- Home

- Collections

- JUNE LI

- Harvest 07 - June 1959

Harvest 07 – June 1959

Harvest

VOL. 1 No. 7

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

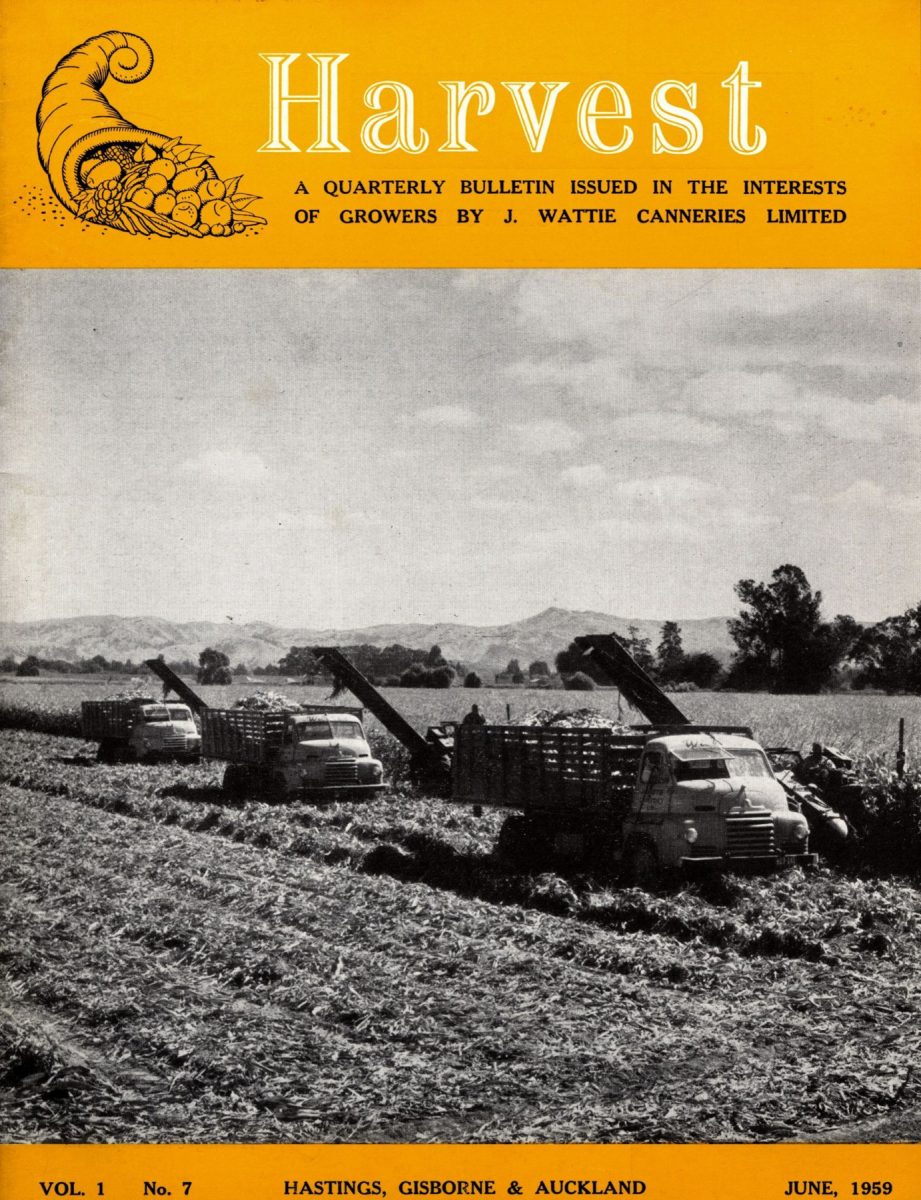

OUR COVER

Corn Harvesting, Gisborne.

FOREWORD

WE ARE VERY PROUD that our Managing Director, Mr. James Wattie, was able to make a trip to Australia recently as a member of the New Zealand Trade Mission. The mission’s accomplishments were gratifying, and to the mutual benefit of both Australia and New Zealand. Mr. Wattie’s part was most beneficial to our Company and to the canning and freezing industry of this country. The advantage of representation by men of ability in their own particular field on such a mission has been amply justified. A man who knows all the ramifications of his own business thoroughly, having grown up with it and having it so much at heart, must be the best possible representative.

Mr. Wattie, we feel, has all the necessary qualifications to render service to his industry. He has built up a canning and freezing industry by far the largest and most efficient in New Zealand. He has had the ability and foresight to do this in a very short period of time. The business of soliciting and gaining overseas trade is nothing new to him. He has been doing this for many years, and has made numerous trips overseas visiting many countries, particularly Britain and the United States. The business he has established overseas has done much to develop the industry and has made no small contribution to earning overseas funds for New Zealand.

Australia is a natural market for our frozen goods, being so close and so alike in many ways. The freezing industry has come a long way in New Zealand, but in Australia its development is many years behind. If we can help to develop the industry over there, it must be to our mutual advantage. The people of Australia want it and need it, but development will take time. It is not just a matter of shipping frozen food to an Australian port. Refrigerated transport, retailers’ equipment and sales promotion must all be developed in accord with one another.

