- Home

- Collections

- JUNE LI

- Harvest 08 - October 1959

Harvest 08 – October 1959

Harvest

VOL. 1 No. 8

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

OUR COVER

Guess who …..

Field Supervisors planning how to cram two days’ work into one.

HARVEST

FOREWORD

SPRING IS HERE – the time of renewed hope and faith in – all that the man on the land sees about him. A time when last year’s failures do not seem so bad after all, and they are put down to experience – experience that cannot be bought or learned from a book. A time when we look forward to the new season ‘ahead with the unfailing hope that it will be the fulfilment of what we would wish it to be.

Spring is to most people the most colourful season of the year, when we see Nature taking on new colours and growth after the winter resting period. New life is in evidence everywhere, both of the plant and animal kingdom. No one can help but look on the bright side again with winter behind them. This is true of all mankind, but more especially of those who have an interest in the soil. It does not matter whether it is the proud owner of many broad acres or a little home garden plot. How often do we see a home gardener turning in the weed patch which was last year’s garden, with new hope and the determination to do a better job this year – even though he may have done the same for years.

This urge to start afresh, and do better each spring, never seems to die in man, and it is well that this is so. The man on the land takes many hard knocks, but he would not remain a farmer if he did not receive new faith each spring. There is always the chance that this year will be the perfect season. It seldom happens, but always could. No matter what happens, a farmer must go on planning and hoping. Experience of previous years is recalled and plans made accordingly.

There is always the unknown which lies ahead and the knowledge that there are seldom two seasons alike. We must anticipate a great deal. We contemplate the correct time to sow crops for the best results on a particular piece of land in a particular year. We wonder if it will be a dry spring or a wet one, cold or mild. No matter how we plan and rely on our experience, Nature always has the upper hand. Our fondest hopes are often dashed by drought or flood, wind, frost or the ravages of disease and pests. It is well that spring does bring fresh hope, and to be pitied is the man who cannot appreciate the revelation of spring.

We are going into the growing season this year in a very much happier position than last year, when no rain of any consequence had fallen for many months. We have a moist subsoil which in most circumstances sees us through the summer months with the aid of some light falls of rain as refreshers.

We hope for our growers’ sake that we have commenced a season that will give satisfaction to all. We have a big year ahead and we are under way with every confidence in our growers. We know that with your usual co-operation, trust and friendship, we can look forward to happy and prosperous times ahead.

