan, also purchased machines, and have for the past two seasons worked in conjunction with our own, making a fleet of thirteen mobile pea harvesters operating in three separate gangs, harvesting up to 70 acres of peas a day, working round the clock.

The advantages of these machines are many, the main one being that a tremendous amount of cartage is eliminated. The pea haulm is left on the field, where it can be utilised to build up fertility or baled for winter feed. Some growers simply allow stock to feed from the hay as it is left on the field.

These machines have been considerably improved by our own engineering staff, and have proved to be another worthwhile first for the factory and our growers.

OUR SILVER JUBILEE

The calendar for 1959 now available to all our grower friends is the first commemorative item in this year’s special celebrations of the Twenty-fifth Anniversary of J. Wattie Canneries Ltd.

Many of you were identified with the Cannery in its day of small beginnings, and we take pride in the fact that men we knew so long ago are still happy to do business with us, as we are with them.

Because the roots of this Company are deep in the soil; because the grower is the man who has always been the foundation of the business, we recall with the warmest appreciation this long association.

It has been a profitable one for us all. We can all remember that twenty-five years ago – when the Canneries started operating so modestly – the best growing land in the district could be bought for £75 to £80 per acre. True, it was then farmland. But that is the point: what was then farmland valued at less than £100 an acre, is today rich cropping land. This is wholly the result of assured markets for processed foods, both canned and quick frozen; and J. Wattie Canneries Ltd. are proud to have been the major factor in this development.

So in our Jubilee year we shall be telling the story, as it should be told, for the information of the rest of New Zealand. We can’t believe that any who live in Hawke’s Bay need reminder or explanation of the role of our province in food production. But with their big-city complex, not a few other provinces are far too prone to ignore the grass-roots of the Dominion’s prosperity.

You – our growers – are key-men in that broad base of this country’s economy. We are happy to acknowledge it.

WE HOLD OPEN HOUSE

During December we were very pleased to welcome local fruitgrowers with their families and employees to our Hastings factory. Visitors were able to see the various steps of pea processing, both for canning and freezing, as well as various other sides of the industry such as quality control and can making.

An opportunity was given for questions following a cup of tea in the cafeteria. Growers expressed appreciation and surprise at the size and set-up of the factory. They also expressed a wish, as fruitgrowers, to see the factory again when their own fruit products were being processed. Many growers saw the factory for the first time, although they had been suppliers for many years.

A further opportunity will be afforded fruitgrowers a little later in the season. Some new peach pitting machinery has been introduced this year and will be well worth inspection. A new and uncanny principle of aligning peaches prior to pitting will be seen. These machines are not in use anywhere else in the world at present. They are produced by the Food Machinery Corporation of America, and are being given a trial run for the first time in New Zealand, thus giving their engineering staff an extra season for trial before the machinery is required for the next peach season in the northern hemisphere.

A suitable date will be arranged, and growers advised through their organisation.

CROP TOPICS

We cannot expect to go through such an unusual season without its effects on crops. Hastings experienced one of its driest sea- sons, with an all-time low rainfall record averted only in the last few days of December. Gisborne district was more fortunate in getting light rain at intervals through the spring and early summer which ensured good growing conditions. Crops in Gisborne show every indication of being the best ever experienced by our Company in that district.

Some crops will be below average, but fruit crops look particularly bright. For the factories, then, the over-all picture is satisfactory. For some of our growers of broad beans and peas, crops have been disappointing. The results of the season show the great advantage of factories in two districts. Providing no serious setbacks are encountered from now on, production should prove very satisfactory indeed.

BROAD BEANS.

After excellent crops last year, this year’s broad beans were disappointing. It is very evident that this crop requires a great deal of moisture. Last season we experienced a very wet spring, and some very heavy crops were produced. This year was dry at planting time and the root zone never received a real soaking at any stage. Many factors have been held responsible, but the theory of lack of moisture has been well proved by one or two areas that were heavily irrigated. The crop improved immediately after irrigation with six inches of water followed by two inches of rain. A small area of one irrigated crop was not covered by the sprinklers, and left ample evidence of the value of water application.

Some worthwhile knowledge of spray materials and their application has also been gained this season. This information will be passed on to growers in Harvest at a later date. The factory has been able to obtain extra beans grown on speculation, so that the pack should be sufficient to meet market demands.

ASPARAGUS.

