- Home

- Collections

- JUNE LI

- Harvest 10 - April 1960

Harvest 10 – April 1960

Harvest

VOL. 1 No. 10

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

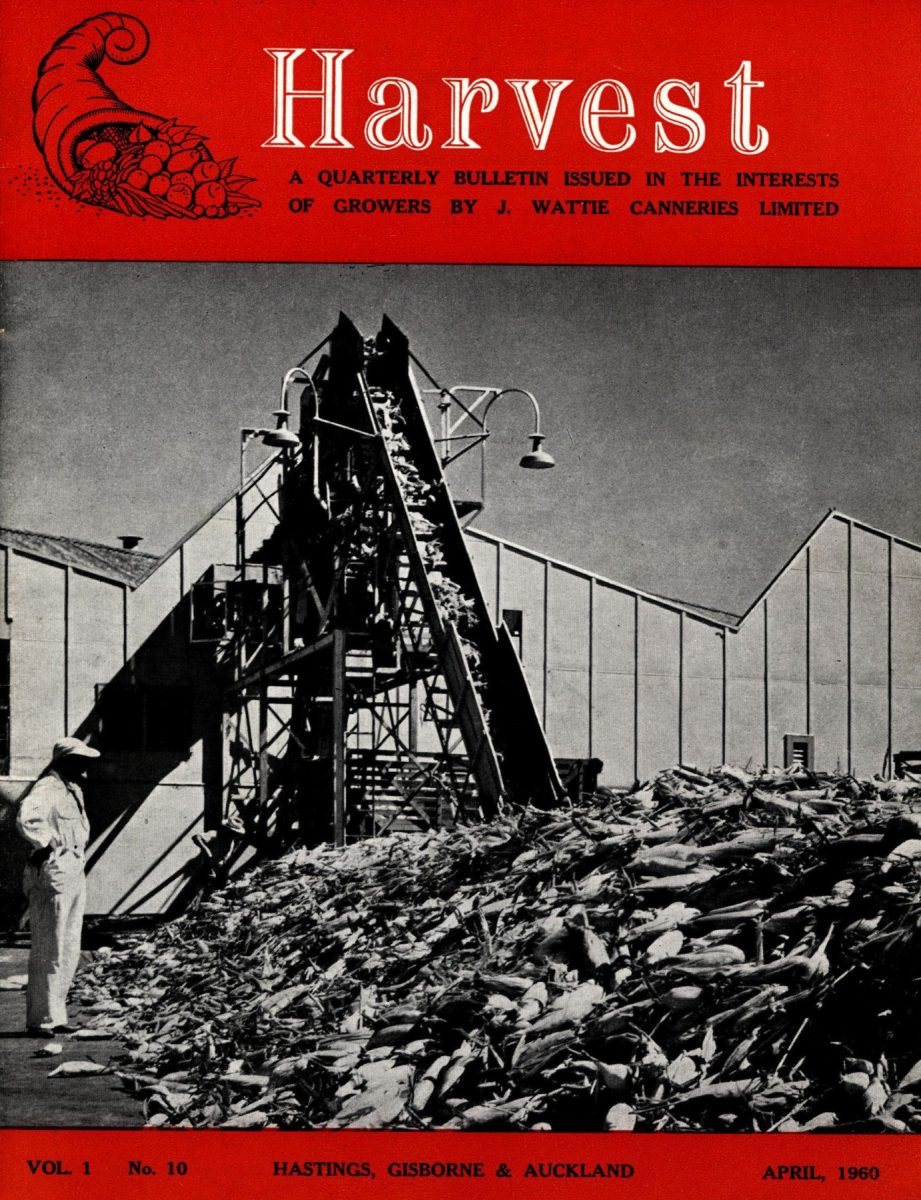

OUR COVER

Sweet corn cobs being elevated into the hungry maw of our Gisborne factory.

FOREWORD

UPPERMOST in the minds of anyone closely associated with J. Wattie Canneries Ltd. is the tremendous development they see about them at the present time. Major extensions and new equipment can be seen in the Gisborne factory. In Hastings, one of the greatest developments in the history of the Company took place with the construction of a huge blast freezer. It was rushed to completion just in time for the pea season. It will be used mainly for the production of free flowing peas, and will put Watties in the position of having the largest plant of its kind outside the United States. Its installation has increased the pea processing capacity of the Hastings factory by nearly 100 tons of frozen peas a day. This, together with the solid or plate freezing and canning in both factories, should give the Company a greater capacity than all other processors in New Zealand put together.

One cannot help but wonder what developments lie ahead and to what proportions production will expand. In the immediate future it will mean greater areas of peas, as with the advent of this vast new freezing plant, overseas orders for free flowing products can now be accepted. Peach and pear production is increasing all the time. The capacity of the peach line has been greatly increased by the installation of new automatic feeds to the pitters. A tremendous new peach peeler and washer has also been installed to cope with the largest tonnage of peaches ever expected. Peach production is expanding rapidly, and our factories must always be a step ahead to ensure sufficient machinery to handle greater quantities from year to year.

