- Home

- Collections

- HILL EF

- Harvest 12 - September 1960

Harvest 12 – September 1960

Harvest

VOL. 1 No. 12

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

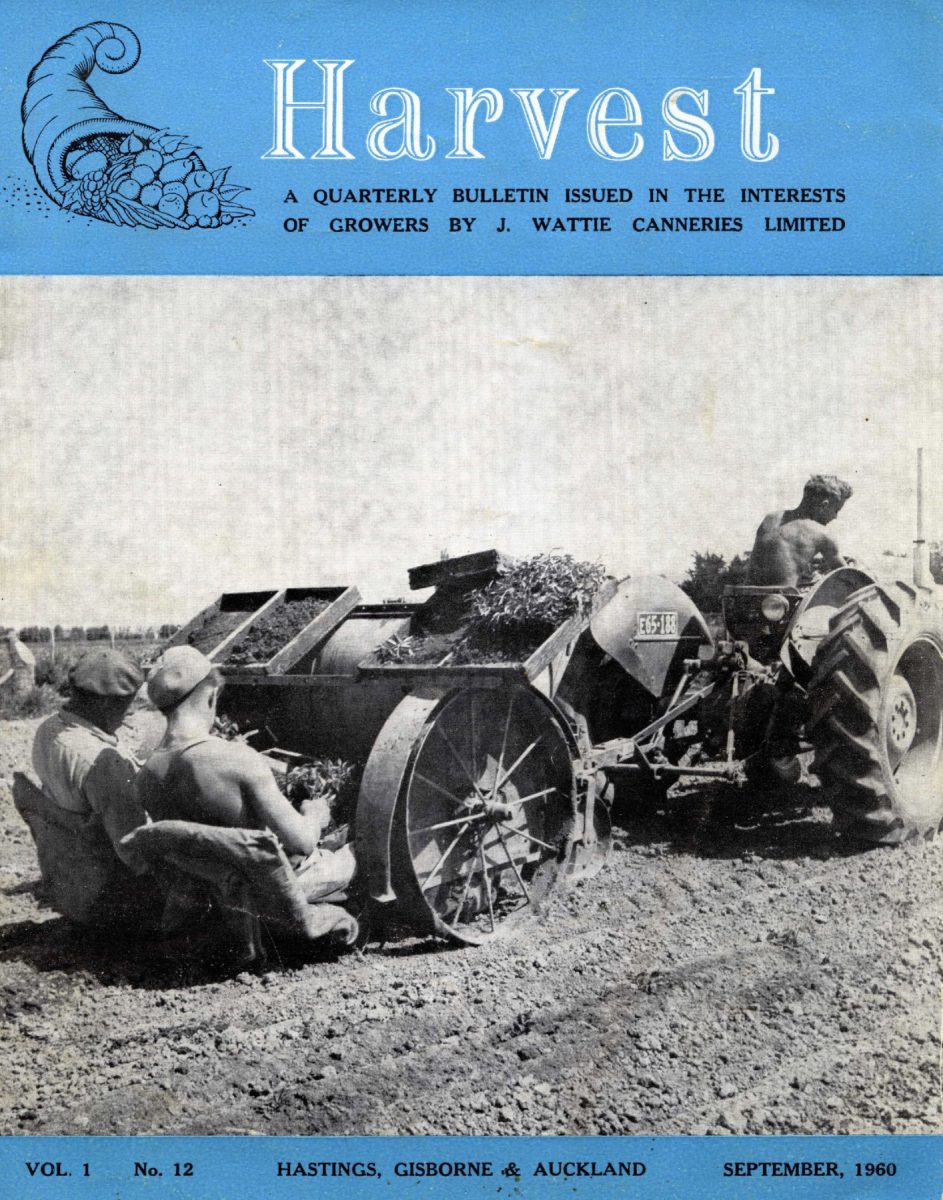

OUR COVER

Planting Tomato seedlings, an important crop in Hastings and Gisborne.

FOREWORD

MOST GROWERS will know that our Managing Director, Mr. James Wattie, has been overseas again. Almost every year for many years either Mr. Wattie or some other representative has made contacts overseas. These trips have been found to pay dividends in many ways. They keep us in touch with the latest developments in food production, machinery and methods of food processing. By far the most important aspects of world contacts are market developments.