This season has been the best for many years. Production and quality on most growers’ areas have been well up on the three previous years. Weed control has been easily maintained. Warm soil conditions, with no excessively wet periods, have been responsible for the increase. It has been proved beyond doubt that we must be prepared to feed established beds adequately, with particular attention to nitrogen fertilizer.

The Company’s production of asparagus from its own farms has helped output considerably this year. One hundred and fifty acres were cut, some for the first time. This is a major addition to the total asparagus output from all sources. With this area in production and many others planted since, it is felt that at long last we are approaching the time when the asparagus pack should satisfy local demand, and a worthwhile shipment to overseas markets can be made.

PEAS.

Gisborne pea crops have been above average this season. In fact, the production will be a record one for the district. Just enough rain fell during the spring and early summer to keep the crops growing well. Too much rain at Christmas time caused some vine rotting, but on the whole the results look very pleasing.

Hastings pea yields were the lowest for many years. An exceptionally dry winter and spring did not provide sufficient moisture for a quick start, which suits this crop. Rain when it did come was too late to be of much benefit. Collar rot and vine rot was excessive following December rains. Soil temperatures were very high, and warm rain with humid conditions provided ideal conditions for disease. Pea mosaic, a virus disease, showed up very badly. More single pods instead of the usual double pod formation also reduced yields. Some crops produced such short vines that it was difficult to pick them up. Spray outfits left deeper ruts than usual, as there had been no rain to settle the soil since planting time, making a clean harvesting job difficult.

To add insult to injury, rain experienced late in December flooded many crops in the Twyford area. Usually either the early or late pea crops are reasonable, but this year crops were poor right through the season. Although the outline of Hastings pea crops is disappointing, the total pea production has not suffered greatly. Gisborne’s fine crops, with a larger area than usual, helped to save the day. When it was realised that the early

crops in Hastings were poor, extra areas were planted. An all-time record area of peas totalling 3,600 acres was planted. As a result all orders for canned peas will be supplied, and the frozen pea budget will be very near our target.

FRUIT.

In spite of heavy crops for the past two seasons, peaches and pears are showing promise of adequate supplies again this year. Small-sized fruit was expected to reduce tonnage early in the year, but heavy rain experienced in late December has made the outlook much brighter. Moisture should now be adequate to ensure good size and quality in both peach and pear crops.

Pears are free from disease and of good size, and are expected to produce an all-time record tonnage delivered to the factory. This is brought about partly by the heavy setting and partly by the fact that we are now accepting a smaller size.

Peaches also show good promise and, if reasonable conditions are experienced at harvesting time should be well up to anticipation.

Apples will also be received in larger quantities this year. The use of apples in baby food has increased the demand for this crop. The varieties arranged for are Sturmer, Jonathan and a few Statesmen. Unfortunately we will not be accepting Ballarats meantime.

TOMATOES.

A record area of over 300 acres of tomatoes should ensure adequate supplies to meet ever-increasing demands for this crop processed in its various ways. In Gisborne, growth is exceptionally good. In Hastings, early crops retain their lead over later planted ones. It is doubtful if later plantings will reach the size of the early ones. Generally the crop shows good promise if reasonable conditions are experienced from now on.

Some concern is expressed at the incidence of disease in both districts. In spite of some wet and humid conditions, late blight (Phytophthora infestans) has been controlled by spraying and dusting. The trouble comes from diseases which cannot be controlled by spraying. Sclerotinia is causing serious losses in some crops. One crop with a 25 per cent loss has been noted. This disease is known as stern rot in places. The plant usually grows normally until well developed, then suddenly collapses completely. Inspection reveals the stem at ground level or just above is completely dried out. Bacterial canker is also fairly prevalent. It also develops as the plant reaches maturity. The first symptom is the yellowing and dying of the leaves and stems in the centre of the plant. It develops slowly, and in many cases the plant collapses before much of the crop is harvested. The bacterium causing the disease can be seed-borne. It is spread readily by spray or cultivating apparatus and picking operations. The variety Scorsby, now grown so extensively, appears more susceptible than our other main variety, Tatinter. Other diseases such as spotted wilt still persist, but never seem to reach alarming proportions.

In spite of these troubles, which come and go according to the seasons, crop averages of recent years have been very satisfactory. Over the past five years they range between 14 and 18 tons per acre.

BEANS.

