$6-million Whakatu meat works expansion

Three-year building plan nearly completed

A $6-million expansion at the Whakatu freezing works, operated by the Hawke’s Bay Farmers’ Meat Company Ltd, is nearing completion.

Work has been proceeding on the expansion programme for three years and will be completed in time for the new season which starts late in October.

This makes the works one of the most modern in New Zealand.

The first part of the expansion completed was the beef boning floor. This system, in which sides of beef travel along on over head rails with different cuts of meat being taken off at different stages, leaving the bare bones at the end of the rail, was brought into use in June, 1969.

Since then ageing and conditioning rooms for lamb destined for the American market have been brought into use.

Another two stages in the processing of lamb, which will come into operation in the coming season, are the blast freezing and cutting rooms to freeze lamb carcases and process them into cuts required by customers.

To operate all the new machinery there will be 300 men and women employed.

A dining room, showers, toilets and locker rooms have been provided for them.

Lamb cuts

In the past 10 years marketing of meat has changed considerably. New Zealand’s lamb was previously sent overseas in carcase form and most of its beef in quarters.

This has all changed.

The majority of New Zealand’s lamb is still sent in carcase form to the major market, the United Kingdom, but there is a growing trade in other parts of the world for lamb cuts.

Quarter-beef exports now make up less than 10 percent of New Zealand’s beef exports. A lot of New Zealand’s beef goes to the United States where it is used in such foods as hamburgers.

The beef boning rooms, the lamb cutting rooms and the associated plant and machinery that go with them, have been designed to meet these changing requirements.

A lot has been said about how the United States meat hygiene regulations are forcing New Zealand meat processing companies to spend millions of dollars.

Some works are nearer the requirements than others. Whakatu has been building up its standards over a period of years as a matter of policy.

Tiled walls

Tiled walls have been used extensively throughout the slaughterboard and boning floor areas, giving clean, fresh surroundings which are a prerequisite to gaining co-operation from employees.

But this $6-million programme is not the end of expansion at the works.

Already work has started on extending the fellmongery. Gradually it will be transferred from the main works site to across the railway line and behind the office block.

Other buildings are being demolished to make way for new coolstores.

No more bent backs for them

No bent backs – that’s the difference for the men who worked under the old beef processing system and are now working in the beef boning floor.

Mr Arthur Hill, who has worked at Whakatu for 19 years, worked on the quarter-boning table and chain.

He said the work he does in the beef boning room is far more pleasant than under the old system.

Quarter boning involved bending over constantly, and lifting. There’s none of that on the beef boning floor.

The new floor is well lit and the surroundings are clean.

Mr Hill is one of 180 men working on this floor when it is operating at full capacity.

Working alongside them are 39 women, including three who work in the pre-trimming room where sides are inspected for hair and excess fat.

When the new season starts there will be another 23 employees, mostly women, in the lamb cutting room.

Lockers, toilets and showers have been provided for both men and women.

