- Home

- Collections

- NEWBIGIN EJD

- Brewery, Business

- Magazine Article 1993 - Hawke's Bay Brewery

Magazine Article 1993 – Hawke’s Bay Brewery

Constant aim: Better methods, better beer

The Hawke’s Bay Brewery, a significant contributor to the region’s economy, is moving into a new era.

The brewery has a new manager – Brent Wright – who has moved from Christchurch, and the changes in management style are already obvious.

There has been a brewery on the Ellison Road, Hastings, site since 1882 and beer has been produced continuously since then.

But apart from the brew house there is little else about the brewery that former owners or workers would recognise. There has been frequent updating and improvement since it first opened – most recently under New Zealand Breweries’ ownership.

Three years ago the company was given registration under the International Standards Organisation ISO 9000 management programmes – becoming the first brewery in the world to achieve this milestone. And this set the brewery on a path of permanent improvement and upgrading in all areas, from the production techniques to the management practices.

Manager Brent Wright is a firm advocate of the programme – and is promising more improvements.

“We are spending just under $1 million a year upgrading our processes – always reviewing them, looking at them,” Mr Wright said.

But the changes are not carried out for their own sake; they must pay off.

“Every time we get an improvement there is a payback and if the payback is within a year you are in net gain in year two. We carefully assess those sorts of issues,” Mr Wright said.

And the point of the continual improvement is to produce the best beer possible and get it into the customer’s glass in the same condition.

The Hawke’s Bay Brewery is owned by New Zealand Breweries, a wholly owned subsidiary of Lion Nathan.

It produces nearly all brands from the company’s stable of beers – Waikato Draught, Toohey’s Blue Label Light, Steinlager Export, Steinlager Blue and Steinlager Dry, Rheineck, Lion Red, Lion Brown, Ice Beer and of course Hawke’s Bay Draught.

One of Mr Wright’s immediate concerns at the brewery is to increase market share.

“We still have considerable room for volume growth,” he said.

The management of the brewery is however realistic about the limited prospect for growth in the overall New Zealand beer market in the short term at least.

Growth for New Zealand Breweries and the Hawke’s Bay Brewery will come, they expect, through taking market share from the competition and producing niche brands that attract people who are traditionally non-beer drinkers.