It is a bright thought that this new trade expansion should come in this our twenty-fifth anniversary year. It will mean much to the freezing industry, to the country and to J. Wattie Canneries Ltd.

Yours sincerely,

Bob June

Hastings Field Supervisor

GETTING THE BEST ASPARAGUS

Asparagus is being planted at a considerably increased rate in Hawke’s Bay. Up until last year only about 700 acres had been established. The 1958 plantings of 300 acres brought the over-all area up to 1,000 acres, this being grown for processing and the local fresh market. We have now reached another planting season, and the new area this year will exceed last season’s, probably bringing the total area to 1,400 acres. This is still a far cry from our requirements, but at last we feel we are getting somewhere. Fortunately the greater part of this area is being produced for Watties, but it will be a few years before it is all in full bearing.

VARIETIES.

Asparagus has been produced commercially for processing now for about twenty years. In the early days the main varieties were Conover’s Colossal and Mary and Martha Washington. About fifteen years ago Wilson’s Nurseries, of Hastings, introduced the variety Paradise from America. It was a definite improvement over the old varieties, and it showed a marked increase in yield. Since then a new strain of Washington, known as Washington 500, has been introduced, and is the main variety being planted at the moment. However, with locally saved seed, it is now doubtful if any of the lines could be said to be any one variety. Little difference can be seen in any of the plantings, the variation of types is so great.

Watties have also some new varieties recently introduced from America, but it will be some years before the results of these are known.

SOME IMPORTANT POINTS.

Asparagus production is very closely associated with seed selection. If there was an easy way of controlling the parentage of asparagus plants so that all plants were producing equal to the best seen in any one crop, then production would be very greatly increased.

Much of the seed now available is locally saved. although Watties have been importing from America for some years, trying to ensure the best type possible. However, asparagus seed production in general in that country is only done by selection, and does not necessarily mean the resultant plants will be uniformly true to type.

Asparagus produces male and female plants, the seed, of course, being produced on the female plant and fertilized by the male. A female plant may be fertilized by one or more male plants, so that not even all the seed from one plant has the same parentage. Selection of seed, then, by noting the characteristics of the plant bearing the seed, is little indication of the resultant plant. It is little wonder then that a great variation is present in our crops. Producing seed of a known type is a plant breeder’s job. There is a great deal of work being done on asparagus breeding. Davis University of California, for instance, has done a tremendous amount of work on it. Other countries, too, are giving it their attention, and it is to be hoped that much more uniform and higher productive asparagus may be more generally available in the future.

To establish an area of high producing first-grade asparagus would mean growing only plants from top class controlled parents. It would take many years, and is really a plant breeder’s job to do this. It would hardly be practicable and economical for most commercial growers to attempt to establish a highly selected strain.

Growers can, however, go at least part way towards ensuring that their seed will be of reasonable quality, by sowing it only from females showing the most desirable characteristics at the time of seed harvesting. With this method the pollinating parent will be unknown, but for most growers this is an uncontrollable factor and will have to be overlooked for practical purposes. Selecting seed from only desirable females will be a step in the right direction, and extra time and thought put into the operation at this critical stage can mean a lot to a grower’s pocket when the plants come into full production.

For the purpose of seed selection from an established area, there are five main characteristics which the chosen seed plants should indicate.