Yours sincerely,

Bob June

Hastings Field Supervisor

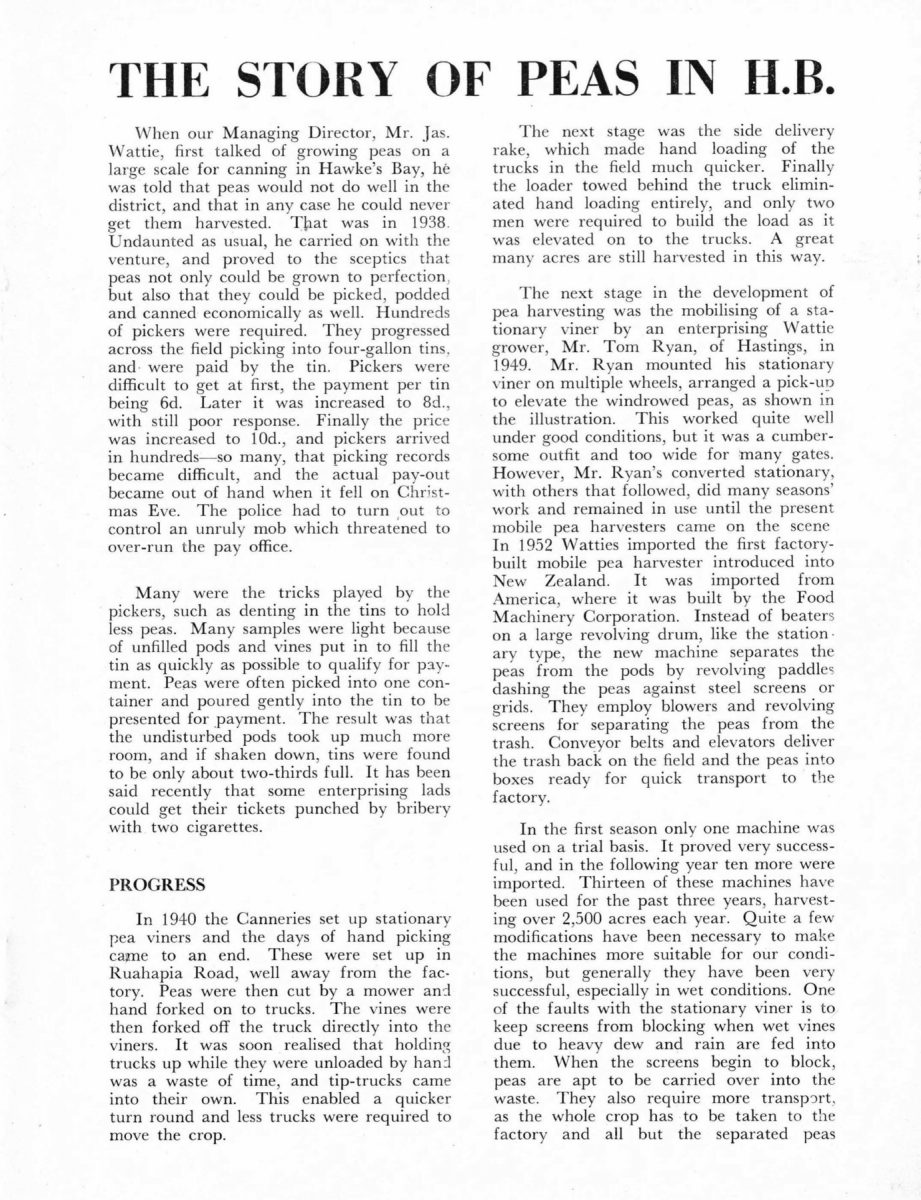

THE STORY OF PEAS IN H.B.

When our Managing Director, Mr. Jas. Wattie, first talked of growing peas on a large scale for canning in Hawke’s Bay, he was told that peas would not do well in the district, and that in any case he could never get them harvested. That was in 1938. Undaunted as usual, he carried on with the venture, and proved to the sceptics that peas not only could be grown to perfection but also that they could be picked, podded and canned economically as well. Hundreds of pickers were required. They progressed across the field picking into four-gallon tins and were paid by the tin. Pickers were difficult to get at first, the payment per tin being 6d. Later it was increased to 8d., with still poor response. Finally the price was increased to 10d., and pickers arrived in hundreds – so many, that picking records became difficult, and the actual pay-out became out of hand when it fell on Christmas Eve. The police had to turn out to control an unruly mob which threatened to over-run the pay office.

Many were the tricks played by the pickers, such as denting in the tins to hold less peas. Many samples were light because of unfilled pods and vines put in to fill the tin as quickly as possible to qualify for payment. Peas were often picked into one container and poured gently into the tin to be presented for payment. The result was that the undisturbed pods took up much more room, and if shaken down, tins were found to be only about two-thirds full. It has been said recently that some enterprising lads could get their tickets punched by bribery with two cigarettes.

PROGRESS

In 1940 the Canneries set up stationary pea viners and the days of hand picking came to an end. These were set up in Ruahapia Road, well away from the factory. Peas were then cut by a mower and hand forked on to trucks. The vines were then forked off the truck directly into the viners. It was soon realised that holding trucks up while they were unloaded by hand was a waste of time, and tip-trucks came into their own. This enabled a quicker turn round and less trucks were required to move the crop.

The next stage was the side delivery rake, which made hand loading of the trucks in the field much quicker. Finally the loader towed behind the truck eliminated hand loading entirely, and only two men were required to build the load as it was elevated on to the trucks. A great many acres are still harvested in this way.

