- Home

- Collections

- JUNE LI

- Harvest 14 - March 1961

Harvest 14 – March 1961

Harvest

VOL. 2 No. 2

PUBLISHED BY J. WATTIE CANNERIES LTD

HASTINGS, GISBORNE & AUCKLAND

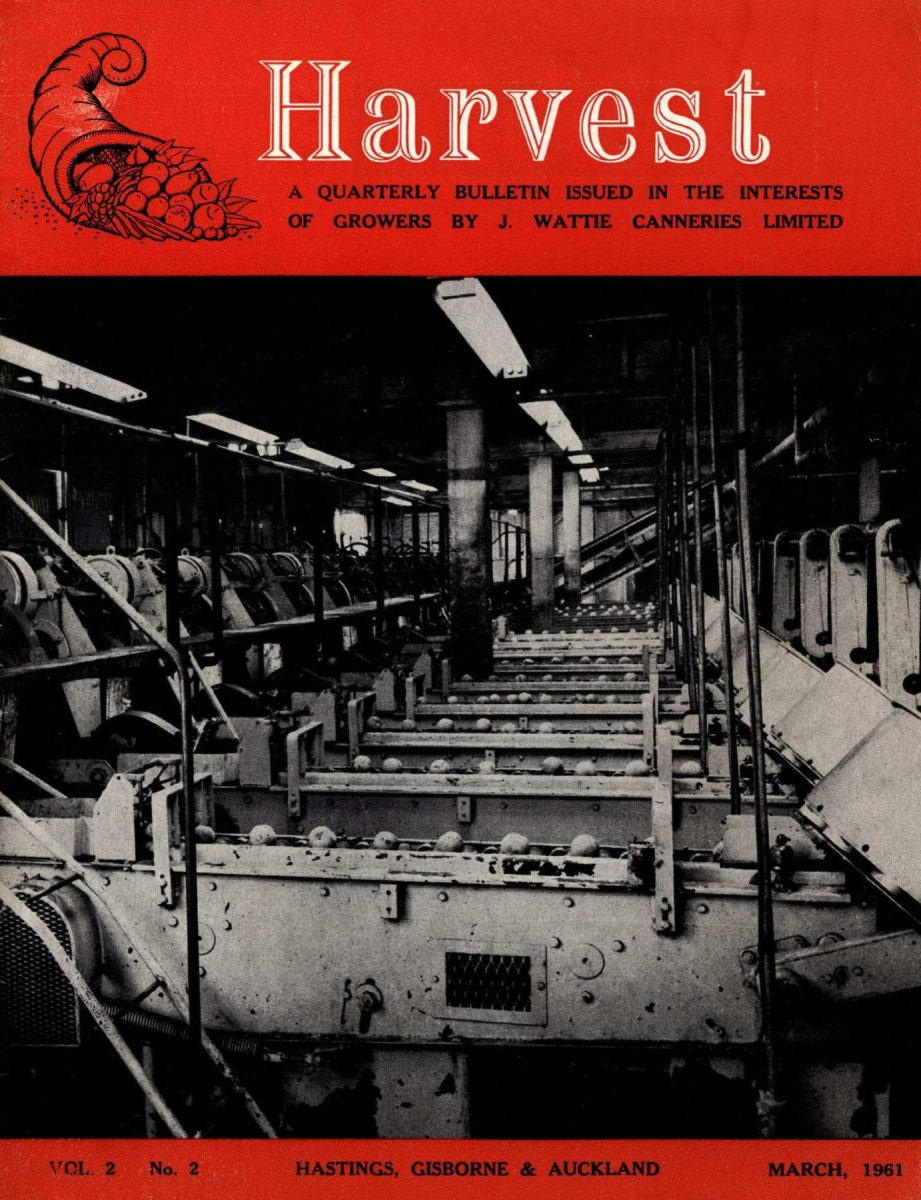

OUR COVER

A battery of Automatic Peach Pitters operating in our Hastings factory.

FOREWORD

The main topic of conversation this summer has been the weather and its drastic results on almost all crops.

“We have never known a season like it,” say the old-timers of both Hastings and Gisborne districts. Statistics prove their remarks to be correct. Anyone knowing Hawke’s Bay or Poverty Bay weather, with its weeks, if not months, of bright sunny weather, finds it difficult to credit that only the odd bright warm day has been experienced during the whole of the planting and harvesting season.