All will agree that the expansion of J. Wattie Canneries has been remarkable over the past few years. New Zealand markets are limited, and if we continue to expand to any great extent, it must be done on overseas markets. Apart from odd seasonal shortages of certain packs, both canned and frozen, there is a full supply of a very wide range of home produced processed food available all the year round. All main lines such as peas, beans, sweet corn, tomatoes, peaches and pears are always available. Even asparagus, which for years was not produced in sufficient quantities to last the season, is now available at all times.

The New Zealand market, of course, is expanding, and we are proud of the lead we hold in it. There was an increase of 45,000 people in the country last year. Give these people three meals a day, and we have 145,000 more meals to provide a day, and nearly 50 million meals a year. Nevertheless, if we are to continue to develop at the present rate, we must do everything possible to foster overseas markets.

Peaches and asparagus in particular have been planted out in greatly increased areas lately. Asparagus should be no problem, because there are few places in the world where it can be grown as well as in this district. Most countries produce only enough for their own needs, so competition is limited. Peaches are a different matter. We pay more for our sugar than any other country in the world. Shipping lanes to the United Kingdom market could hardly be longer. The only thing that can enable us to compete is our high production per acre, which must help keep the cost of the raw material at a reasonable level.

We will be having a Growers’ Meeting on Mr. Wattie’s return, and we feel sure he will have something of interest to tell us once again from the many countries he has visited.

Yours faithfully,

Bob June

Hastings Field Supervisor.

MORE ABOUT THE WHITE-FRINGED BEETLE

The study of the life cycle of the White-fringed Beetle has been undertaken by Grasslands Division of the D.S.I R. in Palmerston North, we understand. Up to the present time we still have no information from this source. As this insect is likely to be a problem, the more we can learn about it the better, and we are passing on in this article information from the U.S. Department of Agriculture, and what we have learned first-hand ourselves. It must be realised that the behaviour of the insect may differ under our conditions from those overseas. Any information that we can obtain, however, must be of use and interest to us.

HISTORY

The Graphognathus specie is a native of South America, it appears. They have spread to the southern parts of the United States, South Africa, Australia, and are now fairly common in New Zealand. In 1936 they were found in Alabama feeding on a peanut crop, and for the next few years, until adequate control measures were developed, thousands of acres were left unplanted because of the ravages of this pest. It was first reported in New Zealand in 1940 It was not until the summer of 1959-60 that it was realised it had such a hold. As stated in the last issue of Harvest, damage in Hawke’s Bay was widespread in pea and tomato crops, and it has been found in large areas of grassland mostly unsuspected and unknown.

