W & R FLETCHER VOLUNTEER FIRE BRIGADE’S LONG AND COLOURFUL HISTORY

An important and colourful aspect of W. & R. Fletcher (N. Z.) Limited’s operations at its Westfield, Patea and Tomoana works are the staff volunteer fire brigades.

Conducted on a completely voluntary basis these industrial brigades have a long and important history in the company’s overall operations, and they draw a special breed of men.

The loyalty of the men to their brigades is borne out by the number of long service emblems awarded regularly at each of the three works.

The Fletcher’s fire brigades have over the years efficiently handled both minor and holding action for major emergencies saving considerable damage and inconvenience at the various works.

One example was the Tomoana fire brigade’s prompt answer to the recent disastrous fire which gutted the beef house.

The brigade started the emergency procedures and mounted a successful holding action while other regular fire service units rushed to the scene.

Their action was highly commended by local fire officers and helped contain the fire to the beef house and away from other operations including the newly constructed mutton slaughterhouse.

The three fire brigades often take part in local competitions and they strongly contest an annual interworks tournament with great rivalry for the various trophies.

W. & R. Fletcher’s general manager, Mr Peter Johnston, said the company and the three works were very aware of dedication and good work put in by the volunteer firemen.

“They put in long hours and have all reached and maintained standards that would be the envy of any industrial brigade in the country.

“Their prompt and efficient action in the past has coped with many an emergency and I am sure they are aware of the company’s gratitude to them.”

Weddel’s World will feature the various brigades in forthcoming issues starting with Westfield in this issue.

Westfield Fire Brigade

The Westfield Freezing Company’s Industrial Volunteer Fire Brigade was first formed in May 1917 and is considered to be one of the oldest industrial Fire Brigades in New Zealand.

During the war years of 1914-1918 and 1939-1945 a number of the Brigade personnel served in the New Zealand armed forces overseas, some with distinguished service.

Over the years the Brigade has been honoured by having six Gold Star members.

The Brigade of today has a membership of fifteen which includes Chief Fire Officer, Deputy Chief Fire Officer, Third Officer, Station Officer, Senior Fireman and eleven Firemen.

The training of personnel is carried out on Monday evenings to make members efficient in handling equipment which is used in firefighting procedures.

A fully equipped fire appliance is in service to deal with fire, ammonia escapes and chemical situations within the plant and is also standardised to meet the requirements of the New Zealand Fire Service Commission.

In the early years of the Brigade a Fire Hose cart-reel was used in fighting fires within the plant. On the sounding of the alarm four firemen would make themselves available to manhandle the cart-reel and proceed to extinguish the fire.

The using of canvas hose with screw couplings made hard work for those running out the hose and many a hand and an arm endured canvas burns.

After a number of years a motorised appliance with a trailer pump was introduced along with more modern equipment. In 1950 alloy instantaneous couplings and rubber lined synthetic hose was obtained and allowed personnel to lay out the hose in a more efficient manner.

From 1958 to the present day the Brigade has been known for its participation in the competition field and has won them at National and Provincial Association levels.

BRASS HELMETS

The competition team have distinguished itself at Auckland Suburban Fire Brigades Association level for many years and have always been recognised by other Brigades by wearing the brass helmets – possibly the only brigade remaining in New Zealand that still possesses brass helmets!

A number of Brigade members have also been appointed in the capacity of Competition Officials at various Competitions throughout the country.

The Brigade personnel have attended numerous fires within the plant over the years some of the major ones being 1940 Wool Floor, 1965 Boning Floor, 1968 Stockfoods Factory and 1977 Main Engine Room.

The efficiency of the Brigade is held in high esteem by members of the New Zealand Fire Service Commission.