Losses through floods alone have been heavy where crops have been completely destroyed. Loss through decrease in yield and poor harvesting conditions in partly affected crops has also been heavy, and the full extent of this loss will not be known for some time even yet. Tomato growers, for instance, had to do a lot of plant replacement during the early part of the year; weeds were more persistent than usual due to continuous moist soil. Extra sprays have been necessary to ward off disease, especially late blight. Now that harvest time is at hand, it is difficult for pickers to make wages, due to light crops and diseased and unmarketable fruit in many instances.

The story is much the same in all crops, whether grown for processing or not. Crops such as grass seed have suffered as badly as others, including peas.

However, no matter how bad things have been, they could always have been worse. Orchardists have probably fared better than most, although crops are patchy, particularly apples. The pear crop was heavy, but losses through disease have reduced production below earlier estimates. Peaches are our last remaining hope. The crop on the whole is lighter, particularly in Gisborne, where the drop was very heavy indeed after fruit set. Hastings factory intake of peaches is expected to show an increase over last year. This is brought about by the increase in production of young trees just coming into bearing.

It takes a year such as this to illustrate the advantages of such a diversity of lines such as we produce. It will be necessary to see how the whole year goes before we know how the factories have fared. Our growers will know very soon, and some with early crops completed know the answer already.

One thing is certain: that anyone on the land, and companies such as ours dependent on its produce, know we are very much at the mercy of the weather and must simply carry on as usual. It is always “Better luck next year” that keeps us going, and always looking and planning ahead. Whatever our fortune, we are in it together – growers and processors alike – so here is hoping for better things ahead.

Yours sincerely,

Bob June

Hastings Field Supervisor.