LIFE CYCLE

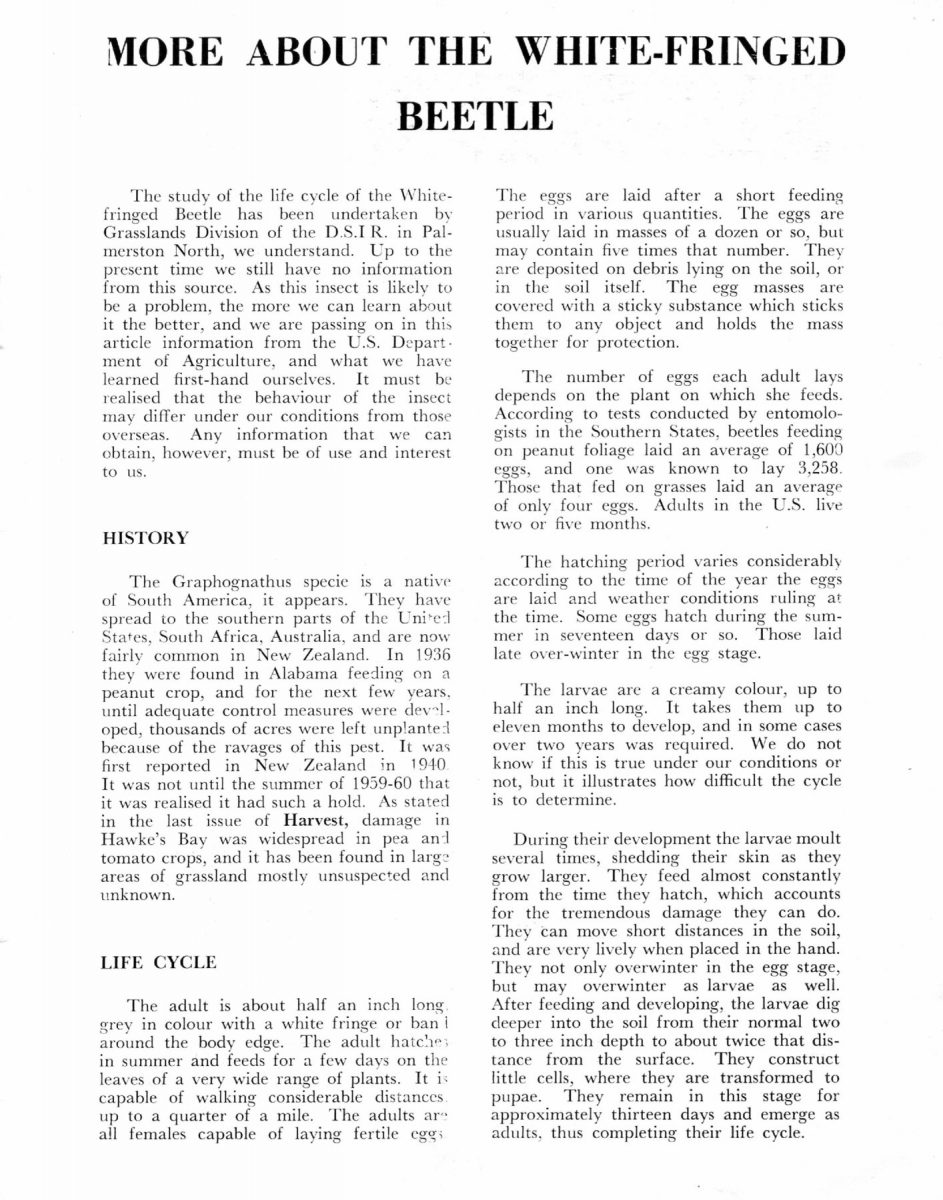

The adult is about half an inch long, grey in colour with a white fringe or band around the body edge. The adult hatches in summer and feeds for a few days on the leaves of a very wide range of plants. It is capable of walking considerable distances, up to a quarter of a mile. The adults are all females capable of laying fertile eggs. The eggs are laid after a short feeding period in various quantities. The eggs are usually laid in masses of a dozen or so, but may contain five times that number. They are deposited on debris lying on the soil, or in the soil itself. The egg masses are covered with a sticky substance which sticks them to any object and holds the mass together for protection.

The number of eggs each adult lays depends on the plant on which she feeds. According to tests conducted by entomologists in the Southern States, beetles feeding on peanut foliage laid an average of 1,600 eggs, and one was known to lay 3,258. Those that fed on grasses laid an average of only four eggs. Adults in the U.S. live two or five months.

The hatching period varies considerably according to the time of the year the eggs are laid and weather conditions ruling at the time. Some eggs hatch during the summer in seventeen days or so. Those laid late over-winter in the egg stage.

The larvae are a creamy colour, up to half an inch long. It takes them up to eleven months to develop, and in some cases over two years was required. We do not know if this is true under our conditions or not, but it illustrates how difficult the cycle is to determine.

During their development the larvae moult several times, shedding their skin as they grow larger. They feed almost constantly from the time they hatch, which accounts for the tremendous damage they can do. They can move short distances in the soil, and are very lively when placed in the hand. They not only overwinter in the egg stage, but may overwinter as larvae as well. After feeding and developing, the larvae dig deeper into the soil from their normal two to three inch depth to about twice that distance from the surface. They construct little cells, where they are transformed to pupae. They remain in this stage for approximately thirteen days and emerge as adults, thus completing their life cycle.

PREVENTION AND CONTROL

In the US. the beetle is considered so dangerous that the public are constantly being told how to identify it and report it wherever it is found. Stringent precautions are taken to prevent its spread on hay, plants or any produce. Officers in quarantined areas are called on to give a clearance to plants, soil, implements and any likely source of danger before they can be shipped.

This information is being handed on to you, our growers, for what it is worth. As you can realise, the very nature of the insect, together with the fact that it will feed on the roots and leaves of most plants. makes it a potential pest that could be serious.

As Gisborne district is not affected up to the present time, the main crops in the Hastings district that will require watching and protecting are peas and tomatoes. There are several materials that will give adequate control. Unfortunately all of them are costly. The chief materials we will be recommending are Aldrin, Dieldrin and possibly D.D.T.

