Hygiene Expenditure Requires Planning In Implementation

The general manager of W. and R. Fletcher (N.Z.) Ltd., Mr Mark Hinchliff, told a financial seminar organised by the New Zealand Freezing Companies in Wellington recently that the timetable for implementing the new Codex hygiene regulations in the freezing industry should be revised for the sake of the New Zealand economy.

Mr Hinchliff said the programme should be spread out over a longer period to reduce the impact of heavy financial expenditure which must be reflected in slaughtering and processing rates. This, in turn, would have to be paid for by the farmer who was presently going through a difficult period.

He said that the freezing companies acknowledged that they must accept some pressure to ensure that the industry was progressively meeting the hygiene requirements, but some commercial sense must be exercised if the industry was to remain economically viable.

Mr Hinchliff said “We are seeking cooperation with our overseas importing authorities; our own Government and those charged with the responsibility of seeing that the industry is maintained for the good of the nation and its trading partners.”

He said some of the new hygiene requirements were necessary and should be carried out with as little delay as possible, but others were quite unnecessary on an immediate basis and could be implemented as and when reconstruction took place. Provided the present procedures and environment were hygienic there should not be extreme pressure to change this virtually overnight.

Mr Hinchliff said a great deal of the expenditure faced by the freezing industry was non-revenue producing and this created problems. If the changes were a purely commercial and economically feasible transaction he had no doubt that the companies would finance the expenditure out of their own resources.

But while some expenditure in question for updating existing works and departments to make them more acceptable hygienically for the high standards now set by overseas countries could be revenue producing it would be difficult to ascertain just how much that would be.

He pointed out the example that if it was necessary to build a new killing floor, then obviously the latest equipment would be installed which would reduce the amount of labour needed in the same way there would be a number of other savings that could be effected by the complete rebuilding of a plant or associated facilities.

And while some pundits would take the view that the projected expenditure of over $200 million should be put to building new freezing works in other locations this would not be possible because of the high cost of construction.

Talking about the actual financing of the money involved, Mr Hinchliff said the freezing companies were looking for repayments to be effected over a 10 year period.

Problems would also arise concerning interest. If a commercial rate of interest was used then the repayments, plus the rate of interest, would be a direct charge against the farmer, and it was doubtful whether the farmer could absorb this direct charge under present conditions.

Mr Hinchliff suggested that some sort of subsidy would have to be given to the farmer to enable him to stand this size of on-cost. He said this would be a straightforward lending operation by the banks or finance houses, but it must be borne in mind that the rate of interest would be fairly high if it was treated as a purely commercial operation. An added complication would be the difficulty some freezing companies would face in borrowing this sort of money without security, a position that would affect a number of companies.

Mr Hinchliff also put forward other ideas of financing the hygiene requirements and concluded by saying that he hoped the freezing companies could arrive at a common approach as to the best method they could recommend for reducing the effect of the huge financial burden the industry faced and at the same time protect the farming community from the full impact of these costs which must inevitably reduce their returns for livestock during a period when the international meat market was suffering from a severe dose of indigestion.

He added it was important that the problems of financing be resolved quickly and that the freezing companies enter into early discussions with the Government so that they could plan for the future.

