- Home

- Collections

- POPPELWELL MD

- Various

- Modern Manufacturing 1955

Modern Manufacturing 1955

Special Hastings Issue

SEPTEMBER, 1955

Modern

Manufacturing

MATERIALS PROCESSES PRODUCTION MANAGEMENT

SERVING NEW ZEALAND INDUSTRY

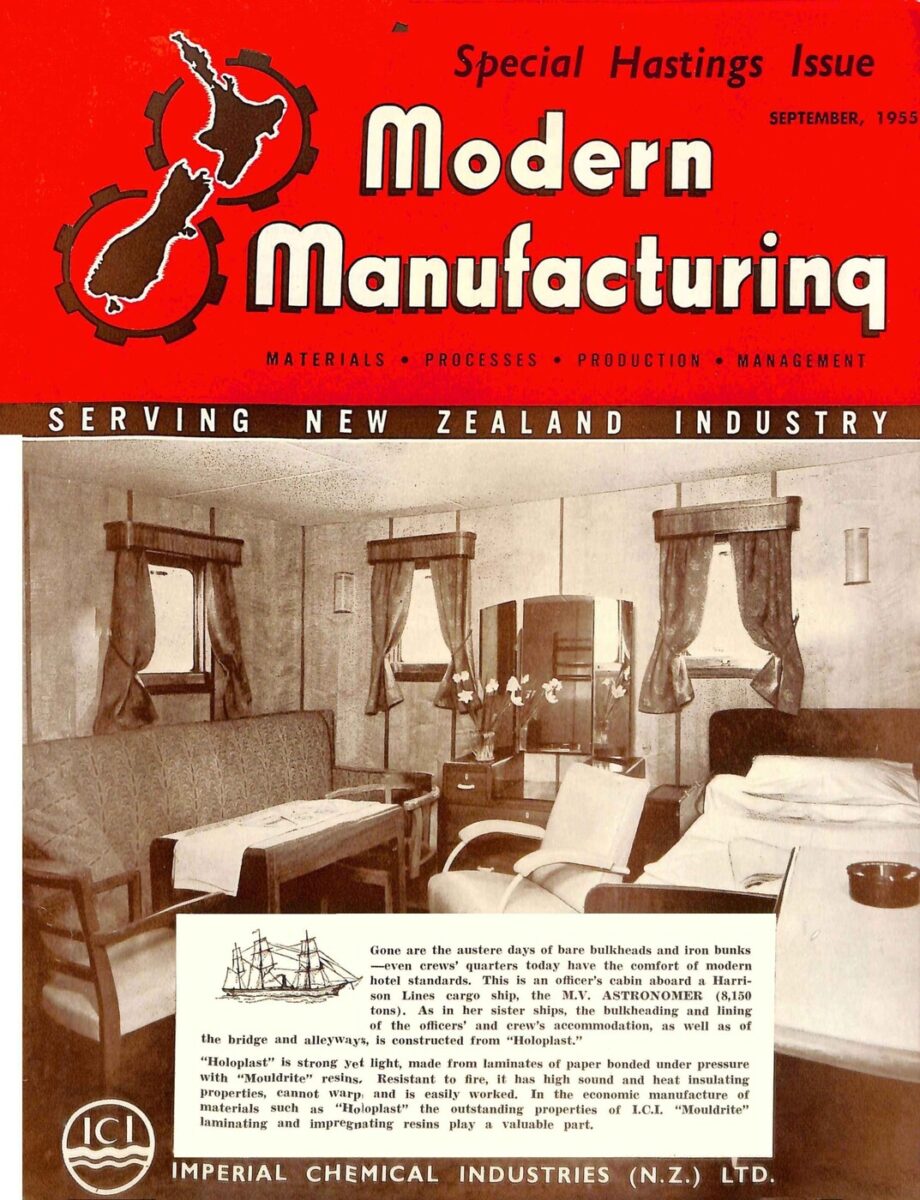

Gone are the days of bare bulkheads and iron bunks -even crews’ quarters today have the comfort of modern hotel standards. This is an officer’s cabin aboard a Harrison Lines cargo ship, the M.V. ASTRONOMER (8,150 tons). As in her sister ships, the bulk heading and lining of the officers’ and crew’s accommodation, as well as the bridge and alleyways, is constructed from “Holoplast,”

“Holoplast” is strong yet light, made from laminates of paper bonded under pressure with “Mouldrite” resins. Resistant to fire, it has high sound and heat insulating properties, cannot

warp, and is easily worked. In the economic manufacture of materials such as “Holoplast” the outstanding properties of I.C.I. “Mouldrite” laminating and impregnating resins play a valuable part.

ICI IMPERIAL CHEMICAL INDUSTRIES (N.Z.) LTD.

[Advertisement]

FOR Quality

IN EXTRUSION AND CUSTOM MOULDED PLASTICS

A.C… have the facilities, know-how and experience which comes naturally from having been the first successful producers in this country of many major Plastics lines readily accepted and widely used in Industry and Home today.

Striving for superior quality A.C.I. brings to its customers the newest in methods and procedures.

A highly specialised tool shop and full engineering facilities make it possible to tool up for any custom order.

A.C.I. will advise you of the suitability of plastic for your job – choose the correct moulding process and most important, select the very best plastic material for your project.

A.C.I. leads the field in progress – and quality plastic products.

AUTO PARTS BABY TOYS RADIO CABINETS

SQUEEZE BOTTLES FOOD PACKAGING KITCHENWARE

BOTTLE CLOSURES INDUSTRIAL HOUSEHOLD

Garnite

CONTOUR PIPING and POLYTHENE PRODUCTS

MANUFACTURED IN NEW ZEALAND BY A.C.I. PLASTICS PTY. LTD. (INC. IN AUSTRALIA), PENROSE, AUCKLAND.

SOLE SELLING AGENTS NEILL CROPPER & CO. LTD., PUKEMIRO CHAMBERS, Box 74, AUCKLAND.

Also Box 583, WELLINGTON; Box 1378, CHRISTCHURCH and Box 703 DUNEDIN.

Page 1

[Advertisement]

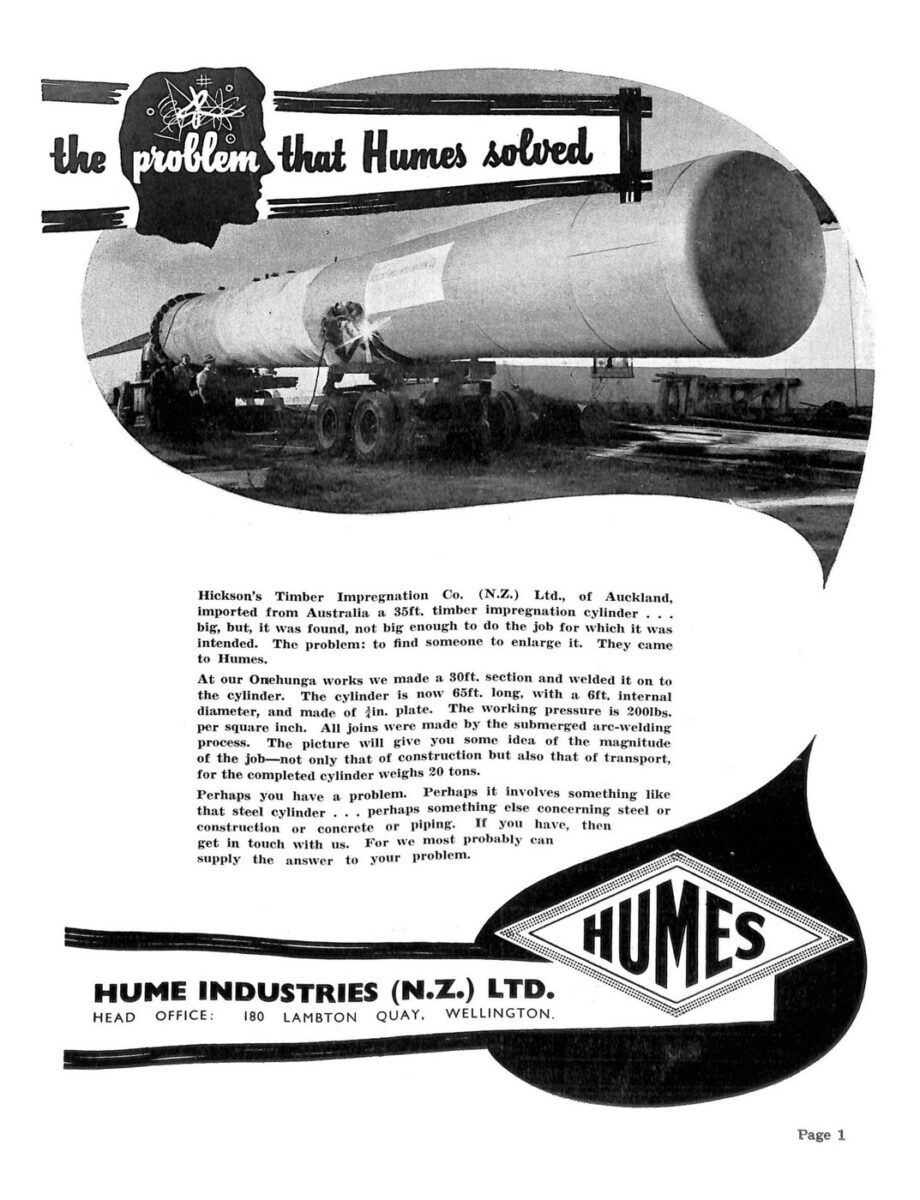

the problem that Humes solved

Hickson’s Timber Impregnation Co. (N.Z.) Ltd., of Auckland, imported from Australia a 35ft. timber impregnation cylinder . . . . . . big, but, it was found, not big enough to do the job for which it was intended. The problem: to find someone to enlarge it. They came to Humes.

At our Onehunga works we made a 30ft. section and welded it on to the cylinder. The cylinder is now 65ft. long, with a 6ft. internal diameter, and made of ¾in. plate. The working pressure is 2001bs. per square inch. All joins were made by the submerged arc-welding process. The picture will give you some idea of the magnitude of the job – not only that of construction but also that of transport, for the completed cylinder weighs 20 tons.

