Slipe quality trusted globally

ONCE considered a by-product of the annual sheep and lamb kill, wool is now a major industry for W & R Fletcher (NZ) Ltd, with production around five million kilograms a year.

Skilful management, a consistently top quality product and a progressive marketing programme contribute to the company’s worldwide success as a producer of slipe wool.

The production of slipe wool is handled within the company’s works and involves the removal of the skin from the slaughtered animal; a thorough cleaning process; the application of a lime sulphide depilatory which loosens the wool from the pelt overnight; skilful dewooling by a wool puller who also grades it into standardised types; and drying.

The wool which is finally pressed into the bales and stamped with the Weddel brand is ready for the textile industry without prior sorting.

High quality

The uniformity of slipe wools, and the careful system of grading into some 90 distinct types, encourages buyers to buy “sight unseen” with the confidence that they will receive the expected grade and quality.

W & R Fletcher Wool Manager, Mr Alan Chapman, said: “Our product is received very well. Buyers realise we have a very high quality control and in turn a quality product. We find that once people have bought our wool, they come back and buy more.”

The company produces 30 to 35 thousand bales a year – 20 to 25 thousand of those coming from the four North Island works and the balance from the South Island. Should the demand be there, however, it can sell 40 to 50 thousand bales to the export markets.

Mr Chapman said, the company’s main markets for conventional unscoured slipe wool are the United Kingdom, France, Germany, Belgium, Italy, the USA and Canada.

Major markets for scoured slipe wool are in the far Eastern countries of Taiwan, South Korea, Hong Kong and Japan and also in Germany, Northern America, the United Kingdom, Italy and Greece.

Buyers in these countries produce primarily carpets and knitwear as end products, both for their local market, and export markets.

Upholstery industries are also beginning to favour wool again as a material, not the least for the fibre’s proven resistance to fire.

Although New Zealand is the largest producer of slipe wool in the world, the export control centre for W & R Fletcher is in Bradford, in the British Midlands. From there, offers are made and received from buyers worldwide.

This “hub of a wheel” in Bradford eliminates double selling of the same stocks and allows an overall view of market strengths.

Success

Intensive management and the right selling and marketing for each season is a major success factor.

“The wool market at the moment is at the bottom of a trough, both in terms of prices and demand,” Mr Chapman said.

“The slackening of demand has been caused by a downturn in the Northern Hemisphere economy.

“Fortunately, particularly in Europe, it looks as if it has bottomed out and is showing signs of rising again. The market is cyclical and next season will show an increased demand.”

Forecast

The ability to forecast future market demand means stocks can be held for availability when the demand increases again.

Although most unshorn lambs wool is produced between November and January, Mr Chapman said: “We make sure that we have stocks of most types of wool for all the season. We do not operate just as a producer, but also as an operating merchant. Our policy is to try and sell direct to the market.”

On future demand for slipe wool Mr Chapman predicted the opening up of a new market in the Far East.

“Wool has been going up to the Far East ever since we first opened up in Japan. In the relatively near future, the manufacturing emphasis will move to a country such as Indonesia, which has a large population and has become more competitive in terms of manufacturing costs,” he said.