This crop has looked well from the start in Gisborne, and rain has made Hastings crops develop well. Several first picks of around four tons per acre have been harvested, so ample supplies of beans should be forthcoming. Due to rains, weed control has been difficult and one or two growers have lost the battle with this old enemy.

Increased areas of pole beans have been grown this year. These looked exceptionally well early in the season, but a virus disease, bean mosaic, is now showing up badly in some crops.

CORN.

Our Field Supervisor in Gisborne reports sweet corn crops as exceptionally good. There are six varieties now being grown commercially, and seven other American hybrids are under trial. Last year’s crop was lighter due to dry summer and autumn conditions, so that the extra tonnage this year will be most acceptable.

OTHER CROPS.

Other crops such as potatoes, carrots, onions, spinach, parsnips, etc., will be adequate for requirements and should bring the weight of crops up to expectations.

TRIAL WORK BEHIND OUR PRODUCTION

An industry associated with food production and processing must keep pace with new developments both in the factory and in the field. J. Wattie Canneries have been responsible for the introduction of many types of machinery into New Zealand. In the field, too, the Company has introduced many new varieties of fruit and vegetables. Last year a brief report on this trial work was published. This year’s trials have been extended considerably. Growers will be interested to learn that new varieties of many crops are being constantly watched with the idea of improving their returns, and from the processing aspect of improving quality. For obvious reasons we do not publish all our observations, but we recommend for the grower’s benefit any new varieties showing improvement over present crops.

DEVELOPMENT PLANS.

A start has been made this year with the development of further apricot varieties. Local seedlings are being budded for field trials of the future. Some apricots crop well in private gardens and are worthy of development.

We are also constantly looking out for a good quality canning peach, to come in during late January. Apart from that, Mike Crooks, our Hastings Assistant Field Supervisor, has started a long-term breeding programme in an attempt to develop suitable canning varieties. Seven different crosses have been completed during the last flowering season. Stones from these crosses will be stratafied and planted out next spring. It will be some years before any results are known.

ASPARAGUS.

This again is a long-term project, but a start has been made in selecting plants of “Washington 500” variety with favourable characteristics. These will be grown under controlled conditions for seed production.

A duplicate trial will also be carried out on the “Coniston” type, developed by Professor E. R. Hudson, of Harewood, Christchurch. This strain was originally developed from the, K.B.F. strain, an English selection by Kidener, of Bedford, and has about forty years’ breeding and selection work behind it.

A commercial area of “Coniston” has been planted next to the Company’s No. 4 Farm, on Mr. W. Montgomerie’s property, last year during the 1958 planting season. It will be interesting to note the development of this block and to compare it with “Washington 500” planted from locally saved and imported seeds. We appreciate the co-operation Mr. Montgomerie has shown. Like ourselves, he is well aware of the fact that if we could get every asparagus plant producing as well as our best, production could possibly be doubled.

BROAD BEANS.

This crop requires a good deal of variety trial work done on it. Very little has been done in New Zealand with regard to new varieties or selection of our older varieties. Nine new varieties were planted out on a trial block last season. Unfortunately it was a poor season for this crop, but two varieties appear to show a distinct improvement over our usual New Zealand-grown ones.

DWARF BEANS.

An attempt has been made over the last few seasons to select one good all-round variety to suit local conditions. Top Crop has given a good performance so far, especially in Gisborne. A white-seeded variety would suit our requirements better. As a result of trials this year we hope to reduce our varieties next season to two only.

Photo caption – Pole Beans suit the small landowner. Bean pickers at work.

Five varieties of green dwarf beans were selected for trial this year and three of yellow wax.

TOMATOES.

It is felt that much more work should be done on the selection of more suitable tomato varieties, particularly those suitable for canning whole. With this in mind, no less than 26 varieties are now growing in our trial plot. One new variety selected from last year’s trials has been planted out on a field scale. We appreciate the interest and co-operation of Mr. Doug Webb in growing these varieties for us.

OTHER TRIAL CROPS.

Quite a range of other crops have been included in this season’s trial area. Seven sweet corn varieties are being tried in Gisborne, as well as the six from previous trials now being grown commercially.

A dozen varieties of peas are included. three varieties of gherkins, and lima beans. Also beetroot, carrots, pole beans. rock melons and spinach.