Pacific Area Encouraging

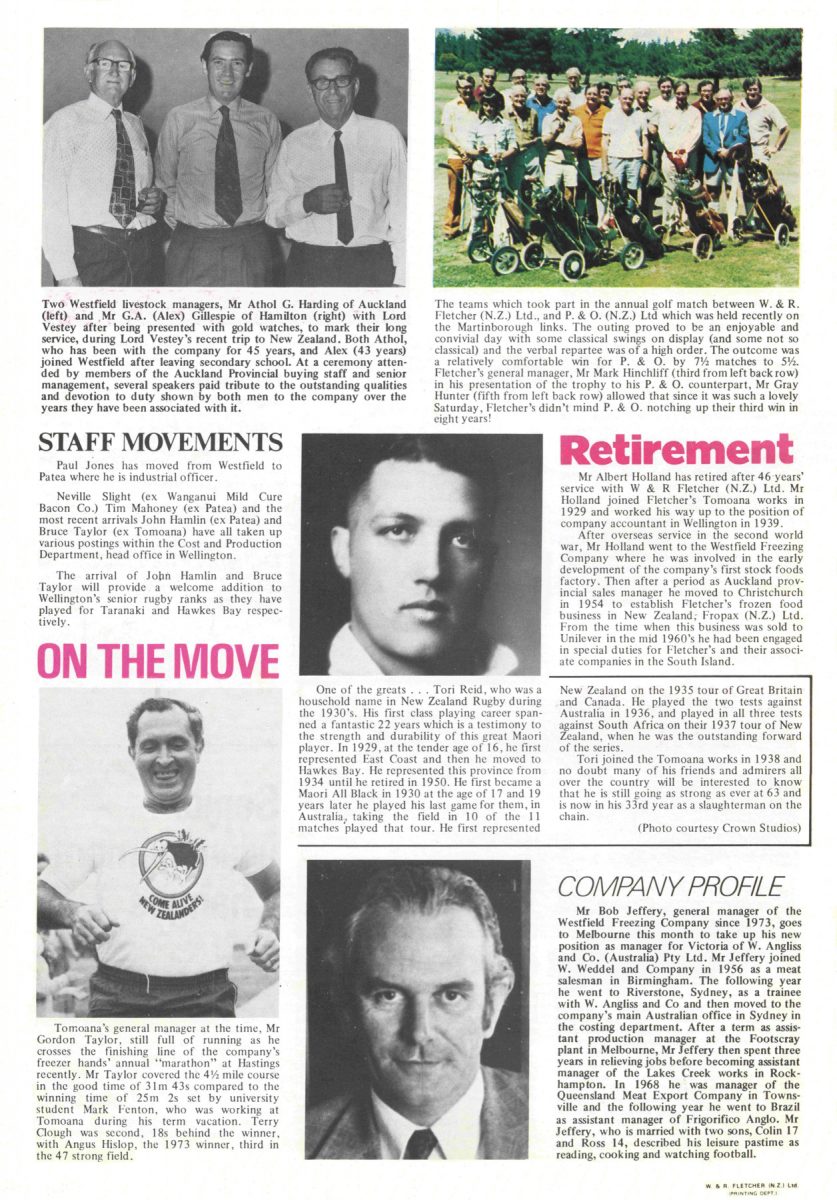

One of the Fletcher Head Office meat export sales staff, Mr Dennis Frederickson, who has just returned from a business tour of the Pacific Islands, reports that business prospects for the area are encouraging.

Mr Frederickson says that although the Pacific market is not often looked on as a large one it is nevertheless a busy one for the company.

“In general the Pacific area, Fiji, the Samoas, Rarotonga, Tonga and Tahiti, is suffering more from inflation than many other countries due to their need to import most consumer items. Prices for their exports are down, tourism has also dropped and unemployment has risen which has had a marked effect on the whole area apart from Tahiti. But despite this our business in the area has increased which is a good sign in these relatively difficult times.”

Mr Frederickson points out that the trade to the Pacific is specialised and varies greatly from island to island. Because of lower incomes many areas require cheaper cuts, used by the local population for curries and stews.

However two exceptions are American Samoa, where the supermarkets are stocked with prime beef cuts, and Tahiti where the economy is boosted by the presence of a large forces personnel and French population who buy mainly chilled beef and lamb cuts which are airfreighted weekly to the island.

Fletcher’s have reintroduced the keg beef trade to Western Samoa. This was once a steady trade when supplied in wooden kegs, and the new product, which will be packed in plastic kegs will be supplied to the area from this month.

Apart from seeking new areas of trade and meat requirements Mr Frederickson says a most important part of his trip was maintaining a personal link with Fletcher’s customers.

“The buyers in these islands appreciate the direct contact between our company and themselves which only goes to further the good-standing of the Weddel brand.”