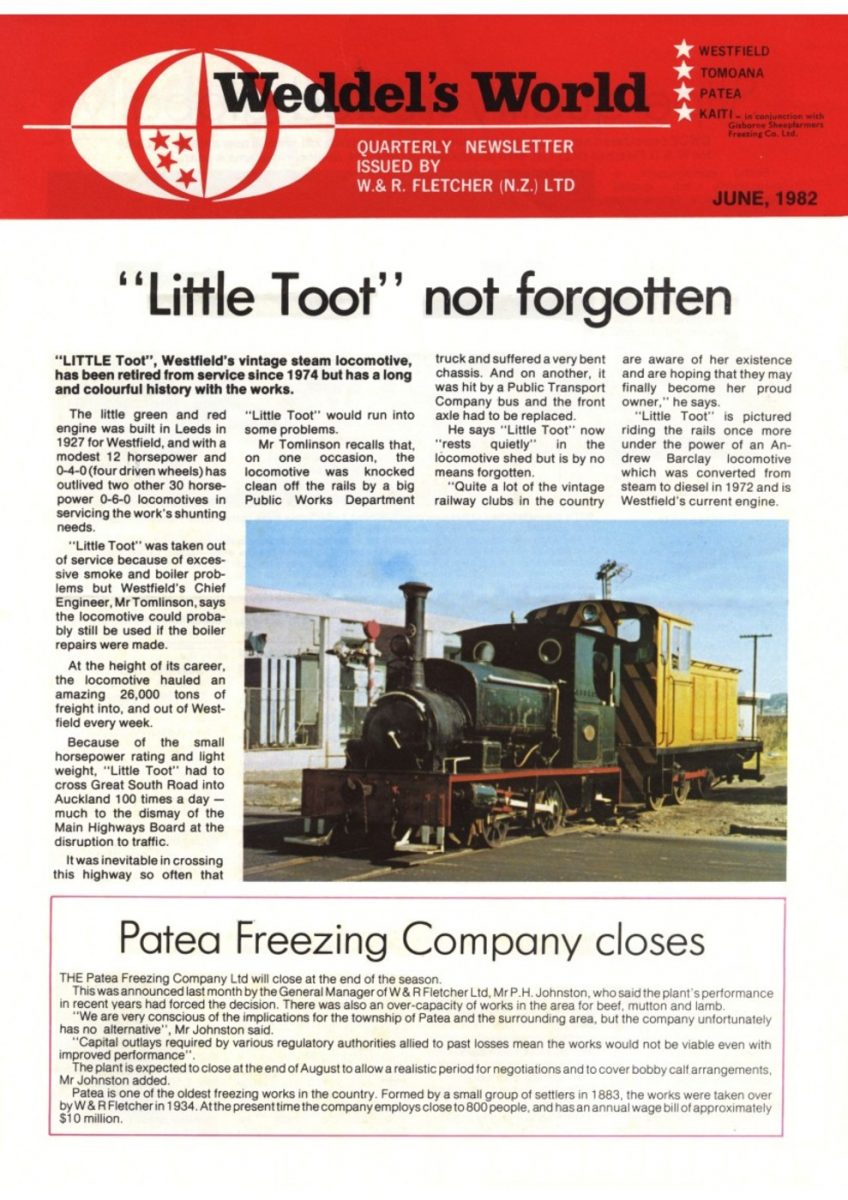

WITH the installation of this new computerised Andar scour train, pictured,the Tomoana Freezing Works has leapt to the forefront of the wool scouring industry.

The Tomoana scouring plant operates on an independent commission basis although normally W & R Fletcher Ltd provides about a quarter of the total throughput in slipe wool about 13,000 bales.

Its annual scouring capacity has averaged 50,000 bales over the past four years. But once the Andar train is in full production, its estimated capacity will be about 75,000 bales.

The plant is computer controlled and fully automatic, and the whole process can be monitored from the control room above the train. The action is the same as a conventional machine, but the new technology will improve efficiency.

The new train reduces water usage and the duration of the scouring process, cuts effluent discharge by about half and cuts energy consumption by 25 percent.

Lamb sales to Korea healthy

FOLLOWING the signing of a contract with a Korean processing company, W & R Fletcher is now producing large quantities of lamb in the form of boneless lamb rolls for the Japanese market.

Export Sales Manager, Mr Bruce Bishop, says that while many well populated areas such as Tokyo and Osaka are not yet large lamb consumers, the possibilities of the market developing are good.

But quite apart from the consumers of the nearby Japanese market, Korea will be feeding an avalanche of western tastebuds in a few years time.

Seoul, the capital, will host the 1988 Summer Olympics and its 15,500 athletes, 3,200 staff members from IOC member states, approximately 1,500 media people and 1,500 members of youth camping groups – not to mention the thousands of spectators.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.