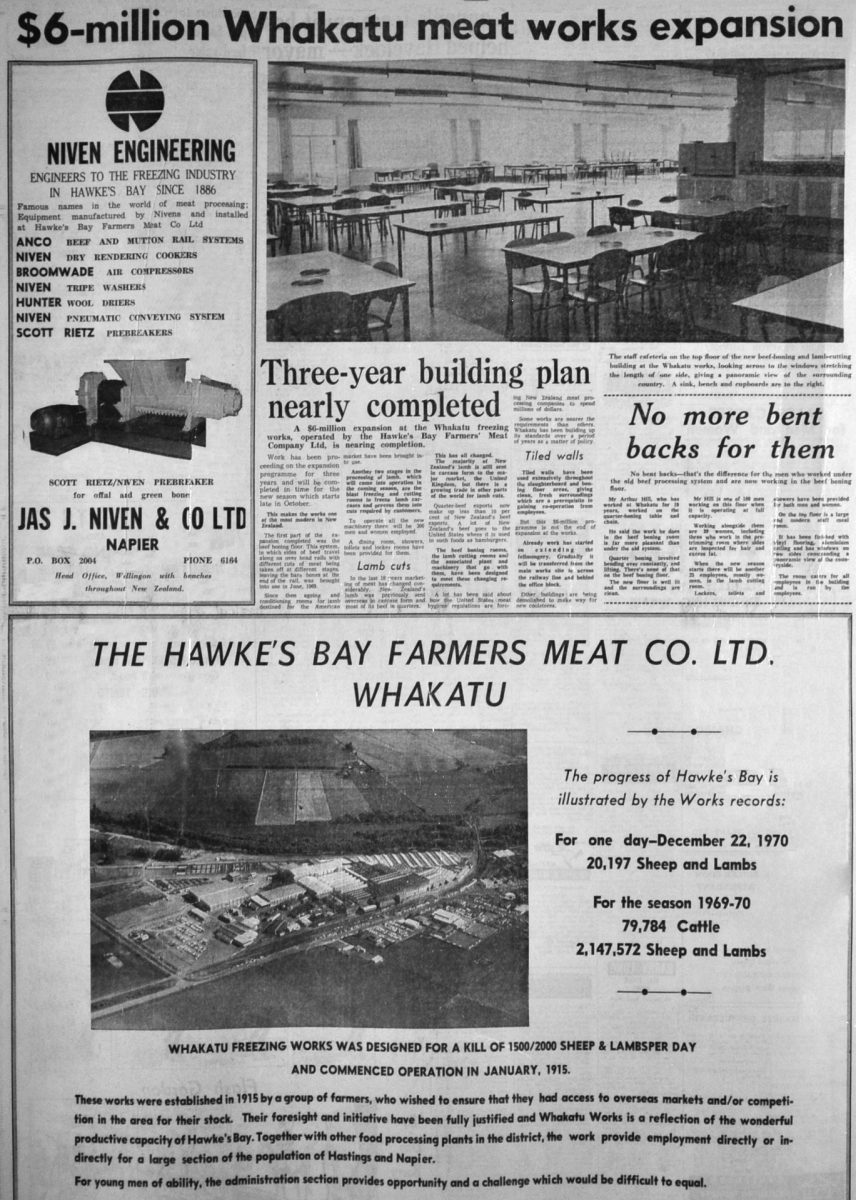

On the top floor is a large and modern staff meal room.

It has been finished with vinyl flooring, aluminium ceiling and has windows on two sides commanding a panoramic view of the countryside.

The room caters for all employees in the building and is run by the employees.

Photo caption –

The staff cafeteria on the top floor of the new beef-boning and lamb-cutting building at the Whakatu works, looking across to the windows stretching the length of one side, giving a panoramic view of the surrounding country. A sink, bench and cupboards are to the right.

[Advertisement]

NIVEN ENGINEERING

ENGINEERS TO THE FREEZING INDUSTRY IN HAWKE’S BAY SINCE 1886

Famous names in the world of meat processing: Equipment manufactured by Nivens and installed at Hawke’s Bay Farmers Meat Co Ltd

ANCO BEEF AND MUTTON RAIL SYSTEMS

NIVEN DRY RENDERING COOKERS

BROOMWADE AIR COMPRESSORS

NIVEN TRIPE WASHERS

HUNTER WOOL DRIERS

NIVEN PNEUMATIC CONVEYING SYSTEM

SCOTT RIETZ PREBREAKERS

SCOTT RIETZ/NIVEN PREBREAKER

for offal and green bone

JAS J. NIVEN & CO LTD

NAPIER

P.O. BOX 2004 PHONE 6164

Head Office, Wellington with branches throughout New Zealand.

[Advertisement]

THE HAWKE’S BAY FARMERS MEAT CO. LTD

WHAKATU

The progress of Hawke’s Bay is illustrated by the Works records:

For one day – December 22, 1970

20,197 Sheep and Lambs

For the season 1969-70

79,784 Cattle

2,147,572 Sheep and Lambs

WHAKATU FREEZING WORKS WAS DESIGNED FOR A KILL OF 1500/2000 SHEEP & LAMBS PER DAY AND COMMENCED OPERATION IN JANUARY, 1915.

These works were established in 1915 by a group of farmers, who wished to ensure that they had access to overseas markets and/or competition in the area for their stock. Their foresight and initiative have been fully justified and Whakatu Works is a reflection of the wonderful productive capacity of Hawke’s Bay. Together with other food processing plants in the district, the work [works] provide employment directly or indirectly for a large section of the population of Hastings and Napier.

For young men of ability, the administration section provides opportunity and a challenge which would be difficult to equal.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.