It will be appreciated that quite a considerable amount of work and effort is being expended on this side of the field work. As no two seasons are alike, conclusions cannot be drawn from one year’s results, so that it becomes a constant undertaking. Some of the projects, such as the development of new peach varieties and asparagus selections, are fairly long-term projects.

TOMATOES . . . As we like them

One of our greatest problems each year is to get tomatoes harvested in good condition. One of the main problems is colour. Only tomatoes of a solid red colour are suitable for processing. Rejections in the past have been mainly because a line lacked colour. Our field staff is ready and willing to give you a line up in the field if you are in any doubt as to requirements. Unnecessary expense of having a load rejected can be avoided if proper supervision is given to picking.

There is always a natural tendency to pick a tomato that is not quite ready. Some growers have made a habit of picking heavily and leaving the cases in the field for an extra day before submitting them to the factory. By that time over-ripe tomatoes often grow “whiskers” and are forced down the drains in the washing process. This does not overcome mixed maturity. More frequent picks, with due respect for colour, are necessary.

Harvesting tomatoes by contract has its problems, but they can be overcome with proper supervision. Although under-coloured fruit is the main source of concern, many other defects, such as worm holes and rotten and badly cracked tomatoes, find their way into the case, which should not be tolerated by the owner. Labour is much more plentiful this year, so a grower has a better opportunity of insisting on a good product.

Toxic residue is another problem which gives us great concern. Mercury sprays are used widely for blight control. This is a deadly poison. It can be used in the early part of the season, but once fruit is nearing maturity it should be discontinued and substituted by copper or zinc sprays. Insecticides such as D.D.T. and D.D.D. should be discontinued prior to picking also. If insecticides are included in all the early sprays, they should not be required after harvesting commences.

Records are now being kept of weigh-bridge inspections of all growers’ lines. This applies to all fruit and vegetables. With waiting lists for all processing crops. these records must be taken into account when future contracts are arranged. The factory has to watch its quality control very carefully, and this must start at the growing point. A policy has always been adopted of receiving a whole consignment on arrival at the factory, or rejecting it completely. In this way the grower knows exactly where he stands. If a line is accepted and then deductions made, the grower feels it is beyond his control, and he is quite right.

We are not embarking on a “get tough” policy. All we ask is reasonable co-operation between supplier and processor, as has always existed, and on very amicable terms.

J. Wattie Canneries’ New Warehouse, Penrose, Auckland

NEW SERVICES FOR GROWING MARKETS

With the opening of this fine modern warehouse at Penrose, Auckland, the Company offers a greatly improved service to merchants and retailers in this largest population area in the Dominion.

No longer wholly dependent upon the mixed warehouse, we are now able to carry for complementary delivery, stocks of every product in the Company’s full range; serviced by our own staff, single-minded in their representation and thus pressing every advantage we possess as against competitors.

The importance of this attention to detail in single-minded promotion of Wattie products through our own ancillary warehousing cannot be over-emphasised; and it is an important development from the viewpoint of the grower, no less than the retail trade.

It’s rather reminiscent of the House that Jack built. The grower regards the foodstuffs as sold when he is paid by the processor: the processor thinks they’re sold when he’s paid by the merchant: and the merchant thinks they’re sold when he’s paid by the retailer: while the retailer thinks they’re sold when he’s paid by the customer. (Note that, “the customer” or spelt a little differently – “the consumer.”)

The crops you produce aren’t sold finally and satisfactorily – opening the pipe-line for more production and more sales – till the foodstuffs are consumed – and somebody gets hungry again.

That’s where our new and enhanced warehouse service plays its important part in the selling cycle. If the merchant delivers the foodstuffs promptly to the retailer, who sells promptly to the shopper, who promptly makes it into meals – the pipe-line of supply stays open and unimpeded, right back to the grower.

This steady, uninterrupted movement of the foodstuffs from the growers’ fields on to the nation’s tables is fundamental to us all. That’s why J Wattie Canneries Ltd., having opened their own fully equipped and staffed warehouse in Auckland, are watching carefully the emerging need in other areas.

The South Island offers particular problems in the shipping bottleneck. At present, Wattie’s maintain in Christchurch and in Dunedin – as in Wellington – commodious supplementary warehouse space on a rental basis. We are well served by our agents in these territories. Our merchant friends render loyal support to the limits imposed by their multiple representation in many brands and products.

