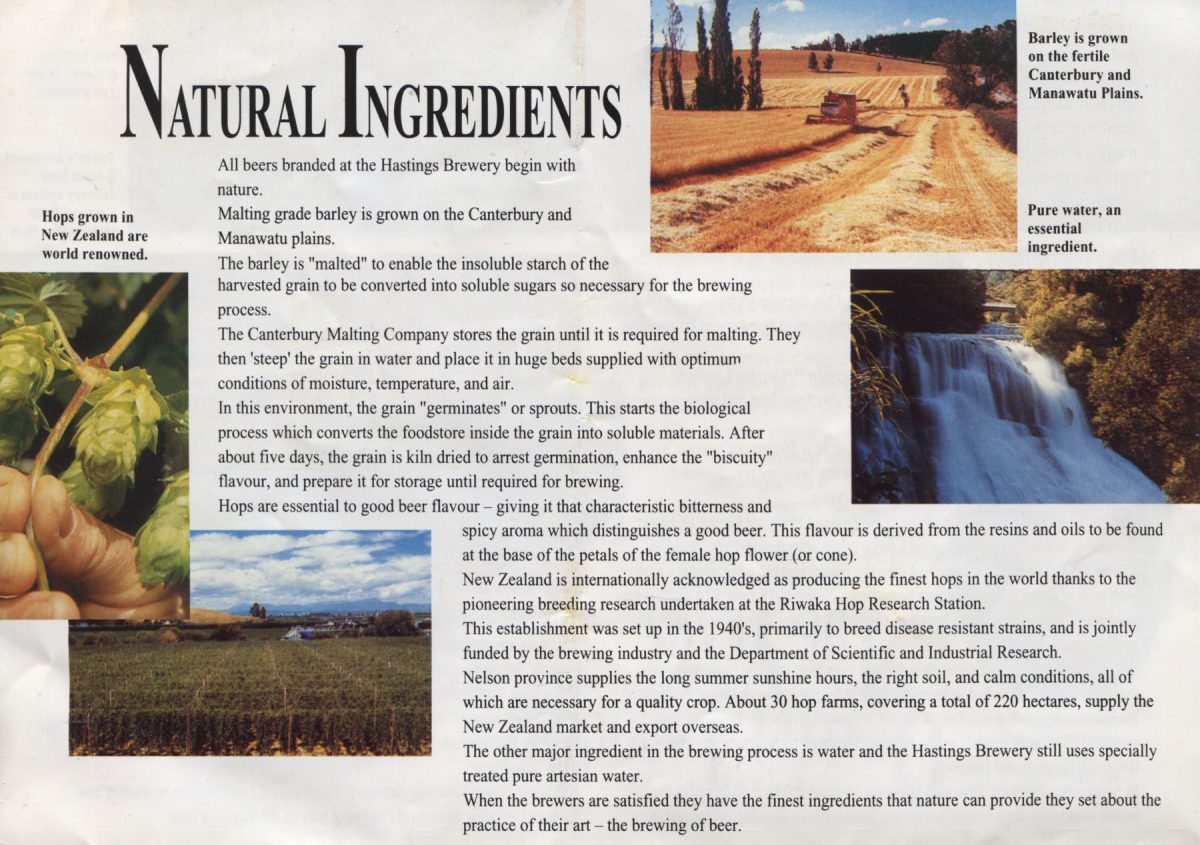

NATURAL INGREDIENTS

All beers branded at the Hastings Brewery begin with nature.

Malting grade barley is grown on the Canterbury and Manawatu plains.

The barley is “malted” to enable the insoluble starch of the harvested grain to be converted into soluble sugars so necessary for the brewing process.

The Canterbury Malting Company stores the grain until it is required for malting. They then ‘steep’ the grain in water and place it in huge beds supplied with optimum conditions of moisture, temperature, and air.

In this environment, the grain “germinates” or sprouts. This starts the biological process which converts the foodstore inside the grain into soluble materials. After about five days, the grain is kiln dried to arrest germination, enhance the “biscuity” flavour, and prepare it for storage until required for brewing.

Hops are essential to good beer flavour – giving it that characteristic bitterness and spicy aroma which distinguishes a good beer. This flavour is derived from the resins and oils to be found at the base of the petals of the female hop flower (or cone).