And so it goes on – these are only a few of the new installations. Others include new boilers, new automatic packers for placing the cans in cartons, new peach-slicing machinery, and many others. All this to reduce labour and handling costs and to develop new products and greater and greater capacity in many food lines, both frozen and canned.

It is exciting and invigorating to anyone associated with our factories. There is a proud and pleasant feeling in being part of such progress, and we trust you, our growers, associate yourselves with it. Without you, all this expansion could not be. Then without us, horticultural production in Hawke’s Bay and Gisborne could not have reached its present proportions, so we could not be more closely associated.

Yours sincerely,

Bob June

Hastings Field Supervisor.

SILVER LEAF OF PEACHES

Silver-leaf or silver-blight is undoubtedly the most serious disease we have to contend with in the production of peaches. With most fungus diseases, a certain degree of control can be obtained by spraying, but so far no satisfactory means of controlling silver-leaf has been developed.

We find many of our growers, especially new ones, have little knowledge of this disease. Some have ideas of the means of spread and control which do not tie up when the nature of the disease is more fully known. Although we cannot offer much assistance at this stage, it is always a help to know as much as possible about a disease. We envy fruitgrowers of other countries where this trouble is not encountered.

Silver-leaf is a fungus disease known as Stereum purpureum. Evidence of any fungal growths are seldom seen in an orchard unless carefully observed. The most common means of identification is the silvery appearance of the leaf. The tree is usually removed before the final visible stage of the disease is reached. If allowed to develop, fructifications may appear on the bark of the tree. However, these grow in various forms, some of which are similar to other fungal growths, and are not easy to identify. These growths sometimes take the form of a flat translucent area, but usually form a thin leathery bract. Large shelf-like bracts or growths belong to other fungi such as the Shelf Fungus (Coriolus Versicolor), but are often mistaken for Spereum purpureum. Silver-leaf fructifications are more likely to be irregular, cup-shaped growths, smooth on the underside. They are not very large – usually less than an inch across. The underside is often purple in colour, but may vary to pink with yellow edges.

HOW THE DISEASE IS SPREAD

The fungal growth or fructifications on the surface of the infected tree produce spores. They may be produced at any time of the year if conditions are favourable. These spores, or seeds, if you like to think of them in that way, become airborne and are carried by wind. If these spores alight on a tree where there is an opening of any kind, they germinate. The growth from these spores, known as mycelium, penetrates the wood tissue, causing it to go brown and discoloured. This discolouration, however, cannot be easily detected, and it is not until the leaves turn silver that we have any means of knowing a tree has been infected. By the time the silver leaf symptom shows, the tree may have had the disease for some time.

It would seem the only way that the mycelium can enter a healthy tree is by the germination of a spore produced on a fructification found on another tree. Spores may carry a great distance and remain viable under certain circumstances.

HOST PLANTS

Unfortunately there are many host plants – which is the greatest problem in control. If only orchard trees contracted the disease, it would be an easy matter to destroy any showing fructifications, and thus the only known source of infection. But other trees and shrubs known to carry it include all pip and stone fruit trees and also raspberries, gooseberries, poplar, willow, lupin, broom and ornamentals such as roses, lilac and laburnum. Any of these plants can therefore produce spores once the fructifications are formed, even after the host plant is dead. It is not difficult to imagine the impossibility of destroying sources of infection in districts where poplars are one of the main shelter trees and willows grow in profusion.

WHY SILVER LEAVES?

The silver appearance of the leaf is not actually caused by the mycelium penetrating it, but by the effect of the fungus on the cells of the leaf. The surface of a leaf is made up of epidermis cells. Immediately below the epidermis layer is a section made up of palisade cells. These latter cells hold the green colouring matter or chlorophyll. The effect of the fungus separates these two layers so that the green colour is masked, giving the silvery sheen appearance.

MANY THEORIES

Growers have many and varied ideas about spread and control of silver-leaf. Many of these ideas have been proved wrong by scientific research. With fifteen years of observation and study of the

disease, our field officers have seen most ideas carried out, but no corrective pattern emerges. What one grower is convinced of can always be disproved by observations in other orchards. Recovery is common even among very severely affected trees. It is this fact that makes the results of many experiments sound feasible, but it is likely that the tree would have recovered in any case. In young orchards in particular, a grower should not be too hasty in removing trees. There is no danger of spread from one tree to another as far as is known, unless the tree has reached the stage where the fungal growths are visible on the outer surface of the tree.

Here are some ideas which quite naturally come to the minds of growers, answered by scientific investigation and many years of observation.

(a) Silver-leaf is found in young trees because infected stones have been used by the nurseryman: Investigation reveals that infected stones are not likely to germinate, but if they do, the disease is not transmitted.

(b) Silver-leaf is spread from one tree to another by means of saws or secateurs at pruning time: This is an idea that is very prevalent. We have known growers point out the fact that the infection has spread along the row in the direction of pruning operations from year to year. But there is no difficulty in finding three or four infected trees in a row at right angles to the direction of pruning operations. Scientific investigation does not uphold this theory, as reinfection is difficult to bring about except by the spore actually germinating on the tree.

(c) That deep cultivation and damage to the roots increases the incidence of silver-leaf: This is certainly feasible, as the disease can apparently enter a wound both above and below ground. Anything that can be done to prevent damage of any kind to the tree should receive due consideration.