BULK HANDLING PEACHES

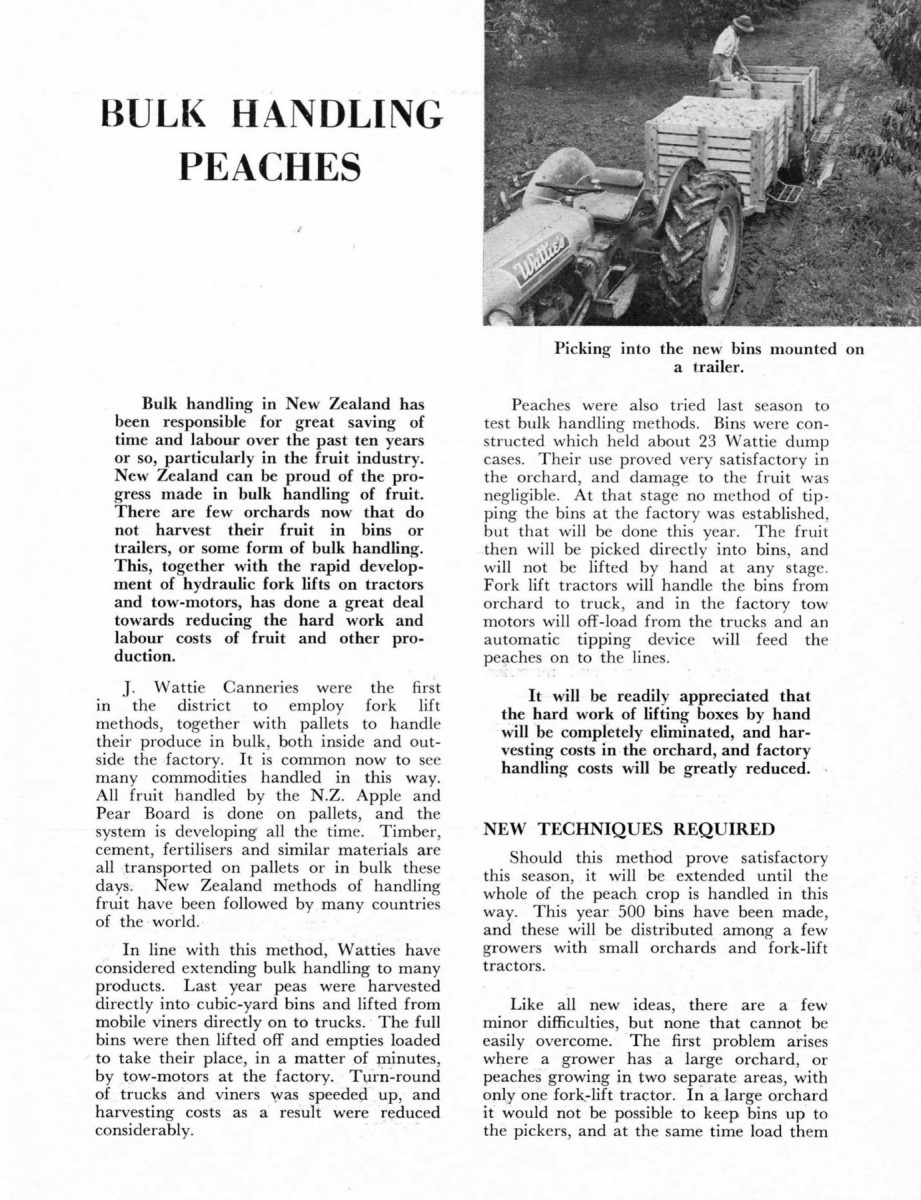

Picking into the new bins mounted on a trailer.

Bulk handling in New Zealand has been responsible for great saving of time and labour over the past ten years or so, particularly in the fruit industry. New Zealand can be proud of the progress made in bulk handling of fruit. There are few orchards now that do not harvest their fruit in bins or trailers, or some form of bulk handling. This, together with the rapid development of hydraulic fork lifts on tractors and tow-motors, has done a great deal towards reducing the hard work and labour costs of fruit and other production.

J. Wattie Canneries were the first in the district to employ fork lift methods, together with pallets to handle their produce in bulk, both inside and outside the factory. It is common now to see many commodities handled in this way. All fruit handled by the NZ. Apple and Fear Board is done on pallets, and the system is developing all the time. Timber, cement, fertilisers and similar materials are all transported on pallets or in bulk these days. New Zealand methods of handling fruit have been followed by many countries of the world.

In line with this method, Watties have considered extending bulk handling to many products. Last year peas were harvested directly into cubic-yard bins and lifted from mobile viners directly on to trucks. The full bins were then lifted off and empties loaded to take their place, in a matter of minutes, by tow-motors at the factory. Turn-round of trucks and viners was speeded up, and harvesting costs as a result were reduced considerably.

Peaches were also tried last season to test bulk handling methods. Bins were constructed which held about 23 Wattie dump cases. Their use proved very satisfactory in the orchard, and damage to the fruit was negligible. At that stage no method of tipping the bins at the factory was established, but that will be done this year. The fruit then will be picked directly into bins, and will not be lifted by hand at any stage. Fork lift tractors will handle the bins from orchard to truck, and in the factory tow motors will off-load from the trucks and an automatic tipping device will feed the peaches on to the lines.

It will be readily appreciated that the hard work of lifting boxes by hand will be completely eliminated, and harvesting costs in the orchard, and factory handling costs will be greatly reduced.

NEW TECHNIQUES REQUIRED

Should this method prove satisfactory this season, it will be extended until the whole of the peach crop is handled in this way. This year 500 bins have been made, and these will be distributed among a few growers with small orchards and fork-lift tractors.

Like all new ideas, there are a few minor difficulties, but none that cannot be easily overcome. The first problem arises where a grower has a large orchard, or peaches growing in two separate areas, with only one fork-lift tractor. In a large orchard it would not be possible to keep bins up to the pickers, and at the same time load them

on to trucks as required. This would be so especially where only a light pick was being made, and pickers were moving from tree to tree fairly quickly. It would take several fork lifts to keep pace.

The answer, of course, is small trailers capable of carrying two or more bins. Several trailers could be towed, one behind the other if necessary. The trailers would have to be built low to enable pickers to place their fruit directly into the bins from their picking bags. A dozen of these trailers have been constructed for use on two of Wattie’s orchards, and seem very satisfactory. They are merely angle-iron frames on wheels to keep costs as low as possible.

It will take time, then, for some of our growers to work around to this stage, and that is why the smaller growers are getting the bins meantime. By the end of the season we may have a better understanding of the whole set-up. All changes take time.

The bins are constructed of wood and strongly made. We do ask growers to handle them with care. They are constructed with open slatted sides to improve air circulation should they be cool stored at any time. The slatted sides also make estimates of part bins easy should this be necessary where contract picking is done. The bins are also constructed to fit one on top of the other, so that good pay loads can still be transported from orchard to factory.

We trust this method of handling peaches will be a great step forward, and we are pleased to be the first once again in establishing this new idea. It will help all round in reducing both grower and factory costs, a point so important to us all.