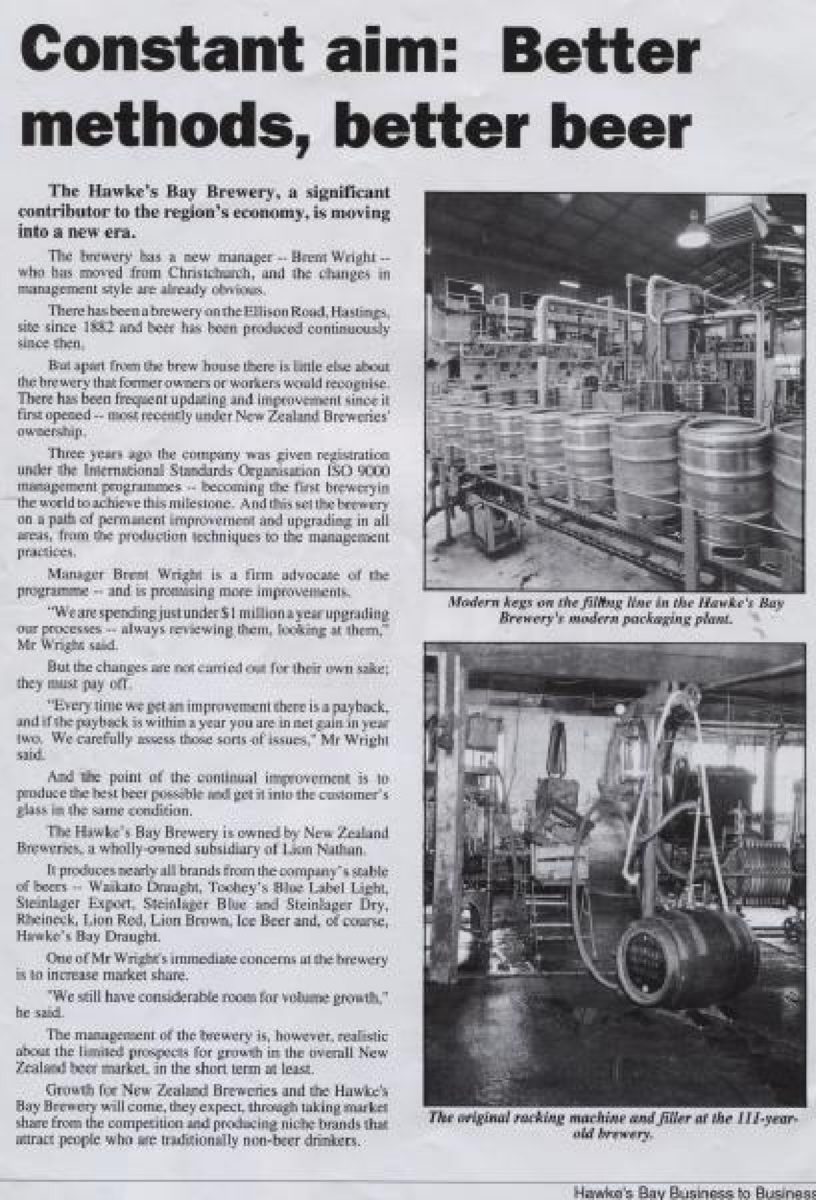

Photo captions –

Modern kegs on the filling line in the Hawke’s Bay Brewery’s modern packaging plant.

The original racking machine and filler at the 111-year old brewery.

Railfreight building up traffic volumes

Flexible, efficient and streamlined, Railfreight now claims to be leading the field in freight-forwarding in New Zealand.

And according to Jim Henderson, manager of the Hastings division, the company has never been busier.

“We now handle all types of freight and are constantly improving our transit lines through the whole of New Zealand,” he said.

“Railfreight has proved itself to its customers. We have become the country’s foremost company for freight forwarding and we are now romping ahead of last year’s figures in the amount of freight we are moving.

“We have an extremely wide range of services for our customers and recently have been asked to handle all of Watties’ freight distribution throughout New Zealand – proof that our service is capable of such a commitment, “ he said.

Mr Henderson said Railfreight had the very latest technology in tracking systems, which meant that any container on the way to its destination could be traced at any time.

This electronic tracking system works like a bar-code scanner and operates hand in hand with electronic weighbridges which can register the weights of containers or wagons as they travel over the weighbridge at speed, eliminating the time taken using older methods.

Railfreight’s relationship with Hawke’s Bay Brewery has been long and constant. It has been freighting malt for the brewery from Marton for the past six years.

” We have developed a close working relationship with the brewery, providing a continuous freighting link which brings its supply of malt from Marton, returning the wagons for the next load,” he said.

Mr Henderson said the Hawke’s Bay fruit season was now in full swing and Railfreight was geared up to distribute the region’s produce to North Island markets.

“We offer fast flexible and efficient service to producers, and one of our greatest assets is the fact that we can tailor freight forwarding needs to suit our clients, “he said.

“Our clients have very stringent time constraints, particularly when freighting perishable produce and we are able to meet these requirements.

“Rail freight is always constantly looking at innovative ways to suit the needs of today’s freight and our customers’ expectations – we’re changing all the time to meet these needs,” he said.

Published by arrangement

Photo captions –

Peter Hynes and Bruce McKinnon with grain containers used by Hawke’s Bay brewery.

Railfreight’s high cube “swap bodies” providing ample room for freight.

A major contributor to the economy

If you were asked what Hawke’s Bay Brewery contributes to the Bay, it’s more than likely you’d say a range of outstanding beers.

While you’d be right, of course, you’d be overlooking another major contribution the brewery makes, and that is the millions of dollars it injects into the local economy each year.

It’s difficult to calculate exactly how much the brewery contributes by way of wages and salaries, maintenance of fleet vehicles and purchases from local businesses – including anything from natural gas to electricity to beer-packaging material.

However, it’s likely to be considerably more than $10 million.

“It’s fair to say we are an integral part of the Hawke’s Bay economy,” says brewery manager Brent Wright.

But the brewery’s impact is even wider. It spends around $8 million annually on ingredients sourced from outside Hawke’s Bay, and pay outs a further $24 million in alcohol duty to Customs plus road-user charges of around $24,000 per year.

They’re big figures indeed. To help put them in some sort of perspective, the brewery pays $6 of alcohol duty on a keg of beer – and then there’s GST on top of that.

What is even more impressive are the production figures. This year the brewery plans to brew 350,000 hectolitres (35 million litres) of beer – enough to fill several Olympic-sized swimming pools.

When you relate the figures to production per employee, it’s likely that 350,000 litres of beer will be brewed for each employee at the brewery this year.

Exactly 100 staff work on the Ellison Road site – 67 in the plant, 17 in distribution, 10 in sales, five in finance and a training/development officer.

“The sheer level of output from the Hawke’s Bay Brewery is one of the things that is most surprising to our visitors,” says Brent Wright.

“Thanks to a high level of mechanisation, technology and efficient systems, we are able to produce a startling amount of beer in a year.”

A very “open” brewery impresses its visitors

A brewery is traditionally a place steeped in mystique where the timeless art of brewing is practised away from the public’s eye.