Perhaps you have a problem. Perhaps it involves something like that steel cylinder. . . . . . perhaps something else concerning steel or concrete or piping. If you have, then get in touch with us. For we most probably can supply the answer to your problem.

HUMES

HUME INDUSTRIES (N.Z.) LTD.

HEAD OFFICE: 180 LAMBTON QUAY, WELLINGTON.

Page 2 Modern Manufacturing

[Advertisement]

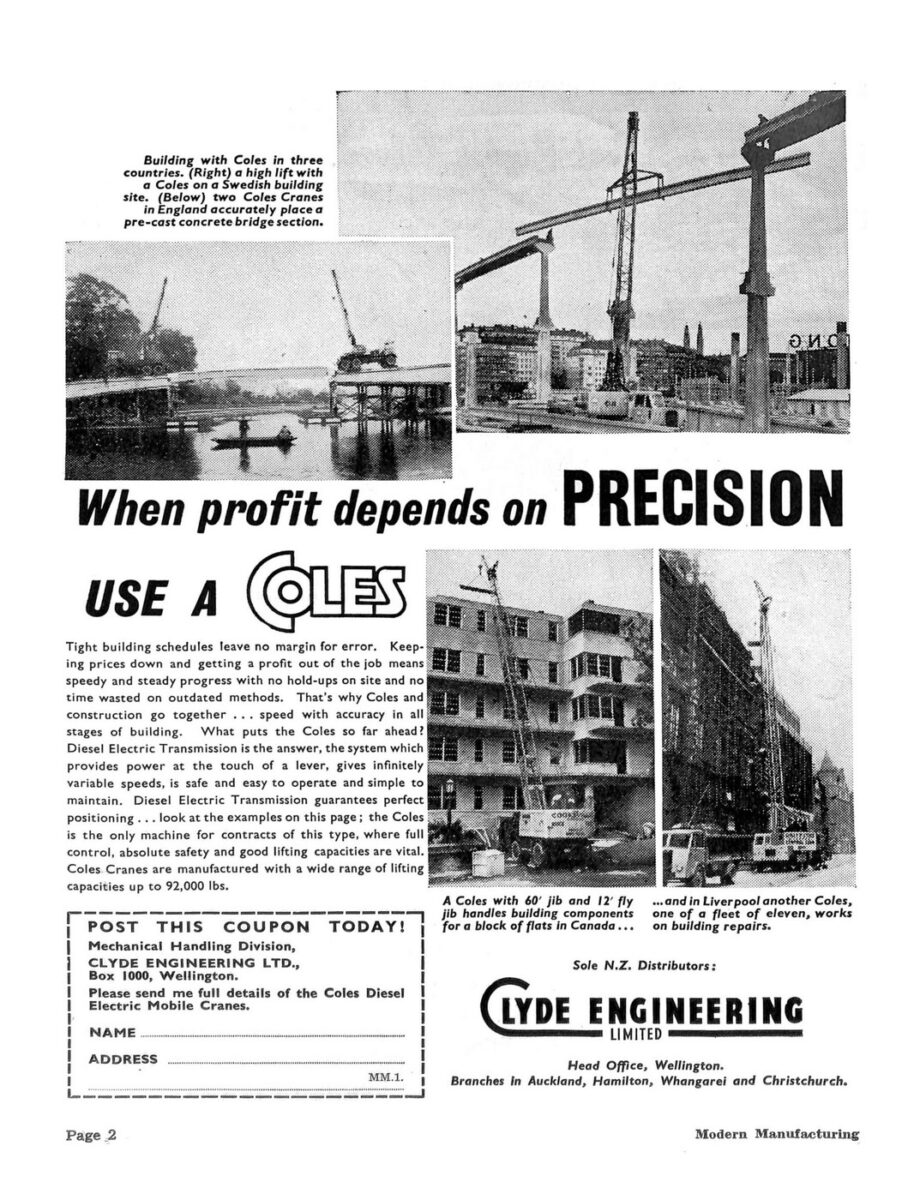

Building with Coles in three countries. (Right) a high lift with a Coles on a Swedish building site. (Below) two Coles Cranes in England accurately place a pre-cast concrete bridge section.

When profit depends on PRECISION

USE A COLES

Tight building schedules leave no margin for error. Keeping prices down and getting a profit out of a job means speedy and steady progress with no hold-ups on site and no time wasted on outdated methods. That’s why Coles and construction go together … speed with accuracy in all stages of building. What puts Coles so far ahead? Diesel Electrical Transmission is the answer, the system which provides power at the touch of a lever, gives infinitely variable speeds, is safe and easy to operate and simple to maintain. Diesel Electric Transmission guarantees perfect positioning … look at the examples on this page; the Coles is the only machine for contracts of this type, where full control, absolute safety and good lifting capacities are vital. Coles Cranes are manufactured with a wide range of lifting capacities up to 92,000 lbs.

A Coles with 60’ jib and 12’ fly jib handles building components for a block of flats in Canada …

… and in Liverpool another Coles, one of a fleet of eleven, works on building repairs.

Sole N.Z. Distributors:

CLYDE ENGINEERING LIMITED

Head Office, Wellington.

Branches in Auckland, Hamilton, Whangarei and Christchurch.

POST THIS COUPON TODAY!

Mechanical Handling Division,

CLYDE ENGINEERING LTD.,

Box 1000, Wellington.

Please send me full details of the Coles Diesel Electric Mobile Cranes.

NAME

ADDRESS

MM.1.

for SEPTEMBER, 1955 Page 3

[Advertisement]

THE RTSC CROUP

COMPRISES

RICHARD THOMAS & BALDWINS LTD

AND

THE STEEL COMPANY OF WALES LTD

STEEL AND COILS

FROM THE CONTINUOUS STRIP MILLS

(Hot-rolled and cold-reduced)

STEEL PLATES

GALVANIZED STEEL SHEETS

TINNED SHEETS • LEAD COATED SHEETS • TERNE-COATED SHEETS

COLD-REDUCED TINPLATE

(Electrolytic and hot dip)

STAFFORDSHIRE HEAVILY COATED TINPLATE

WELSH CHARCOAL TINPLATE

BLACKPLATE

SALES ORGANIZATION:

RTSC EXPORTS LTD

RTSC HOUSE PARK STREET LONDON W1 ENGLAND

REPRESENTED IN NEW ZEALAND BY

REPRESENTED IN

RTSC & GOLLIN (N.Z.) LTD.

Auckland P. O. Box 199 Wellington P. O. Box 794 Christchurch P. O. Box 390 Dunedin P. O. Box 500

RTSC GROUP

THE LARGEST OUTPUT OF STEEL SHEETS AND TINPLATE IN EUROPE

Page 4 Modern Manufacturing

[Advertisement]

Pleasantly illustrating the fact

… that we are amongst the leaders in the fabrication of

STAINLESS STEEL SINKBENCHES WASHTUBS, etc. for the household

HOWEVER WE ALSO SPECIALISE

In the fabrication of many articles in Stainless Steel for numerous industries.

To list but a few:-

MILK HOLDING VATS STAINLESS STEEL FLUES

CHEESE VATS STAINLESS STEEL PRESSINGS

TROUGHS FLANGES, BENDS and ELBOWS

HOSPITAL STERILISERS IN ANY RANGE OR SIZE

EQUIPMENT FOR THE MEAT INDUSTRY BAIN MARIES

WE SHALL BE PLEASED TO QUOTE FOR ANY ARTICLE IN STAINLESS STEEL FOR OUR PRICES ARE COMPETITIVE.

WRITE, PHONE OR CALL FOR PROMPT, EFFICIENT SERVICE.

Burns & Ferrall Ltd.

GREAT SOUTH ROAD – PENROSE – AUCKLAND, S.E.6

PHONE 596-719

for SEPTEMBER 1955 Page 5

Modern Manufacturing

MATERIALS PROCESSES PRODUCTION MANAGEMENT

Vol. 7, No. 1 SEPTEMBER, 1955

Contents

Page

Editorial 6

Current Comments 6-7

Productivity is an Attitude 9-13

HASTINGS 15-70

Message from The Mayor 16

Greater Hastings, Inc. 17

The Town and District 18-21

Materials – Handling 71-73

New Qualities for Concrete 74-75

Automation 77

EDITOR:

R. Westgate

BUSINESS MANAGER:

S. M. Niblock. M.S.M.A. (Eng.)

EDITORIAL OFFICES:

409 Upper Queen Street

Telephone 43-458

Address all Correspondence to Editor,

MODERN MANUFACTURING,

P. O. Box 3159, Auckland, C.l

New Zealand

REPRESENTATIVES

United Kingdom –

COWLISHAW & LAWRENCE (Advertising) Ltd.

28 New Bridge St., London

E.C.4, City, 1542 and 5118

Telegrams and Cables:

Cowlawads, Cent., London

MODERN MANUFACTURING

is registered at the G.P.O.,

Wellington, for transmission through the post as a magazine

SOLE SUBSCRIPTION AGENTS

R. HILL & SON LTD.

Union House, Quay St., Auckland.

RATES:

N.Z. & U.K., 25/- p.a.

Australia, 31/- p.a.

U.S.A. & Canada, 4 dollars p.a.

Pages 6 and 7 Modern Manufacturing for for SEPTEMBER 1955

EDITORIAL current comments INDUSTRY’S GROWTH – EASTERN TRADE – ATOMIC POWER

Who Speaks for Manufacturers ?

IN the December-January issue of this journal attention was drawn to the fantastic position that the manufacturing-importer occupies in the ranks of the Manufacturers’ Federation. The obvious frequent conflict of interest was noted, and the point was raised whether the best interests of New Zealand industry could be served by undue reliance on the counsel of those whose stake in the economy is divided between manufacturing and importing.