The next stage in the development of pea harvesting was the mobilising of a stationary viner by an enterprising Wattie grower, Mr. Tom Ryan, of Hastings, in 1949. Mr. Ryan mounted his stationary viner on multiple wheels, arranged a pick-up to elevate the windrowed peas, as shown in the illustration. This worked quite well under good conditions, but it was a cumbersome outfit and too wide for many gates. However, Mr. Ryan’s converted stationary, with others that followed, did many seasons’ work and remained in use until the present mobile pea harvesters came on the scene. In 1952 Watties imported the first factory-built mobile pea harvester introduced into New Zealand. It was imported from America, where it was built by the Food Machinery Corporation. Instead of beaters on a large revolving drum, like the stationary type, the new machine separates the peas from the pods by revolving paddles dashing the peas against steel screens or grids. They employ blowers and revolving screens for separating the peas from the trash. Conveyor belts and elevators deliver the trash back on the field and the peas into boxes ready for quick transport to the factory.

In the first season only one machine was used on a trial basis. It proved very successful, and in the following year ten more were imported. Thirteen of these machines have been used for the past three years, harvesting over 2,500 acres each year. Quite a few modifications have been necessary to make the machines more suitable for our conditions, but generally they have been very successful, especially in wet conditions. One of the faults with the stationary viner is to keep screens from blocking when wet vines due to heavy dew and rain are fed into them. When the screens begin to block, peas are apt to be carried over into the waste. They also require more transport, as the whole crop has to be taken to the factory and all but the separated peas

Stage 1: Picking peas by hand twenty years ago, at Hastings, for the first pea-canning venture in Hawke’s Bay, by Watties.

carted away again. On the other hand, the separation process of the static type viner does less damage to the pea itself, and in dry conditions a better sample of pea can be obtained with less bruising and cut skins.

Wet vines do not interrupt harvesting with the mobile viner, but if ground conditions become too wet and soft, then harvesting operations must cease. Mobile viners are readily transported from place to place. If the vines are of good length, the pick-up device pulls the crop from the ground without mowing. However, short crops have to be mowed and side-raked, as the pick-up fingers cannot get sufficient grip to pull them up cleanly, resulting in too many unvined peas being left behind.

A big advantage of these machines is the return to the field of the vines after threshing. Farmers treat the haulm in various ways. Some disc or plough it into the soil to build up organics. Others turn cattle or sheep in and feed it off as it lies. However, most growers turn it once or twice to dry and then bale it. The baled pea hay has become an important sideline. It often brings high prices for winter feed, and in most years is keenly sought after. Stock will eat it in preference to any other hay, and do well on it.

THE FREEZING INDUSTRY

One of the major developments in the pea industry has been the introduction of quick freezing. This took place shortly after the war and was first established in New Zealand by Lever Brothers. Since then other companies have followed, including J. Wattie Canneries in 1956. The freezing of peas and other vegetables as well as fruit has now become a major development in the Company, and its sale of frozen peas has increased steadily from year to year until now it enjoys a large percentage of the frozen food trade.

A continuous blast freezing plant is being installed in the Hastings factory at the present time. This is the largest and most modern in the Southern Hemisphere. This plant will enable our Company to supply free flow peas in quantity for the first time.

The tendency both in New Zealand and overseas is toward this type of frozen pea, rather than the solid pack. As usual, we are keen to supply the consumers according to their tastes, and we trust the results will be

a greater tonnage of frozen peas from now on. The new plant will also be utilised for many other products.

Frozen peas require close attention to maturity. To produce a consistent high-quality pack a quick and accurate means of measuring maturity is necessary. This is now obtained by samples from each load being placed in a machine known as a tenderometer. It is an electrically-driven machine which severs the sample placed in a grid. The action of the grid in severing the peas is registered on a dial. Payment to growers is made at varying rates according to these readings. The softer pea and lighter crop per acre is therefore worth more per pound than the more mature and heavier crop. The price to the grower increases from 2.5d. per pound up in stages of five points on the scale. This ensures the grower a fairly uniform payment for his crop, no matter at what stage it is harvested.