At the Hawke’s Bay Brewery, however, little, apart from the jealously guarded secrets behind each brew, is kept from the enquiring public.

This is because the brewery has a policy of opening it’s doors to the outside world at virtually any opportunity.

Most of the visitors take part in one of the guided tours held every Wednesday morning. During these tours they get to see every step of the brewing process, from the arrival of the raw barley and hops to the packaging and loading of the finished product.

Brewery manager Brent Wright says it’s a lot to assimilate for those who have never seen a brewery before, but visitors are almost always impressed by what they see.

“When you drink beer you seldom think about the many steps the beer has gone through to arrive in your hand,” Mr Wright says.

“In this respect, a trip through the brewery places a whole new dimension on beer for many people.”

Surprises

Perhaps the most striking thing for a first-time visitor is the rich, seductive smell of maturing beer. Another surprise for many is the relatively small number of people required to make such large quantities of beer.

While the weekly tours are the most common means for “outsiders” to view the inner sanctum of the brewery, the front doors are often opened wide for schoolchildren and for fund-raising activities.

Many Hawke’s Bay people will remember visiting the brewery as part of vocational training at secondary school.

“We regularly have secondary school kids at the brewery, some for one day, some for two days and some even longer,” Mr Wright says.

One reason schoolchildren come to the brewery is because its staff work in a wide range of different disciplines

“In many ways the brewery is like a microcosm of the world outside ”Mr Wright says.

The public will have another chance to see the brewery on Sunday December 12 when it’s doors will be opened as part of fund-raising for Hastings Frimley School

[Advertisements]

The Truck Specialist

HASTINGS PANEL REPAIR & SPRAYPAINTER

We are one of Hawke’s Bay’s leading truck & heavy machinery painters

WE PANEL & PAINT –

TRUCKS STOCK CRATES

HEAVY MACHINERY

AEROPLANES

HELICOPTERS CARS

CARAVANS BOATS

WE SPECIALISE IN FLEET COLOURS WITH I.C.I.

Ring Jock Nicoll

876 7297

ORCHARD RD HASTINGS

In Emmersons Transport Yard

Proud to be associated with Hawke’s Bay Brewery

YOUR ONE STOP

SERVICE & SUPPLY CENTRE

PLUMBING SUPPLIES

PVC PIPE AND FITTINGS

DRAINAGE SUPPLIES

POLYETHYLENE PIPE AND FITTINGS

POLYETHYLENE TANKS

GALVANISED PIPE AND FITTINGS

QUALITY TOOLS

RIVETS & FASTENINGS

NZIG GAS & EQUIPMENT

LPG GAS & EQUIPMENT

FOR HAWKE’S BAY’S MOST COMPREHENSIVE RANGE OF PRODUCTS & SERVICES

SEE US FIRST

Suppliers to Hawke’s Bay Breweries

A.W. HOLDER & SONS

501 WARREN ST NTH.

PHONE 878 5093

1024 OMAHU ROAD

PHONE 879 8030

HASTINGS

How brewers control their product’s final taste

The Hawke’s Bay Brewery’s product is monitored from start to finish to ensure the beer that leaves the gate is just right.

Yet, despite some of the most sophisticated monitoring equipment available, the most important test takes place on the taste’s buds of brewers Keith Blackwell and Colin Garland.

Keith Blackwell has been refining his sense of taste for the past 15 years since he “fell into” the job while working in the company’s Palmerston North brewery during studies for a bachelor of technology and bachelor of science degrees.

“I liked the company, I liked the people I worked for, I liked the product – it just seemed natural to join it”. Mr Blackwell said

He moved to Hawke’s Bay eight years ago as a brewer, turning his talents to the range of Hastings beers.

The brewing process begins with several people tasting and examining the malted barley and water to be used to make the beer to ensure it is of unblemished quality.

In the brew house the malt is crushed and mixed with hot water. Natural enzymes convert the starches to sugars which the yeast can use to produce alcohol.

The resulting liquid, called “wort”, is separated from the barley husks and some solids. Liquid sugar and hops are then added to the wort, which is heated to sterilise it, stop the enzymes working and extract the flavours from the hops.

The resulting mixture is transferred from the brew house to fermentation tanks, where yeast is added. At this point the wort becomes beer.

The beer is brewed in 120,000- litre fermentation tanks – the equivalent of 120,000 jugs. However, it is brewed at a slightly higher concentration than the finished product, and each batch in a fermentation tank will eventually produce 159,000 litres of beer.

Once a brew is complete the yeast is removed and transferred to maturation tanks, where time improves the flavour.

From maturation the beer is passed through a filtration system which produces “bright beer”. And at this point carbonated water is added, before the beer goes into storage tanks.