The question has now been brought to the fore again by Mr. H. Korman, a member of the Council of the Auckland Manufacturers’ Association, who has quite rightly affirmed the absolute necessity for import controls “to protect the vital interests of true manufacturers in this country.”

The irony of it all is though that Mr. Korman has taken up a challenge issued not by one of the sworn and proven opponents of New Zealand industry, but by no less a person than the president of the Otago and Southland Manufacturers’ Association, Mr. T. E. Roff, who has appealed to manufacturers not to “hide behind the clock of import controls.”

Mr. Roff has importing interests, and is certainly entitled to have them, as Mr. Korman concedes. But is he, as Mr. Korman asks, fitted to speak on behalf of the Manufacturers’ Federation, which has consistently campaigned for import control as the key to flourishing New Zealand industry?

It makes nonsense of Federation policy if those ostensibly committed to it are perfectly free to repudiate it at will. It cannot be repeated too often that there are sworn and proven enemies of New Zealand industry, and divisions within the manufacturers’ own ranks are not likely to escape the attention of these people.

Internal division is the classic forerunner of external attack, and the leaders of the Federation should remember this. If they do, they will boldly and courageously face up to a problem that certainly has come no nearer to solution through being shelved or glossed over for so long.

Manufacturing Leads

THOSE who seem congenitally destined to go on taking a jaundiced view of industry’s growth in New Zealand have lost no time in trying to “play down” the significance of the fact that in 1953-54, for the first time, manufacturing contributed more than farming to the national economy. The arguments used show the specious reasoning on which critics have to rely when they attempt to discredit trends that strength the national economy.

For instance, as part of the process of belittling the importance of the manufacturing industries, much is made of the fact that their growth has been greatly aided by the farming industries. Of course this is so, but is not the reverse equally true, and should not the new stature of manufacturing be made the reason for acknowledging its impressive contribution to the national well-being?

The point about the whole line of argument that sees manufacturing as a kind of parasitic and precarious growth is that fundamentally it denies the wisdom of a balanced economy and the interdependence that exists between town and country. Accordingly it should be opposed as often and as vigorously as possible.

Lost Orders

A REPORT that New New Zealand recently lost lost substantial English orders for milk powders because the company asked to supply could not secure export licenses is alarming in the extreme. And the story, as it has been reported, reflects credit on none of the parties concerned. It goes like this:

A representative of an Auckland manufacturing company who was visiting Britain was offered the orders – which were “entirely new business” – but because the Dairy Products Marketing Commission has a marketing monopoly for milk powders, was unable to obtain the necessary export licenses. It is assumed that as a result the business went to Continental suppliers.

Surely two points must occur to all those who have no special axe to grind in this matter. Firstly, it may be asked, what was there to prevent the company offered the orders from “tying up” the business for New Zealand – if not for itself, then for the commission? And secondly, why was it that the commission, with all the facilities it has for keeping in touch with the market, in the dark about this new business – and big business – that was offering?

What’s Happening in the East?

THE continuing round of military conferences arising out of the South-East Asia Treaty organisation underlines the apparent lack of attention being paid to implementing the economic side of the treaty. Neither are the limited number of S.E.A.T.O. economic talks that have taken place in any way very encouraging.

In June economic experts from the treaty countries met in Karachi, and New Zealand was represented by officials of the External Affairs Department and the Treasury. Whatever was achieved at this meeting it has been kept curiously secret, even though discussion was to have centered on “steps” which might be taken to promote economic progress and social well being in the Treaty area.”

Perhaps the reason for the veil of secrecy is to be found in the pre-conference statement by the Minister of Defence and External Affairs, Mr. MacDonald, that “the Karachi decisions would probably have a defence slant, distinct from the Colombo Plan assistance measures.” This being so, has not the time come for a reassessment to be made of the whole value of S.E.A.T.O. as a means of developing New Zealand’s trading relations with the countries of South-East Asia?

This is a mater of vital concern to primary producers, manufacturers and commercial interests. Spokesmen for all these groups have acknowledged the potential that exists for expanded New Zealand-South-East Asia trade and have at various times called for direct New Zealand commercial representation in South-East Asia to open up new markets.

Given present trends, the question that must now be faced is whether the Dominion’s interests in this direction can best be served by a commercial representative to Mr. Foss Shanahan’s staff (which is concerned virtually exclusively with the country’s obligations under S.E.A.T.O.), or by a representative completely freed from what can only be described as the disappointingly restricted terms of reference of the South-East Asia Treaty Organisation.

Safer Heaters

IT is little to the credit of a section of New Zealand industry that members of the public are being forced to take the initiative in pressing for safer electric heaters. Latest body to bring the matter to the attention of the Government is the Wellington Plunket Society, which is seeking to have the sale of heaters without adequate guards made illegal.

As the Society points out, legislative action along these lines has already been taken in both Britain and Sweden. There is no reason why the New Zealand Government should not follow suit.

The Standards Institute is at present working for the adoption of a standard specification for guards for all heaters, but far from obviating the need for legislation this actually makes the need all the greater. A law prohibiting the sale of heaters which are a hazard to children would ensure to the whole community the full benefit of the Institute’s work.

Scramble for Markets

AMONG the more interesting comments on the International Conference on Peaceful Uses of Atomic Energy held in Geneva in August was that of the influential American publication “U.S. News and World Report”. The journal said that although the conference was described as scientific, non-political and non-competitive,

“The fact is that it is shaping up as the start of a race for world leadership in the application of the atom to industry … what it boils down to is a good old-fashioned scramble among nations for new atomic export markets.”

Early this year it was reported that the British Government had decided to “go all out” to supply export demands for atomic power plants, and it was then estimated that over the next 20 years this new trade would be worth something like £2,000 million to Britain. And at the Geneva meeting the managing director of the British Atomic Energy Authority bluntly told delegates that Britain has commercial atomic secrets which she refuses to share with other countries because of their value in the future race for atomic markets.

Intriguing thing about the “good old-fashioned scramble” that is developing is that it promises to produce the most spirited rivalry not between East and West, but between Western countries themselves, and especially Britain and the U.S. Agreements that the Soviet Union has already concluded with her East European partners and China open up an enormous field for her exports of atomic equipment and when she looks beyond that vast market it is likely to be to the under-developed countries.

Meanwhile the situation should be exercising the close attention of those in New Zealand who are likely to be eventually responsible for advising on the placing of overseas orders for atomic equipment. The country must derive considerable satisfaction from the knowledge that when the times comes for the Dominion to purchase plant we are unlikely to be at the mercy of something akin to the shipping monopoly.

Page 8 Modern Manufacturing

[Advertisement]

LOCK OUT ACCIDENTS

GUARD WITH wire mesh

SAFETY FIRST! In planning safety in your works – call in Wirecraft Ltd. Wireguards are built to specifications submitted by customer or to details taken by our representative. In every instance, guards are designed and constructed for quick installation and conforming to the requirements of the Industrial Safety Act.

wireCRAFT LTD.

INDUSTRIAL Safety WIRE GUARDS

Great South Road, S.E.6 P.O. Box 25, Penrose

Wire and Metal Workers, Phone 594-0229

for SEPTEMBER 1955 Page 9

PRODUCTIVITY IS AN ATTITUDE – and Attitudes can be Changed

This article reviews the findings of productivity groups from Britain and the Continent who compared their practices with those current in the U.S. The author, who is well known as an industrial consultant, was associated with the visits of many of the groups to the U.S.

By PETER DRUCKER

(Nation’s Business)

DURING the past few years the American business system has been examined, probed and dissected as no other economic system has even been. Several thousand hand-picked experts – businessmen, technicians, educators, workers and union officials – from every country of Western Europe and from almost every industry, have been touring the United States since 1949 to find out for themselves what influences American productivity. Organised is some 200 “productivity teams,” under the Marshall Plan, and influenced by funds which the European governments provided, they have looked at foundries, textile mills, business schools, breweries, printing companies and labour unions. Most of them have stayed long enough to get more than a tourist’s view.

Officially the programme goes by the name of “Technical Assistance”; and the purpose is to find American techniques for European use. The bias toward techniques is emphasised by the selection of teams who normally come either from one industry, locomotive building for instance, or from one technical speciality such as cost accounting or industrial engineering. The teams arrive in the United States expecting to find the cause of American productivity in techniques and processes. Yet, I know of no team which did not speedily discover for itself that techniques are not the really important thing, and certainly are not the real cause of productivity.

“Productivity is an attitude of mind,” the report of the team from the British letterpress printing industry stated; and in one way or another every team has said the same. Attitude, social organisation and moral value – those, the visiting experts report, underline and explain the industrial achievement of the United States.

Even in such a technical area as the use of machinery, visitors see attitudes rather than the abundance of capital, the lack of wartime destruction, or some other material factory as the main cause got such achievement. A British team investigating the making of brushes, for instance, remarks that machinery is being used successfully in the United States in operation normally regarded in British practice as unsuitable for mechanisation.

Five things in particular impress the visitors as being fundamental, and at the same time as presenting the greatest contract to Europe:-

1 – The Discovery of Management

“The United States has made a major discovery – that it is management which makes the wheels go round,” a successful French manufacturer said. “We are still largely organised on the belief that all a business needs is a supply of capital, after which it will run itself. In the United States basic decisions are made by men who know the business from the ground up, who consider it their main interest in life, and who get their jobs because of their competence. As a result business attracts the best minds in the country, and that, more than anything else, explains how Americans got where they are today.”

Every report stresses the central importance of a management responsible for the success of the business, familiar with it and chosen for competence. The most glowing tribute to management and to its importance came from a group of British labour leaders:-

“We are convinced that it is efficient management who set the pace of productivity in American industry. American trade union officials can reply on management to be sufficient progressive.” Every trade unionist on the teams comments upon the confidence in management’s competence, fairness and integrity that he finds among American workers and trade union leaders.

2. – Productivity as a Social Principle

Every team believes that its own country must raise productivity to survive. Yet most of the visitors, whether labour or management men, still tend to look upon increased productivity as primarily a way to increase individual business profits.