SLUG AND SNAIL CONTROL

Slugs and snails are often a problem in home gardens, glasshouses and nurseries. In a wet year such as we are experiencing this season, slugs have also done considerable damage to field crops. They were present in their thousands in pea crops this year, and are also damaging bean crops at the present time. Wet weather with long grass and heavy weed growth have given this pest very suitable conditions.

NEW CONTROL METHODS

None of the normal insecticides used in orchard or field crops will give control of this pest. In the past it was an expensive business mixing up poison baits to try and overcome the damage done by slugs and snails. Often the bait deteriorated quickly, necessitating frequent replacements, making it still more costly.

Now a new preparation is readily available which will give cheap control over longer periods than before. It is a granular form of bait with metaldehyde as its active ingredient. The granules are formulated in such a way that wet soil or rain does not readily dissolve them or allow them to disintegrate.

APPLICATION; RECOMMENDATIONS

Being in granular form, application is made simple and cheap. For home gardens or nurseries, about 10 granules to the square yard can be scattered in likely places, or in little heaps placed between plants. For field application, the rate advocated is 6 to 7lbs. per acre. In dense crops such as lettuce, as much as 20lbs. per acre may be required. It may also be an advantage to double up in a band surrounding a crop, particularly if the area nearby 15 in grass or a crop likely to harbour the pest. A second application is sometimes necessary if conditions favour the slugs.

We have been quoted costs by a local firm at 4/3 per lb. in 4lb. lots, reduced to 3/9 per lb. in hundredweight lots.

Metaldehyde is poisonous, so great care should be taken to keep this material away from children and poultry.

FIELD STAFF REPLACEMENT

Stuart Thomas

We are very pleased to welcome Stuart Thomas to our Hastings field staff. This makes good the loss of Mike Crooks, who left us recently to take up a similar position with a freezing company in Australia.

We are indeed fortunate in having Stuart join us. An employer is seldom able to obtain the services of a man already doing fine work of a similar nature in the same district and already well acquainted with local growers and conditions. For these reasons Stuart’s services are all the more appreciated and valuable. From the day he came on the staff, he was able to go straight into his work with very little instruction. He joined us at the beginning of January, and probably every one of our fruit growers has had a call from him by now, and he is also acquainted with many other growers as well.

Stuart is a man of fine character and has a happy disposition which enables him to get on well with growers and inspires their confidence. He is a very practical man with a sound knowledge of both fruit and vegetable production in Hawke’s Bay and other districts.

For the past two years he has been employed by the Horticultural Division of the Department of Agriculture in Hastings. The department’s loss was a great gain for us. However, he is not lost to the industry or the district, and will continue to give of his services and knowledge freely. His reputation amongst his fellow workers in the Horticultural Division was a fine one, and growers are high in their praise for him.

Stuart is a practical man, having had his own farm for a time in North Auckland. His farming career came to an end as the result of an accident. He then worked for a well-known seed firm for many years. This gave him a sound knowledge of an important fundamental of food production. The knowledge gained in the Department of Agriculture that followed, together with the practical work he has done amongst orchardists here and in Nelson, have given him a wealth of knowledge fitting him well for his present task.

TREVOR BAKER ALSO JOINS STAFF

Many growers will also have met another member of our staff who has been with us for the last few months. He is another local man, Trevor Baker.

Trevor has come on our staff to look after the very important task of inspecting all produce as it comes over the weighbridge His experience since the war, when he served in the Navy, has fitted him well for this task, and field work as well, where he has already done a great job during the pea harvest.

Here again we have a practical man who has been a market gardener and later a buyer for produce firms in Hawke’s Bay. He has also done a lot of work in local orchards, making him a good all-rounder. Trevor has a happy knack of picking up and retaining knowledge easily. He recently took a course with the New Zealand Technical Correspondence School. He completed the course with high honours, being second equal in marks for the whole of New Zealand.

Growers will soon realise that Trevor is able to talk to them in their own language with a sound knowledge of his work and a keenness to further his knowledge as much as possible in anything pertaining to the land. His life’s work since leaving the Navy has been associated with either work on the land or dealing with growers and their produce. This experience gives him an excellent background for his work with us.

Photo caption – Trevor Baker

BROWN ROT CONTROL OF PEACHES

In our last issue of Harvest a new technique of controlling brown rot in peaches, after they have been harvested, was described. It consisted of picking peaches slightly immature but fully grown, and then placing them in a ripening room at about 94 deg. F. This temperature ripens the fruit, but stops rot development.