The entire process is monitored by computer but the brewers taste the beer through each stage.

Sampling their products is something both brewers obviously enjoy, and yes, they do swallow the samples. “Unlike the case with wines, the after taste is an essential part of the overall flavour of beer- that’s why we swallow,” Mr Garland said. “We do consume a bit, but over a tasting run we’d be lucky to get a whole glassful”.

The brewers use temperature and time to control brews – and vary their recipes to allow for any change in the quality of the ingredients such as the malt.

Their aim is to produce a totally consistent batch each time, one that meets the very highest standard set by New Zealand Breweries.

[Advertisements]

CALTEX

WHEN ONLY THE BEST IS GOOD ENOUGH!

Proud suppliers to

HASTINGS BREWERY

FUEL & LUBRICANTS

Delo. Miles better

Starcard Hotline 0800 733 835 Toll Free

CALTEX OIL (NZ) LTD

TUATU STREET

NAPIER

PHONE 835 3252

Telecom

proud to provide communications for Hawke’s Bay Breweries

AllenBank office products

ARE PROUD TO SUPPLY HAWKE’S BAY BREWERIES WITH ALL OF THEIR OFFICE AND FURNITURE REQUIREMENTS

AllenBank Are Suppliers of Quality Formway Products

AllenBank office products

416 West Heretaunga Street Phone 06 876 9908

Hastings Free Fax 050 883 5131

ICE Beer – innovation from Hawke’s Bay Brewery

The Hawke’s Bay Brewery takes the credit for the development and recent launch of a new type of beer in New Zealand – ICE Beer.

ICE Beer is distinguished from other beers by its unusually smooth taste and drinkability, the result of an ingenious brewing process that is currently possible in this country only at the Hawke’s Bay Brewery. Following maturation the beer is put into what are known as “ice chambers” – large tanks with refrigeration coils running through them.

The beer is super-chilled to the point where some of the water content in the beer freezes, forming clusters of ice crystals along the refrigeration coils. The ice helps draw natural impurities from the beer, removing much of the bitterness that is normally associated with beer. The result is, quite simply, an incredibly smooth beer.

“The icing improves the flavour profile,” said brewer Colin Garland. “It removes some of the harsher characteristics and gives the beer a fresher taste.”

In drawing water from the beer, the process also leaves a brew of higher alcohol strength – 4.7% in the case of ICE Beer.

After a period in the ice chamber, the ice and impurities are filtered off, again at super-chilled temperatures.

The response to ICE Beer since its launch in early November has been outstanding, leaving the brewery working seven days a week to keep up with demand.

“People are really taking to the smooth, unique taste of ICE Beer – sales are exceeding even our most optimistic projections,” said sales manager Peter Joseph.

The Hawke’s Bay Brewery was chosen to develop and produce ICE Beer largely because of its high quality standards, which are essential to brew to the high specifications demanded for ICE Beer.

It is an exacting process but one that has brought great pleasure for the many people involved in its development and execution.

ICE Beer has quickly become somewhat of a phenomenon since it first appeared in North America earlier this year. For example in the space of little more than six months, ice brewed beer has captured around 11% of the Canadian beer market.

“There is a real move toward beer with a smoother taste and more drinkability – and no beer provides this better than ICE Beer, ” said Hawke’s Bay Brewery’s manager, Brent Wright.

The development of ice brewed beer is a good example of how the Hawke’s Bay Brewery excels in producing niche beers for specific markets.

“We have the flexibility to be able to turn our hand to virtually any sort of product development,” Mr Wright said.

“From a brewing point of view, it is no exaggeration to say the opportunity to develop ICE Beer was like a dream come true, and it has given immense satisfaction to the many people at the brewery who have been part of this development. “The fact that it is selling well is, of course, very satisfying.”

Photo caption – The ice-encrusted tap of the ice chamber – hence the name “ICE Beer”

[Advertisements]

REGAL CATERING

WINDSOR LODGE

Fantasyland

Hastings

“Proud to be caterers for NZ Breweries”

“Catering especially for you – at our place, or yours”

WINDSOR LODGE – Top venue, Plenty of Parking Licensed Bar, Parties from 20 upwards

At YOUR PLACE – Full catering service and a selection of menus to suit individual requirements

SPORTS CLUBS BUSINESS FUNCTIONS FAMILY WEDDINGS

PHONE: 0-6- 8764271 A/HRS 0-6-878 9108

PC PETERSON CHEMICALS LIMITED

ADHESIVE DIVISION

Proud suppliers of Label and Packaging Adhesives to

HAWKE’S BAY BREWERIES

“WE STICK WITH YOU”!