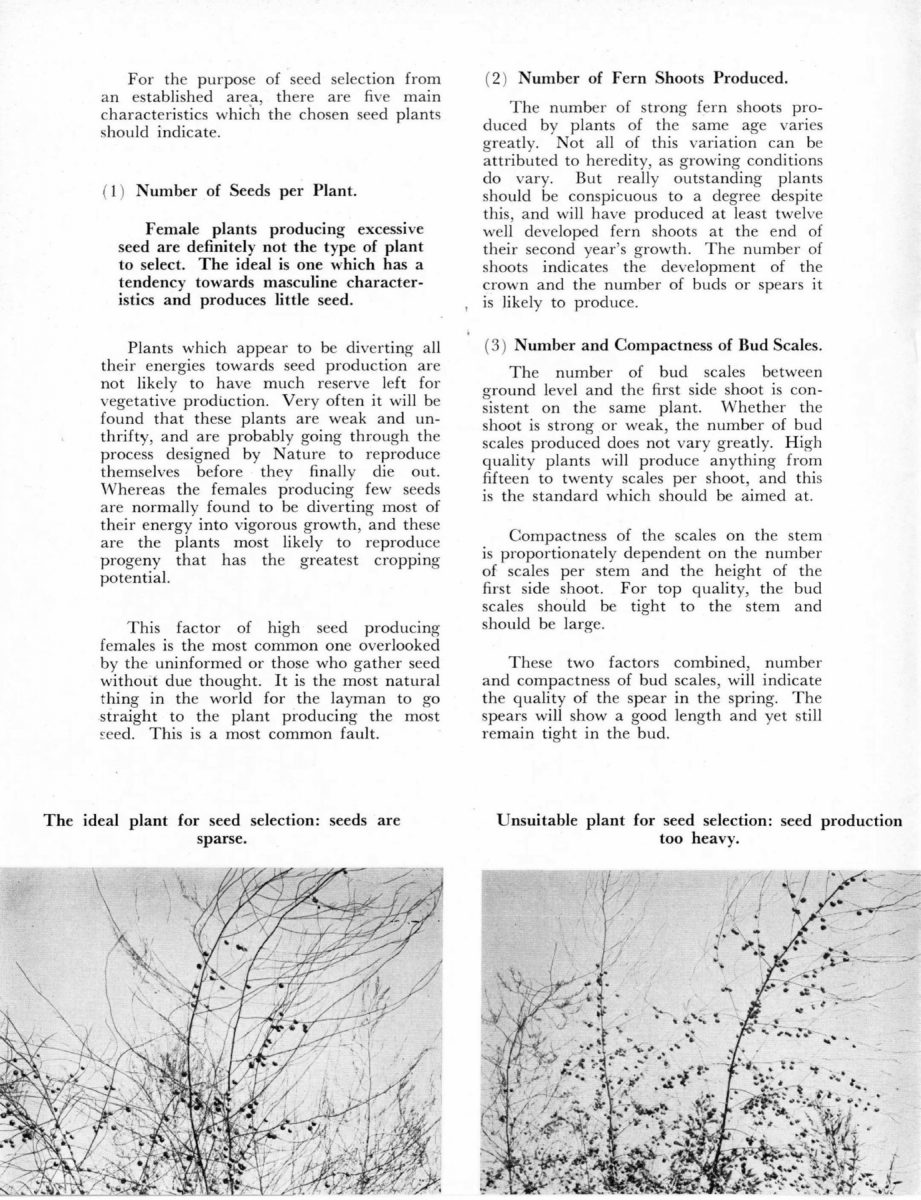

(1) Number of Seeds per Plant.

Female plants producing excessive seed are definitely not the type of plant to select. The ideal is one which has a tendency towards masculine characteristics and produces little seed.

Plants which appear to be diverting all their energies towards seed production are not likely to have much reserve left for vegetative production. Very often it will be found that these plants are weak and unthrifty, and are probably going through the process designed by Nature to reproduce themselves before they finally die out. Whereas the females producing few seeds are normally found to be diverting most of their energy into vigorous growth, and these are the plants most likely to reproduce progeny that has the greatest cropping potential.

This factor of high seed producing females is the most common one overlooked by the uninformed or those who gather seed without due thought. It is the most natural thing in the world for the layman to go straight to the plant producing the most seed. This is a most common fault.

(2) Number of Fern Shoots Produced.

The number of strong fern shoots produced by plants of the same age varies greatly. Not all of this variation can be attributed to heredity, as growing conditions do vary. But really outstanding plants should be conspicuous to a degree despite this, and will have produced at least twelve well developed fern shoots at the end of their second year’s growth. The number of shoots indicates the development of the crown and the number of buds or spears it is likely to produce.

(3) Number and Compactness of Bud Scales.

The number of bud scales between ground level and the first side shoot is consistent on the same plant. Whether the shoot is strong or weak, the number of bud scales produced does not vary greatly. High quality plants will produce anything from fifteen to twenty scales per shoot, and this is the standard which should be aimed at.

Compactness of the scales on the stem is proportionately dependent on the number of scales per stem and the height of the first side shoot. For top quality, the bud scales should be tight to the stem and should be large.

These two factors combined, number and compactness of bud scales, will indicate the quality of the spear in the spring. The spears will show a good length and yet still remain tight in the bud.

The ideal plant for seed selection: seeds are sparse.

Unsuitable plant for seed selection: seed production too heavy.

The ideal plant with high branching characteristics.

This plant is unsuitable: it branches too low.

(4) Height of First Side Shoot.

The height of the first side shoot should not be lower than twelve inches and may be as high as eighteen or twenty inches. It would be difficult to lay down any set standard on this point, as the height of ridging, depth of crown and age of plant all come into consideration. But generally speaking, only the very highest branching plants should be selected, and whether the height is fifteen or twenty inches will depend on the factors already mentioned.

(5) Vigour and Health of Plant.

Strong, vigorous and healthy plants normally stand out very clearly, but unless they have all the above characteristics they will not be worth considering. Vigour alone is not required; it is an important factor, but unless it is diverted into the production of quality asparagus it is not of much use.

Watties have this season commenced a long-term programme in the breeding for quality and quantity of asparagus. Out of an area of 60 acres, twenty plants have been selected for this purpose. We have made a very hard selection, as can be appreciated when it is realised that these twenty plants represent a selection from some 300,000 plants or more.

It will require at least three or perhaps four years of careful growing and collecting data on the quality and performance of these plants before any breeding can be conducted. However, a start has been made, and we hope that in the not too distant future Watties will be able to offer to the district a breed which is superior in every respect to those at present grown.

IS IT SAFE IN THE CAN?

Many questions are asked from time to time on various aspects of canned and frozen foods. Some of these are worthy of mention in this publication.

1. Is it safe to leave food in an open can? Yes. There is no question whatsoever that it is just as safe to keep food in the can it comes in as it is to empty it into another container. This has been thoroughly investigated.

A few acid foods may dissolve a little iron from the can, but this is not dangerous or harmful to health. Cans and foods are sterilized in the processing, but the dish into which the food might be emptied is far from sterile. It is likely to have bacteria on it that will cause food to spoil. The principal precaution in keeping food is “keep it cool and covered,” whether in the original can or another container.

SPRAYING of SWEET CORN

Although chemical weed sprays have been in use for many years, little was known of their usage and effects on spraying sweet corn crops until five years ago.

