Long serving manager retires

MANAGER of New Zealand Stockfoods Ltd and W & R Fletcher’s longest serving Wellington employee, Mr Ken Stephenson, retired last month after 44 years’ service.

Mr Stephenson joined the company at 18 years of age, as assistant purchasing officer, but shortly afterwards joined the Royal New Zealand Air Force. He went to Canada on an air training scheme and served in the British coastal command and transport squadron as a navigator, seeing service in Britain, Europe and the Pacific throughout the Second World War.

Following the war, he returned to New Zealand and the purchasing department before being seconded to Jack Kent’s local sales team.

In 1976, Mr Stephenson was appointed N.Z.S.’s manager and became responsible for merchandising outside the Auckland area. Three years later he received a gold watch for 40 years service.

A keen and very capable cricketer and tennis player “in his day”, he now enjoys golf. His wife, Doreen, does valuable work translating material into braille for the Foundation for the Blind. They have three married children.

Mr Stephenson’s wide experience and valuable contributions to the company will be greatly missed. Good luck for the future!

Top telex team vital

TUCKED away at Head Office are three people who operate the communications nerve centre of W & R Fletcher (NZ) Ltd. Without their skill, valuable time and business could be lost.

Eleni Fiso joined Supervisor John Thorn and Karen Tapp recently, and is by now, quite used to the din caused by two teleprinters and two telex machines.

Telex communications work requires high levels of concentration, initiative, an ability to work under pressure, and a thorough knowledge of the workings of the company.

“You have got to have your wits about you as nothing is the same from one moment to the next – one minute you will be doing an overseas telex on wool and the next, a local one on shipping,” John said.

“You must know what is going on and quite often what someone in another department is thinking!”

John, Karen and Eleni operate two teleprinters which relay directly to the Westfield, Kaiti and Tomoana Works. At the Tomoana end are Valerie Hope and Fiona Hearn. Duties at Westfield are shared by Ainsly Samson, Pamela Luhrs and Mavis Tobeck.

“We also operate two telex machines which cater for inland and overseas traffic to customers of W & R Fletcher,” John said.

London

And not only is there speedy contact nationally, but also internationally to the London office. A Datel machine and the twelve-hour difference between New, Zealand and Britain allow continuous exchanges of international information.

Because of the volume of information being transmitted, it is compressed using electrical impulses. Two hours of transmission time is reduced to about five minutes and the material is printed at about 700 words a minute.

John has worked on telex machines worldwide, gaining his initial training while he was in the Navy for 10 years and has been with the company since June last year. Karen changed her position as a Head Office junior for a telex machine and on-the-job-training, as did Eleni.