Also major suppliers to many other packaging related industries in the food and beverage areas of the Hawke’s Bay Region

For technical assistance information or service contact:

Peterson Chemicals Ltd

PO Box 19041

AUCKLAND

Phone (09) 828 4089

Fax (09) 828 0347

Local Representative

Greg Donaldson

Mobile 025 451 983

Home (06) 358 7647

Fax (06) 359 4649

Company working to make work attractive

The Hawke’s Bay Brewery is a great place to work according to staff.

The brewery has a low staff turnover– with many employees having been on the site for more than 10 years.

One of these is quality assurance manager Peter Krafft. Peter has worked in the Hawke’s Bay Brewery for 22 years after moving to New Zealand from England, where he worked at Truman Hanbury Buxton Ltd’s brewery.

He believes there is something special about a brewery which makes a great place to work. “Once you are in a brewery you stay there” he says.

Human resource officer Brendon Hurst attributes the low staff turnover to a combination of factors – including the sort of workplace it is, the type of people who work there and the rewards of the job.

“In terms of remuneration we pay for a job well done” Mr Hurst said.

“We are a company that rewards excellent effort – which in turn tends to attract excellent staff.

“We expect people to perform to high standards but we don’t expect people to achieve what they are not equipped for.”

To equip workers with the necessary skills the company runs comprehensive training schemes covering all aspects of the job at hand.

“The Hawke’s Bay Brewery is committed in training and developing the people within the company for our benefit as well as for their personal benefits.” Mr Hurst said.

The brewery’s employment policies are aimed at dealing with a worker as a whole person.

Manager Brent Wright calls it “the holistic approach”.

“If workers are happy at work the will be happy going home.. If they are unhappy at home they will be unhappy coming to work. So we have to treat the family and worker as one.

“We run a lot of family-oriented activities so kids know what their dads are up to – when they’re at work. We have monthly family barbecues”.

The brewery also provides a gymnasium for staff.

“through an emphasis on fitness we tend to have employees who are healthier and more productive” Mr Wright said.

The company also provides are bar where employees can drink after work. The beer is free and the bar is run by a trustee group of employees.

“We promote a healthy respect for beer. We are very conscious of the fact that if anyone is picked up drink-driving from here then it might necessitate shutting the bar. So everyone treats it with respect. I’m proud of it” Mt Wright said.

Packing worker Ivan Moeke has been at the brewery only three years but loves the company, his job, and the products. “it’s one of the best jobs I’ve had.”

Mr Moeke especially likes the various jobs around the packaging plant.

Workers rotate through the jobs so no one becomes bored or losses [loses] concentration.

Training for employees is a top priority for the brewery.

The company runs its own staff training programmes as well as paying for employees to attend outside courses – such as those at the Hawke’s Bay Polytechnic.

The internal training programmes have recently been expanded to cover all aspects of the brewery operation.

“Traditionally the training budget has been focused more at the managerial level, and it is only in the last year that we have started to swing the balance around to our technicians – the people who operate the plant,” said Mr Wright.

The brewery is in the process of getting all its training systems registered on the New Zealand Qualifications Authority framework so qualifications staff gain will be recognised nationally.

“If we can provide our people with recognised skills then we have done a really good thing,” said Mr Wright.

“Our objective is to create portable skills using the NZQA framework and our own skills training. That’s my vision for it.”

The new training system will see workers gain a “Certificate in Food and Beverage Production” certificate. The skills learnt on the courses will be applicable to other large food or drink industries – such as the Wattie group.

Human resource officer Brendon Hurst said the company had been working on the training programmes with the unions covering the site.

The unions had experience with similar training programmes in the past and had been extremely helpful, Mr Hurst said.

Photo caption – A new brewing kettle at the Hawke’s Bay Brewery

THE BURTON BREWERY AT THE TURN OF THE CENTURY: The brewery was established by Mr George Ellis, who was later to become a Mayor of Hastings. The brewery was located with excellent access to water from the two wells on site which are still in use today.

BELOW: Major modifications are now part of the modern brewery.

Close links with Hawke’s Bay community

What do Hawke’s Bay’s top rugby talent, aspiring university students and a rescue helicopter have in common?

The answer is the support of the Hawke’s Bay Brewery.

They are among just a few of the groups who enjoy sponsorship from the brewery each year.

“As a major employer and industry in the Bay, we feel a sense of duty in putting as much as possible back into the community,” says brewery manager Brent Wright.

The young

The focus of the brewery’s sponsorship is with the young – the people who represent the future of the province.

One way the brewery can help give young people the best possible start in life is by helping to ensure they reach their potential, whether this be on the sports field or in the classroom.

Every year the brewery offers eight tertiary scholarships worth $2,500 each. While scholastic potential is a criteria, an important reason for awarding the scholarship is to ensure a student is financially able to attend university.