FURTHER DEVELOPMENTS

So much for the progress in the harvesting of peas in Hawke’s Bay. There have been many other changes in handling and processing. Automatic and continuous pressure cookers were first introduced by Watties. This system of cooking greatly improved flavour and quality, as well as speeding up the process. Better systems of washing have been introduced. The Company was the first to introduce flotation washers to separate foreign matter from the peas.

Wattie Canneries was the first food processing factory to introduce radio telephone communication between field officers and the factory. Radio sets are now installed in all field service cars and trucks and in the petrol tanker which services the tractors and viners in the field. This ensures constant contact between the harvesting and processing operations, eliminates many stoppages and prevents a build-up of harvested peas above factory capacity – an important factor in quality control. It eliminated many miles of unprofitable running and speeded up repair and maintenance work on the harvesting fleet. All these improvements have greatly improved the quality of peas to the consumer.

Hand picking of peas a little over twenty years ago seems a far cry from modern methods of harvesting. Many other production methods have changed and are still changing. Among others, there is a constant search for better varieties. Each year new varieties are grown under trial. Those grown to-day are quite different from those of many years ago, although some varieties such as William Massey and Greenfeast have stood the test of time.

CULTIVATION METHODS CHANGE TOO

A few years ago most peas were grown in rows drilled fourteen inches apart. In the last ten years this has gradually given way to seven-inch spacing. One of the main reasons for this has been the development of weed control by sprays rather than by cultivation. Modern harvesters also operate more efficiently on crops that are not ridged by cultivation. With modern weed sprays, cultivation is no longer necessary except in exceptional circumstances.

Stage 2: A stationary viner of past years, converted to a mobile unit, 1940.

Pea seed is supplied by the factory at cost. This is done to ensure that all peas are of the same type. This helps in even maturity. All seed is tested for germination and is treated with a chemical to prevent rotting in the ground under adverse soil conditions.

GROWER PROTECTED

The production of any crop is risky because of the possibility of unfavourable conditions such as excess rain, frost, hail, exceptionally dry conditions, or disease. Peas are a fairly hardy crop, but in certain. years many acres have been lost by flooding. The Company has always come to the aid of a grower in these extreme circumstances, and has often either replaced the seed free of charge, or has at least compensated the grower in some way.

The same is true in the loss of a crop at harvesting time. If heavy rain is experienced when the peas are ready, harvesting operations must cease. Also exceptionally dry conditions can bring peas to maturity very quickly, making it impossible to harvest them all. No grower has ever been left to stand the complete loss of crop. High quality seed is sown so that, should the crop be missed, we can still accept the seed for the following season at a price to give the grower approximately the same return as if the crop was harvested green.

There are not many crops that can be grown with such a degree of insurance against loss. This, and the fact that a pea crop assists farmers in keeping their pastures in good order, makes peas a popular crop. We have never had any difficulty getting our areas. Indeed, this season land being offered for peas and other crops has become an embarrassment, and more than 2,000 acres had to be turned away.

The pea industry, then, has come a long way in the past twenty years – from hand picking and hand forking of the crop to modern harvesting methods where the whole process is done by machinery, apart from the loading and unloading of boxes of peas on and off the trucks. Even this is now being eliminated by the use of fork-lift tractors in the field. No doubt there will be other improvements as time goes on. because the pea industry in New Zealand is of considerable importance and must make progress. A large export market for peas has been developed by J. Wattie Canneries and for many years has earned overseas funds for the country.

Part of Wattie’s modern fleet of mobile pea harvesters in operation

N.B. The peas are not mown, but are pulled automatically into the machine for podding.

ASPARAGUS GRADES AND PRICES

With the increase in volume of asparagus now coming to hand, it has been possible to increase the price for the 1959 season. A new production line has also been installed which will further reduce production costs One of the greatest factors influencing payment to growers is quality. If only first grade asparagus was received, it would be possible to pay much higher prices for it. However, we must be practical about it. A grower with a small area who can go over the crop each day if required, is able to keep the quality high and uniform. On large areas, the number of cutters varies from day to day, and at odd times nearly double the number may be required to get over the whole area quickly.