During this period results have shown that effective weed control can be obtained by spraying corn at the correct time with the correct materials, with no resultant damage to crops; but also detrimental and sometimes extremely drastic effects have resulted from incorrect application of the sprays.

Experiences over the past five years have shown that: –

(1) Sweet corn plants are considerably more susceptible to injury from hormone sprays than maize. Also a variation in susceptibility to injury occurs on different varieties of sweet corn, the Golden Cross Hybrids, which have been the main ones grown in Gisborne, being the most sensitive.

(2) Applications of the amine salts of 2.4.D up to 2 pints per acre of 4lbs. acid equivalent materials have not caused damage to corn in any season when applied to plants from four inches to six inches high.

(3) Damage in some form to corn has occurred in each season when spraying has been carried out after the plants are past six inches high.

The extent of the damage has varied according to the effects of climatic conditions at time of application and to the lateness and strength of application. It has been very obvious each season that damage becomes progressively worse with the lateness of spraying.

The effects of late spraying vary from: –

(a) An unnatural forcing of growth and development of more: but much smaller cobs per plant.

(b) Suppression of growth and formation of low-set and small cobs with corresponding reduced yields.

(c) Formation of malformed and multiple cobs of various forms up to the serious distortion shown in the illustration.

(d) Stalks of plants become extremely brittle and make efficient mechanical harvesting very difficult.

The total weight of the two cobs in the photographs was 3lbs. 8ozs. The weight of the usable cobs was 1lb. 6ozs. (39.29 per cent. of total), and the wastage 2lbs. 2ozs. (60.71 per cent. of total).

While the cobs shown above were some of the most seriously affected in the past season, a total of 150 acres of sweet corn in Gisborne was seriously affected by late spraying. Weighing of cobs from measured sections of rows from these crops showed recovery of usable cobs to vary from 70 per cent. to 90 per cent.

Photo captions –

Showing two usable cobs: the rest wastage

Showing malformed cobs resulting from late applications of 2.4.D.

As can be seen from the above figures, losses in processing can be considerable, and as all these undesirable effects can be eliminated by spraying at the correct period, more consideration will have to be given to this aspect of growing corn. Evidence has shown also that increased yields can be expected by early spraying as against late spraying.

Recommendations for weed control in sweet corn crops are:

Apply 1½ pints to acre of the amine salt of 2.4.D (4lbs, acid equivalent) when corn plants are from four inches to six inches high in any crop that is not entirely free of weeds.

Do not cultivate before spraying and not until at least seven days after spraying. Wherever possible, cultivate twice before corn plants become too high to work.

In cases where spraying is essential and has not been carried out in the safe period, due to adverse weather, apply spray with dropped arms to base of plants and not over foliage.

FACTORY FIRSTS

Last year J. Wattie Canneries Ltd. launched out on yet another new product, Baby Food. Put up in small cans specially made for the purpose, the venture has proved a successful one. Imported baby foods of many kinds have been available for some years, and their use in New Zealand is now becoming more popular.

The raw material for this food is selected to produce the best possible food for baby. Its preparation and processing receives separate and special care to ensure only food of quality hygienically pure and wholesome, going into the can. Vitamins are of special importance and their retention is safeguarded as much as possible.

Our baby food has been accepted by such organisations as the NZ. Plunket Society, and is generally recommended by doctors and dietitians. A good range including several fruits and vegetables is now available, a range to give variation to the baby’s diet. Its smooth texture makes it most acceptable to a baby’s taste, and it is found that they will often eat this food when they have turned down home prepared foods of a similar nature.

Baby food has now been followed by a range of Junior Foods. This is prepared from similar materials, but is coarser in texture, just right to follow on after the fine smooth-textured baby food. This line has just recently been released, and is now being distributed in a wide range through- out the country.

For adults: Try a can of baby food apples with your pork.

FIELD TALK

ONE CROP A YEAR IS BEST

It is natural that growers want to get the maximum returns from their land at all times, yet our field men often see an all-out effort to this end fail. Farmers of long experience are less likely to fall down in their efforts than the new chum.

We get many enquiries from growers wanting to grow two crops in one season. It is seldom that Nature will allow it. At odd times over the years, second crop peas have been planted in an effort to increase supplies for late orders. Only once to our knowledge has this been successful. Even then, the quality of a late grown crop is seldom good.

Nature cannot be controlled to any extent, and our climate will not allow crops too much out of season. Land must be fairly light and exceptionally well drained to enable very early crops to be planted. Soil of this nature is not apt to hold its moisture sufficiently to give a worthwhile second crop. The long View must be taken in all types of farming, and it seems advisable that one crop, treated correctly and planted at the best time to suit the particular soil type, must pay off in the long run. If need be a cheap cover crop can follow, either to feed off or turn in, and be most beneficial. This keeps the soil in good condition for subsequent crops.

BROAD BEAN PRODUCTION IN H.B.

J. Wattie Canneries first introduced frozen broad beans to the New Zealand public four years ago. The first crop of 25 acres was grown on our No. 2 Farm near Hastings. The following year over 100 acres were grown by contract, and the results were most encouraging to both growers and processors alike. Last season’s crop was very disappointing owing to extremely dry conditions which ruled from planting time to harvest.