For best results, the materials should be broadcast over the land and worked into the top two or three inches before planting. This ensures deposits of the insecticide over the whole root area. It can be put in with the fertiliser and applied with the seed, as in the case of peas.

RECOMMENDATIONS

TOMATOES: Broadcast 2lbs. per acre of Aldrin with your normal fertiliser mix and work into the soil before planting. The alternative, which will give protection until the plant is well under way, is to mix 4oz. of 50 per cent. Dieldrin wettable powder in 40 gallons of water used in the planting machine, allowing half a pint of water per plant. Greater or lesser amounts can be added according to the amount of water given to each plant.

Do not use Dieldrin emulsion, as the materials used in the emulsion will destroy the roots. Severe losses were experienced last year through its use.

PEAS: For best results again the insecticide should be broadcast with normal fertiliser applications and worked into the soil prior to planting. However, as most peas in the district are given surpentine [ serpentine ] phosphate through the drill with the seed, the insecticide could be added in this way. We recommend a minimum application of 1.5lbs. of Aldrin per acre, and where the pest is known to exist, 2lbs. should be the rate.

You will note that Aldrin rather than Dieldrin is recommended. It is true that Dieldrin will give much longer protection and therefore would be the better material to use with peas, as it would give protection to the pea crop and to the grass following for two or three years. It is a matter of price. Growers should consider this according to the use their land will be put to after the pea crop. We will be pleased to discuss this matter with you, if you wish Dieldrin super containing 1lb. of pure material per cwt. would cost £12/10/- per ton more than Aldrin at the present time. These materials are available at local works; mixes are only done in five ton lots. All local produce firms will be carrying stocks containing 1lb. Aldrin per cwt.

Photo caption – The Adult Beetle, which feeds above the ground.

D.D.T. is another material that could be used. Ten pounds of 100 per cent. material is the overseas recommendation, and where stock is grazed on the land afterwards, the application seems very high. We have had growers claim that they had control in lucerne using only 2lbs. per acre normally used for grass grub control, but this is not a recommendation.

Forewarned is forearmed, and we strongly recommend that you treat this pest as a potential enemy this year, or at least until we feel reasonably sure of altering recommendations. Remember that a sub-lethal treatment is a waste of money and that full recommendations will give protection for two to four years. Working costs out on this basis, it eases the burden at least a little.

Photographs by courtesy IVAN WATKINS LTD.

DANGER OF POISONOUS SPRAYS

Spray residue on tomatoes has always been a matter of great concern by the quality control staff. We will be talking to individual growers again on this subject. We would ask for your co-operation in this important aspect of tomato production for processing.

With most fruit and vegetables it is possible to stop spraying well before picking, to give time for dangerous spray residues to disseminate. Tomatoes have to be sprayed during harvest to control or prevent insect damage and diseases such as late blight.

NO MERCURY SPRAYS

It has been proved without any doubt that the fungicides including bordeaux mixture, copper oxychlorides and the ethrylene bisdithiocarbonate (Dithane M) will all give adequate control of fungus disease if properly applied. In the Hastings district a considerable amount of phenyl mercury compounds have been used. This could be safe enough in the very early stages, but it is too dangerous to risk at any stage. Residues of mercury sprays have been found over sixty days after application, and we therefore feel it best to eliminate it completely from the tomato spray programme.

Mercury is a very deadly poison. If it is allowed in the spray programme at all, there is always a risk of it being used after fruit set. As there are other suitable materials available, please arrange your sprays accordingly. Tomatoes with any mercury residue will not be acceptable at the factory.

Photo caption – White-fringed Beetle Larvae, which feeds vigorously on roots and stems below ground.

PERSONALITIES

Seated by his beloved weighbridge control is Harry Helm, one of the best known of all our staff personnel, and one who is in contact with our growers more than anyone outside the field supervisors.

Wherever you go you hear remarks from those who use the weighbridge, as to what a great chap Harry is. Every truck driver in the district knows him as Harry, and have probably never heard his surname at any time. As the weighbridge is a public one, its operator comes into contact with hundreds of truck drivers. One thing certain, they will all receive the same happy and genial treatment. It does not matter if they have a couple of cases of beans in the back of their car, or whether they are driving the largest of articulator trucks, it’s all the same to Harry.