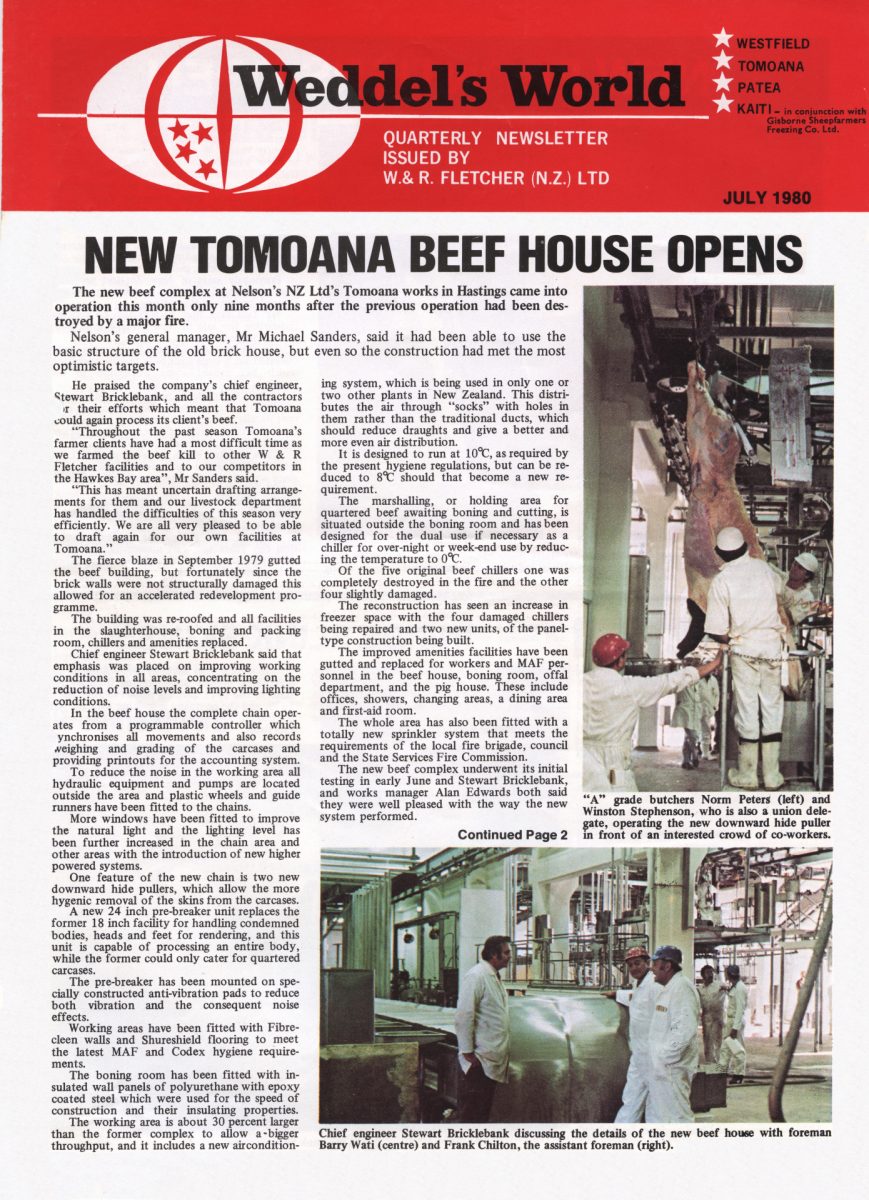

The Westfield Fire Brigade:

Back row from left: Firemen: S. Shepherd, P. Bedard, G. Clark, K. Gainfort, J. Sinclair, J. Pavard.

Front row from left: Fireman R. Benn, 3rd Officer N. Lyon, Chief Fire Officer R. Whittle, Senior Fireman M. Bradfield, Fireman G. Jones.

Absent were Deputy Chief Fire Officer F. Horspool, Station Officer K. Riley, Firemen G. Miers and H. Smith.