VARIETIES.

Last year we introduced the white-seeded type of broad bean for canning. This is the only variety that can be produced in this way without becoming discoloured in the can. This gave even poorer results than the green-seeded types which included mainly Early Long Pod and Coles Dwarf. These two varieties have been the main varieties grown in New Zealand for many years.

Numerous varieties were grown under trial. Most of these were English, and one or two showed promise and have warranted field scale trials this year. It appears that little or no selection or trial work has been done on broad beans in this country for many years. In the past they have been grown only by the home gardener. Since we commenced processing them, making them available all the year round in a frozen pack, more attention is being paid to this crop, and our trials indicate that a good deal of improvement over existing varieties will take place. The improvements include cropping ability, flavour and colour.

PLANTING.

When broad beans were first planted on a field crop basis, very little was known of the best cultural practices. The first year we planted them in rows of three feet apart and seeds about six to eight inches apart in the row. We found that this was too dense, and are now recommending four feet to four feet six inches between rows and ten to twelve inches for seed spacing.

Planting for this season has been completed. It seems that planting should be done in the first half of the month of May. This gives seed a reasonable chance of germinating readily, and the plant rooting system becomes well enough established to allow the plant to overwinter well. If planted too late, seed is apt to germinate very slowly or even rot in cold, wet soil conditions. All seed has been treated against damping off, but this is only effective to a certain degree.

Planting is a problem, particularly if the seed is variable in size. The use of corn planters, potato planters and converted grain drills have all been tried with varying success. As the number of seeds per acre is not great, small areas of four or five acres can readily be planted by hand, dropping the seed in trenches made by moulders. The soil should be left flat after planting so that a mould can be put on the plants later as the first part of weed control. Little cultivation is necessary, as it is only required to keep weeds under control, which do not flourish until picking time approaches.

SPRAYING.

Diseases and pests in broad beans are not a great problem as a rule. By planting at the correct time, rust should not be serious. Chocolate spot can be troublesome at times. The recommendations on experience so far suggest the use of T.M.T.D. and Dithane to be best against fungus diseases.

The main insect pest of broad beans has always been the black aphis. Many materials such as nicotine sulphate, Malathion and Lindane have been used with varying results. Last season one of our crops was sprayed with the systemic spray Metasystox. This gave complete control through the picking period with one application.

CAUTION.

Metasystox is one of the first systemic types of spray used commercially and has proved a great success; a systemic material being one, of course, which is actually taken into the plant tissue. Any sucking insect then, such as aphids, receive a lethal dose as they feed off the protected plant. The effective period after application varies according to the kind of plant and time of application.

As this material is apt to affect humans if taken into the body in any quantity, we must make it clear that it is not to be used after pod formation or a month prior to harvest. To be safe – not later than 10th September.

Play safe, and be sure to enquire about rates and application from our field officers before applying Metasystox. More of these systemic sprays are now on the market and will be tried this year. We will be giving our growers information on new systemics as they become available.

Asparagus should be planted soon

Lifting asparagus with a potato digger.

Growers who will be planting out asparagus should be all set to go. They should have their land either already deep ploughed or ready to have this done, with any grass and weeds completely killed. Any levelling or drainage necessary should also be completed.

Now is the time to start digging out plants. Wet weather can be utilised for separating and sorting crowns. The lifting can be done with a potato digger as shown, or by ploughing them out and then lifting them out of the furrow with a fork.

Stacked in a shed with some soil still adhering to them, they can be allowed to dry out a bit to assist in the job of separating and sorting. They can then be stored in a cool but dry place. If allowed to become wet in storage, mould is apt to develop. They store well in sacks or cases held in a cool store at about 32 degrees F.

Plant out in rows six to seven feet apart, according to implements that are going to be used in subsequent years. Place the plants fifteen to eighteen inches apart in the rows in good deep sandy or silt loams. Some like to plant closer to get a higher yield the first two or three years of cutting. Depth varies according to soil types, but seven to eight inches below normal ground level is usual.

After the soil has been reasonably worked, trenches are easily made by ploughing both ways with a single-furrowed plough.

Planting is done in teams – one person placing the plants, and another covering the plants by pulling soil in with the feet. In this way each plant receives individual attention and few misses should occur.

Trenches should be smoothed after planting while the soil is still loose, to make chemical weed control effective. This can be done by pulling a light chain harrow partly rolled up to fit into the contour of the trench. Any similar implement is effective. The C.M.U. sprays used are pre-emergence sprays and will not be effective if the trenches are lumpy.

C.M.U. can be used at 3lbs. to the acre, and will give good control if properly applied with plenty of water – up to forty gallons per acre. This material settles readily, so watch agitation carefully. Uneven distribution is the cause of most failures.

Contact our field men before you start. We will be pleased to assist in any way possible. There are also fuller details in the July, 1958, issue of Harvest.

CROP REVIEW: 1958-59 SEASON

We are drawing near the close of another production year, our twenty-fifth anniversary year, which has had many ups and downs from the growers’ point of view. Hastings production per acre has tended to be lower for the most part, whereas Gisborne has turned up with records for practically every crop produced. The wisdom of having a factory in two production areas has been well and truly substantiated this year.