We often wonder how he keeps his mind on an even keel, as there are times when trucks are queued up waiting with all sizes and shapes and weights. It is not just a case of weighing the load, but there are tare weights to deduct. Sometimes a load will have more than one weight of pallet on board, and even different types of cases. Meantime, the radio-telephone set-up is based in the weighbridge office, and all sorts of enquiries come over the air. Then there are produce firms asking weights of certain loads, when perhaps their copy of a docket has gone astray. There is change for weighbridge charges to be balanced, and a hundred and one other matters to see to, such as the sale of four-gallon tins and checking incoming and outgoing dump case records.

Very few people realise what a busy life Harry Helm leads, yet through it all there could not be a more genial character. His accurate and meticulous work is appreciated by his customers and the company alike.

It was in 1944 when he joined the staff, and he has hardly missed a day’s work since he started. We are proud of him, and we know our growers would be pleased to see that he has been placed first in a series of personalities to appear in Harvest.

Photo caption –

HARRY HELM

Our well-known Weighbridge Operator.

FROST CONTROL in ORCHARDS and MARKET GARDENS

For the next few weeks growers will be on tenterhooks wondering about frost. We are really very fortunate when we consider the few drastic frosts we have had over the past few years. There have been losses, but there has not been a widespread loss for a long time. That is no reason to think that we can sit back and do nothing. Destruction of fruit by frost is something we can do a great deal to eliminate entirely or reduce to a point where crops are not seriously affected. Any orchardist who does not prepare for frost in most parts of Hawke’s Bay is throwing away a very sound insurance premium in the form of firepots and a supply of fuel oil.

NEW METHODS NEEDED

The present system of 100 gallon pots or so to the acre of ground, and burning various grades of fuel oil, will control any frost likely to be experienced in our district. It is, however, a dirty, costly job, and we are still looking for something more efficient and less costly. The poor combustion of an open oil flame without forced draught results in very low heat unit output. It also brings the “smog” problem, which must get worse as more areas are planted. It is reasonable to suppose that the time must come when this method will be disallowed, as it has in other parts of the world.

J. Wattie Canneries Ltd. spent a considerable sum last year in an endeavour to distribute warm air from burning fuel oil and blowing it over a large area. It was only partially successful. This year we are trying another device imported from South Africa, where it has been very successful. We are not entirely sold on the idea, but it is worth thorough investigation. It could be that it would have a place in conjunction with the present set-up of fuel pots. It also has very definite possibilities as a sprayer and the present unit is adaptable for this purpose.

NEW PRINCIPLE

The principle of this trial machine, known as the “Rypkul,” is not to generate a large amount of heat, but to produce a fog over the cropping area preventing the loss of heat by radiation. It prevents frost by conserving the heat constantly being radiated by the earth and every object on it. Flat country is essential, as it would be impossible to maintain the blanket fog effect where the country is too steep or undulating.

The fog is produced by vapourising fuel oil and water. One machine is capable of covering a very large area up to 150 acres, and if it was successful, several orchards could be covered by a single unit. The unit is portable, so that it can cope with drift.

Market gardeners or strawberry growers will welcome this machine if it proves successful here. Ground crops are difficult to protect because frost is heaviest just above the earth’s surface. Heat from frost pots rises quickly, often leaving a shallow layer above the ground not effectively controlled. Fruit trees, being off the ground, are easier to protect.

Unlike frost pots, which actually heat the air over a great depth, no heat is produced by this unit at all. It is necessary then to create the protecting fog before the temperature reaches danger level. This, of course, requires someone on the job over a longer period, but one man can do this, where the other method requires more men plus the added labour for refueling, and placing the pots out and taking them in each year. Its actual operating costs are also light, burning about 15 gallons of diesel oil per hour.

Our main concern, until it is tried, is drift. It remains to be seen if the fog can be held just where it is required under our actual conditions.

SEASONAL REMINDERS

(a) Damp, finely worked firm soil will radiate heat over a longer period than a rough and dry soil. It is advisable to roll the land before putting the fire-pots out.

(b) Grassed orchards should be kept mowed reasonably short, even if it means moving the pots occasionally.

(c) New pots are slow to light. It is as well to light them during the day and allow them to burn for half an hour or so beforehand. The soot which builds up

on the sides holds a certain amount of oil and makes lighting much easier.

(d) Have your thermometers tested in advance. If they vary, select others with the same reading at low temperatures, or mark the variation plainly on them so a stranger can read them accurately.

(e) Do not hang the thermometers in a tree or near a building. Trees and other objects are all radiating heat, remember, and a false reading can easily be obtained.

