greater the chances of keeping increases in killing charges to a minimum.

He said that in spite of the greater capacity, spreading the kill is still a necessity. Although the new works would kill all the district’s stock, it could not achieve it all at peak time.

Designed to meet the demands of world markets, including the United States, the Middle East, Britain and the nations of the European Economic Community, the new works clearly place the Gisborne area on an equal footing with other districts in New Zealand in the killing of mutton and lamb.

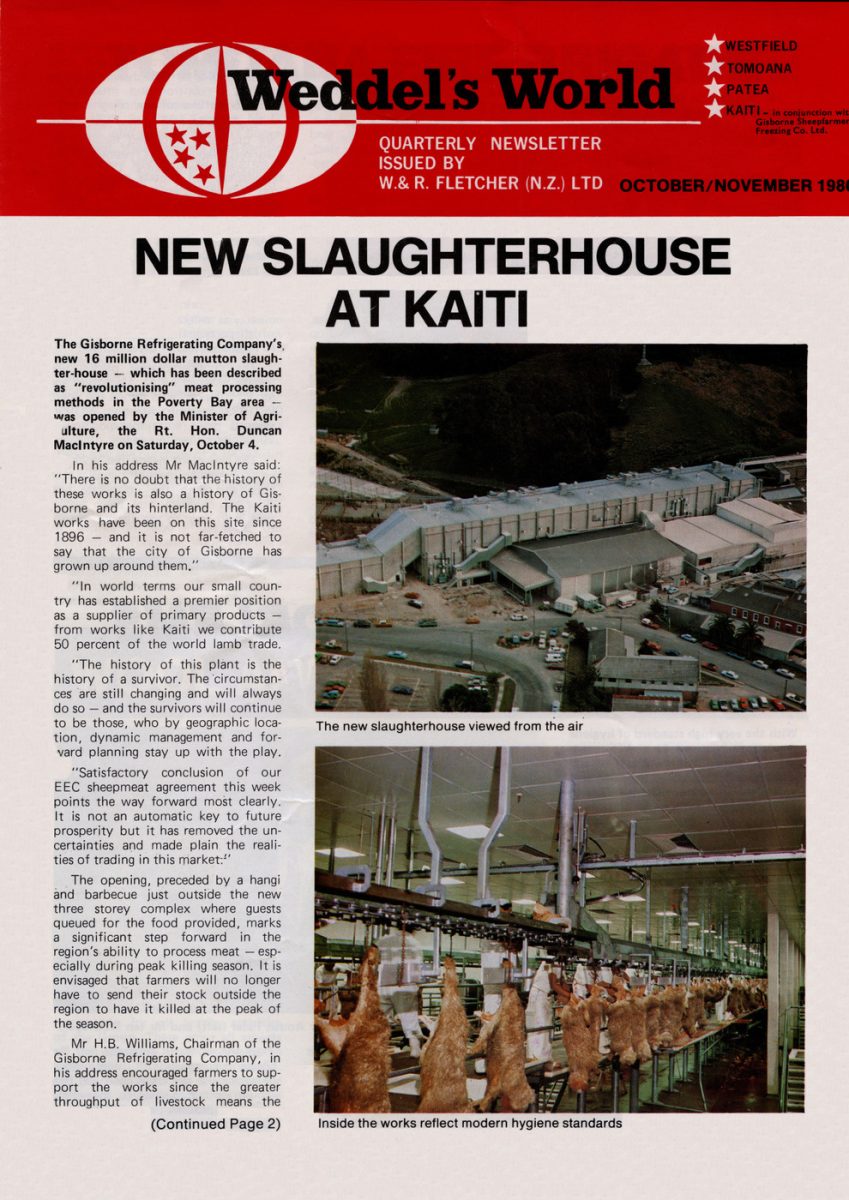

Development at the Kaiti works – associated with the Vestey group since 1930 – was initiated in 1973 and the new slaughterhouse comprises three chains, a blast freezing unit sorting and palletising rooms, and is capable of processing more than 10,000 lambs per day – which can be frozen and bagged in a 22-24 hour cycle.

The freezer complex comprises two freezer tunnels which work on a four tier system, and will handle some 9,600 sheep each day. Any excess production will be either further processed for North American requirements, or frozen in three extra freezer rooms.