When ripening is completed suitably for processing, the fruit is removed and if necessary placed in a cold room to stop the ripening process until required. A great deal of investigation has been done on this aspect of brown rot control in Australia, and also in the Nelson district of New Zealand. Results have been promising.

Investigations of a similar nature are now being undertaken in Hawke’s Bay. Mr. W. R. Fletcher, of the Fruit Research Division of D.S.I.R., and other research officers have been engaged on this work this season at the Fruit Research Station, Havelock North. The investigations are being carried through to the canning stage by our Chief Chemist, who will process the fruit at various stages to carry the experiment to its conclusion.

Stimulating Visitors from Overseas

During the course of a year, we receive many hundreds of visitors. Most of these visitors are New Zealanders, but there are also many from various countries of the world. Overseas travellers tend to pay the factory a visit because of some particular interest or previous contact. It is this type of visitor that we are always particularly pleased to welcome. The exchange of ideas is of great interest, and in most cases something of mutual benefit is derived from the contact.

FIELD OFFICERS’ BENEFIT

Although field men endeavour to keep abreast of world trends in horticultural practices by reading various publications, time does not permit a great deal of such study. It is always a pleasure to meet someone from another country and exchange ideas. A great deal of knowledge is gained in this way. This knowledge often finds its way into local practice. It would not be difficult to name many methods and materials which have been put into use here as a result, both by our own staff going overseas, and by overseas visitors paying us a call.

ONE OF THE BEST

From a field officer’s point of view, one of our most interesting and instructive visitors recently came from Sweden. He was Dr. Bertil Hylmö, Research Manager of A. B. Findus, a large food processing firm of Sweden. Dr. Hylmö is also a botanist of some standing, and is an assistant Professor, teaching botany at Lund University in Sweden.

Primarily interested in pea production in New Zealand, Dr. Hylmö, and other members of the Findus staff, spent some weeks at our factories studying our methods. During a prolonged visit such as this it is possible to learn a great deal, and we appreciate what these men did to help us. We appreciated, too, the way in which they offered information and were happy to discuss any aspect of production.

GREAT BENEFIT

A great deal of information of value was gained from our friends from Sweden. Much of it has already been put into practice, and a great deal more will be followed up next season. Much of interest has been retained by our field staff. To us it is really amazing the organisation that goes into pea production in Sweden. Average yields are much higher than we can boast. Harvesting methods have received great attention. They are able to harvest under very wet conditions, for instance – a very important point in a year such as we have experienced. Preparation of land receives great care, even down to taking certain bacterial counts in soil prior to planting. Peas are grown only every six years in the same field, and then only if certain bacterium are not present in too great a number. Pea sampling is done very thoroughly with many large samples taken prior to harvest. Special varieties have been selected, and everything possible seems to have been done to get every last pea possible harvested and processed in perfect condition. Quite a number of tests in the field and in the factory have been undertaken here at Dr. Hylmö’s suggestion, and some very interesting data has resulted from these investigations.

We have over the years had many associations with practical men from many other canning and freezing firms, particularly from England and the USA.

OUR STAFF ALSO TRAVEL

Not only have we gained much knowledge from overseas visitors, we have from time to time had members of our own staff on overseas tours. These trips have been responsible for much up-to-date machinery in our factories, and modern methods of food handling and labour-saving devices. Mr. J. Wattie, our Managing Director, himself has had numerous trips to many parts of the world. A great deal of our modern machinery has been purchased as a result of his trips. Many of our processing methods too have been the result of his travels, to say nothing of the establishment of overseas markets so valuable to us.

Other members of the executive staff who have had the opportunity of seeing for themselves how things are done in other parts of the world include Gordon and Ray Wattie, sons of our Managing Director. Many new ideas of these two practical men who have grown up in the food processing industry, have been put into practice on knowledge gained from other parts of the world. Bulk handling of peas, put into practice last year, is just one example.

Our Chief Chemist, John Fielding, was able to make a trip to England and America; John Coles and John Carrington, our Chief Engineers of the Hastings and Gisborne factories, were able to tour Australian factories last year.

The latest member of our staff to have the opportunity of a trip to the U.S.A. is Jim Anderson, our Can Plant Supervisor, who has only just returned. Jim went away to investigate the latest refinements in can making, to further his knowledge of the technical side of things, and to inspect machinery to be purchased for our own can plant.