“There is no question there are a number of talented youngsters out there who, through lack of financial resources, face a real disadvantage when it comes to tertiary education.” Brent Wright says.

“Our aim is to do what we can to help them overcome this hurdle.”

Sports teams

The brewery is involved in the high-profile sponsorship of the Hawke’s Bay Draught Magpies, as well as the Lion Red League Cup, the Hawke’s Bay Bowling Association and touch rugby in Hawke’ Bay

The sponsorships do not end with sports teams. The brewery is also involved with the Lowe Walker rescue helicopter and a variety of smaller charities.

Photo caption – A tank-farm fermenter being hoisted into place at the brewery in the 1960s. Technology built into this fermenter’s walls enabled it to be outside; earlier ones had had to be indoors for the sake of temperature control.

High-tech tanker trains developed in Hastings

The Hawke’s Bay Brewery relies on one of the most modern refrigerated beer-tanker systems in the world to transport bulk beer.

The heart of the distribution system is the fleet of huge “B-train tractor/trailer vehicles which are one of the most visible signs of the company.

Distribution manager John Moodie said the Hastings brewery began developing the beer tankers in 1988 in response to the increasing quality of the beer flowing from the Ellison Road site.

“My aim is to deliver top-quality beer in top-quality condition” John says.

The tanker units the brewery developed in Hastings are also being used to deliver beer in Auckland and the South Island.

Under the old delivery system with unrefrigerated tankers, air pressure was used to get beer in and out of tanks. The beer was warmed in the sun as it sat on the trucks, it reacted with the oxygen in the air and became frothy as it sloshed around the tanker.

The company decided to solve the warming problem by building refrigerated tankers. “Then other quality issues were raised– such as air in the tanks,” Mr Moodie said.

The result was a high-tech tanker unit able to carry 9600 litres. A complete B-Train carries 19,200 litres of beer in top condition.

The heart of the new tanker units is a sophisticated computer which controls every condition affecting the beer – as well as loading and unloading.

The beer is pumped into tanks by carbon dioxide instead of air, and the space at the top of the tank is filled with carbon dioxide. The computer and pumping system ensures the beer runs at a constant flow.

Inside the tanks are baffles designed to stop the beer from sloshing around and to reduce froth.

“So we are protecting the beer all the time,” Mr Moodie said.

AS well as the systems to keep the beer fresh, the tanker-trailers have several other advanced features.

The B-trains run to all points across the lower North Island as one unit – a Kenworth tractor with an articulated trailer towing another trailer.

Once in a main centre such as Wellington the articulated unit and trailer become two separate tanker/trailers, which are then passed over to an owner-driver for local deliveries. When empty the trailers can be hooked together again and brought back to the brewery.

The tanks are washed out between each trip – the computer system prevents the tanks being filled with beer before they have been washed.

The company sought advice from the DSIR and United States experts about the construction of the trailer units and how to make them as stable as possible.

That advice was put into practice to build safe and stable vehicles despite the weight of the loads to carry.

All trucks are carefully monitored for cost and checked for efficiencies.

Eastern Truck Centre has the contract to maintain the fleet of tractors and trailers and keeps the brewery informed of the performance of the vehicles.

Tractor units have been known to get 240,000 kilometres out of a set of driving tyres.

One five-year-old Kenworth tractor unit has just turned over 1.3 million kilometres– averaging around 21,000 kilometres a week. And it has covered its last 300,000 kilometres at a cost of seven cents a kilometre.

“We didn’t believe it when we first saw the figure” Mr Moodie said.” We checked it and it was right. It’s an almost unbelievable result.

The truck is driven by two drivers in a double shift and they are proud of that result.” he said.

Driver Earle Patrick has been with the Hawke’s Bay Brewery for 28 years. He swapped from working in the brewery to driving to get away from shift work and to meet people.

He says the new B-train units were a pleasure to drive. “They are there to do a job and they do the job well as far as the beer and its quality are concerned. They also handle very well and have all the `mod cons`,” he said.

Photo captions –

A refrigerated transporter at the brewery.

…and the way things were in the 1930s

A spent-grain hopper at the Hawke’s Bay Brewery

[Advertisements]

Enerco Gas East

“Proud to be associated with the Hastings Brewery”

For all your NATURAL GAS or L.P.G. requirements in both domestic and commercial situations.

Visit our modern Gas Centres in the Mid City Plaza, Napier or the Westend Shopping Centre, Hastings, or phone for a “FREE NO OBLIGATION QUOTATION”

NAPIER 835 6936 HASTINGS 876 6422

Enerco Gas East

“We are the Experts”

HAWKE’S BAY

Business to BUSINESS

MAGAZINE is proud to present this publication for the Hawke’s Bay Brewery

Quality scheme brings high world ranking

Hawke’s Bay Brewery’s quality assurance manager, Peter Krafft, is a strong advocate of the IOS 9002 quality management system.