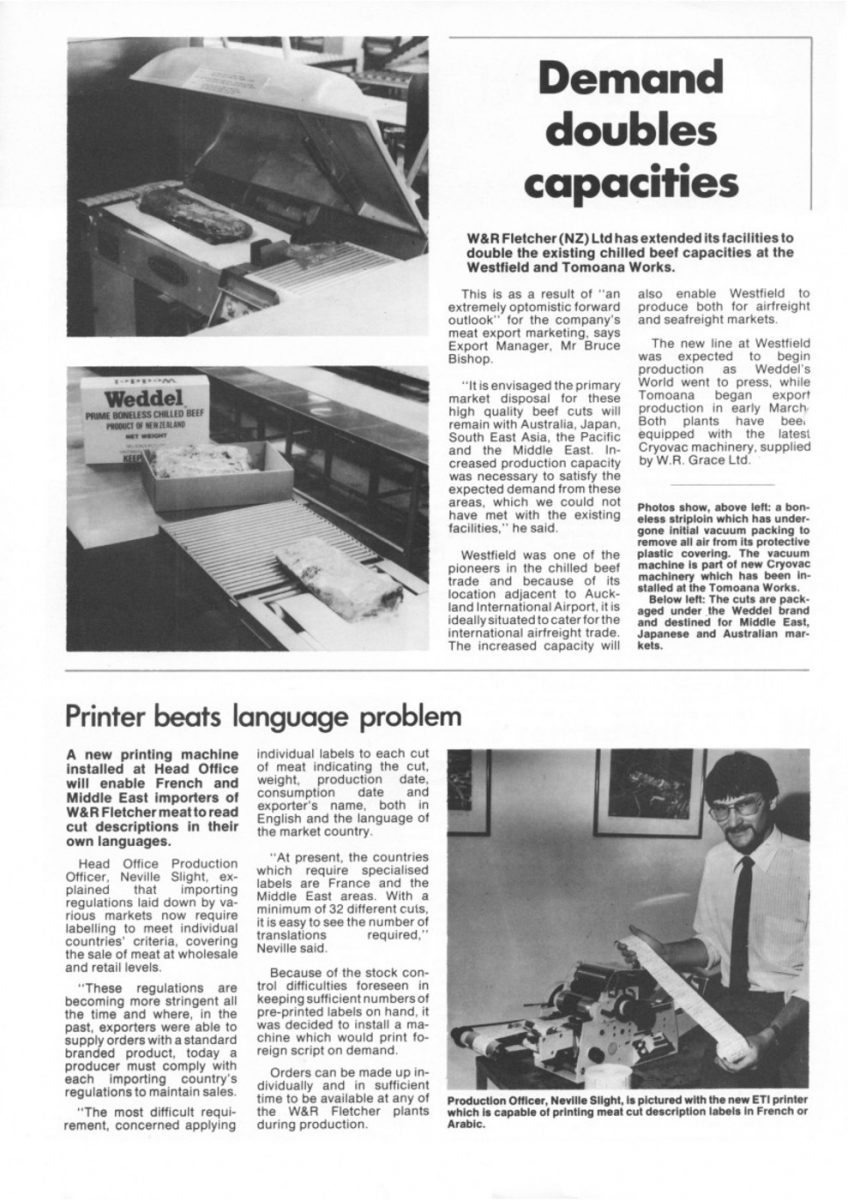

Photo caption – PICTURED is the Head Office telex team (from left): Karen Tapp; Supervisor, John Thorn; Eleni Fiso.

Obituary:

Mr A. H. Niker

IT IS with regret that Weddel’s World reports the death late last year of Mr A. H. Niker, a well respected senior London colleague.

Following a period in London and the Argentine, Mr Niker was seconded to Wellington between 1936 and 1953, where he was in charge of cost and production. On his return to London, he became assistant to the Australasian Manager, Mr G. Drabble.

He was later in charge of the Secondary Industries, which included Fropax, before taking up a position as assistant to Lord Vesty. At the time of his retirement, he was responsible for the Management Services Department in London.

He is survived by his wife and two daughters.

A well-earned retirement

AN ASSOCIATION of 47 years with W & R Fletcher (NZ) Ltd’s Gisborne Refrigerating Company, ended with the retirement at Christmas of Works Manager, Mr Wally Varley.

He began working with the company as a scales clerk in 1935 and later gained experience as a slaughterman. After training in pig and calf dressing, Wally became what was then known as an all round slaughterman, at at time when there was very little mechanisation.

With 12 years seasonal work behind him, Wally was appointed as assistant foreman in the Kaiti slaughterhouse in 1950, and senior foreman about four years later.

After he became Works Manager in 1963, Wally became involved in developing supervisory management skills, in foremen throughout the industry.

He also recalls the first inter-office sports meeting held in Gisborne in 1974, and the pleasure he experienced while competing in the axemen’s events against workers from all parts of the industry.

In his “younger days” Wally was a prominent axeman who competed widely and even now appears in local chopping events with some success.

He is actively involved in the Gisborne Search and Rescue team and is past president of the city’s canoeing and tramping club, often leading parties of trampers. He has done extensive mountain climbing on Mounts Cook, Ruapehu and Egmont.

As for his retirement plans, Wally hopes to see more of New Zealand with his wife, Win, who “washed my dirty gear in the early days, and patiently listened to freezing works’ problems thereafter”.

He hopes to do some “modest” mountain climbing and explore remote areas with a pack and fishing rod. Between training for a marathon and wood carving, Wally also wants to do some farm work to remain in touch with the pastoral industry.

Kaiti’s recently retired Works Manager, Mr Wally Varley.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.