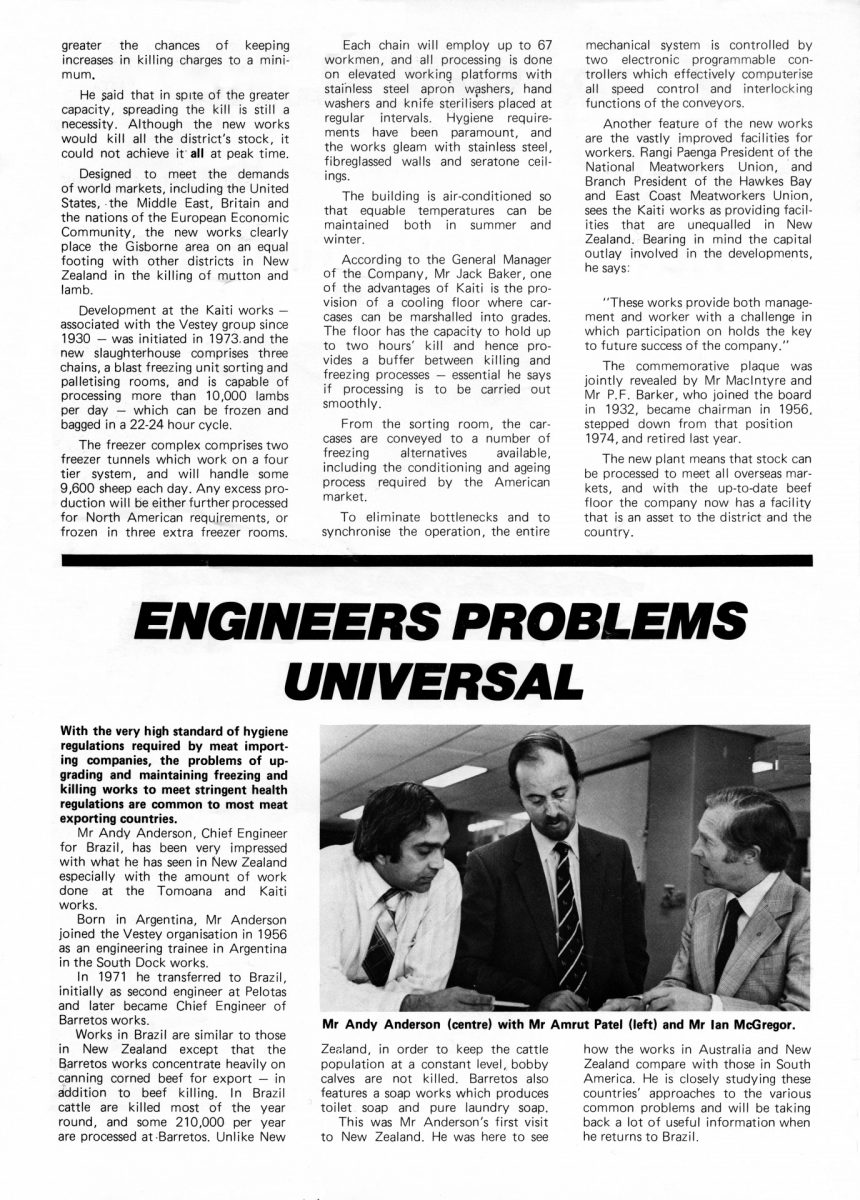

Each chain will employ up to 67 workmen, and all processing is done on elevated working platforms with stainless steel apron washers, hand washers and knife sterilisers placed at regular intervals. Hygiene requirements have been paramount, and the works gleam with stainless steel, fibreglassed walls and seratone ceilings.

The building is air-conditioned so that equable temperatures can be maintained both in summer and winter.

According to the General Manager of the Company, Mr Jack Baker, one of the advantages of Kaiti is the provision of a cooling floor where carcases can be marshalled into grades. The floor has the capacity to hold up to two hours’ kill and hence provides a buffer between killing and freezing processes – essential he says if processing is to be carried out smoothly.

From the sorting room, the carcases are conveyed to a number of freezing alternatives available, including the conditioning and ageing process required by the American market.

To eliminate bottlenecks and to synchronise the operation, the entire mechanical system is controlled by two electronic programmable controllers which effectively computerise all speed control and interlocking functions of the conveyors.

Another feature of the new works are the vastly improved facilities for workers. Rangi Paenga President of the National Meatworkers Union, and Branch President of the Hawkes Bay and East Coast Meatworkers Union, sees the Kaiti works as providing facilities that are unequalled in New Zealand. Bearing in mind the capital outlay involved in the developments, he says:

“These works provide both management and worker with a challenge in which participation on holds the key to future success of the company.”

The commemorative plaque was jointly revealed by Mr MacIntyre and Mr P. F. Barker, who joined the board in 1932, became chairman in 1956, stepped down from that position in 1974, and retired last year.

The new plant means that stock can be processed to meet all overseas markets, and with the up-to-date beef floor the company now has a facility that is an asset to the district and the country.

ENGINEERS PROBLEMS UNIVERSAL

With the very high standard of hygiene regulations required by meat importing companies, the problems of upgrading and maintaining freezing and killing works to meet stringent health regulations are common to most meat exporting countries.

Mr Andy Anderson, Chief Engineer for Brazil, has been very impressed with what he has seen in New Zealand especially with the amount of work done at the Tomoana and Kaiti works.

Born in Argentina, Mr Anderson joined the Vestey organisation in 1956 as an engineering trainee in Argentina in the South Dock works.

In 1971 he transferred to Brazil, initially as second engineer at Pelotas and later became Chief Engineer of Barretos works.

Works in Brazil are similar to those in New Zealand except that the Barretos works concentrate heavily on canning corned beef for export – in addition to beef killing. In Brazil cattle are killed most of the year round, and some 210,000 per year are processed at Barretos. Unlike New Zealand, in order to keep the cattle population at a constant level, bobby calves are not killed. Barretos also features a soap works which produces toilet soap and pure laundry soap.

This was Mr Anderson’s first visit to New Zealand. He was here to see how the works in Australia and New Zealand compare with those in South America. He is closely studying these countries’ approaches to the various common problems and will be taking back a lot of useful information when he returns to Brazil.

Photo caption – Mr Andy Anderson (centre) with Mr Amrut Patel (left) and Mr Ian McGregor

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.