(d) That summer pruning reduces infection: Spores of stereum fungus will not live long in high summer temperatures. Therefore, if the tree is pruned at that time it could be a help. Unfortunately this is not very practicable, especially with canning crops such as Golden Queen peaches. Detailed pruning could not be done because the fruit-bearing wood this year should in theory be eliminated at pruning time. Pruning immediately after the fruit is harvested would have little advantage, as it is running into cooler autumn temperatures in any case.

(e) That slitting the bark of infected trees will assist in recovery: There seems no scientific reasoning behind this theory. In any case, some trees have been known to recover which have been treated in this way, but so have many trees that have not been treated at all.

(f) That extra fertiliser, especially nitrogenous kinds, will help an infected tree to recover: It would seem reasonable that anything that can be done to keep a tree in as healthy a state as possible must assist recovery.

(g) That forcing young trees too much makes growth and cell structure more open, thus making the entry of the disease more likely: This theory has not been investigated as far as is known, but it is a general belief.

(h) That grassing-down reduces silver-leaf incidence: The mere fact of grassing down must reduce any possible entry through the roots. If slower growth is a controlling factor, grassing-down could assist in this way. However, actual observation in Hawke’s Bay does not support the theory, as some grassed orchards have a very high rate of infection, even where great care has been taken in sealing pruning cuts.

(i) That the location of an orchard has a considerable effect on incidence: An orchard situated near a source of infection, especially on the windward side of infected trees producing spores, must be subjected to a greater degree than one isolated from such source.

(j) Other control attempts are many and varied, but none have given any satisfactory results. They include driving copper nails in trees, placing liberal applications of copper sulphate around trees or in holes drilled in trees, and many others.

(k) That replacement trees planted where silver-leaf trees have been removed are less likely to contract the disease again: It would appear that there is no carry over from the old diseased tree in any way, which is the only bright spot on the horizon at the moment.

This year a considerable percentage of infected trees in nurseries have been noticed in the vicinity of Hastings, in spite of careful painting of all cuts. If peach stones don’t produce infected seedlings, then it would appear that infected bud wood has been the cause. It would be very easy to take bud wood from a tree that actually has the disease but does not show the symptoms.

Many trees show signs of the disease in the spring and throw it off, sometimes only temporarily. At the time of bud selection it may not show at all. It would be a wise precaution to make a preliminary inspection of bud wood trees in the spring in early October and again at bud selection time. Young trees should be avoided, as they tend to mask the symptoms more than an older bearing tree.

INVESTIGATION AND CONTROL

In spite of a great deal of investigation, no really effective control measures can be offered as yet. Growers’ organisations from time to time have asked that scientific investigation be stepped up. Only recently another attempt was made in Hawke’s Bay in this direction.

In the past, the only worthwhile recommendation that could be made was to cover as many pruning cuts as possible with a protective material immediately after pruning. This must be of great assistance, but is far from being the answer. Cases have been known when every cut, even to secateur cuts, have been painted for the first three years of a tree’s life, and still silver leaf made its appearance. However, growers are still urged to take this precaution.

A more modern means of control being investigated by Plant Diseases Division in New Zealand is the application of an antibiotic spray after pruning, thus preventing the germination of a spore taking place on all cuts. That is all right as far as it goes, but it is well known that the disease can gain entry through openings in a tree by other than pruning cuts. Spereum purpureum is a plant growth. Therefore we are dealing with a plant within a plant and a material of a systemic nature is required to deal with the problem once infection has taken place. However, if a material that will even reduce infection can be produced, it would be a tremendous help. Any means of reducing the ravages of this disease would be most welcome by fruitgrowers of New Zealand.

THISTLE CONTROL IN ASPARAGUS

Numerous materials have been used with varying results in an effort to eradicate Californian thistle (Cirsium arvense) in asparagus. Very promising results have been obtained on two of Wattie’s farms in the past season. The material used was Weedozol.

Applied through a boom on established beds immediately following cutting, it practically eliminated the thistle in one application. The rate was 8lbs. of Weedozol to the acre in 40 gallons of water. There was no apparent damage even though some short spears were sprayed.

Spot spraying was also carried out in one-year asparagus in fern and in established beds in fern. Being a contact spray, damage to the asparagus was severe, and its application could not be recommended at this stage of growth, even though care is taken to keep the spray away from the asparagus as much as possible.

Plenty of water – not less than 40 gallons per acre – is recommended. The material is readily translocated through the underground stem system and plants have been seen to die at a considerable distance from the point of application. “Cali,” as it is often called locally, grows in colonies spreading considerable distances by means of its underground stem and root system.

It seems that one of our worst weeds in asparagus has been brought to heel at last. Spray should be applied while the plant is young and vigorous and in the rosette stage two to four inches high.

Secretary to Leave

John Clapcott, who has been Secretary of J. Wattie Canneries since 1946, is to leave the Company towards the end of March. The news has come as a great surprise to everyone, and it is difficult at the moment to think of things ever being quite the same without him. Growers as well as staff will miss him very much. His pleasant personality and genial manner have endeared him very much to everyone who has met him and dealt with him over the years. It is sad news.

