Classy new shell for HB sculler

Hawke’s Bay champion singles sculler Tony Bone has taken delivery of a new American-made shell built by a firm which provided the United States oarsmen with their gold-medal winning eight at the Tokyo Olympics.

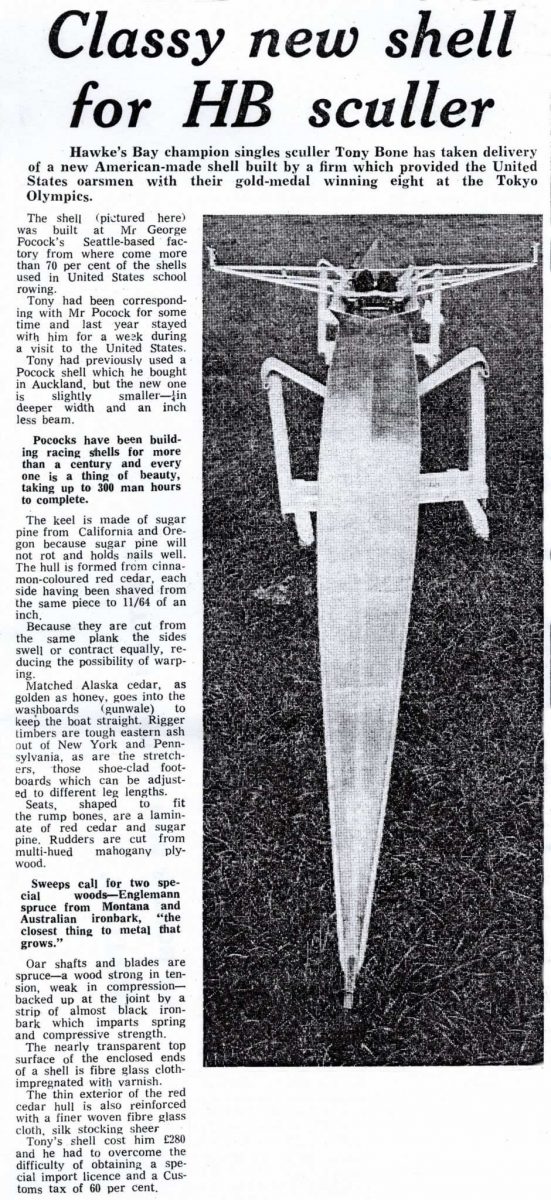

The shell (pictured here) was built at Mr George Pocock’s Seattle-based factory from where come more than 70 per cent of the shells used in United States school rowing.

Tony had been corresponding with Mr Pocock for some time and last year stayed with him for a week during a visit to the United States.

Tony had previously used a Pocock shell which he bought in Auckland, but the new one is slightly smaller – ¼in deeper width and an inch less beam.

Pococks have been building racing shells for more than a century and every one is a thing of beauty, taking up to 300 man hours to complete.

The keel is made of sugar pine from California and Oregon because sugar pine will not rot and holds nails well. The hull is formed from cinnamon-coloured red cedar, each side having been shaved from the same piece to 11/64 of an inch.

Because they are cut from the same plank the sides swell or contract equally, reducing the possibility of warping.

Matched Alaska cedar, as golden as honey, goes into the washboards (gunwale) to keep the boat straight. Rigger timbers are tough eastern ash out of New York and Pennsylvania as are the stretchers those shoe – clad foot boards which can be adjusted to different leg lengths.

Seats, shaped to fit the rump bones, are a laminate of red cedar and sugar pine. Rudders are cut from multi-hued mahogany plywood.

Sweeps call for two special woods – Englemann spruce from Montana and Australian ironbark, “the closest thing to metal that grows.”

Oar shafts and blades are spruce – a wood strong in tension weak in compression – backed up at the joint by a strip of almost black ironbark which imparts spring and compressive strength.

The nearly transparent top surface of the enclosed ends of a shell is fibre glass cloth, impregnated with varnish.

The thin exterior of the red cedar hull is also reinforced with a finer woven fibre glass cloth silk stocking sheer

Tony’s shell cost him £280 and he had to overcome the difficulty of obtaining a special import licence and a Customs tax of 60 per cent.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.