(f) Construct suitable shields to protect the thermometers from the direct rays of the sun, to prevent bleaching of the liquid. It also assists in obtaining more uniform readings. The back and sides only of a 7in. x 7in. fruit case serve the purpose. Place them to hold the thermometer 4ft. 6in. from ground level.

(g) Have plenty of thermometers both inside and outside the area to be protected. This is particularly important if your land is undulating. Temperatures can vary considerably in an individual orchard.

(h) Inspect thermometers frequently when danger period approaches. Don’t take any notice of your neighbour. Variations in temperature are too great in a short distance for this.

(i) Have a quick, efficient means of refilling pots. Frost fighting is tiring enough at the best of times. A tanker easily filled from reserve stocks, and with a suitable hose and shut-off taps attached to it for filling pots quickly, is important.

(j) Fit new wicks in lighting torches each year and test them for a free flow of liquid to speed up lighting.

(k) Light pots on the side of the drift first. It may only be necessary to light alternate ones at first.

(l) Do not put fires out too soon. Remember temperatures continue to drop even after sunrise.

PEA GRADES and PRICES, 1961

Most growers will have received a letter setting out the pea grades and prices for the coming season. The prices for the corresponding tenderometer reading remains the same as last year. The exception is the reintroduction of a grade below the 95 reading which now becomes No. 1 grade.

So that there is no misunderstanding, we are setting out here last year’s as well as, the current grades and prices, so that you can better understand the setup. Grades have been changed from year to year as the system has settled down after the introduction of the tenderometer for testing maturity some years ago. Originally the grades started at grade 1 for peas with a tenderometer test of 85 and under. In practice we found that peas at this reading were not satisfactory for the factory or the grower. We aim at taking peas nearer the 100 mark, and have therefore made grade 1 as 95 and under. The over 120, which previously was grade 9, now becomes grade 7 due to the elimination of the two top grades.

1959-60 Season

Grades Tenderometer Reading Prices

4 100 and under 4.3d. lb

5 101-105 3.7d. lb

6 106-110 3.3d. lb

7 111-115 2.9d. lb

8 116-120 2.6d. lb

9 Over 120 2.5d. lb

1960-61 Season

Grades Tenderometer Reading Prices

1 95 and under 4.8d. lb

2 95-100 4.3d. lb

3 01-105 3.7d. lb

4 106-110 3.3d. lb

5 111-115 2.9. lb

6 116-120 2.6d. lb

7 Over 120 2.5d. lb

BEHIND THE SCENES

TRIAL WORK 1960-61 SEASON

The need for trial work is recognised as a very important part of the field work required in a food processing industry. Each year a great deal of time and thought is given to this important aspect. In the coming season we will have the greatest range of trials so far undertaken. They will consist mainly of bean and pea variety trials.

BEANS

Some of the latest varieties from America will be planted out, using our present variety, Processor, as a standard. Many of these varieties have been bred to give not only a completely stringless bean of good flavour and colour, but also a bean which develops straight pods well clear of the ground. They also develop the bulk of their crop at one time, with the idea of mechanical harvesting, where the whole crop is taken at one operation.

TOMATOES

Many varieties have been tried over the past years, but we always seem to come back to our old-timers, Tatinter and Scorsbv. We will be growing a few varieties again to try to get a more uniform sized tomato for canning whole. The main trial work, however, will be in the endeavour to obtain control of sclerotinia.

PEAS

Several varieties of peas will be grown again. These have been imported in the everlasting search for a suitable early pea which is hardy enough to stand planting out in August. Our present variety, Victory Freezer, has proved a wonderful cropper, and stands wet and cold as well as hot and dry conditions very well. The only drawback for early planting is the length of time to maturity in the early part of the year. William Massey always used to be planted first, and gave us an extra week’s harvesting season, but it was not hardy enough. We do not like to ask growers to produce a crop which has not a reasonable chance of giving worthwhile results.

We are also interested in a slightly smaller pea and one with the darkest colour possible. Colour is a very important characteristic, and is becoming more important as more and more of our peas are frozen and less canned.

We are also giving pea seed treatment of various materials a trial this year. In the past we have been using Spergon almost

Photo caption – A view of a Trial Plot on a Wattie Farm.

exclusively. It is a good material, and growers have always liked it because of the ease with which it flowed in the drill. However, there are two other materials which may be an improvement.