John is to go into business on his own account, and he is to be admired for his energy and initiative. Fortunately he is to remain in Hastings, so he won’t be lost to the host of friends he has made. Very few men are fortunate enough to have the personality of John Clapcott. His sense of humour has carried him through many a rough patch, and it would be true to say that no one has ever heard him complain. It is equally true that he has never been known to make any adverse remarks about anyone, which is a wonderful statement to be able to make.

Keen of mind and generous with his time, he has been a great help to the Company and individuals alike. Everyone feels a sense of loss at John’s departure because he was a man that everyone could go to with a problem, personal or otherwise, and could always rely on his good judgment and help.

Many growers have expressed their regret at hearing of the change, and join with his fellow workers in wishing him every success in his new venture. Presentations will be made by the staff in a token of the esteem in which he is held.

Photo caption – J. E. Clapcott, Esq.

FACTORY EXPANSION

NEW FREE FLOW BLAST FREEZER

Free-flowing peas and other products are now available in quantity for the first time in New Zealand. This is due to the installation of a gigantic new blast freezer in Wattie’s Hastings factory. It is true that free-flow-pack peas have been available in small quantities before, but the plants in use are very small. Some factories simply use their plate freezers, placing the peas on trays in thin layers and then hand packing them. This, of course, is not an economic method and results are not always satisfactory.

ONLY ONE OF ITS KIND

The plant installed for the pea season just ended is the only one of its kind outside the U.S.A. It is the latest development in the production of free-flowing frozen products. It consists of a tunnel through which runs a steel mesh belt 8ft. wide and 100ft. long. The first 30ft. belt is a pre-cooling section where the temperature is just below freezing. The rest of the tunnel is brought down well below zero, and this cold air is forced through the peas or other products by very high capacity fans. This tremendous blast of sub-zero air freezes the peas quickly as they travel through the tunnel on the endless mesh belts. The speed and temperature can be varied as required to vary the capacity.

Over three and a half tons of peas an hour, running continuously day and night, can be handled with this new equipment. It is indeed a great sight to see this continuous flow of peas eight feet wide being fed into the tunnel in a constant stream. At the other end the peas are fed to packaging equipment by a screw-type feed or conveyor. This deposits them into a chute at the bottom of which are the various sized packages ready to receive them. Some of them are placed in 501b. multiwall bags. They can either be shipped in this form or packed later into any sized container desired.

One fascinating piece of equipment is an automatic weighing and packaging machine. Rolls of printed polythene are fed into one part of the machine and the peas are elevated into a hopper above. The machine forms the bags, fills them to the desired weight and seals them. They are then deposited on a conveyor ready to be packed in cartons. A zero storage room is located alongside the packaging department ready to receive the packages immediately they are packed.

MANY ADVANTAGES

In many parts of the world free-flow food has become more popular than solid packs. This is understandable, as the housewife may buy in larger, more economical packages, place them in her freezer and use them as required without having to resort to chopping pieces off solid blocks. There are many advantages from the production side too. One great feature is the economy of labour. The washing and inspection of the food is the same as required for any method of processing, but apart from a routine check of the feeding device, no labour at all is required to carry out the freezing part of it. Labour is required for packaging and storage, of course, but less than that required for solid or plate freezing.

Another great advantage is that peas can be packed in bulk such as the 50lb. multiwall bags used this season. This speeds up production and utilises labour at peak periods. These bulk bags can then be repacked into any sized container later on at will. Consumption of products in individual sized containers can never be forecast. With this new method, packing can be done as required and obviates carrying over unwanted sizes. Most export orders are for free-flow peas, and we are now able to participate in this trade in quantities never before possible.

A TRIBUTE DUE

The construction of this tremendous freezing plant was a great feat of engineering and co-operation by all concerned. The complete plant was in production exactly fifteen weeks from the time the first part was ordered.

A tribute is due to John Cole, our Chief Engineer, who was responsible for the overall construction and assembly. Our own engineering staff carried out all the fitting side of it. Electrical equipment involved bringing in extra heavy feeder cables from outside transformers with numerous fittings involving oil switches and so on. This was ably handled by David Garland, our Chief Electrician, and his staff. Keith Perrin, Head Carpenter, and his men played their part in the woodwork side of things, so the whole thing is a credit to these men who worked long hours and were often held up for parts which were delayed by manufacture and shipping.

A great many people both inside and outside the firm contributed to making this tremendous undertaking possible in such a short time. Our Managing Director, Mr. James Wattie, showed that he has lost none of his usual enthusiasm and drive, and was responsible in overcoming obstacles which would have seemed impossible to many. Our Factory Manager, Ray Wattie, followed the whole job through by constant supervision and drive; evidence of a great knowledge of food processing equipment he has gained over the years both in New Zealand and overseas.

The fact that the whole undertaking operated without a hitch from the time the first switch was thrown in, is a great tribute to all concerned. The installation of this plant has placed Wattie’s foremost in the field of free-flowing frozen food in New Zealand, and gives us a plant second to none in the world.

Land Levelling

An excellent Leveller locally made.