The reason for such variable production is not difficult to find. Production goes hand in hand for the most part with weather conditions. The summer of 1957-58 was very dry, and this was followed by a record dry winter in both Hastings and Gisborne districts. This meant that we went into the spring with no reserve moisture in the subsoil at all. In Hastings spring conditions were also dry, but in Gisborne sufficient rain, well spread throughout the early summer, was adequate to keep the pea crops growing steadily, and this followed right through the year, boosting all other crops as well. We are facing another winter without ample early rains. It is to be hoped we get a reasonably wet winter, otherwise fruit trees must suffer from any continued lack of subsoil moisture.

In spite of these adverse conditions, the over-all production from both factories has been fairly satisfactory. A brief summary of individual crops gives some points of interest.

PEAS.

In Gisborne, fairly frequent rains through spring and summer which wet the root zone, and combined with warm soil conditions, produced the heaviest crop of peas to date. Crops planted up to mid-September, in particular, developed exceptionally long top growth, and maturity in these crops was very uneven. Weed growth was more prolific than usual, but good control was obtained by D.N.B.P. sprays except in crops with heavy growth of Prince of Wales Feather. M.C.P.B. sprays were used where this weed was present, with good control, but with some very undesirable effects on maturity.

In Hastings, there was not sufficient rain at any stage to set pea crops off to a good start. Rain which did fall in December was too late to do much good. The result was poor crops right through the season. and the average was probably the lowest ever experienced. Even maturity was difficult to obtain, as many of the crops ripened quickly with very short vine growth, Growth was so short in some cases that it could not be picked up cleanly by the harvesting machines thus reducing the yield still further.

One point stood out very clearly – a point we have been trying to drive home for many years. It was very noticeable that where grass was turned over early, crops were much heavier than where working-up was done just prior to planting. In the land worked early, what moisture there was in the soil was available to the pea crops. Land that was worked late had its moisture taken up by the grass, and in some soil types there was not sufficient moisture to germinate the seed evenly.

GREEN BEANS.

In both Hastings and Gisborne districts dwarf green bean crops were very satisfactory, with averages up by nearly one ton per acre over average in Gisborne. There were exceptions. In Hastings the variety “Top Crop” failed to germinate well where rain fell shortly after planting. Pole beans of the Blue Lake variety produced up to twelve tons to the acre, but areas planted late received severe damage in a February gale and never recovered. Two crops planted in the same area for two consecutive years were very severely infected with bean mosaic.

A considerable area of yellow wax beans was grown this year. The variety was “Kinghorn Wax.” It produced very well in Hastings even though it was not planted till early January, but in Gisborne results were disappointing.

Many varieties were tested for their cropping ability and for flavour, texture and colour in the finished article. As a result, only two varieties of green beans will be grown commercially next year. These are both white-seeded varieties, namely Blue Lake pole beans and Processor dwarf beans. All other varieties such as Pearl Green, Top Crop, Tenderbest and Seminole lacked colour and flavour and were not in the picture, compared to these two. Processor has been grown in the Hastings district for the past three years and has cropped well. It has yielded over four tons per acre in the first pick, and over seven tons for the season, so we can recommend it with confidence.

SWEET CORN.

All our sweet corn is grown in the Gisborne district. At the time this crop is harvested, the Hastings factory is fully employed on peaches, pears, beans and tomatoes. Production economy is better served by growing sweet corn in Gisborne, an area well known for this type of crop for many years, rather than processing some in each factory.

Climatic conditions were most favourable this season, and production was over 18 cwt. higher than any previous record. Six varieties were grown commercially, but the greatest area was planted with Golden Cross Hybrids. All varieties yielded well, but two, Golden Harvest and Golden Monarch. The latter produced a heavy crop of over eight tons per acre, but cobs were too large. None of the other six varieties of new hybrids grown in row trials showed any improvement on the older Golden Cross Hybrids.

TOMATOES.

The season’s budget for this crop was exceeded. That Gisborne should have a record crop of over eighteen tons per acre accounted for this. Hastings received its estimated quantity after additional planting was made in view of the adverse spring weather. The average was five tons lower than last year, and the lowest for five years; the average tonnage being thirteen tons to the acre. Although the quantity was satisfactory, quality in the latter part of the year was poor.

FRUIT.

Pear crops in Hawke’s Bay were an all-time record. The William Bon Cretien [Chretien] variety for canning was also a record crop, with about a 25 per cent. greater tonnage canned than ever before. The fact that smaller pears were accepted (2¼ inch) was partly responsible for this. Quality was good and recovery excellent.

Peaches were disappointing, both in quality and quantity. The early crop estimate was just reached, but a later estimate raising the quantity by 300 tons, was not forthcoming due to the heaviest drop ever experienced.

In February, we experienced a very heavy southerly gale followed by rain. At the time we were pleased that very little loss due to the gale was experienced. Rain which was badly needed fell after the wind ceased, and it was due to this rain that the estimate was increased. As the fruit started to mature, however, it also started to fall. It was noticed that it made no difference if the trees were young or old, irrigated or non-irrigated, grassed down or clean cultivated; the drop was general. Even spray programmes were compared for results. It is considered that the severe check as a result of the wind and marked drop in temperatures checked the flow of sap to the fruit and the normal ripening process was cut short. This is followed out by the fact that the peaches this season were soft and flabby. Even immature fruit was spongy in texture. As a result of this poor quality recoveries were low, with a higher percentage of peach chunks than anticipated.