Three years ago the Hawke’s Bay Brewery had the distinction of becoming the first in the world to gain ISO 9002 accreditation. Now the brewery is going one step further and offering training and advice on quality matters to other industries.

When the brewery decided to revitalise its systems it look around for a benchmark against which to measure its progress.

“At the time, ISO9002 was just a convenient benchmark,” Mr Krafft said. But it did not take long for the company to become “totally enthusiastic” about the programme.

The ISO9002 is based on simple, common-sense way to run a business, Mr Krafft said.

It forces you to look closely at your internal systems to overcome any shortcomings. It points you in the direction of continual improvement so you do not get complacent.”

The brewery began ISO9002 programme by asking questions of people on the shop floor about how they felt job practices could be improved. The aim was to produce a standardised work method for all jobs and overcome situations whereby people were doing the same job in different ways on different shifts.

“Standardising methods resulted in an immediate improvement in efficiency and increased output.

“Standardisation was the first step in the process of gaining ISO 9002 accreditation because it allowed us to build a platform for all upgrading aspects of the brewery.” Mr Krafft said.

The road to IOS 9002 also involved making all workers aware of the importance of customer satisfaction.

Each internal department is a customer of another department– we aim for total customer satisfaction whether that customer be a drinker of our product or a colleague in the brewery.” Mr Krafft said.

“THE IOS philosophy is the same as a brewer’s– you are working to make perfect product.”

Brewery manager Brent Wright says the IOS system also makes it easier to introduce changes to the plant.

“Quality systems are part of our culture now, and having those systems in place makes change easier because people have more confidence making decisions, and in the outcome of those conditions,” Mr Wright said.

“It gets back to customer services. It’s as important to know your internal as your external customers, so you can rely on other people to do their jobs properly.”

Mr Krafft said there were problems with the programme in its initial stages. Some workers were suspicious about the change that was about to occur.

However, the company kept the communication lines open and “flattened the management structure” and all workers accepted it.

Now the workers on the floor were an enthusiastic part of the programme and were responsible for quality control in their own areas. Everyone in the place was responsible for quality.

The workers responded well to their new responsibilities, MR Krafft said.

“They had a hand in writing the manuals – they own them, so they don’t see the system as `management-imposed`,”

“There are lots of resources and undeveloped ideas amongst staff which, if developed, can save large amounts of money.”

The introduction of the IOS programme has meant change in Mr Krafft’s job. “Twenty years ago it was fair to say I was a trouble shooter. Now the philosophy is to avoid the troubles”

Photo caption – An intricate diatomaceous-earth filter at the Hawke’s Bay Brewery.

[Advertisements]

Watch for Our Specials

HAWKES BAY DRAUGHT BEER

Brewers since 1882

NAPIER 143 Carlyle Street

Phone 06 835 8802

CLIVE Main Road

Phone 06 890 0533

WAIPAWA High Street

Phone 06 859 8502

DANNEVIRKE High Street

Phone 06 394 8086

Supporters of HB Brewery

SUPER FRIENDLY

Super Liquor

GENERAL MACHINERY

Quality – for less

So much more than just tools

Specialists in:-

Hose Camlock Fittings Hose Clips Punch Lock Hose Reels

All types of hose (not hydraulic)

At the best prices in town

Eastbourne St, West, Hastings

(next to Hibernian Club)

Phone 878 7152

EASTERN

TRUCK & MARINE

Proud to support and service

The Fleet of New Zealand Breweries Ltd

Hawke’s Bay

95 Austin Street Phone (06) 843 0400

Onekawa, Napier Fax (06) 843 0408

The Super Liquor chain serving the Hawke’s Bay area has outlets in Napier, Clive, Waipawa and Dannevirke. The philosophy of the managers is to offer and maintain a friendly and efficient service to their clients. All outlets specialise in providing full services for functions, including equipment hire and delivery.

The chain is closely linked to the Hawke’s Bay Brewery, enabling all the outlets to maintain a guaranteed supply of the brewery’s products.

Packaging made perfect – final stage of production

The final stage in the brewing process has precious little to do with the staples of beer – yeast, hops, barley or water.

It is the packaging plant, where staff are responsible for ensuring that literally thousands of litres per hour of a range of different beers are packaged without a hitch.

While the brewers earlier in the process were responsible for making the beer taste just right, the packaging plant must ensure the product looks just right on the shop floor.

“It’s an exacting task and one that requires concentration by staff,” says packaging manager Anne Coles.