This is the best time of the year to attend to a very important aspect of farming practice: that of land levelling. There are many advantages of having farm and particularly cropping land reasonably level, but the operation should not be undertaken without due consideration to many aspects.

POINTS TO CONSIDER

Most of our flat cropping land has been laid down by the action of rivers, and as a result there are undulations and variations in soil types. In places, recent floods have deposited light silts in ridges and strips overlying better soil. It can often be a distinct advantage to spread these ridges out in a thin layer, making the whole area more uniform. Some crops, especially peas, must grow uniformly over the whole field to get the most out of them. Harvesting has to be done with respect to the ripest peas in a crop. If ridges dry off or ripen prematurely the rest of the area may be sacrificed, and results are very unsatisfactory to the farmer and processor alike. It results in poor returns and a poor or mixed quality product.

Old beds of small streams are in evidence in many places. Filling these low areas in is often desirable, but this should not be done without due consideration. These old beds still act as run-off and natural drainage outlets in many cases. It is far better to have one depression through a field than to fill them in and increase the area affected by ponding water. The whole drainage system of your own and surrounding farms, with an eye to retaining natural slopes and run-off, must be studied. You have an obligation with regard to surrounding property. It is unlawful, not to mention un-neighbourly, to cause water to run off your land on to another. The same applies when placing barriers to water running off surrounding land on to your own if you are interfering with natural drainage.

ADVANTAGES

Anyone who has had anything to do with harvesting of any kind, realises the advantages of a level surface. It does not matter whether it is mowing a crop of hay or peas, cultivating row crops, spraying or harvesting. If machinery runs smoothly over the ground without bucking and lurching, it must do a beteer [better] job. Even if a farmer starts with level land, it often becomes rough and uneven if he is inexperienced in the use of implements. Incorrect setting of discs can leave a field like the waves on the sea in no time. Insufficient attention to ploughing strike-outs and finishes can also throw levels out.

Plenty of evidence of this is seen during pea harvesting operations. In some crops, mowers or pea harvesters can be adjusted

low to the ground and left there with assurance that it is safe. In others, the surface is so rough that it is impossible to do a good harvesting job. In moving some crops, one part of the cutter bar may be on or under the ground, while the rest of the bar is clear and not cutting cleanly. Most complaints of poor harvesting jobs are the direct result of poor soil preparation and finish by the farmer himself, and no fault of harvest operations.

WAYS OF LEVELLING

There are many ways of levelling land. In the past, road graders have been used extensively. Tractor grader blades may be given a limited use. Factory-built land levellers are also obtainable. They are mounted on wheels with hydraulic controls for blade movement. Carry-alls are very good, and more economical where large amounts of soil have to be moved considerable distances. When smaller amounts of soil are required to be moved, factory-built levellers are good and are used by local agricultural contractors.

One of our growers, Mr. S. D. Agnew, and Mr. N. T. Kitching, a contractor, pooled their ingenuity and produced the outfit shown in the heading photograph. It is doing a great job and has been responsible for levelling many acres of land around Hastings. The levelling board itself is eighteen feet long and fifteen inches deep, with a steel cutting edge along the base. The board is free to tilt for filling and emptying, and this movement is operated by an hydraulic ram mounted on the draw bar. Support to the ends of the board is obtained by adjustable chains which also enable it to be set at an angle. It is a simple and ingenious device ideal for land levelling where soil is only required to be shifted short distances.

Soil should be reasonably dry, no matter what means of levelling is employed. Wet soil will not flow freely, and packing which results makes it difficult to get back into good condition for subsequent cultivation and cropping. Handling wet soil, whether in levelling operations or normal working and cultivation, destroys its original structure. This often requires extra time and expense with less satisfactory results. Soil handled in the right condition is easier to work and the resultant crops must benefit.

STORAGE LOSS IN PEARS

Although loss in pears after delivery to the factory is not great, it was higher than usual this year. The main cause was collapse due to Pink-eye, and to a lesser degree Black-end, a physiological disease which has been present in certain orchards for many years.

PINK-EYE

Very little is known of this trouble, but it is getting progressively more serious as time goes on. Some seasons it is more prevalent than others. This year it has been worse than usual and has been responsible for the loss of many hundreds of cases in the orchard, as well as some loss after delivery to the factory. The disease has been known in Hawke’s Bay for many years.

As far as we know, Pink-eye has not been identified as a fungal, bacterial or virus disease, and therefore falls into the category of a physiological trouble, although there is now some evidence to show it may be fungal. Early symptoms are a bright pink discolouration of the calix. Later a distinct yellow area appears surrounding the calix, and in a matter of hours the flesh becomes soft and mushy. The whole pear may collapse overnight, or it may progress more slowly. It is impossible for pickers to eliminate it all at harvesting time, and therefore a certain amount is lost in storage.

Some orchards are worse than others. Old trees seem worse than young ones. There is also a theory that some spray materials are responsible for its increase, but this has not been proved conclusively enough to make a statement. All the same, there seems a definite drop in Pink-eye where the good old-fashioned Bordeaux sprays have been used. Maturity also seems to vary with some spray materials. We would be pleased to discuss these theories with growers, as it would be out of place to condemn materials without drawing more definite conclusions over many years’ trials.