Lamb to help handicapped

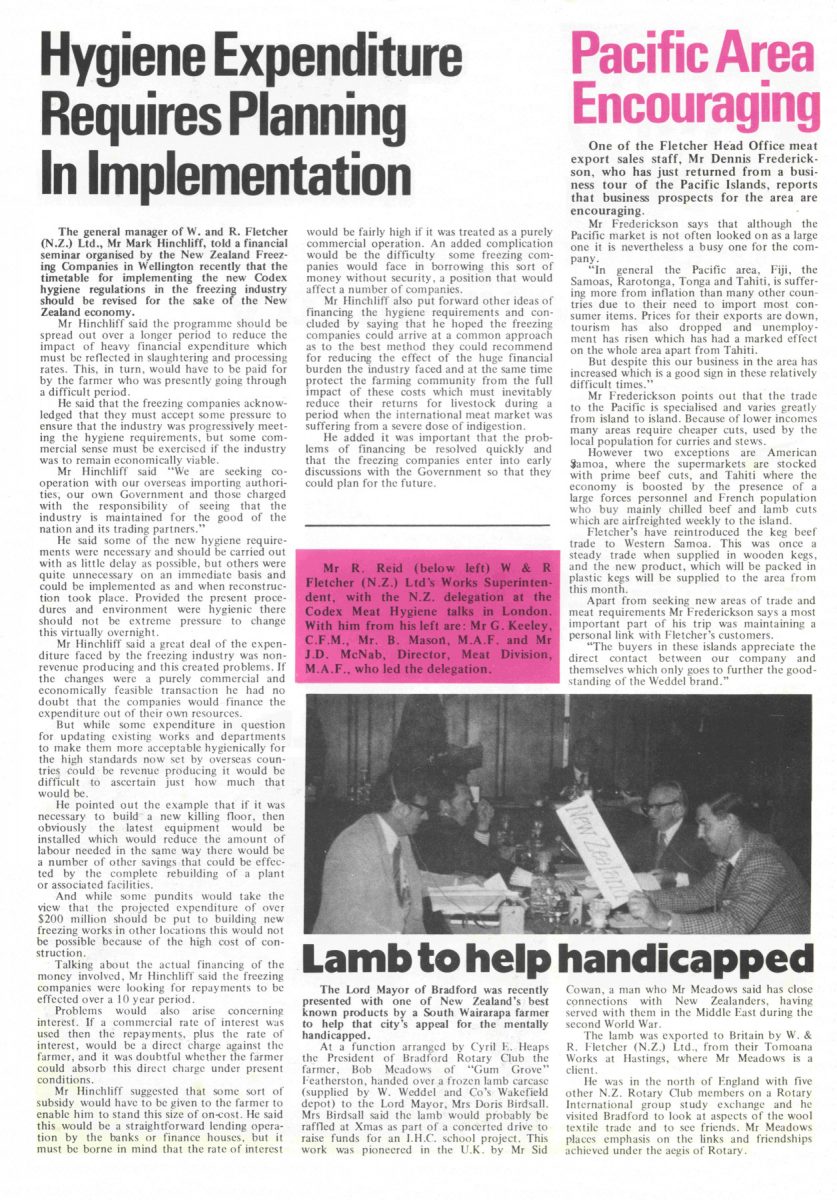

The Lord Mayor of Bradford was recently presented with one of New Zealand’s best known products by a South Wairarapa farmer to help that city’s appeal for the mentally handicapped.

At a function arranged by Cyril F. Heaps the President of Bradford Rotary Club the farmer, Bob Meadows of “Gum Grove” Featherston, handed over a frozen lamb carcase (supplied by W. Weddel and, Co’s Wakefield depot) to the Lord Mayor, Mrs Doris Birdsall. Mrs Birdsall said the lamb would probably be raffled at Xmas as part of a concerted drive to raised funds for an I.H.C. school project. This work was pioneered in the UK. by Mr Sid Cowan, a man who Mr Meadows said has close connections with New Zealanders, having served with them in the Middle East during the second World War.