Weed control, including pre- and post- emergence trials, will also be carried out. Some of these will be done on our own and some in co-operation with Ivan Watkins Ltd., New Plymouth.

OTHER WORK

A few trials including strawberries, carrots, parsnips, sprouting broccoli, beetroot and sweet corn will receive attention. Disease and pest control of certain other crops will also be investigated.

MORE FACTORY EXTENSIONS

It is always a healthy sign to see any firm extending their premises, as it means they are going ahead. Last year Gisborne increased their floor area by 20,000 sq. ft. This year building in Hastings is now under way, extending warehouse space by 25,000 sq. ft. with a 20ft. stud. This will allow storage up to five pallets high in parts of the building.

NEW ZERO STORAGE

Up to the present time two small zero storage rooms on the premises have taken small quantities of frozen foods, and most bulk supplies were held in outside stores. The new zero space will be large enough to eliminate a large proportion of outside storage, and will reduce double handling and storage costs. With a floor space of 10,000 sq. ft. and a high stud, it will have space for several thousand tons. It will allow room for fork lift handling and reduce hand labour to a minimum.

The new building has taken up most of the yard room previously used for storage of machinery and dump cases. To make up for this loss of space, a start has been made in shifting houses owned by the Company across the road from the main building. The photograph shows a house being removed to a new site on No. 1 Farm. This house, together with a new Farm Manager’s residence on No. 2 Farm, has increased accommodation for more permanent farm staff.

Photo caption – Moving a house to make more room.

CHANGES in FIELD STAFF

NEW MAN FOR GISBORNE

By this time our Gisborne growers will have met Brian Phillips, our new assistant field supervisor in their district. We feel sure they will find in Brian someone who can talk to them in their own language, because he is a practical man. Having grown many canning and freezing crops such as tomatoes and beans in the Hawke’s Bay area, you have a man who can speak from practical experience and one who is very keenly interested in all crop production.

A pleasing personality, and not afraid of work, we feel confident Brian will be an able assistant to John Renouf, who has reached the stage where it is humanly impossible to do all he would like to do.

Brian has been a Wattie grower for many years, and we welcome him to our field staff. We feel certain our Gisborne growers will do their part in making him feel at home.

MIKE CROOKS LEAVING

Hastings is losing Mike Crooks at the end of September. Having been offered a position in New South Wales, as field officer to an Australian freezing company, Mike has the opportunity of taking charge of field operations for a company which is expanding rapidly. Although we are very sorry to lose Mike, it is natural that a young man should want to take responsibility on his own shoulders and launch out into new fields.

Conditions in Australia will be quite different from what he has been used to here. No doubt the experience he has had with us will stand him in good stead. We wish him every success and hope he and his wife enjoy their new life so far from home.

Ron Cawood will be taking up the reins as assistant to Bob June, our Chief Field Supervisor. Fortunately Ron has had a season’s experience behind him and is known by most of our growers.

The vacancy created will mean added work for these two field men, as Mike Crooks had been with us long enough to take a good deal of responsibility. No appointment as third man in the field has been made meantime.

USEFUL DATA

LAND MEASURE

8ft. x 1 mile equals 1 acre.

6ft. x 7620ft. equals 1 acre.

120 ft. x 363 ft. equals 1 acre.

220ft. x 198 ft. equals 1 acre.

10 yds. x 484 yds. Equals 1 acre.

10 sq. ch )

4840 sq. yds. ) equals 1 acre.

43560 sq. ft. )

APPLICATIONS PER ACRE

1oz. per sq. ft equals

9ozs. per sq. yard

2722.5lbs per acre.

1oz. per sq. yd. equals

302.5 gals. per acre

1pt. per sq. yd. equals

605 gals. per acre.

WATER MEASUREMENTS

1 pint equals 34.66 cu. in

20ozs.

1¼lbs.

1 quart equals 69.32 cu. in

40ozs.

2½lbs.

1 imp. gal equals 1 .2 U.S. gals.

0.16 cu. ft

1 cu. ft water equals 6.25 Imp. gals.

7.48 U.S. gals.

62.5lbs.

1 acre in. water equals 101.2 tons.

3,630 cu. ft.

22,700 Imp. gals.

27.152 U.S. gals.

4.7 Imp. gals. per sq. yd.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

September 1960People

- Ron Cawood

- Mike Crooks

- Harry Helm

- Bob June

- Brian Phillips

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.