Bulk Handling Peas

Bins being moved from Viner to Truck by Fork Lift Tractor.

As the result of a trip overseas by Ray and Gordon Wattie recently, bulk handling has now been successfully extended to peas. The results have been very satisfactory in every way. A tremendous saving in labour, a quicker turn round of trucks carting the peas and extended vining hours for the mobile harvesters have been the direct result. Quality has not been impaired in any way.

After several American methods were studied, it was decided to construct 9 cu. ft. steel bins equipped with wheels in which the peas were to be placed both from the mobile and static pea viners. On the mobile harvesters two bins were carried. Empty bins were placed on the viners either by hand or with a fork lift. While full bins were being loaded from the viner to the truck, the operators were able to replace them with empties left close by. As a result, harvesting operations only had to be halted for a minute or two and they were on the way again.

Previously the labour expended in handling boxes was tremendous both in the field and at the factory. Trucks now have quick turn round at both ends, and as a result the whole system was speeded up and costs reduced.

CHECK ON QUALITY

Extensive tests were carried on throughout the season with regard to temperature build-up and microbe counts, and our Chief Chemist is very pleased with results. The use of wooden boxes in the past made cleaning after use very difficult, even though new boxes were made each year. With the steel bins, washing was carried out as each bin was emptied, so that hygienic conditions were better controlled than in the past. As with any method of pea harvesting, the most important factor is the processing of the peas as soon after harvest as possible.

NO MAIZE WILT IN NEW ZEALAND

In the last issue of Harvest, mention was made in an article on forecasting maturity of peas and sweet corn that the heat unit system was also used in forecasting diseases. Bacterial wilt of sweet corn has been forecast in the U.S.A. by this method, but it is a disease that has not developed in Gisborne and is not known at all in New Zealand.

LEAF STRIPE

A disease which is prevalent, however is Maize Blight, or leaf stripe as it is known in most places. Leaf stripe is a fungal disease caused by the fungus Helminthosporium turcicum, and is prevalent in maize and sweet corn throughout New Zealand and many other parts of the world. It varies considerably from year to year according to seasonal conditions.

SYMPTOMS

Leaf infection first shows up as small spots which enlarge to form green or silvery grey elongated areas. Several of these may join together, forming long narrow infected areas. If conditions are favourable, several of these lesions may join until large leaf areas are affected. It is these long strips of infected leaf which give rise to the name leaf stripe.

CONTROL

In order to obtain any means of control over a fungus disease, it is necessary to know something of its source and conditions best suited to its development. Leaf stripe fungus is able to survive for many months on old corn stalks. Spores from this source become airborne and infect green tissue during the following growing season. Wet weather with showers or foggy conditions, or periods of heavy dews, provide ideal conditions for development. Moisture is very necessary for spore production. In dry seasons, then, we would expect leaf stripe to be of little importance; but in some seasons it could become more serious.

Destruction of the corn plant after harvest so as to destroy sources of re-infection, is one of the most important means of control. However, this would have to be done throughout the whole district. It would be of little use one grower practising careful crop hygiene if his neighbour left his corn stalks exposed throughout the winter and following spring.

Although burning of corn stubble is condemned in respect to maximum return of organic matter, it may have some merit. It would, of course, be better to turn the crop into the soil but complete coverage is necessary, particularly if another corn crop is to follow in the next season. A succession of crops in the same land would certainly increase the chances of re-infection, and is not recommended even though it has been done for many years in some districts.

Control by spraying in U.S A. is practised but has not been developed in New Zealand as yet. Work is also being done overseas in developing resistant varieties.

We acknowledge reference to “Leaf Stripe of Sweet Corn and Maize,” by I. G. Forbes, in the NZ. Journal of Agriculture, January, 1960

WORLD FRUIT STATISTICS

Published in “American Grower” recently and computed by Dana Dalrymple, of Connecticut University, are the following percentages of world fruit production. To anyone who has not travelled through Europe, the grape production comes as rather a surprise with 35.5 per cent. of all fruit production. Grapes are followed by apples with 14.6 per cent, a figure which is increasing rapidly.

Others include oranges 12.9 per cent, bananas 11.4 per cent, olives 5.5 per cent, peaches 4.7 per cent, pears 3.4 per cent, plums 2 per cent, lemons and limes 1.7 per cent, grapefruit 1.6 per cent, pineapples 1.6 per cent, dates 1.2 per cent, figs 12 per cent, cherries 1 per cent, apricots 5 per cent, nuts 5 per cent, and strawberries 3 per cent.

NEW ZEALAND PRODUCTION

The following is the New Zealand fruit production forecast for 1960, supplied by Horticulture Division field officers and published recently by the Department of Agriculture in the “Orchardist”: –

Apples in New Zealand are well in the lead with 3,900,000 bushels, or 65.51 per cent of all fruit production; pears 565,000, 9.4 per cent; peaches 759,000, 12.75 per cent; apricots 206,000, 3.46 per cent; nectarines 54,000, 91 per cent; plums 172,000, 2.89 per cent; cherries 18,000, 3 per cent; quinces 18,000, 3 per cent; citrus 261,450, 4.39 per cent. Citrus fruits were made up of 84,900 bushel cases of Standard lemons and 24,000 Meyer lemons. New Zealand grapefruit, 127,600 bushels, made up the bulk of other citrus, followed by sweet oranges with 13,800.