With this fluctuation in the labour force required, there must be times when it is difficult to keep the length of spears within the desired limits. The factory management appreciates this fact, and has always been very tolerant. With the number of growers now supplying the factory, many of them new, we set out herewith a brief outline of our quality control specifications and prices.

RAW ASPARAGUS – QUALITY CONTROL

1. Every delivery of asparagus over the weighbridge is to be inspected for quality.

2. A sample of not less than 100ozs. will be taken from random boxes from each delivery. (Note: Number of boxes sampled will be not less than half the square root of the number of boxes in the load.)

3. Standards of quality are to be assessed as follows: –

(a) Length of Spears: Spears are ideally required to be between 5in. and 7in. in length.

lst Grade: Will have not more than 15% by weight of asparagus with spears either less than 5in. or more than 7in. in length.

2nd Grade: Will have not more than 20% by weight of asparagus with spears either less than 5in. or more than 7in. in length.

3rd Grade: Will have not more than 25% by weight of asparagus with spears either less than 5in. or more than 7in. in length.

Sub-Standard: Over 25% by weight of asparagus with spears either less than 5in. or more than 7in. in length.

(b) Seedy Heads: Spears ideally have compact heads showing no sign of seed.

lst Grade: Will have not more than 15% by weight of asparagus showing open seedy heads.

2nd Grade: Will have not more than 20% by weight of asparagus showing open seedy heads.

3rd Grade: Will have not more than 25% by weight of asparagus showing open seedy heads.

Sub-Standard: Over 25% by weight of asparagus spears showing seedy heads.

PAYMENT ON GRADING

Grading for payment will be made on the lowest rating under either (a) or (b).

lst Grade Price: 10d. per lb. (i.e. asparagus must be lst Grade under headings (a) and (b).)

2nd Grade Price: 9d. per lb.

3rd Grade Price: 8d. per lb.

Sub-Standard: By arrangement only between field supervisor and grower. Otherwise Sub-Standard asparagus is not acceptable.

TREMENDOUS INCREASE IN AREA

Up until 1957 there was only about 700 acres of asparagus being grown in Hawke’s Bay. With the drop in sheep and dairy products and other factors, farmers looked for a diversification of their land utilisation They turned their minds first to annual crops such as peas and beans, but soon found that the field was limited in these crops. Field officers were able to point out the advantages of permanent crops such as asparagus, and the result has been a very significant increase in the last two years. Enquiries already made indicate a fairly heavy planting again next year.

From the 700 acres planted over a period of nearly twenty years, up to 1957, the area rose by 300 acres in 1958 to 1,000, and in the 1959 planting season just finished a further 500-odd acres has been added, bringing the total to just over 1,500.

It will be three or four years before the full impact of this area will be really effective, but the New Zealand market for canned and frozen asparagus has already been fully supplied, so from now on the only market for this increase is overseas.

It has been realised for some time that the local market would soon be saturated, and Watties have already paved the way for the export of some of their asparagus pack. There is a huge export market available, but only if we can keep the price within reason. The whole asparagus industry must now be based on this fact, and growers must realise that some of the higher than market prices now being offered cannot be maintained if the industry is going to continue to expand.

The question of labour is uppermost in many growers’ minds, and indeed it must be considered as one of the most important factors in the limitations of asparagus growing. Had the increase been more gradual this question may not have been so important. With the area more than doubled in two years, there is going to be a sudden demand on labour which may bring complications.

HARVESTING COSTS MUST BE WATCHED

The ever-rising cost of harvesting various crops is now one of the main controlling factors in the production of food. In some crops it is having a stifling effect, making the cost to the consumer so high that consumption cannot be maintained. This could already be said of asparagus. If the cost on the grocer’s shelf is raised any more, then turnover must be reduced.