OTHER CROPS.

Asparagus showed an improvement over the three previous years, but broad beans were very poor. Mention of these early crops was made in the last Harvest.

All other crops have been satisfactory.

Taking the year as a whole, production figures should be nearly up to the budget quota, peaches being the greatest disappointment. In spite of a few setbacks, the tonnage of all crops processed will be the largest ever handled, so that all-over results are very pleasing for this our twenty-fifth anniversary.

WATTIES STAND FAST

Growers’ costs are still tending to rise, and the net return from their crops has declined, if anything, over the past few seasons. This trend is general whether the produce be wool, butterfat, fruit or marketed vegetables. In some cases, too, the returns for vegetables produced for processors has been reduced by one or two firms.

This Company has been approached both last year and again recently, in an effort to lower our prices to the growers for freezing quality peas, broad beans and tomatoes. We are standing firm, and are now tentatively booking areas as far as our known requirements will permit, at the same prices as last year.

We trust you, our grower friends, appreciate this fact. You know, at least, that with Wattie’s you have a solid, reliable market for your produce which does not vary to any extent from year to year.

With production costs rising, an increase would be more in line than a decrease – for you, and for us. However, we know you appreciate the full situation. Although your costs have risen, ours have risen even more, with items such as transport costs, to name just one, affecting us to a greater extent than it does a grower. With our production level rising over the years, and methods in factory technique improving all the time, we have been able to absorb rising costs to a certain extent. This is certainly no time for any of us to embark upon price rises; we will do well to hold the present line.

Growers have long been able to look ahead and develop cropping projects with the comforting knowledge that the market for their crops handled by J Wattie Canneries is fairly managed, and is assured and consistent.

GROWER COMPETITION KEEN.

As we have stated on previous occasions, we are constantly turning away would-be growers for many of our crops. We are therefore in the happy position to issue contracts to growers who can constantly supply the best quality to the factory. We do not like to chop and change, and our growers’ lists reveal that any change has been very small and gradual. We try to be absolutely impartial and give all our growers the same consideration. However, we must consider certain factors such as distance from the factory in the case of peas, suitable soils, the grower’s equipment and so on. We would not accept a tomato contract, for instance, unless we knew that the grower was able to spray them effectively.

Quality is a watchword becoming more important all the time. Most of our growers know that we keep a record of the condition of each load of produce received. If the quality is consistently poor in spite of the fact being pointed out at the time, then this must be taken into consideration when new contracts are made for the following year.

THE GROWER’S PART.

With the general reduction in prices to the producer of primary produce in New Zealand, there seems little likelihood of an increase in price in the immediate future for any fruit or vegetables supplied to processors. It is up to the grower, then, to endeavour to reduce his costs, as this factory has had to do. This is very easy to say, but not so easy to carry out. Nevertheless, our field men in their travels often notice unnecessary expenditure that could be avoided.

CONTRACT LABOUR.

One of the greatest single expenditures for certain crops such as beans, tomatoes and fruit is the harvesting costs. Much of this work is done by contract gangs who over the years have gained a hold on the growers which is now difficult to control. Contract prices have crept up over the years, plus demands for free transport, tax payment, petrol allowance, gangers’ allowance and so on. At times of labour shortage growers have been held at ransom, and once they give in to an increase, it is most difficult to reduce prices again. Surely a contract worker must realise that he cannot make high wages every day of the season. He must be prepared to work for less at certain periods, knowing that at other times he will make more than a working wage, thus balancing out well over the season.

Although contract costs have increased, the same cannot be said of efficiency. A source of concern at times to the grower and processor alike is the lack of co-operation and the rough work carried out by some contractors. Labour is no longer in short supply. Last season it was difficult to find employment for all that was offering, except at a period late in the year. Growers are partly to blame for the situation. They have not held together as a body at any stage. When a grower offers more to be sure of getting his own crop harvested, he does not realise, perhaps, the far-reaching effect it may have. His gang and others immediately say they are getting such and such a price from Mr. so-and-so, and refuse to work unless they get the same elsewhere. One grower is played against the other, and there is no end to it. Why, for instance, should we pay twopence a pound and more for picking beans, when in the Nelson district the price is one penny farthing or 1/6 per bucket, according to the March, 1959, issue of the NZ. Commercial Growers’ Journal?

COST OF SPRAYING.

Another major cost in production of many crops is spraying. Tomatoes, for instance, demand a great deal of spraying to give adequate control of disease and pests. Most of our growers have this down to a fine art, but there are some who lose all the way down the line for the sake of one or two extra sprays correctly timed. Wastage of fruit through the ravages of the tomato caterpillar, as an example, should not be tolerated. A constant coverage of D.D.D. will give complete control. It has been noticed that growers using dusting machines have been the worst affected. Investigations indicate that the cost of the application of dust is so high that growers feel unable to face the expenditure and try to get by with fewer applications. Dusters are quick and efficient in the hands of a good operator, but unless the costs of horticultural dusts can be reduced, their use will not be maintained.

PEA PRODUCTION COSTS.