Sub-tropical fruit figures were given in tons, with tree tomatoes heading the list with 832 tons, followed by Chinese gooseberries with 452 tons, passionfruit 94 tons, feijoas 37 tons, persimmons 7 tons, a total of 1,422 tons.

The berry fruit crop is expected to yield 1,825 tons, made up as follows – Raspberries 833, strawberries 655, gooseberries 172, black currants 89, boysenberries 51 and loganberries 25 tons.

CROP TOPICS

Bean Harvesting near Hastings

PEAS

In spite of a severe setback in planting during the latter part of October and early November due to excessively wet conditions, the budget for peas was exceeded. In Hastings the returns were very satisfactory, but in Gisborne early estimates were not reached, due mainly to exceptionally long vine growth.

Trouble was experienced in both districts with off-coloured peas, due again to long vine growth. Peas on the lower portions of plants could be found lacking colour, while pods exposed to the light on the same plants were of good colour. New bulk handling methods proved most satisfactory on mobile and static viners, as did new mowing equipment and viner feeds in Gisborne.

BEANS

The bean crop in both Hastings and Gisborne has exceeded expectations, although there are still some crops to be harvested. A warm rain in early February made the Hastings crop secure. In fact, it saved the day for many and will probably result in some record tonnages. The variety Processor, grown in Hastings, has again put up a great performance with first-class quality. Pole beans have been the best to date, with little or no disease.

Harvesting has caused some concern in Hawke’s Bay. With a record fruit crop and the biggest area of tomatoes ever grown in the district, a much greater labour force than usual is required. Many pickers have been brought in from outside districts to cope with the extra areas. Some crops have been lost due to over-maturity through lack of pickers. Rain also delayed picking, with further loss. However, budget figures will still be exceeded and good quality has been maintained. The over-all loss to growers will not be of great consequence.

TOMATOES

Quality in the early part of the season was good, resulting in a greater percentage than usual of tomatoes suitable for whole-peel canning. Humid conditions and rain during the third week in February makes the outcome of the season difficult to predict, although sufficient supplies should be forthcoming with reasonable luck.

In Hastings, many crops have contracted late blight due mainly to poor spraying. Sclerotinia has taken a heavier toll than usual, due to warm humid conditions. Planting was delayed by October floods ruining many thousands of seedlings. By the time these were replaced the season was very late. By the end of February very little had been picked from some of these late crops. It is to be hoped good weather is experienced in March, otherwise these conditions will have reduced the average considerably in both districts. Some areas have grown tremendous plants which will need plenty of sun to ripen them.

Extra machinery has been installed to cope with supplies. We know our growers have labour available, so the rest is up to the weather man.

SWEET CORN

Reports from our Gisborne Field Supervisor state that the sweet corn crop is a good one. The average tonnage should be very gratifying over the whole season. Apart from some rain making harvesting a little trying, conditions on the whole have been good. Planting had to be delayed in the spring due to unsuitable soil temperatures. This tended to shorten the season, but due to the reduced area this year, the harvesting has been maintained with crops taken at the correct time for best quality.

BEETROOT

With the loss of beetroot areas due to October floods, production has lagged behind requirements. With areas now coming along, ample supplies should be obtained. Late planted crops had to be delayed so as not to coincide with the peach season when all available labour will be required. Final harvest for the season will therefore not be made until April.

OTHER CROPS

Other crops such as carrots, parsnips, potatoes, gherkins and apples should supply all our needs satisfactorily.

PEARS

In spite of lighter crops of canning pears in Hawke’s Bay, the factory received the same quantity as last year. Large sizes made up a great deal for the lighter crop, but many pears were diverted to the factory which previously had been sent to other markets.

Losses due to collapse have been higher than usual. The collapse is due mainly to a trouble known locally as “pink eye.” Processing was retarded due to slow ripening of pears after removal from cool stores. However, processing was completed before any quantity of peaches came to hand.

PEACHES

Provided nothing untoward happens between the time of writing and harvest, there will be an all-time record peach crop. The tonnage for both factories is expected to be nearly 3,000 tons. There is always an air of expectancy just prior to a peach harvest because so much can happen in a very short time to dash our hopes. Last year a cold mid-February gale made the fruit soft and of poor quality and caused an exceptionally heavy drop.

All we can say at this stage is that with all old trees showing a consistently heavy crop, plus a great number of young trees coming into bearing, the stage is set for a big show. Size will be the limiting factor, as with such a heavy crop a slight variation in the size of individual fruits can mean a big variation in tonnage.

CAN YOU BEAT THIS?

Seen in a peach orchard the other day were poplar props holding up heavily laden branches of Golden Queens. The props were covered in silver-leaf fructifications. The bracts of the fungus were quite healthy, thank you, and covered the prop from top to bottom. Neither willow nor poplar should be used for orchard props at any time. Manuka, on the other hand, makes much better props and is free of silver-leaf.