New Zealand is internationally acknowledged as producing the finest hops in the world thanks to the pioneering breeding research undertaken at the Riwaka Hop Research Station.

This establishment was set up in the 1940’s, primarily to breed disease resistant strains, and is jointly funded by the brewing industry and the Department of Scientific and Industrial Research.

Nelson province supplies the long summer sunshine hours, the right soil, and calm conditions, all of which are necessary for a quality crop. About 30 hop farms, covering a total of 220 hectares, supply the New Zealand market and export overseas.

The other major ingredient in the brewing process is water and the Hastings Brewery still uses specially treated pure artesian water.

When the brewers are satisfied they have the finest ingredients that nature can provide they set about the practice of their art – the brewing of beer.

Photo captions –

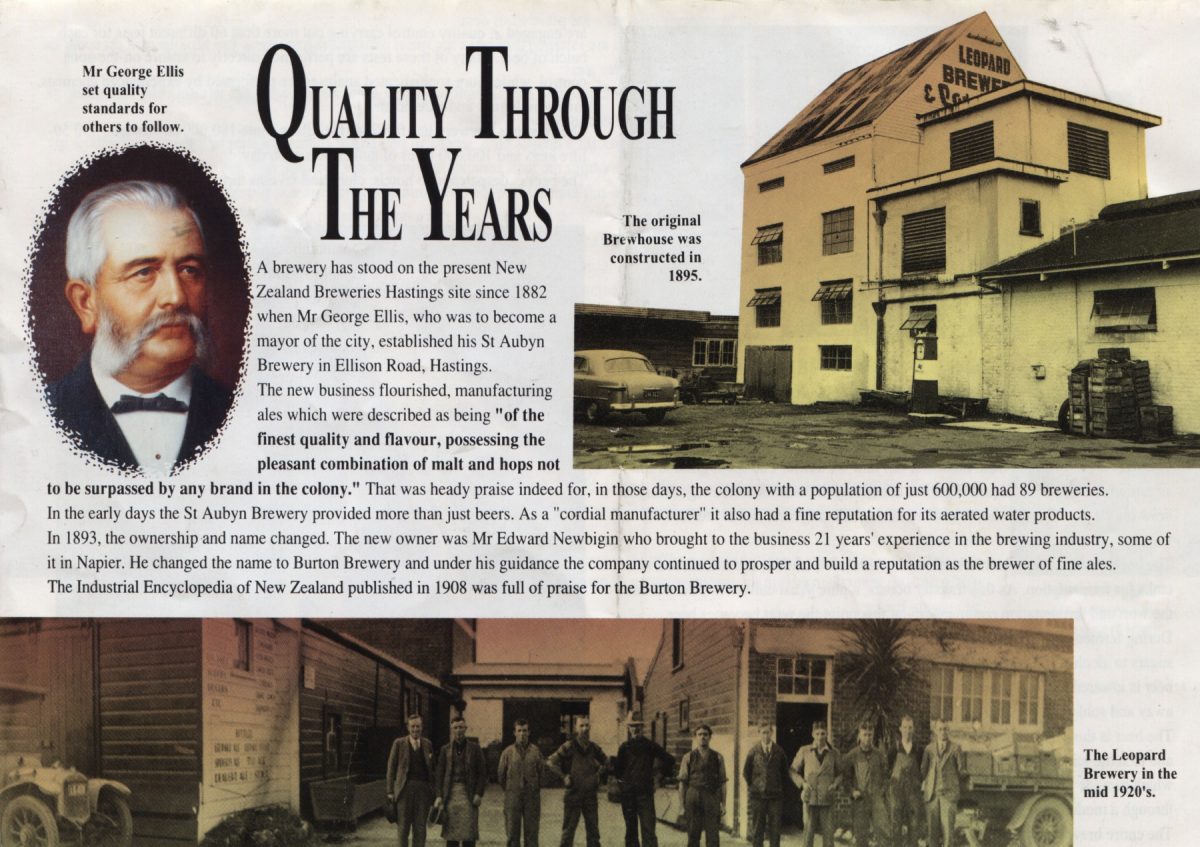

Hops grown in New Zealand are world renowned.

Barley is grown on the fertile Canterbury and Manawatu plains.

Pure water, an essential ingredient.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.