Visitors find that Americans look upon profits not as the rationale of increased productivity, but as the reward for the social benefits such productivity brings: higher wages, cheaper prices and more good for the consumer. They report that managements of profitable companies hardly mention profits when they discuss productivity, but stress the duty of business to increase productivity even if no immediate increase in profits results.

The visitors also find that American industry not only talks this way, but acts it too. They find it taken for granted in labour negotiations that an increase in productivity justifies a corresponding increase in wages. They find in companies, large and small, that management salaries and bonuses take into account performance, efficiency and productivity rather than profit figures alone. They find elaborate attempts, such as the suggestion system which they mention over and over again, to reward individual workers for contributions to productive efficiency.

It is to this concept of productivity that visitors attribute to the basic American attitude toward technological progress. Precisely because in the United States increased productivity is a social, if not a moral responsibility. American industry and American labour – so visitors report – believe in, and accept, technological change rather than resist it.

3. – The Attitude Toward the Market

Visitors cannot be blame for believing, when they reach the United States, what has been told them; that the major factor in American distributive system is the continental span of the market. Few productivity teams have departed without having learned better.

Of course the United States is a market larger in territory and in numbers than any country of Western Europe, but it is not the width of the market which constitutes the real difference; France, Italy, Germany and England each offers a larger market than that actually covered by the majority of American businesses with their concentration on on region or area. It is in depth that the American market differs basically from other concepts and business practice – a qualitative rather than a quantitative difference.

One example – and it is given again and again by visitors – is the structure of the American automobile market in which last year’s car will compete direct with a new model. Another is the television market. What impressed one team the most was a comparison between a mail-

(Continued overleaf)

for SEPTEMBER, 1955 Page 11

order catalogue and that of an expensive sporting goods store definitely in the luxury class. They found that practically every kind of merchandise offered by the latter store also was to be found in the mail-order catalogue. “That ‘wealth’ is not just an economic term but a social one in the United States; that it means that there are the same things for the rich and for the poor, this none of us understood – and it is important.”

Closely connected with the concept of the mass market is the American attitude toward the capacity of the market. “We put our stress on the actually existing market which we tend to take for granted. You look for the potential market,” is one way some of the visiting terms put it. “We consider it our job to fill existing demands, you in the United States go out to create demands.”

Basically the visitors’ usual concept is that of a given, static market. Hence a new product is seen as cutting into the markets of all the existing products; competition as taking away sales. The American concept, so visitors report, is that the market is indefinitely expandable. New products create their own demand; competition broadens the market for all.

It is to this that visitors attribute, for instance, emphasis on research: technical, market, product; the pricing policy of progressive companies who often price a new product according to its expected eventual market rather than according to present cost or immediate sales, or the willingness to develop a new product first and consider its market later. All of these visitors consider significant factors in America’s high level of productivity.

4. – Productivity Based on Diversity and Experimentation

Practically every team starts its tour by asking: “What is the standard American cost-accounting system?” “Does the typical labour contract give the union a voice in the setting of production standards?” “What is the typical American pricing policy?” “What is the foreman training programme?” When told there is no such thing as “the American policy” they are incredulous.

It is not only that they are steeped in the prevailing myth of American uniformity. In their own country or their own industry such things are usually uniform, set by government, by an industry-wide labour contract, a nation-wide labour law, compulsory nation-wide arbitration, or by trade associations or cartel. In fact, most of the teams cannot, at first, imagine that important practices and polices could be anything but uniform.

However, most of the team eventually come to the conclusion that diversity is a major cause of American productivity. It means constant experimentation with new methods, ideas and approaches. “Almost every company we have seen,” wrote a Scandinavian team, “was working on something new, something it was experimenting with in foundry techniques or in personnel methods. No two companies were alike. As a result, the entire industry is forever questioning its methods, working on improvements, trying to find a better way.”

Even less expected and more baffling to visitors is the prevailing co-operation and the free exchange of ideas and experience. They know when they arrive that American business is highly competitive; they find even more competition than they usually expected. Intensive competition, they believe, must mean secretiveness. It must mean refusal to disclose anything which might help the competitor.

5. – The Importance of the Human Being

Industrial training, management development programmes, the opportunity for workers to rise to the top, are important factors in America’s productive capacity. Such factors as the informality in plants and offices. the attention paid to making work easy for the worker, the skill of the foreman in leading his people, are only a few of the things every visiting team noticed. American labour relations seem to them to be based on deep respect for human beings.

The close co-operation between stewards and management is remarked upon again and again; and several teams have underlined the friendly and relaxed atmosphere of American labour negotiations. That they are sincere in the compliments is shown by the fact that the United States always is asked to include a

(Continued overleaf)

[Advertisement]

Be in at the Finish!

We’ve solved some pretty intricate Finishing problems for other firms

… we can for you.

Consult us on Finishes for:

METAL – GLASS – PLASTICS

WOOD FABRICS

Specialists in …

BONDERISING – PARKERIZING – PYLUMINIZING HI-BAKE ENAMELS – LACQUERS

WRINKLE AND PLASTIC COATINGS

We’re always busy, but glad to see you.

Call any time.

MODERN FINISHING CO. LTD.

Corner West and France Streets,

Newton, Auckland.

Phone 48-757

Page 12 Modern Manufacturing

[Advertisement]

We Specialise …

in all Boiler and Pressure Vessel work and the manufacture of Digesters, Rotary Driers and other equipment for the Food, Fertilizer, Dairy and Cement Industries.

A 100 H.P. BOILER supplied to Prestige Hosiery, Wellington

Seagar Bros. Ltd.

General Engineers

CUSTOMS ST. WEST AUCKLAND, C.1.

C.P.O. Box 513

PHONE 44-903

ENGINEERS, BOILERMAKERS, SHIPBUILDERS, WELDERS, PATTERNMAKERS, FERROUS & NON-FERROUS FOUNDERS. COMPLETE SHIP REPAIR SERVICING INCLUDES ELECTRICAL, REFRIGERATION, COPPERSMITHING, SHIPWRIGHTING, BOILER & STOVE BRICKING, CARGO GEAR ANNEALING & TESTING.

ENQUIRIES SOLICITED

for SEPTEMBER, 1955 Page 13

labour relations expert in the American management teams which go to Europe.

Most visitors believe that the United States avails itself of a much larger percentage of its human resources than their own nations do.

How much of the American attitudes have the productivity teams taken home with them? Techniques and processes have been adopted wholesale and with good success in many cases. The productivity teams would be the first to stress, however, that techniques and processes without the underlying attitudes would not do much good. Yet precisely because attitudes are important, success has been slow. Attitudes do not transplant fast or well.

The greatest obstacle, however, has been that the American beliefs and principles require something of which most nations have a shortage: management. It becomes quite obvious in talking to visiting teams that the major reason for the stranglehold of the cartel system on an economy is not protectionism, but simply the absence of management. The cartel largely eliminates the need for management by eliminating problems of pricing, merchandising, competition, labour relations or technical efficiency. For this reason the emphasis on the training and development of management on all levels which recently has emerged in the Marshall Plan countries represents a major victory; but it also means that progress will be slow.

After all, though Americans today take for granted the basic attitudes to which productivity is credited, everyone one of them was, 30 or 40 years ago, nothing but the pet obsession of a few visionaries. Certainly the productivity teams supply something which neither American dollars nor arms can supply: a constructive programme, a goal and a vision.

INDUSTRIAL TELEVISION AND ATOMIC SCIENTISTS

HOW to obtain information on conditions in a reactor which had been in service for some years was a problem which recently faced atomic scientists of the United Kingdom Atomic Energy Authority at the Windscule plutonium factory at Sellafield, Cumberland. Direct observation was an impossibility owing the the intense radio-activity, even when the reactor is shut down for maintenance. An industrial television camera, suitably protected, provided the answer.

Its small size – 5 ¼ x 4 x 11 3/8 in. – enabled it to be inserted through a narrow conduit to the interior of the reactor, whence it televised pictures over a closed circuit to monitoring equipment installed at a safe distance. This installation enabled scientists to study the exact conditions obtaining in the reactor.

Another example of how industrial television is providing invaluable visual information on the conditions of plant and in a manner impossible to obtain satisfactorily by means of human agency is that of a recent installation by the British Electricity Authority at a new power station in Derbyshire. The fuel used for heating the boilers is pulverised coal, which is jet-injected into the furnace with the air stream and is ignited by pilot oil-burners, the latter being extinguished as soon as full combustion has taken place. In such an operation, it is vital to ascertain that the fuel has fully ignited, as a firing failure, if unobserved, could result in a serious explosion.

In the past, observation had had to be maintained through inspection ports in the wall of the furnace, a procedure which made supervision difficult in modern stations which control is exercised from a point which may not be immediately adjacent to the boiler. Experiments were carried out with an industrial television camera, fitted with a special air-and-water-cooled lens, and installed in the explosion door aperture at the base of the boiler.

The industrial television control unit and monitors were placed at a convenient point alongside the combined boiler and turbine control panel. The experiment was successful, the B.E.A. engineers being able to follow, at the control panel, all phases of the boiler ignition procedure and to detect conditions of imperfect combustion within the area under observation.

Photo caption – Synthetic plastics have found their way into an enormous range of products. Plastics, antibiotics and synthetic fibres are the top three developments in the past 35 years.

Page 14 Modern Manufacturing

[Advertisement]

WHEN IT’S A QUESTION OF INDUSTRIAL FLOORING

DOES IT RESIST ACID OR FAT?

IS IT TOO COSTLY?

IS IT HYGIENIC?

IS IT JOINTLESS?

WILL IT WEAR?

IS IT SMOOTH?

IS IT DUSTLESS?

IS IT SLIPPERY?

WINSTONE LTD have the answer

LINOTOL (illustrated)

Laid in situ on existing concrete or wooden floors.

For Printing Works, Schools, Factories, Bakeries, etc.

Withstands wear from wheeled traffic.

Dustless, Fire-resistant, Jointless, Sanitary, Warm under-foot.

RUBCRETE

A fleximer type flooring – highly resistant to acids, alkalies, fats, sugar, greases, oils and most solvents.