It is largely for this reason that staff in the packaging plant regularly rotate their jobs – sometimes as often as every 10 minutes – to ensure concentration is kept to a maximum. Of course it also helps keep any boredom at bay.

At present the packaging plant is operating 12 hours-a-day, seven days a week to keep up with the demand for Christmas and to ensure sufficient of the new ICE Beer product is packaged for a voracious market.

Not only the popularity of ICE Beer put pressure on the packaging team in terms of volume; it has also been a challenge in terms of presentation.

ICE Beer is packaged in clear glass bottles; and quality presentation is therefore critical.

The packaging plant has seen many changes over the years, including a recent major modernisation. One of the biggest changes at present is the swing toward “stubbies” (pint) bottles.

“In the old days it was almost a quarts. Now consumer convenience is dictating that we package beer in stubbies,” Mrs Coles says.

Photo caption – Bottles moving at speed along the brewery’s bottling line

Hawke’s Bay Draught – new beer’s big impact

No province in New Zealand loves its draught beer as much as Hawke’s Bay.

Draught beer accounts for a remarkable 90% of the beer consumed in the Bay, compared with typically around 75% for the rest of the country.

Hawke’s Bay drinkers, therefore, can honestly claim to know their draughts. There is one draught, in particular, that they have come to know and love and it’s named after the Bay itself.

It’s Hawke’s Bay Draught, or simply “Beer of the Bay”.

In just 16 months since it was launched, Hawke’s Bay Draught has made a big impact.

In New Zealand’s most competitive battlefield for draught beer, this one has carved out more than 10% of the market – and the brewery has big plans to take it further.

“Hawke’s Bay Draught has made strong inroads since its launch,” said New Zealand Breweries marketing manager Craig Cooper.

“But we aim to further cement its position as the beer of the Bay, instilling a sense of pride and ownership of the brand throughout the province.

New Zealand Breweries and Lion have had considerable success with their regional brands in other areas, as evidenced by the strong growth of brands like Canterbury Draught and Waikato Draught.

Hawke’s Bay Draught is targeted, in particular, among the younger age groups – those who are actively involved in sport and getting the most out of life.

It is no coincidence, then, that the provincial rugby team bears the name “Hawke’s Bay Draught Magpies”.

And While 1993 will never be remembered as a vintage year for the team, it was a year when Hawke’s Bay Draught became the beer for choice for a growing number of Hawke’s Bay drinkers.

Eternal springs of crystal water on brewery site

The Hawke’s Bay Brewery sits proudly above some of the finest water in the country – and relies on this crystal-clear water for making fine beer.

A brewery uses up to 14 litres of water for each litre of beer produced — most of it to keep the brewing areas and equipment and tanks clean.

So it’s fortunate the brewery has two wells on site taking water directly from the aquifer under the Heretaunga Plains.

The water is so pure it needs only ultra-violet light to sterilise it before it can be used in the brewing process. UV sterilisation does not change the taste of the water.

Says quality assurance manager Peter Krafft. “The wells are probably one reason why the brewery was built here in the first place.”

The company has a commitment to the environment and its pure water supply, and Mr Krafft is on the “Friends of the Aquifer” group as a company representative.

“We are fairly big users of the aquifer water,” Mr Krafft said.

The commitment to the continuation of a pure water supply reflects the company’s philosophy of minimising its environmental impact.

The brewery recycles as much as it can – right down to the heat used in the brewing process.

There are several heat-exchange units throughout the brewery. As hot water used in the brewing process is cooled, the heat is used to warm the water entering the process.

One of the biggest by-products from the process is yeast. The fermentation process produces three times as much yeast as is added to start the process. Once fermentation is complete the brew is cooled so the yeast stops working and settles out of the liquid.

The yeast is then returned to storage tanks to wait for the next brew. The yeast can be used up to eight generations before fresh yeast is introduced.

But the old yeast is not wasted – it is sold for use in other ways.

Another by-product of the brewery is carbon dioxide, given off by the yeast during fermentation. This carbon dioxide is collected as it is produced to aerate the beer and, among other things, to make it fizz.

“We are constantly working to reduce waste – because waste is money, and because waste harms the environment,” said Mr Krafft.

Manager Brent Wright said the brewery worked constantly to stay ahead of the legislation governing the environment. “We want to meet the needs of the community around us.”

Mr Wright says the new Resource Management Act is a large piece of legislation which industry needs to come to grips with – and stay ahead of.

Photo caption – Yeast tanks at the Hawke’s Bay Brewery

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Description

Advertorial in “Hawke’s Bay Business to Business” magazine

Subjects

Format of the original

MagazineDate published

December 1993Publisher

Hawke's Bay Business to BusinessPeople

- Brent Wright

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.