This Company has warned growers of this aspect of food production on many occasions, yet we see picking gangs holding growers at ransom when they know a crop has to be picked or lost. We now have a growers’ organisation setting out picking costs as recommendations to growers, and if everyone would stand by these all would be well. We find that anomalies keep creeping in with pickers demanding petrol for travelling, ganger money and many other extras. If cropping is to expand, harvesting costs must not be allowed to increase further. Nearly every increase given to asparagus growers in the last few years has been handed on to cutters, leaving the grower no better off. We trust growers will stand fast on this point from now on. It can be done without any hardship to pickers, as they are already earning in excess of award wages for the greater part of the season.

FIELD TALK

One of our Hastings growers who has had a fairly large area of pole beans in the last couple of years, has struck on a novel idea to prevent the strings from drifting along the wire as the result of wind.

He is using four-ply cotton string over a top wire and binder twine along the bottom. The binder twine along the base tends to stretch badly. It should be put in place in plenty of time and stretched several times prior to stringing. Wire is better for the bottom, even if fairly light, such as telephone wire, which is sometimes available.

Our grower used a fairly weak solution of glue size to hold the string in place. A pound of size was sufficient for an acre, so material costs did not amount to much. A brush was used to apply it, and the operation was quick and effective. It was applied top and bottom, but this is not really necessary. Top application should be sufficient.

Last year rabbits were responsible for cutting the binder twine in a few places. The fact that the bottom was also glued helped in this instance because the string was still in place and made repairs simple. Rain did not affect the glue, which remained effective for many weeks.

Peach trees being cut back to bud: Wattie’s Nursery, Hastings

THE PEACH TREE SHORTAGE

We wish to apologise most humbly to those growers who relied on us to supply peach trees and in the end did not receive any or all of their orders. We accepted the responsibility of supplying because a shortage this year was anticipated a long time ago. But of 4,000 trees which nurserymen in New Zealand agreed to supply, we received less than 2,000. As a result some of our growers who wished to plant received no trees at all, and others only part of their requirements.

We appreciate very much the way our growers have accepted the failure to supply when it was pointed out that it was beyond our control. In most cases we were not notified beforehand that orders would not be supplied in full, but when they arrived they were far from the number expected.

Some orders of up to 300 trees were not honoured at all. So you see we did our best, but if the trees are not forthcoming there is nothing we can do about it this year. We certainly can obviate a repeat occurrence.

A CHANGE IN FUTURE

With considerable peach planting still going on, we will not be caught in a similar position again. We will have a minimum of 16,000 trees available for our growers next year which no one can touch except through our Company. These trees have been produced for us solely for our growers. The bud selection is also our own, so you can place your order with us in confidence knowing that you will get well-grown trees of good type.

We shall continue to produce some trees each year, even if we may have to destroy any surplus. This is not the first time we have been let down, but we trust it will be the last.

BEAN AND CORN AREAS ARE NECESSARILY REDUCED

For the first time for many years it has been found necessary to reduce the areas of green beans and sweet corn for the 1959-60 season. This has been brought about mainly because of record crops last year creating a carry-over. In order to get back on an even keel again, production must be reduced. Year after year the tendency has been to gradually increase acreages, which made it possible to retain old and constant growers, and to take on new ones from time to time. It is considered the reduction will be of a temporary nature, and that next season the acreage will be assessed to give a more or less consistent area from year to year.

A consistent and uniform area each year is the ideal, but unfortunately it is impossible to assess influencing factors such as weight of crop and market demands. It is always wise to have sufficient stocks to carry supplies throughout the year. A shortage can mean a lost market. The market price and supplies of fresh fruit and vegetables have a considerable influence on the sale of processed foods. The demand by the housewife is never consistent from year to year, which adds to the problem. With all these influencing factors to consider, it is impossible to estimate requirements very far ahead.

We do appreciate the way you, our growers, have accepted the situation. Reducing areas brings many difficulties. No matter how the distribution of the available area is made, some growers have to be eliminated altogether, and field officers have a difficult task in trying to be fair to all.

Unfortunately we cannot offer any other crop as an alternative except peas. The pea area to be planted this year will be an all-time record. Other crops have been fully booked since last season and are fairly consistent. We have never experienced such a demand for contracts from both old growers and would-be growers. It is unfortunate that a reduction coincides with such a demand.