The lamb was exported to Britain by W. & R. Fletcher (N.Z.) Ltd., from their Tomoana Works at Hastings, where Mr Meadows is a client.

He was in the north of England with five other N.Z. Rotary Club members on a Rotary International group study exchange and he visited Bradford to look at aspects of the wool textile trade and to see friends. Mr Meadows places emphasis on the links and friendships achieved under the aegis of Rotary.

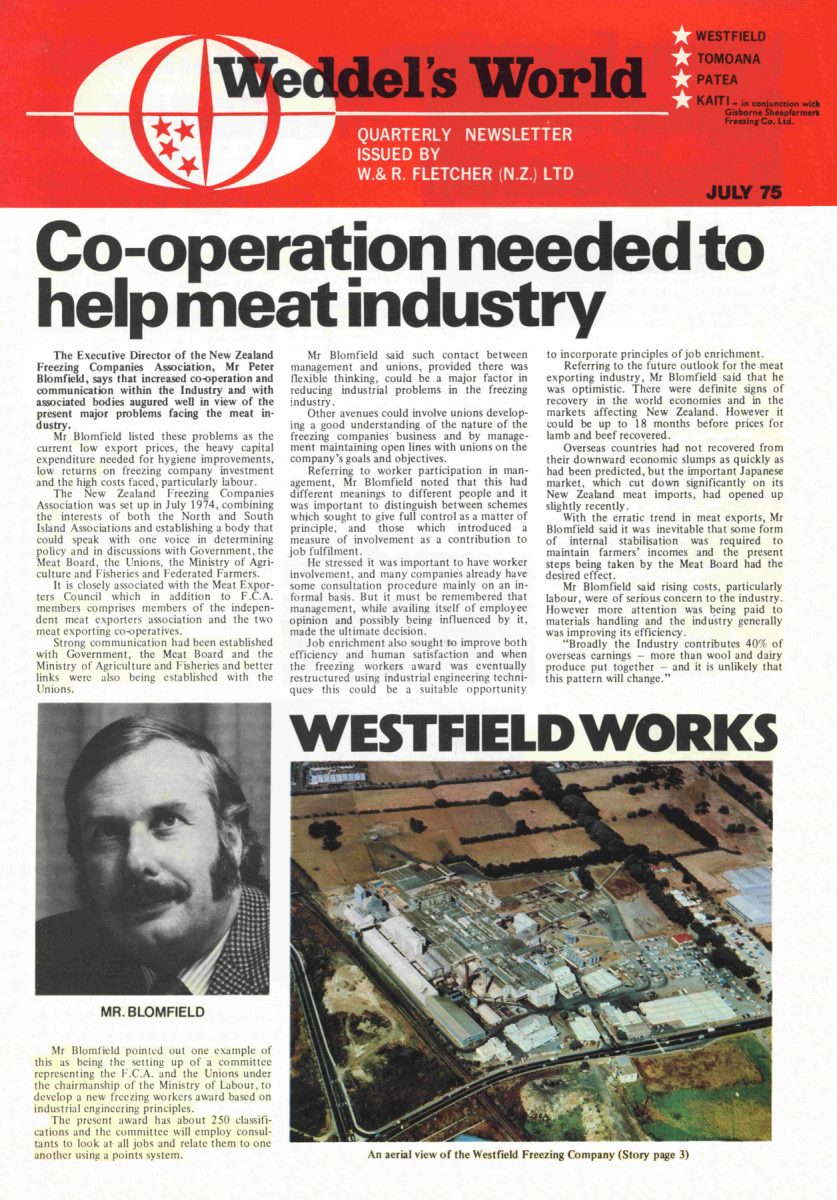

Photo caption – Mr R. Reid (below left) W & R Fletcher (N.Z.) Ltd’s Works Superintendent, with the N.Z. Delegation at Codex Meat hygiene talks in London.With him from his left are: Mr G. Keeley, C. F. M. Mr. B. Mason, M. A. F. And Mr J. D. McNab, Director, Meat Division, M. A. F., who led the delegation.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.