Firing pottery the anagama way

Anagama in Japanese, means hole in the hillside. Eight hundred years ago the Japanese were firing pottery using these anagamakilns [anagama kilns], and are still doing so today but, fewer and fewer are being used.

Kamaka potters, Estelle and Bruce Martin have an anagamakiln [anagama kiln], not in the hillside but dug into the ground, and have just finished their second firing. Mr Fujii, world renowned potter from Himaji in Japan, has been working with the Martins and given very valuable assistance and advice with this last firing.

The kiln, which holds 1500 pots (3-4 months’ work) burns wood which is fed continuously into the oven, giving temperatures of 1350 a centigrade, thus firing the pots, and the wood ash puts on the glaze simultaneously. The kiln is loaded, then covered with an arch of firebricks, which is in turn covered with an insulating blanket and finally it is covered and sealed with straw-packed clay.

The loading takes nine days, the firing another ten, and then the very careful cooling, which gives the glazing the colour, another ten days. Not a method for the impatient.

At the opening of the kiln on Sunday, June 12, an interested group gathered, including Sir Richard and Lady Margaret Harrison. Mr Fujii gave the history of the anagama method, and we learned that one has to be a dedicated potter to use it, because 30/40 per cent of the results are imperfect. Therefore as it is not the most economical method of firing pots, many Japanese potters have stopped using it. It is however, the most challenging and rewarding method from the creative aspect, and Mr Fujii hopes that New Zealand will continue to have anagama kilns, and asked for people to support the Martins whenever they fire in this way.

Many people helped with the firing, the oven needing to be stoked round the clock, and turns were taken with the night shift for the ten day and night period.

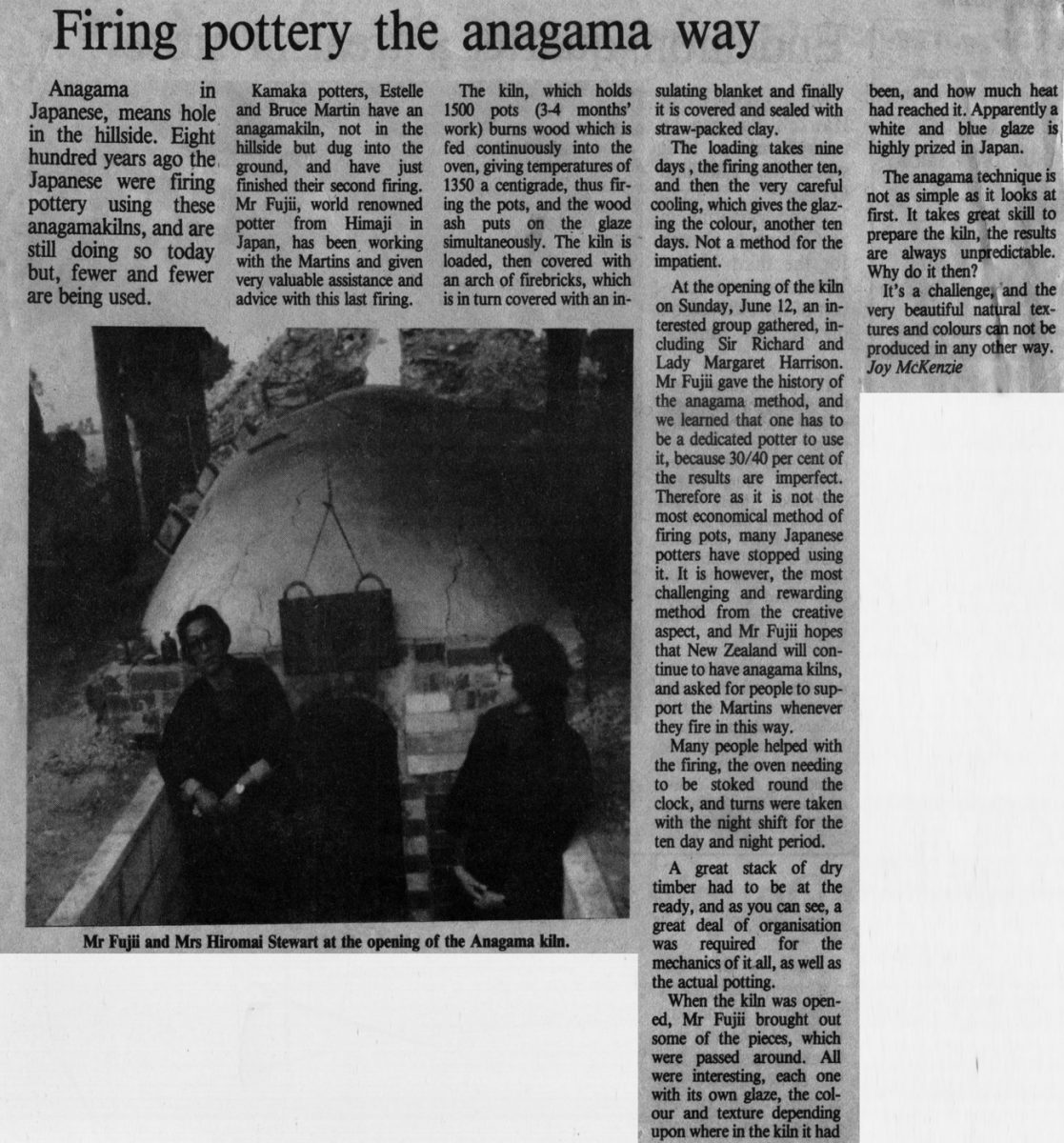

A great stack of dry timber had to be at the ready, and as you can see, a great deal of organisation was required for the mechanics of it all, as well as the actual potting.

When the kiln was opened, Mr Fujii brought out some of the pieces, which were passed around. All were interesting, each one with its own glaze, the colour and texture depending upon where in the kiln it had been, and how much heat had reached it. Apparently a white and blue glaze is highly prized in Japan.

The anagama technique is not as simple as it looks at first. It takes great skill to prepare the kiln, the results are always unpredictable. Why do it then?

It’s a challenge, and the very beautiful natural textures and colours can not be produced in any other way.

Joy McKenzie

Photo caption – Mr Fujii and Mrs Hiromai Stewart at the opening of the Anagama kiln.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.