For Ablutions, Processing rooms, Kitchens, etc.

We supply and lay all types

WINSTONE Ltd.

69-77 Queen Street, Auckland. P.O. Box 395.

Branches throughout N.Z.

for SEPTEMBER, 1955 Page 15

Hastings…

FLOURISHING HAWKE’S BAY PROVINCIAL CENTRE

IN the space of less than half a century Hastings has grown from a straggling collection of wooden buildings to the Dominion’s newest city. A thriving and prosperous centre, Hastings is ideally located in a district rich in the production of fruit, meat and wool. This fertile area’s glorious climate is second to none in the country; the productive capacity of its land is world renowned.

Side by side with the development of the district’s rural lands has been the steady growth of industry in the fast growing centre of Hastings. Particularly in the past decade, many important industries have been established in the city, most of them closely allied with primary production.

Page 16 Modern Manufacturing

“Our Blessings are Numerous”

HASTINGS has a history of only 80 years. The first sale of sections in Hatings [Hastings] (called “Hicksville” in early documents) occurred as late as 1873. The borough was constituted in 1886. I have heard some of our residents say that they can remember when Heretaunga Street was a swamp and the home of pukeko.

Today we have a thriving, prosperous and progressive community of 20,000 people in the borough area of 2,600 acres, as “urban” population – that is, within a radius of three miles from the Post Office. Nearby is the fast-growing “dormitory” borough of Havelock North.

Hastings will be formally proclaimed a city in September 1956, during our annual Blossom Festival. What explains this progress, which is so remarkable when it is remembered that our sister centre – much older than ourselves – only 12 miles distant has shown great progress and now has a population exceeding 20,500?

The Heretaunga Plain by which we are surrounded is probably the most naturally fertile area in New Zealand. Our orchard industry is highly developed and produces upwards of 2,000,000 cases of apples, pears and stone fruit each season. Hugh crops of peas and other vegetables are grown for canning at Hastings. In the district are two of the largest freezing works in the Dominion. The tremendous wool clip adds its income to Hastings’ financial wealth.

Or blessings are numerous. Our problems are only those associated with growing pains. From the foresight of our early administrators we have derived many advantage, including such civic amenities as a fine block of civic buildings and the Municipal Theatre. The borough is favoured by numerous splendid parks and reserves. Early administrators also established the Mangaroa forest reserve which is now coming into profit, also the Windsor Park motor camp, well known throughout New Zealand for the excellence of its amenities and appointments. Cornwall Park and Frimley Park are beautiful areas of trees, shrubs and flowers.

The spirit of civic enthusiasm finds expression in our Junior and Senior Chambers of Commerce and the Rotary Club and most particularly in our public relations organisation, Greater Hastings, Inc., which works in close liaison with the Hastings Borough Council. This happy and efficient set-up has been apparent on many occasions in the past three years.

We look forward with confidence to a continued and rapid development of the natural resources of the surrounding district of this northern City of the Plains.

W. E. BATE,

Mayor of Hastings.

for SEPTEMBER, 1955 Page 17

GREATER HASTINGS, Inc.

for a brighter town and a better spirit of citizenship

GREATER HASTINGS INC., which was originally started by a band of enthusiasts just over five years ago with the intention of brightening our town and creating a better spirit of citizenship, has in the short space of time of its existence far outgrown these aims and objects and is now functioning very successfully indeed as a Public Relations Office for Hastings in conjunction with the Borough Authorities, as well as organising other activities for the town.

It has proved what a need a growing town like Hastings has for a Public Relations Office and our capable and genial Organising Secretary, Mr. Ken Sparks, is very fully occupied in his various duties. The office of Greater Hastings has now become the focal point for visitors to our town who seek any information pertaining to the different amenities and facilities we are able to offer them.

In this respect, we are very happy to extend to all interested industrialists who would like any information whatever regarding expansion or development a cordial invitation to contact our Secretary, and can assure them of our whole-hearted co-operation in supplying them with all details they may require.

Two big attractions which have become nationally famous in recent years are the Hastings Highland Games, which are held annually at Windsor Park, Hastings, during Easter, and the Hastings Blossom Festival, another annual function held in the first week of September each year; these two big functions are Greater Hastings activities.

Our Camping Ground, which is ideally situated at Windsor Park, an area of 62 ares, with wonderful amenities for all outdoor amusement for campers, is another facility which Greater Hastings has sponsored in conjunction with the Borough Authorities, and here again we are proud to extend an invitation to all visitors to come and enjoy a holiday in these wonderful surroundings.

H. B. POPPELWELL,

President,

Greater Hastings.

Page 18 Modern Manufacturing

“A Glorious Climate, Rich Fertile Soils and High Productivity”

The wealth of Hastings has multiplied many times since 1870, when land was offered for sale at £3 an acre.

HASTINGS is one of the largest provincial towns in New Zealand, with an urban population of 26,000, and is renowned for its glorious climate, rich fertile soils and high productivity. As the distributive centre and market town of the fertile Heretaunga Plains, Hastings has grown rapidly in keeping with the increasing prosperity of the Hawke’s Bay Province.

Eighty years ago the centre of Hastings was little more than a swamp. About 1870, Mr Thomas Tanner owned the land in the centre of which is now Hastings and he offered an acre of land at £3 an acre for every 3 acres ploughed – and to accept payment in labour. In 1871 he offered a block of 640 acres between Hastings and Havelock North at £4 an acre, without getting a buyer. In 1910 the capital value of the borough was £1,370,000 – today the capital value is over 19 ½ million.

Within the 2,613 acres of the borough boundaries are:

The largest fruit cannery in New Zealand, with a 1954 production of over 10,000 tons of vegetables and fruits of 27 million units.

A quick freeze factory producing

A recent aerial view showing part of the business area of Hastings. The town covers an area of 2,613 acres, of which 130 acres are occupied by well-planned parks and reserves.

for SEPTEMBER, 1955 Page 19

THE WEALTH OF HAWKE’S BAY AND THE DISTRICT OF WHICH HASTINGS IS THE CENTRE AND MARKET TOWN

SHEEP run totalled 4,800,00 at June 1954, of which 3,000,000 were breeding ewes, 80,000 rams, 320,000 wether, and 1,400,00 lambs and hoggets, there being 2,935 sheepowners, occupying an area of 2 ¾ mission acres of farmland. More sheep are run to the acre in Hawke’s Bay than elsewhere in New Zealand.

WOOL sold in 1953/54 totalled 160,000 bales – the greatest number in New Zealand – realising over £11,000,000 at an average of £70 a bale. Five of the six wool-broking firms operating in the district have their head office in Hastings. This wool, among the finest crossbred in the the world, is bid for by buyers from all over the world.

CATTLE: There are over 800 dairy farms of over 90,000 acres carrying 500,000 cattle and 50,000 dairy cows.

ORCHARDS: Over 1 ¾ mission bushel cases of fruit are harvested annually from the 415 registered orchards (50 trees and over). In 1954, with 224,462 pip fruit trees, 138,951 stone fruit trees and 1,384 citrus fruit trees, covering over 3,300 acres, the yield from these trees was easily the highest in New Zealand.

GRASS-SEED production exceeds 4 million pounds annually, the yield of perennial ryegrass being the highest in New Zealand at 497lbs. per acre.

MARKET GARDENS AND SMALL FRUITS cover an area of over 7,000 acres of which in 1954 over 4,500 acres were in peas, 500 acres in asparagus, 450 acres in tomatoes, and 450 acres in vineyards. Fruits and vegetables of all kinds are produced and dispatched to all part of New Zealand as well as being canned, deep frozen, and bottled for export and local consumption.

packages of vegetables for export and local consumption.

A dairy factory with a 1954 production exceeding 1,787 tons of butter and 105 tons of cheese, half of which is exported. Some 2,000 farmers supply this co-operatively owned dairy company.

A milk treatment station, one of the most modern in New Zealand, pasteurising and bottling 2,000,000 gallons of milk and 25,000 gallons of cream annually, washing and filling 13 million pint bottles and 2,000,000 half-print bottles, and supplying 100,000 gallons of milk to schools.

An egg-floor, receiving an average of 750,000 dozen eggs annually to be pulped for export and local consumption, chilled and sold in shell.

Stock saleyards where more livestock is sold annually than at any other centre in New Zealand (50,000 sheep at an annual ewe fair).

A racecourse of 84 acres, with seating accommodation in imposing stands, which, outside the main centres, are easily the best in New Zealand. Many of New Zealand’s famous racehorses have been trained here.

A camping ground recognised among the best appointed and most popular in New Zealand in a park of 51 acres.

Five sawmilling and timber yards, handling the dressing, drying and

Page 20 Modern Manufacturing

[Advertisement]

AERIAL AGRICULTURE LIMITED

AERIAL WORK CONTRACTORS

P. O. BOX 259 PHONE 2840

QUEEN ST., HASTINGS

CONSULT US FOR:

AERIAL TOPDRESSING

Highest quality performance assured by the use of fully experienced pilots and ground staff operating the latest and best aerial top-dressing equipment – Fletcher FU24 and D.H.82 Tiger Aircraft “Airtop” Bulk and Bag Hydraulic Aircraft Loaders.

HORMONE SPRAYING

Last season we sprayed 48% of the total area covered in N.Z. We achieve a very high degree of accuracy in application. For Thistle and Weed Control, we have already sprayed thousands of acres with remarkable success.

CROP DUSTING

We are the first to undertake this in N.Z. Aphis in rape and cut-worm in barley were treated with 100% results.

SEED SOWING

We, uniformly and accurately, at whatever height per acre required, sow new pastures or oversow with clovers. Costs are competitive.

for SEPTEMBER, 1955 Page 21

treating of native timbers (rimu, matai, kahikatea and totara), New Zealand exotics (radiata pine and Douglas fir), Australian hardwoods and American softwoods.

The largest fruit receiving depot in New Zealand, the Apple and Pear Board’s building with an area of handling and dressing, drying and 60,000 sq. feet and cold storage space for 120,000 bushel cases of fruit.