GREEN BEANS

Reducing the area of beans brings various difficulties. We have told asparagus and peach growers becoming established that we would endeavour to assist their establishment by making bean contracts available to offset their costs. There are few crops so suitable for the purpose.

Bean contracts will only be about one third of last year, and unfortunately this reduction has come in a year when there has been a record planting of asparagus and peaches. The problem of making an equitable distribution to growers is one of the field staff’s most difficult tasks.

We have pole bean growers with posts and wire in position since last year. There has been considerable expense involved and it is considered these growers should receive some preference.

There are growers on leased land who made enquiries about the 1960 crop while last season’s crop was still in the ground. This was necessary so they would know if they could renew their lease. At the time they were told that a renewal should be safe. If they do not get a bean contract, it is difficult to find an alternative use for the land.

Then there are peach and asparagus growers who have gone ahead with their planting on the assumption that at least some of their costs would be offset by growing beans between the rows. Also we have growers who have produced main crop beans for many years who feel they have equal claim.

So from a field man’s point of view, let’s hope we are on the up and up next year again.

BROAD BEAN CROPS NEED ROGUEING

There are considerable areas of white-seeded broad beans in the Hastings district this year. Owing to drought conditions throughout last winter and spring, this crop was most disappointing, and larger areas have been planted this year. Green-seeded varieties are required for the frozen trade, and although they appear to be more vigorous, they are unsuitable for canning, This type turns a very dark colour in the can. The flavour is satisfactory, but their appearance is far from attractive.

A white-seeded variety has been developed in Europe which holds its colour well when canned. Watties introduced this variety last year, but owing to crop failures, were unable to produce enough to make them available to the public. We hope for better results this year.

ROGUES MUST BE REMOVED

Unfortunately the white-seeded varieties are not stable. Rogues appear no matter how the seed is selected. These odd plants throw dark flowers, while the true variety has a pure white flower.

It will be the grower’s responsibility to go through their crops once they are well in flower and pull out all dark-flowered plants. This is the only time that it is possible to eliminate these off types, and if this is not attended to, crops cannot be accepted for processing. It is impossible to pick out the green seed on the inspection belts in the factory, but they show up very decidedly in the can and completely ruin the pack Crops showing any off type beans cannot therefore be accepted.

The percentage of dark-flowered plants should not be great, so that it would not be difficult or costly to remove them. Our field officers will be inspecting crops from time to time, and advice about rogueing and spraying will be given if and when the need arises.

IS PROCESSED FOOD NUTRITIOUS?

The questions are often asked: How does the canning process affect the food value of fruit and vegetables? Is the food value inferior to that of frozen foods?

Our Chief Chemist, John Fielding, has this to say:

Taking the Vitamin C content as a standard of nutrient value, the canned product gives high retention of food value. To get the maximum nutrient value from vegetables such as peas, they would need to be picked fresh from the garden and eaten raw. Once peas are harvested they begin to lose Vitamin C immediately. Hence the importance of processing as rapidly as possible after harvesting has taken place.

Cooking destroys some of the Vitamin C, and therefore the frozen product has a higher nutrient value than the canned pro- duct as purchased over the counter. However, in most cases the frozen product has to be cooked at home, so any advantage will invariably be lost. The canned product cooked in its container retains a large proportion of Vitamin C both in the solids and in the liquid in which it is cooked. Therefore it is fair to say there is little difference in nutrient value between canned and frozen peas cooked and served at home. Both products would be superior to peas purchased from a greengrocer’s shop, where they may have been picked several days earlier. This would apply to most fruit and vegetables.

WHAT IS THE LIQUID IN THE CAN?

This liquid is the water in which the food is cooked. It may have been seasoned with salt, sugar, or both. This liquid contains soluble food values such as certain minerals and vitamins which have been extracted from the food. Whenever possible this liquid should be used in preparing the food, or used for soups, gravy or sauces.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Description

Michael Crooks and Bob June on cover

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

October 1959Publisher

J Wattie Canneries LtdPeople

- Michael Crooks

- R (Bob) I June

- Tom Ryan

- James Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.