Jim tells us he thinks such trips well worth while. With modern methods of travel, a great distance can be covered in a quick time. If a proper itinerary is worked out beforehand, a great deal can be fitted into a very short time. He is high in his praise for the American worker. They work hard, and are very keen in specialising in particular aspects of their individual trades. Their organisation is very efficient, and makes one think that people in New Zealand could do a lot more for their country if they were prepared to work harder and more efficiently. There is a vast difference in the service expected and received between the two countries. The American expects service and gets it, says Jim.

We trust that these visits will continue between our friends overseas and our own staff. Much good has come of them already. They are indeed a great stimulus to our industry.

LEAF ANALYSIS OF APPLES

In “California Agriculture” recently there was an interesting short article by E. L. Proebsting, Professor of Pomology, University of California at Davis. The article showed the uptake of N.P.K. by leaf analysis, and is quoted here in part.

An apple orchard was shown to be low in phosphorus and potassium as a result of leaf analysis. Test plots were established in 1952, and fertilised with nitrogen, potash and phosphates. In 1956 potassium sulphate alone was applied. The amounts of phosphorus and potassium were greater than ordinarily used by growers.

Monthly analyses of leaf samples throughout the summer of each year showed maximum N.P.K. in spring, with a gradual decrease during summer. Calcium and magnesium increased steadily, sodium was negligible at all times, manganese showed no definite clear-cut pattern.

Although the potassium level was low, being less than .5 per cent. in some samples, no definite symptoms were present, and trees made no response to added potash.

The conclusion drawn is that a zone or level for each element is present in an apple tree. If a tree falls below that level there is a response, but if above the level, response is nearly always absent. The extent of this zone of uncertainty, where response can be determined by trial, is rather wide for nitrogen perhaps less so for potassium, and undetermined for phosphorus. There have been so few cases of phosphorus response in deciduous orchards that reliable levels of deficiency have not been established.

The fact that apple trees in this particular district, that were deficient in phosphates and potash, according to leaf analysis, failed to respond to fertilisers, indicates that leaf analysis is a useful tool when used with other tests, but leaf analysis is not adequate by itself in determining of fertiliser programme.

PEACH DISEASE IDENTIFIED

For some years odd peaches have been noted from time to time with irregular patches of the skin which have lost their fuzz and have a brown lacey or russety appearance. This has now been identified by the Horticultural Division as Powdery Mildew, or to be more exact, Rose Mildew (sph aerotheca pannosa).

The affected parts of the peaches look something like the Stark Blemish found on the Stark variety. Whereas Stark blemish is believed to be a Virus, this disease is of a fungous origin. Species of powdery mildew are common to many plants, but some plants have a specie which attacks them and no other. We are familiar, for instance, with powdery mildew of apples (Podosphaera leucotricha). We are also familiar with mildew on grasses, cereals and peas, and on many garden plants such as delphiniums and asters, and leafy vegetables including swedes and cauliflowers. Roses are often attacked, and it is this specie of mildew which has been found to cause these patches on peaches.

Furthermore, horticultural officers have noted that an infected area can always be traced to some diseased roses in the Vicinity of the orchard. It appears then that a new host can be added to those attacked by this particular fungus.

The disease is not serious, but does appreciably affect the appearance of fruit offered for sale, making it very unsightly. Control can be gained by the use of Karathane, a well-known fungicide.

NOTE THIS NEW NUMBER

As an extra service to growers, Stuart Thomas; our new field officer, is now on the telephone. As this number does not appear in the directory, would growers please make a note of it for future reference – HASTINGS 82-661

STRAWBERRY MULCHES

Picking Strawberries mulched with Black Polythene.

Last season a small area of strawberries was planted on one of our own farms. It was planted for various reasons – 40 test several varieties under local conditions for their ability to crop, resist disease, and to ascertain their quality and suitability for processing. In conjunction, an area was planted using black polythene as a mulch, to test its suitability and cost for this crop.

TYPES OF MULCHES

There are, of course, various materials suitable for this purpose and they serve many uses. A material should be chosen to serve the following requirements: –

(a) To keep the fruit clean. It should keep the fruit from touching the soil and also prevent heavy rain splashing soil on to it.

(b) To allow free air circulation around the fruit and plant, preventing such diseases as botrytis from taking charge in adverse conditions.