A municipal theatre with a seating capacity of 1,350 and one of the largest stages in the Southern Hemisphere.

Just outside the present borough boundaries are:

Two of the largest freezing works in New Zealand, which kill for export over 100 million pounds annually of the finest lamb and mutton, daily killings during the season exceeding 26,000 lambs. Some 74,000 head of cattle are killed annually for the chiller beef trade.

The Hawke’s Bay Agricultural and Pastoral Society’s Showgrounds, regarded as the most beautiful in New Zealand, with an area of 133 acres. The 1954 Annual Spring Show was the 85th, with an attendance on “People’s Day” of over 30,000.

The Hawke’s Bay and East Coast Aero Club and Aerodrome at Bridge Pa. Founded in 1928 following the visit of Sir Charles Kingsford-Smith, the club now has six aircraft and the aerodrome is also the headquarters of nine aerial topdressing companies and their aircraft and also of the N.Z. Aerial Mapping Company.

Photo captions –

The Tomoana showground of the Hawke’s Bay Agricultural and Pastoral Association cover an area of 133 acres and are regarded as the most beautiful in New Zealand. Picture shows the Waikoko gardens, which form part of the grounds.

View of part of the business area looking south.

Page 22 Modern Manufacturing

[Advertisement]

BAILLIE MOTORS LIMITED

Hawke’s Bay’s Live Sales

and Service Organisation

PROVIDING EFFICIENT TRANSPORT

FOR NEW ZEALAND’S

GREATEST EXPORTING PEOPLE

Ever extending but never large enough. The present headquarters of Baillie Motors Ltd.

THE Sheep Industry is the Dominion’s greatest money earner – over 56 per cent of our Export Income comes from the sheep (wool, £88 millions, frozen lamb, mutton, skins, etc. £48 millions). One eighth of this total (£17 millions) comes to Hawke’s Bay. An additional estimated £4 millions for exports of beef, fruit, canned goods, grass and clover seed, etc., gives Hawke’s Bay’s 98,000 population an export income of £214 per head (compared with £112 per head for the rest of the Dominion). The great Sheep Industry and the other lesser but most important activities call for efficient transport – and plenty of it – for which they can well afford to pay.

Recently we called on Baillie Motors Ltd. a powerful organisation which has built up a unique business with headquarters in Hastings and branches in Napier and Wairoa and representation in Waipukurau. We wanted to find out the reason for this large organisation in a town the size of Hastings. We were given the above revealing facts.

A FAR-SIGHTED FOUNDER

When he set out to enter the business of selling and servicing cars and trucks, Mr. Guy Baillie first embarked on a tour of self-education.

for SEPTEMBER, 1955 Page 23

He travelled the U.S.A., giving special attention to the Assembly Plants, Research Divisions and Proving Grounds of General Motors. Returning to New Zealand at the end of the year (1936) he founded in Hastings the business of Baillie Motors Ltd. as the Hawke’s Bay dealers for General Motors with agencies for Vauxhall-Bedford and Pontiac. No doubt his selection of Hastings followed some research into possibilities with perhaps a study of some figures related to those with which this article opens.

It was a modest beginning; Capital £6,000 and a staff of 9 people. At the outbreak of War in 1939, this had grown to 30, but dwindled to 11 during the national emergency. Today the business is again reaping the benefit of careful planning, wise management and the sound base of research and investigation on which it was originally founded. The staff now numbers 74 and the Registered Capital is £60,000.

LIBERAL OUTLOOK TOWARDS STAFF

The founder attributes the success which has followed his enterprise to the practical application of the golden rule in all dealings both with the public and with his staff. By providing incentives and encouraging key men to accept higher responsibilities, he has gathered around him a happy, efficient team each of whom gives the impression that he or she is personally interested in you – and in the business of Baillie Motors Ltd. You have only to speak to any member of the organisation to understand why the business has grown to take so large a part in the transport of the Dominion’s greatest exporting people.

Photo captions –

Present Baillie Motors Bedford Trucks Division and Engineering Shop. This central three-quarter acre block, corner of Queen and Nelson Streets is the site on which it is proposed to build modern premises to become Baillie Motors Headquarters.

The Wairoa Branch.

Page 24 Modern Manufacturing

[Advertisement]

Interior view of our well-stocked modern store.

ESTABLISHED 62 YEARS

We are Agents for:

Unique Sash Balances

Sandy Louvres

Dexion Slotted Angle

Whirlpool Washing Machines

Motala Stainless Steel Sink Units (Swedish)

Stockists of:

IMPORTED TIMBERS Oregon – Cedar – Keruing – Japanese Oak

NZ TIMBERS Rimu – Matai – Tawa – Rewa Rewa – Radiata Pine

HARDWARE:

Lime, Cement, Steel, Galvanised Iron, Drainpipes, Galvanised Piping, Pinex, Gibraltar Board, Interior Fittings, Wonderheats, Champion Electric Stoves, Tayco Water Boilers, Paints, Netting, Nails, Doors, Plywood, Basins, Baths, Tap Fittings, Corrugated Fibreglass, Glenburn Bricks, etc.

H. H. Campbell & Sons Ltd.

Timber – Glass – Hardware – Oil and Colour Merchants

PHONE 2770 2759 P. O. Box 389

603 KARAMU ROAD HASTINGS

for SEPTEMBER, 1955 Page 25

[Advertisement]

Single Divan Bed with Duncan Rest” Pocket Spring Mattress on Spring Bed Base.

Steel Double-Decker Bunks

The Secret of the most Comfortable Rest in the world – Duncan-Rest Mattress with Spring Bed Base.

Steel Single Bed.

Manufacturers of

DIVAN BEDS

POCKET SPRING MATTRESSES

INNER SPRING MATTRESSES

WIRE MATTRESSES

UPHOLSTERERS SPRINGS SINGLE & DOUBLE CONE

SPRING UNITS

TENSION SPRINGS

TORSION SPRINGS

STEEL BEDS & BUNKS

POCKET SPRING PILLOWS

REPETITION WOOD TURNINGS

Duncan’s FURNITURE MANUFACTURING CO. LTD.

“The Bed People”

TELEPHONES 2849 2819 4203

P.O. Box 143.

405 AVENUE ROAD EAST HASTINGS N.Z.

Pages 26 and 27 Modern Manufacturing for SEPTEMBER 1955

The success story of

MORRISON MOTOR MOWERS

… started in HASTINGS seventeen years ago …

SINCE the early days of Motor Mowers Limited, tens of thousands of New Zealand and Australian lawns have been trimmed and cared for by Morrison Motor Mowers.

As with all successful products, changes have been made from time to time, gradually improving this tremendously popular Motor Mower. When customers reported difficulties, these were smoothed out or eliminated. For instance, long grass and tangled weeds no longer trouble a Morrison owner because an anti-clogging guard has been added. The Morrison now operates smoother and faster with rear rollers running on ball bearings. One hand controls the completely automatic clutch …

…and so the staff of 75 at Motor Mowers Limited, Hastings, keeps progressing rolling forward with after-sales-service matching the quality of the mower itself. Today, there are 450 re-sellers and service agents in New Zealand and a growing number in Australia where Morrison Motor Mowers are selling as fast as they can be made and shipped.

And the Morrison Motor Mower has two sturdy brothers – the new Morrison Motor Scythe and the all-purpose Morrison MK2 Cultivator. Morrison is going ahead … an industry born in Hawke’s Bay, thriving in Hawke’s Bay and employing more and more Hawke’s Bay men and women.

THOUSANDS OF MORRISON MOTOR MOWERS HAVE BEEN SOLD IN NEW ZEALAND & AUSTRALIA.

Photo captions –

Above: the Motor Mower’s modern plant, 1000 Karamu Road, Hastings.

Above: The latest model of the ever – popular Morrison Motor Mower – the lowest priced complete motor mower in New Zealand by pounds and pounds!

Right: The new Morrison Motor Scythe – ideal for cutting long grass – trimming road verges, controlling weeds.

Above: The Morrison Cultivator – a high grade machine powered by a 1 H.P. Villiers engine.

for SEPTEMBER 1955 Page 29

[Advertisement]

19 Years of Progress …

FOWLER, DRUMMOND & WADDELL LTD.

HASTINGS

Makers of Quality Furniture

An aerial view of the factory and yards

Wholesale Suppliers to Most Districts of the North Island

Part of the Assembly Department

OUR LARGE FACTORY IN HASTINGS HAS A STAFF OF OVER 50 SKILLED TRADESMEN AT YOUR SERVICE

Page 30 Modern Manufacturing

NELSONS (N.Z.) LTD.

Tomoana Freezing Works have contributed to the wealth of Hawke’s Bay since 1883

The Tomoana Works is one of the most modern structures of its kinds in the world. Daily capacity of the works is about 13-14,000 sheep and lambs and 500 cattle in addition to other stock.

for SEPTEMBER 1955 Page 31

from modest beginnings …

THE Tomoana Works were started in a very modest way by Messrs. W. Nelson and J. N. Williams in the year 1880 for the manufacture of the Extract of Meat in connection with the “boiling down” of sheep. In the following year, Meat Preserving was added to the industry.

FROZEN MEAT

In 1882 the Colonial World was electrified by the arrival in London on the 14th May of the ship “Dunedin” with the first cargo of frozen meat from New Zealand (consisting of 4,460 carcasses of mutton and 449 carcasses of lamb) and the sale of it at (for those days), fabulous prices, a fact which resulted in freezing works being demanded all over the country. Thus, in the early part of 1883 the Company of Nelson Bros. Ltd., was formed in London with what in those days was a large capital and freezing buildings were commenced at Tomoana in the middle of 1883 to deal with 400 sheep a day – capable of being increased to 800 a day. As showing how little it was realised at that time the big things looming, the Manager (Mr. W. Nelson), was subjected to a good deal of quiet chaff for supposing that even a regular supply of 400 sheep a day would be forthcoming, much less 800. In 1884 the Works shipped during the whole season 41,000 sheep and 10 bullocks. The combined capacity of the Hawke’s Bay Works is now about 13-14,000 sheep and lambs, plus cattle, calves and pigs per day.