A fleet of fine new delivery trucks has been provided for the more expeditious despatch of the Company’s products throughout Greater Auckland. An interesting point is that, although they are the largest practicable for congested city streets (7-tonners), a full load will frequently get no further than the adjoining districts; for example, Otara, where the volume of sales has already mounted so greatly through such modern outlets as the Otara Supermarket, that our fleet is already fully extended.

After all, something over one-third of the population of New Zealand is concentrated within the Auckland Province, and we have gone out to meet this challenge.

But a company of our size, with its growing roots so deep and so widespread, cannot rest on its oars, nor be wholly dependent upon others for its merchandising. As our Sales Division creates mounting demand for Wattie products, improved services must be established. In this determination lies the security of the future – the growers’, the processor’s, the merchants’, the retailers’, and the consuming public’s. An expanding market profits us all.

BETTER RETURNS FOR PEAR GROWERS

Pears will be accepted this season without being sized by the grower. This is virtually a considerable increase in price because the extra labour involved in putting them over a grader will be eliminated. Should this prove satisfactory this season, it will become the common practice next year. It is therefore up to you, our growers, to co-operate to the best of your ability to make this new venture a success. This will require a change of harvesting technique in many cases.

Many growers have developed the doubtful method of applying cling sprays and then picking the whole crop at one time. This is poor policy, of course, from many points of view. Maximum size cannot be expected, because the smaller fruit cannot fully develop while the larger sizes remain on the tree. An uneven ripening of the resultant crop in this case is experienced; because some of the fruit is over- and some under-mature when picked. The grower is losing a distinct advantage of size on the later maturing fruit on the tree. If two or three picks are made there is no reason why the whole crop cannot be brought up to canning size.

We are not condemning the use of cling sprays – far from it. They have become an established and important factor in fruit-growing. Pears react well to their use and give the grower some insurance against loss of crop through wind. With the use of cling sprays, however, there is the tendency to reduce picks, and the resultant mixed maturity has been the cause of fruit reaching the processing line and the consumer of the fresh fruit in a wasteful condition.

The price paid to the grower will be the same as last season – that is, fourpence per pound for pears of 2½ inches and larger. The factory is also accepting pears down to 2¼ inches in diameter. Each load will be inspected at the weighbridge. If it is seen that some fruit is under 2½ inches in diameter, part of the load will be graded and the percentage of small fruit assessed. Fruit from 2¼ to 2½ inches will be accepted at threepence per pound. If fruit of under 2¼ inches is included, the whole load will be rejected. In this case it will be the grower’s responsibility to remove the under-sized fruit before resubmitting it.

We trust that this scheme will prove as successful as it does with peaches. Growers will understand that any fruit under commercial grade should not be included. We have always accepted fruit of commercial and fancy grades, so there is no change there. By working to these requirements a tremendous amount of labour usually expended in the grading and sizing of this fruit can be eliminated, resulting in a higher return for the grower.

Asparagus for Intending Growers

Just a reminder to those who intend to plant asparagus this coming season. Early preparation of land is important. Any persistent weeds such as Californian thistle. couch grass or doab should be dealt with immediately. Where land levelling is required, it is wise to do it while the soil is dry and easily worked. If the land is in grass, it must be worked up in time to destroy turf completely before planting time. Once the weather breaks, in the autumn, it is often too late for these important factors of preparation.

There will be a large area of asparagus being planted this season. There are still some plants available, but any grower who requires plants would be well advised to contact our Field Supervisors at once.

PEAR SPRAYS.

One of our W.B.C. pear growers has apples interplanted in part of his orchard. To avoid copper damage to his apples, this section was sprayed with Captan, while the other received a Bordeaux programme throughout.

Fruit on the Bordeaux programme was later in maturity. It was rougher in appearance, but was free of black spot and of more uniform maturity. It also showed less evidence of “pink eye.” Where Captan was used throughout, the fruit was badly infected with black spot, resulting in fruit being unfit for sale. The skin apart from the “spot” was clear and free from russet, but maturity was much more forward and uneven.

This was an observation on one orchard only, where the two sprays were used by one operator. On other orchards Captan sprays gave good black spot control and good, clear-skinned fruit of beautiful appearance. It would appear that Captan will give control providing there is no initial infection in the early part of the year.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

March 1959Publisher

J Wattie Canneries LtdPeople

- Professor E R Hudson

- R (Bob) I June

- W Montgomerie

- James Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.