(c) To prevent reflected light causing excessive temperature build-up and in turn causing sun scald.

(d) It should not provide a harbour for insect pests and diseases.

(e) It should act as an insulator preventing high soil temperatures and undue loss of soil moisture. It should assist in preventing weed germination.

(f) It must be cheap and easily laid.

All these attributes are difficult to find in any one material. Most local growers have used either straw or sawdust. The latter seems to be most favoured at the moment. It is certainly easily obtainable and cheap to apply. Perhaps its chief fault is its tendency to adhere to the fruit, especially after strong winds.

PLASTICS USED EXTENSIVELY

In other parts of the world, materials such as paper or plastic sheets are used a great deal. We see these materials advertised, and no doubt they are very well suited to many crops and many localities.

With this knowledge, we used about 500 yards of 36 inch wide black plastic sheeting last year. First a slight mound was made and the plastic stretched over it with the edges buried in the soil to keep the wind from getting under it. Holes were then made at the desired intervals and the plants set out. In spite of the holes being kept as small as possible, enough air got through them to lift the sheets and some of them pulled free of the soil altogether. To overcome this trouble, wire stakes were cut and binder twine was used to lace the whole sheet down in conjunction with the edges being covered with soil. This proved successful but of course, added to the cost. Once this trouble was overcome, it seemed most successful for the remainder of the season.

SECOND YEAR DIFFERENT

In the second season, some of the old sheets were left intact and new sheets extended to new plantings. This year, of course, was most unusual in that it continued to rain every few days throughout the whole spring and summer. In spite of a tremendous setting of fruit, the harvest was-most disappointing. Colour was difficult to get, and any slight depression in the plastic held little pools of water. Where the fruit touched this water, it rotted very readily and became useless. Sun scald during the odd hot day was also severe.

It was very well demonstrated that although this material proved most satisfactory the first season, its use could not be recommended as a result of this last wet season’s results. Furthermore, the cost of the material, plus the expense of anchoring it securely and the slower planting through holes in the sheet, render it more costly than sawdust.

This is just one more case which illustrates that you cannot be sure of any trial involving crops in one year’s experience. This is true of most things we set out to prove by trial, whether it be a variety trial, manurial, spray, irrigation, cultivation, disease resistance or any other aspect of crop production. There is always the unusual season, of course, which proves very old and approved methods unsuitable. However, the use of plastic sheets for strawberry mulches certainly cannot be recommended here. This is also the opinion of other growers in the district who have found it unsuccessful.

NEW FREE SOIL SERVICE TO GROWERS

FREE SOIL ANALYSES

A great amount of fertiliser must be wasted because it is applied without knowing if it is required, or in what amounts. One well-known world-wide company with local agents in Hastings and elsewhere is now offering in New Zealand a free soil analysis service. Recommendations are also made for specific crops as a result of the analyses.

Many growers have taken advantage of soil analyses before, of course, but it has been a costly item, especially where several tests were required on one property. It has usually paid dividends.

Soil sampling is not the complete answer to fertiliser requirements, but at least it is the best guide that can be offered. There is a great deal we do not know about the assimilation of food by the plant, but if we know our soil is deficient or over-supplied in a particular nutrient, then we can save ourselves a great deal by choosing a fertiliser accordingly.

The interpretation of a soil analysis is important. There is a fund of information on the most important nutrients for particular plants, and those responsible for the soil analyses will be taking this into account and advising accordingly.

Our field officers will be available to help growers with soil sampling. A start has been made getting samples away for the broad bean season just ahead. It is always a help to know of previous crops and fertiliser application in a sampled field.

Another recommendation is to leave check plots in each crop without fertiliser, to note any benefits derived. It is sometimes interesting to do a small area with an extra dressing as well, to try and ascertain the economic limits of quantities required for particular crops.

As far as we know, this is the first time a free soil sampling offer has been made in New Zealand No doubt growers will take advantage of this offer, and the recommendations made as a result.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

The donor of this material does not allow commercial use.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Subjects

Tags

Business / Organisation

J Wattie Canneries LtdFormat of the original

BookletDate published

March 1961Publisher

J Wattie Canneries LtdPeople

- Jim Anderson

- Trevor Baker

- John Carrington

- John Coles

- Mike Crooks

- John Fielding

- W R Fletcher

- R (Bob) I June

- Stuart Thomas

- James Wattie

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.