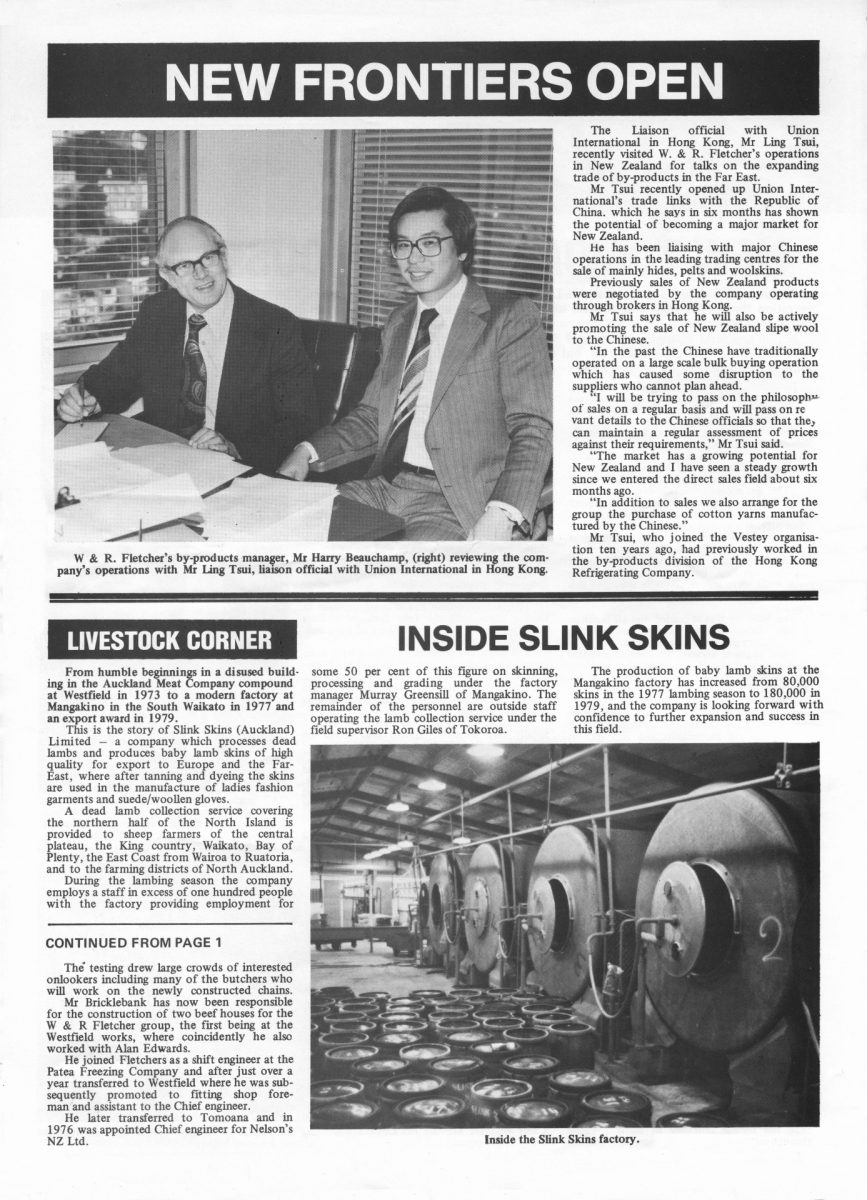

NEW BOARD CHAIRMAN

The New Zealand Meat Producers Board has elected Mr Adam Begg as its new chairman to succeed Mr Charles Hilgendorf, chairman for the past eight years.

Mr Begg, who farms at Stirling, Otago, was appointed to the Board in 1969 as a Government nominee. He was elected as producer representative in 1976 and had been deputy chairman of the Board since 1974.

During his 11 years on the Board, Mr Begg has served on all of the organisations internal committees, was chairman of the promotion and marketing committee and is at present chairman of the shipping committee.

Mr Begg, who is 48, comes from an Otago farming family. He was educated at John McGlashan College, Dunedin, and then returned to the family farm. He farmed in partnership with his brother for about eight years before establishing his own farm at Stirling in the late 1950’s.

He is engaged mainly in producing prime lambs but runs sheep for cross-bred wool and fattens some cattle.

The Board elected Mr Norman McRae as its new deputy chairman.

Mr McRae, 49, who farms a beef and sheep property at Mokoreta, near Wyndham, Southland, was appointed to the board as a Government nominee in 1976. He resigned from this position recently and successfully contested the producer vacancy on the Board created by the retirement of Mr Hilgendorf.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.