In February 1884, freezing was commenced and the following 31st March the first shipment consisting of 9,000 sheep averaging 75 ½ lbs., was made by the sailing ship “Turakina”. In a very short time the freezing capacity was doubled and in 1891 the machinery department was completed re-modelled and the original machines scrapped. The freezing building was also re-modelled and the killing capacity increased to six times its original capacity, which was the position at the First World War period.

FOUR STOREYS

In 1924 the Works were completely rebuilt in reinforced concrete and brick to four storeys and since then further major additions and improvements have been made (upwards of £300,000 since the Second World War), until now it is one of the largest and most modern structures of its kind in the world. This progressive policy has kept the Works capable of processing the increased production of the fertile lands of Hawke’s Bay and continual expenditure is being made to ensure keeping abreast of the latest developments in processing and marketing New Zealand’s primary products.

In the 1930’s when the chilled beef trade commenced, Tomoana was one of the first works to provide facilities and the ship chilled beef in quantity. These facilities are constantly being added to in order to cope with the expansion of this trade.

Tomoana was a pioneer in the development of the numerous by-products of the industry and the “Tomoana” brand of all stock foods and fertilisers is well-known throughout New Zealand.

From its very humble beginning in 1883, Tomoana has grown until in 1955 it provides work for upwards of 1,000 employees with an annual wage pay-out of over half a million pounds and uses in the course of a year, stores and materials such as coal, electricity, timber, lime, packages etc., plus transport by rail and road, amounting to a further £400,000. All this apart from the money distributed in the purchase of all classes of livestock.

Page 32 Modern Manufacturing

[Advertisement]

visit …

The Leopard Brewery

(D. H. NEWBIGIN)

Hastings Street North

HASTINGS

TELEPHONES 4318, 2764 P. O. Box 171

For All Your Requirements

STOCKISTS OF

Export Ale

Pale Ale

Hawk Ale

D. B. Lager

Pilsener Lager

Red Band

Crown

Guinness Stout

Tennent’s Lager

Newbigin’s Stout

And the finest selection of Spirits, Liqueurs and Wines Available

ALWAYS INSIST ON LEOPARD PURITY

SOFT DRINKS

Open Saturdays – 9 a.m. to 12 Noon, 2 p.m. to 5.30 p.m.

for SEPTEMBER 1955 Page 33

[Advertisement]

Representing

ANDERSONS LTD.

ANDREWS & BEAVEN LTD.

ALFALAVAL SEPARATOR CO. LTD.

ARVIKA-VERKEN, SWEDEN

A. M. BISLEY & CO. LTD.

F. T. F. EVANS & CO.

FARM EQUIPMENT CO. LTD.

GALLAGHER ENGINEERING

M. J. HOOPER & CO. LTD.

REID & GRAY LTD.

ROTAVATORS LTD.

BULL & HODGINS LTD.

Heretaunga Street West

PHONES 5223

4160

(Private) 3703 Hastings

2350 Napier

P. O. BOX 137

Agricultural Machinery Merchants

Blacksmiths – Engineers

Page 34 Modern Manufacturing

[Advertisement]

FURNWARE SERVICE

Where Efficient Plant and Careful Management Unite High Quality and Low Price

Production-line methods applied to Woodware have built this flourishing Hastings enterprise, employing over a hundred people. For versatility of plant, large scale operations and value for money. Furnware fills a unique place in New Zealand industry.

FOR THE MANUFACTURER

COMPONENTS OF WOOD

If you use wooden components in the manufacture of your products, we should like to quote you. Following are just a few from our large-scale orders:-

WOODBENDING

for Chair Backs – Wicker Perambulators – Invalid Chairs, etc.

AUTOMATIC LATHE-TURNED ARTICLES

such as Tool or Utensil Handles, Textile Bobbins, Lawn Mower Rollers.

VACUUM CLEANER BRUSH STOCKS, ETC.

FOR THE BUILDER

BOTH TRADE AND AMATEUR

KITCHEN UNITS

Fully assembled

Time Saving

All Units Match up for Size

Competitive Prices

Delivery within 4 weeks

We have supplied Kitchen Joinery for a vast number of State Houses and Private Homes, including the largest private housing contract completed in New Zealand (600 homes). Of highest quality, built

to rigid standards, of selected timbers and highly-skilled workmanship. We illustrate some of our 17 different units.

LETTER BOX

SHAVING CABINET (19)

CORNER SHELF (16)

HOT WATER CUPBOARD

SAFE

SINK BENCH (1)

DRESSER UNIT (4)

WALL CUPBOARDS DOUBLE DOOR (8)

SINGLE DOOR (12)

BIN UNIT (15)

for SEPTEMBER 1955 Page 35

[Advertisement]

High-precision Woodware Components, Fully-assembled Kitchen Units,

School and Household Furniture sent all over New Zealand

FOR SCHOOLS AND LARGE OFFICES

We enjoy a large volume of work on behalf of Education Boards and Schools. Large quantities of School Furniture leave our plant regularly. School Desks and Chairs are a specialty. We also supply a limited quantity of school gymnasium equipment, such as vaulting boxes, spring boards, wall-bars, balancing benches, etc.

TUBULAR STEEL SCHOOL FURNITURE: We have recently installed plant for the manufacture of Tubular Steel School Furniture including “bonderising” metal treatment before painting.

OFFICE DESKS are being turned out in quantity for Government Departments, large enterprises, etc., in a wide range of sizes and prices. These are all to standard specifications.

Furnware Douglas Office Chair

FOR THE WHOLESALER

AND LARGE RETAILER

WOODEN TOYS such as seaside spades, skipping rope handles, junior cricket bats, etc.

KITCHEN CHAIRS, STOOLS, TABLES, etc.

BABY CHAIRS of all kinds, OCCASIONAL TABLES.

FUNERAL CASKETS.

“Would we make it?” If it’s wooden, we would.

Furnware Wheelback Chair

AN INVITATION

You are cordially invited to visit us when you are in Hastings. Our Modern Factory in Queen Street West houses a most up-to-date Woodware plant and we should be glad for you to inspect this. At the same time, you will be able to judge the quality of workmanship and materials in our productions.

IF YOU USE MACHINE WOODWARE LET US QUOTE YOU.

FURNWARE

FURNITURE & WOODWARE LTD.

416 QUEEN STREET WEST – HASTINGS

Box 1 Telephone 3509

Page 36 Modern Manufacturing

[Advertisement]

Authorised Hawkes Bay Dealers

for

International Harvester Coy.

Sole Distributors of:

INTERNATIONAL – Motor Trucks, Wheel and Crawler Tractors and Farm Machinery

UP-TO-DATE SERVICE AND SPARE PARTS FACILITIES, QUALIFIED AND EXPERIENCED I.H.C. TRAINED MECHANICS

TRAVEL AGENTS: LAND – SEA – AIR

INSURANCE

VICTORIA INSURANCE COY., FIRE & ACCIDENT

NATIONAL MUTUAL LIFE ASSOCIATION

Agencies include:

WOLSELEY SHEEP SHEARING MACHINERY

WOLSELEY ELECTRIC FENCES

BUZACOTT ROTATING SPRAY DIPS

CHAFFEY’S REVOLVING DOCKERS

“WEEDONE” HORMONE SPRAYS AND MACHINERY

QUIBELLS SHEEPDIPS

GRAIN, SEED AND PRODUCE MERCHANTS

WOOL AND STOCK AUCTIONEERS

Dalgety

AND COMPANY LIMITED HASTINGS

(Incorporated in England)

for SEPTEMBER 1955 Page 37

[Advertisement]

OUR MODERN FACTORY

… An interior view of our Modern Tye Retreading Factory in Hastings. Machinery used is the most modern available from the famous American LODI Retreaders.

An enviable reputation for first class workmanship is enjoyed right throughout the district and tyres are sent in for attention from the furthest points of Hawke’s Bay.

Service

Country Clients receive the benefit of our 24-hour service and Tyres are loaned while Retreading is being done.

THE HAWKES BAY

TYRE & RUBBER CO. (Limited)

for SEPTEMBER 1955 Page 39

[Advertisement]

INDUSTRIAL AND AUTOMOTIVE

ELECTRICAL SERVICE

WE REPAIR MOTORS

ALL SIZES

WE REWIND ARMATURES

STATORS – ROTORS

PROMPT MAGNETO

REPAIR SERVICE

AUTOMOTIVE ELECTRICIANS

JOHN HILL LTD.

(Established 1927)

ELECTRICAL ENGINEERS

Phones: 2116, 2339 MARKET STREET – HASTINGS Phones: 2116, 2339

Page 40 Modern Manufacturing

[Advertisement]

HASTINGS

Implement Sales & Service Ltd.

FIRST-CLASS EQUIPMENT

EXPERT WORKMANSHIP

ROUND-THE-CLOCK SERVICE

In Five Years our business has shown remarkable growth.

This is where we started five years ago.

Implement Sales and Service Premises in Hastings.

AGENTS FOR: Boothmac Farm Machinery and Pumping Equipment Perma-build Pre-fabrications Moffat Virtue Shearings Plants and Spraying Equipment Waldor Glass Houses Atom Tractors Mono Pumps

for SEPTEMBER 1955 Page 41

[Advertisement]

HUME INDUSTRIES (N.Z.) LTD.

A recent aerial photo of the Hastings factory.

Nationally known for

CONCRETE

PIPES ANS PRODUCTS

STEEL

PIPES AND FABRICATION

EARTHENWARE

PIPES AND FITTINGS

SUPPLIERS TO MANY GOVERNMENT DEPARTMENTS AND LOCAL BODIES

HUME INDUSTRIES (N.Z.) LTD.

CAROLINE ROAD HASTINGS PHONE 2670

Page 42

J. WATTIE CANNERIES LIMITED

The Heretaunga Plains, of which Hastings is the natural centre, are New Zealand’s most important horticultural district. That part of the plains associated with the growth of fruit and vegetables covers approximately 7,000 acres, with an undefined but immense area for further expansion. Best known name in the industry based on the growing and canning of the fruit and vegetables raised in this rich district is that of J. Wattie Canneries Limited.