The margin of profit in peas is seldom great. High returns of up to £100 per acre are few and far between. J. Wattie Canneries have been responsible for a gradual reduction in pea seed prices over the years. If we are to maintain the standard of seed, this has about reached the limit, so growers must look to the reduction of their own costs, if possible. A few points we have noticed may be a help to some. For instance, a grower who has had the most consistently high returns is one who never sows more than three bushels of seed per acre. Our recommendations have always been from three and a quarter to three and a half bushels, according to the time of the year and other conditions. Seed is an expensive item, and sowing rates should be watched closely. Weed spray rates, too, require close attention.

There is sometimes wasted effort expended on soil preparation. Discing prior to ploughing saves a great deal of extra work and unnecessary packing in final working. Discing, except for the first cut after ploughing, should always be at a different angle for fullest benefit. Care should be exercised to see that the working prior to planting leaves the paddock smooth and level. We sometimes hear complaints that there is wastage in our pea harvesting methods. Very often this is beyond our control if the paddock is rough. This is especially true if vine growth is short and mowing is necessary. Last season no rain was experienced to consolidate the ground after planting, and weed sprayer wheels left deep ruts which made a good job of mowing impossible. Strike-outs and finishes should receive special attention. In some cases much unnecessary work is done prior to planting. Provided there is no green turf showing, it is better to delay final working until shortly before planting.

Implements should be in good condition. We have seen growers operating discs with blades so badly worn that all they were doing was packing the soil. Thought should be given to the correct implement for the job. The correct use of the roller and chain harrows may save hours of work. All these points, and many others, are very important in reducing production costs. Our field officers are always happy to assist where possible. They are constantly in touch with various methods employed and are in a position to pass on any worthwhile methods they pick up in their travels.

LABOUR PROBLEMS IN H.B.

Wattie’s free bus service

The demand for labour in Hastings at certain times of the year is increasing as more and more industries are becoming established. There are now four food processing firms operating in Hastings, all requiring labour at the same peak production periods. Many other industries have been established in the area – all competing for labour.

J. Wattie Canneries, the pioneers in food processing in the Bay, have gone to considerable expense year by year to introduce more and more machinery, much of it automatic, to reduce labour requirements. But even automatic machinery requires labour for supervision and maintenance, and there is a limit to it in any case. There are, and always will be, many jobs that cannot be done by a machine.

Therefore the supply of labour for food processing factories will become more acute as time goes on. This is particularly true in March, when tomatoes and peaches are rolling into the factory in their thousands of cases a day. At peak periods we have received over 10,000 cases of peaches and 5,000 cases of tomatoes per day, to say nothing of apples and beans coming in at the same time. Most of this produce is perishable and must be processed immediately. The labour needed to handle this bulk of raw material is substantial, and with peach production in particular, developing rapidly, the labour requirement is going to increase.

WAYS AND MEANS MUST BE FOUND

We cannot and must not let this problem of labour stifle development. Enough peaches have been planted, and will be planted next year, to double our production in two years and treble it in six. Other crops such as asparagus and pears are increasing rapidly. All this production planning is of no avail if we cannot get labour to handle it.

During the peak of last season, Watties ran a free bus from as far afield as Waipukurau, forty miles away, to alleviate the situation. It was expensive, but there was no alternative. A considerable number of our employees already come from outside the district, and the need for more such seasonal labour is now well demonstrated.

REASONS FOR SHORTAGE.

Increased industry has already been mentioned as a reason for labour difficulties, but there are others. Normal population increase should compensate for much of this expansion, but as factory capacity increases more produce must be grown to supply it, so that more people are required in the field to produce it. This applies particularly to harvesting operations. People naturally prefer to work out of doors, so that there is not a serious shortage on the production side in the field. This kind of employment also receives assistance under the present concessions in the P.A.Y.E. system of taxation, and makes competition more difficult. Under the present system many people refuse employment, not because they do not wish to work, but because it is not worth while if it is classed as secondary employment with a small net pay package.

We don’t make these statements in a political sense, but it gives you, our growers, some idea of the problems that beset an industry such as ours. You can be assured we will do our utmost to keep pace with the labour problem for your sake and our own.

After all, it’s an embarrassment of the right sort: we’re just outgrowing our clothes!

Felicitations

On May 23rd our Assistant Field Supervisor, Mike Crooks, married Miss Sue Crichton, of Havelock North.

Mike joined our staff on November lst, 1957, and is now a well-known figure flying about the country in his Field Service car. During the eighteen months he has been on the staff, he has made a very good impression indeed on all those associated with him. Many growers of their own accord have stated their pleasure at the good work done by Mike and the pleasing manner in which he carries it out. We of the staff are very pleased with his accomplishments to date, and feel sure that as his knowledge of his field of work widens, he will be able to shoulder the greater efforts and responsibilities required of him with confidence.

Mike’s choice, Sue Crichton, cannot help but make an impression on all who meet her. Until recently a school teacher, she has a most pleasing personality and charm. Her parents, Mr. and Mrs. Colin Crichton, are well known and respected. They have created a pleasant family atmosphere commented on by many, which is reflected in their daughter’s character.

We all wish Mike and Sue all that’s good and fine in their married life, and trust that their life together will be blessed with health and happiness for many, many years to come.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

June 1959Publisher

J Wattie Canneries LtdPeople

- Colin Crichton

- Miss Sue Crichton

- Mike Crooks

- R (Bob) I June

- James Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.