PROMOTION

Arnold Smith, who has been Chief Accountant in Wattie’s head office in Hastings, has been appointed to take over from John Clapcott as Secretary. Arnold has been with the firm for a number of years, so that he will be taking over in his new capacity with a thorough knowledge of the affairs of the Company.

FIELD TALK

Talking things over.

BULK HANDLING OF PEACHES

Growers will be interested to hear that trials with bulk bins will be made to handle peaches this year. These bins will hold the equivalent of 23 Wattie dump boxes. They are, of course, made to handle with a forklift. They have a solid bottom with slatted side of 4 x 1 timber to facilitate ventilation should they need to be cool stored. The first lot of twenty have been made and will be tried on our own farms this season.

The factory management has had bulk handling of many crops in mind for many years, and handling peas in this way is now established. No means of mechanically tipping the peach bins will be available this year, but that is an easy matter once we establish the advisability of a change over.

BLACK-END

Black-end is a physiological disease confined to William Bon Chretian [Chretien] and Packham’s Triumph pears. It is further narrowed down inasmuch as it is only troublesome on certain stocks. Most New Zealand pear trees are propagated on Kieffer, William Bon Chretian, Winter Nelis and Winter Cole seedling stock. These stocks do not produce black-end fruit as far as we know. It appears that oriental pear stock, pyrus serotina, were used extensively at one time, and has been responsible for most of the trouble.

The fruit of affected trees usually fail to size up well. Later a dark discolouration appears at the calix end of the pear; this gradually increases until finally it turns completely black. It often cracks in the final stage and soft rot sets in. It is at times difficult or impossible to see at harvest time, but will show up later in storage. The flesh is very hard and of a gritty texture, and becomes utterly useless.

NO CURE

There is no known cure for this disease, but it is possible to graft another unsusceptible variety on to the stock and thus save time that would be taken to replant. If no other variety is required, then there is nothing else to do but pull out the affected tree. The sooner this is done, the sooner a useful tree will be producing in its place. There are some trees that have been producing black-end pears in the Hawke’s Bay district for many years. Had the grower done something about it years ago, he would have had a healthy tree in bearing by now. It is useless hanging on in hopes that something will overcome the trouble. They may be better some years than others, but nothing has been known to overcome the disease.

It is a great disappointment to wait seven or eight years for a tree to come into bearing, and then find the fruit is useless. Where only a few affected trees appear in a block of Williams, they can often be grafted over to another variety such as Winter Nelis or Beurre Bosc to assist pollination.

Infected trees have been cured by inarching with root stocks of pyrus communis. Once the original trunk is sawn through and the inarched stock takes over completely, the trouble disappears. This proves conclusively that only certain stocks give rise to the trouble. Unfortunately inarching is slow and difficult, and is not recommended to deal with black-end. Better to work over with an unsusceptible variety or remove the tree and replant.

Aerial Spraying Trials Unsatisfactory

As mentioned in an earlier publication of Harvest, a further trial on weed control in peas by fixed-wing aircraft was to be carried out. This has now been completed by two types of aircraft in two consecutive seasons. The results are far from satisfactory.

Last year a trial was made with M.C.P.B. with patchy results in spite of a perfect location with no obstructions. The ’plane used was a Cessna, and it seemed as if the speed was too great to allow good penetration. This year a slower Tiger Moth was employed, and with permission from the Air Department, a mixture of D.N.B.P. and M.C.P.B. was used. Coverage was poor, with strips missed, but apart from that, penetration was unsatisfactory, and weeds partly protected by pea foliage did not receive enough material to kill them. By harvest time weeds were above the crop in many places.

It is felt the quantity of water used is not sufficient to give good coverage. Large amounts of water in excess of 20 gallons per acre would most likely improve the results, but the cost of applying higher rates would make it prohibitive. It seems it would be wise to continue with ground operated machines – at least until helicopters become available in the district once again. Helicopter application proved satisfactory when used a couple of years ago.

OTHER CROPS

Fixed wing aircraft are being used more and more for various insecticide and fungicide applications to many crops in Hawke’s Bay. Some are satisfactory, some not, depending on the material and type of crop. Systemic sprays for aphid control on broad bean crops proved very satisfactory last spring. Fungicides were applied at the same time. The same claim cannot be made for caterpillar control in dwarf beans. The nature of the plant makes penetration difficult, although systemic action is of great assistance. Potatoes can be kept free from disease and pests, provided enough applications are made. Fixed wing spraying of dwarf tomatoes cannot be recommended on present indications, especially if growth is vigorous. Control in adverse conditions would require very close ratio sprays with large quantities of water. The costs would then be prohibitive.

We would like to pay tribute to the boys who fly the planes. It is certainly not their fault if results are not good. The use of fixed wing planes for these various crops could possibly be developed, but until much greater quantities of water can be applied economically, no great success can be expected.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

April 1960Publisher

J Wattie Canneries LtdPeople

- S D Agnew

- John Clapcott

- John Cole

- I G Forbes

- David Garland

- R (Bob) I June

- N T Kitching

- Keith Perrin

- Arnold Smith

- Gordon Wattie

- James Wattie

- Ray Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.