FOR many years fruit in the Hastings district, growing under ideal conditions, was produced in sch abundance that it was far in excess of demand. The orchardist was gaining reward for his efforts, but grew dangerously complacent about the colossal waste which results from over-production and limitation of markets.

None was more conscious of the waste of excellent fruit than Mr. J. Wattie, who for some considerable time had realised the loss and prospective loss of surplus fruit. In his capacity as manager of Hawke’s Bay Fruitgrowers’ Ltd., a packing industry, Mr. Wattie had given considerable thought to the means of creating a market for processed fruits.

He discussed with friends the prospects of pulping fruit for jam making. Soon he was able to attract the practical assistance of a few small investors, and it was from this small beginning that the prospect of canning was seriously considered.

The original Company was registered in 1934 with a capital of £1,250, subscribed by 28 members. The premises were leased from the Hawke’s Bay Fruitgrowers’ Ltd. for a period of five years, and the purpose of the Company was the pulping of fruit for jam makers, and the first order being 81 tons of fruit pulp. During this momentous year in the Company’s history, some experimental canning operations were carried out with improvised plant, which was replaced in the fruit season of 1935 by what was then standard canning equipment purchased in Australia by Mr. Wattie.

QUALITY

Originally designed for the handling of peaches and pears, this machinery did not preclude the hand peeling and coring of fruit, as well as the hand halving and stoning of peaches, and not the least laborious method, the hand packing of each can.

In the first season there were 25 on the payroll, and the factory was a modest little establishment in a building which has been remodelled, part of which is now the First Aid centre. The variety of canned peaches was Golden Queen, which to this day has proved outstanding in quality.

As a result, subscribers were found with sufficient support to increase the capital to £10,000 by June 1935. Coincident with this increase the leased premises were purchased, and a policy of expansion, with a basis of increased efficiency and high quality was established.

CRISIS

In 1936 there developed a crisis which strained the Company’s resources to the limit. The gale in February and the frost in October of that year had the most devastating effect on production. It was 26 years since the area had experienced such a frost. The peach crop was wiped out and only 10 per cent of the pear crop remained.

The Directors actually faced the question of closing down. By approaching the Company’s distributors however, on the market for canned tomatoes, they in turn contacted the merchants and assured the Company it was well worth attempting. Contracts were let for 250 tons, and the whole pack was sold.

In his report to shareholders at the third annual meeting of the Company in September, 1937, Mr. Wattie said that the Company possessed as up-to-date a plant as any in Australasia, with a capacity of 26,000 cans per 8-hour day. He was undaunted by the previous season’s catastrophe, as the whole pack of the peaches, pears, tomatoes and peas for the coming season was tentatively sold. He was convinced that though production was in the hands of the elements, the supplies that would be available in a few years, given reasonable weather conditions, would make the factory the premier canning concern in the Dominion.

ASPARAGUS

Still another prophetic development had its dramatic results. Work of a pioneering nature had produced small packs of peas and asparagus which had been enthusiastically received. Peas necessitated the installation of special machinery, and this plant was soon obtained.

As opposed to the imported bleached type of canned asparagus, the Company processed this commodity green, and though nervous about its reception at first, it was soon evident that the market for this variety would be one of the most successful on the Company’s record. Extensive plantings were undertaken that year by Asparagus Ltd., and together with other contractors, production followed which established this commodity as a major line.

During the war new problems were faced by the Company and in every way met. New installations included the establishment of a Government dehydration plant later to be purchased by the Company – and together with other new machinery this

The Hastings laboratory, where all products are tested for the maintenance of quality and food values.

Page 43

quickly enabled the factory to reach a productive capacity which exceeded that of any other cannery in the country.

In 1951 the Company decided to establish a factory in Gisborne, the centre of a district particularly well suited for the production of sweet corn and peas, with additional prospects because of exceptionally good soil and climatic conditions for extensive production of fruits and vegetables. Indeed, some authorities predict a production value in Gisborne as great as or even greater than that of Hawke’s Bay.

A valuable site was acquired from the Gisborne Sheepfarmers’ Frozen Meat and Mercantile Co. Ltd., together with a leasehold property from the Gisborne Harbour Board. A short time later the property of Clare and Clare, adjacent to the main factory building was purchased. The complete area covers approximately 6 ½ acres, and is situated by the waterfront, with its own rail siding adjoining the coastal harbour facilities.

In 1950, Gordon Wattie and Ray Wattie, sons of the Managing Director, travelled extensively in the United Kingdom and U.S.A., in order to study production methods. Their experiences included several months of practical work under the normal conditions of employment in similar factories. Mr. Gordon is now Managing Director at Gisborne, and Mr. Ray is Manager of the Hastings factory.

HOW PEAS ARE CANNED

An outline of the processes that take place between the cropping of peas and the canning.

WHEN the field supervisor decides that peas are in the correct stage of maturity for canning, the harvesting team with mobile harvesters moves on to the field. These machine gather the growing vines as they travel along, threshing the peas and delivering them into boxes for transport to the cannery, spreading the vines on the ground for ploughing in, thus enriching the soil by returning the nitrogen.

In the 1953-54 pea season, J. Wattie Canneries Ltd. owned and operated the largest fleet of these mobile pea harvesters in the world.

CLEANING

The peas are fed through a winnower and then through a water flotation machine to remove extraneous material and over-ripe peas. Rod reel washers then apply high pressure water sprays while the reels rotate.

The peas are then automatically pumped to the factory canning lines, at the head of which are the first inspection belts where members of the staff are skilled in discarding peas not up to standard as they pass along.

BLANCHING

Peas then pass through the blancher, where they are carried through hot water at a controlled temperature. Among the reasons for blanching is shrinkage by expulsion of gases contained in the plant cells. This helps to obtain a high vacuum in the finished product, together with the proper fill of the cans. After blanching, the peas pass over another inspection belt and are then elevated to the hoppers on the filling machines. These machines fill a predetermined weight of peas and boiling brine to each can, thus ensuring the exclusion of air.

HEAT PROCESSING

The cans are then mechanically conveyed to the closing machine, which double seams the tops. They are now ready for heat processing, which involves exposure of the sealed container to steam under pressure for a correct period of time. The aim is to ensure complete sterilisation which is carried out in large automatic pressure cookers.

In these the cans are conveyed through a steam pressure chamber for a set period of time, and then on into a cooling section where they are subjected to cold water sprays. The cans leave the pressure cooker cooled down to 90 degrees F., and as they are still wet with cooling water they automatically pass through an air blast drier, leaving them in a suitable condition for labelling.

The labelling machine is connected behind the can drier so that cans run continuously on through the labeller and into the automatic case packing machines. All that remains now is the lidding and wiring of cases or the glueing of cartons, which is carried out by the latest mechanical operations.

Photo captions –

Harvesting a crop of tomatoes.

Directors (left to right) : A. I. Rainbow, H. G. Carr, J. Wattie, J. E. Clapcott (secretary), A. E. Redgrave, G. J. Wattie.

The cafeteria at the Hastings factory.

Page 44 Modern Manufacturing

[Advertisement]

de PELICHET McLEOD & CO. LTD.

Head Office: HASTINGS – P. O. Box 205 – Phone 3561

Branches at

WAIPUKURAU, P. O. Box 100 – GISBORNE, P. O. Box 201 – NAPIER, P. O. Box 22, Ahuriri.

STOCK AND STATION AGENTS

WHOLESALE MERCHANTS

PRODUCE MERCHANTS

FARMING MACHINERY

SHIPPING AGENTS

WINE AND SPIRIT MERCHANTS

GRAINS, SEEDS, SEED CLEANING

WATER SYSTEMS, SHEARING PLANTS

INSURANCE AGENTS

WOOL BROKERS

New Zealand Representatives for

DESOUTTER BROS. LTD. LONDON

Manufacturers of

PNEUMATIC & ELECTRIC PORTABLE TOOLS

DRILLS

SPANNERS

SHEARS

SCREWDRIVERS

GRINDERS

TAPPERS

NIBBLERS

MORE THAN 70 TYPES OF MACHINES IN STOCK

RESELLERS ESTABLISHED THROUGHOUT NEW ZEALAND – ASK US FOR THE NAME OF YOUR LOCAL SOURCE OF SUPPLY

de PELICHET McLEOD & CO. LTD.

HASTINGS

for SEPTEMBER, 1955 Page 45

[Advertisement]

EVER SINCE 1907 VIDAL’S

HAVE FLOURISHED

IN THE HAWKE’S BAY

SUNSHINE

VIDAL’S vineyards were first established in the ideal Hawke’s Bay climate before 1907, but from that year dates the actual establishing in the province of an enterprise that has done so much to put Hastings on the map as a wine-growing centre.

Today VIDAL’S wines, which have won several gold medals for excellence, are known throughout the length and breadth of New Zealand for their reliability and first-class quality – for a bouquet and a flavour that that drawn enthusiastic comment from connoisseurs both here and overseas.

Sherries, Port, Burgundy, Claret, Madeira, Hock – all these fine wines are vinted by Vidal’s and available from Hotels and Bottle Stores throughout New Zealand.

Vidal’s

wines

TRUE CONTINENTAL FLAVOUR

Page 46 Modern Manufacturing

HASTINGS BRANCH

of Williams & Kettle Ltd.

“A Modern Service to Farmers in a High-producing District”

Hawke’s Bay is responsible for a considerable proportion of this country’s prosperity; it is a signi[…] show the quantities of wool sold by auction in Napier than at any other centre. The following figures show the quantities of wool sold at auction at individual centres in New Zealand for the season 1953-54:

NAPIER 164,322 bales

Auckland 149,436 bales

Wanganui 106,889 bales

Wellington 130,762 bales

Christchurch 134,487 bales

Timaru 63,083 bales

Dunedin 137,743 bales

Invercargill 116,177 bales

WOOL A MAJOR ACTIVITY