- Home

- Collections

- JENKINSON EB

- Whakatu Freezing Works

- Newspaper Supplement 1976 - Whakatu Works Feature

Newspaper Supplement 1976 – Whakatu Works Feature

The Daily Telegraph

THE HAWKE’S BAY FARMERS MEAT CO., LTD.

Friday, January 30, 1976

WHAKATU WORKS FEATURE

$11m complex meeting future needs

The Hawke’s Bay Farmers’ Meat Co Ltd has placed Whakatu more conspicuously on the map, thanks to a multi-million-dollar building an [and] a mammoth spread of concrete.

The project is a complex comprising freezer and storage capacity to accommodate the company’s ever-increasing lamb and mutton tally. Buildings and plant are ready for use.

The complex was opened today by the Minister of Agriculture, Mr MacIntyre.

The entire concept conforms to the standards of hygiene and efficiency required by the frozen meat industry at international level. This has involved the company in the expenditure of $10,750,000.

Milestone

The construction of the freezing and storage complex has meant building 10 new blast freeze rooms and three freezer stores, each more than 900,000 cubic feet in content.

The project is the most momentous milestone in the company’s 63-year-old history.

“It is not intended that the completion of the new complex will increase the daily kill,” said the general manager, Mr I. D. Cameron.

The company is currently awaiting a decision from the Minister of Agriculture and Fisheries on an application to establish a new works at Takapau.

“Any increase that will take place will come at the new works,” said Mr Cameron.

The company was formed in 1912 with an initial capital of $50,300 and the works cost $60,300. Today the capital is $5 million and the assets exceed $22 million.

In its opening season, 1914-1915, the works killed 123,900 sheep and lambs and 3190 head of cattle. It took 45 years for the first million sheep and lambs to be killed in a season and the tally was 1,056,668 in 1958-1959.

However, it took only a further 11 years to double this figure, and in 1969-1970 a record 2,147,527 sheep and lambs were killed.

Started in the uneasy economic climate of the years preceding the 1914-1918 World War, the company was established to operate as a meat processing works and to provide these facilities for the farmers of Hawke’s Bay.

The company has always endeavoured to fill this role by keeping its plant and equipment to the standards needed to satisfy its overseas clients and veterinary authorities. The completion of the latest project is a further stage in the implementation of this policy.

Replacements

Early in 1972 the company was faced with a need to replace some aged blast freezers and cold stores. This was influenced by the Ministry of Agriculture and Fisheries requirements to meet demands being made by the EEC countries. This included the fact that wood must, before long, be completely removed from refrigerated areas.

In the light of the difficulties of rebuilding existing sections of the works while production still continued the company made a bold decision.

This was to build a bridge over the road and the main Wellington-Gisborne rail-way and build new facilities on a property already owned by the company.

Throughout 1972 planning for the project continued and the financial arrangements were concluded.

Work started in November and to clear the site a double-storeyed house was moved. Then followed the removal of 16,000 yards of topsoil and backfilling with thousands of yards of compacted river shingle.

Mr Cameron said that a tribute is due to the main contractor, J. C. Mackersey Ltd, Hastings, who has completed this tremendous programme in a little under three years.

Major items in the new complex include:

– Marshalling floor for carcase mutton and lamb, fully air conditioned and capable of holding 8000 lambs.

– Ten blast freeze rooms each capable of freezing 2000 lambs in 14 hours.

– Three freezer stores each nearly 1 million cubic feet.

– Passageways for conveyers, staff and fork lift movement.

– A completely enclosed loading out platform and railway siding capable of holding 14 insulated railway wagons or 24 shipping containers.

– An electrical switch-room and refrigeration plant room.

– Staff amenities and office block.

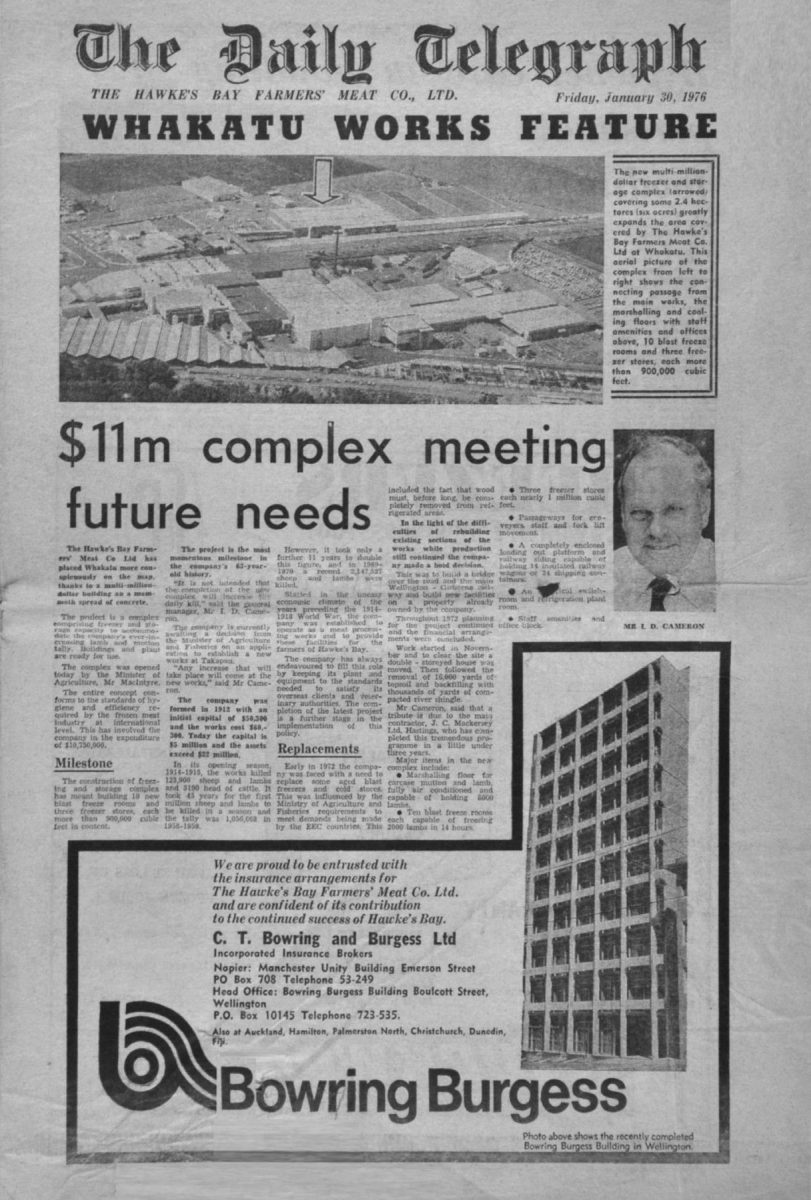

Photo caption – The new multi-million-dollar freezer and storage complex (arrowed) covering some 2.4 hectares (six acres) greatly expands the area covered by The Hawke’s Bay Farmers Meat Co. Ltd at Whakatu. This aerial picture of the complex from left to right shows the connecting passage from the main works, the marshalling and cooling floors with staff amenities and offices above, 10 blast freeze rooms and three freezer stores, each more than 900,000 cubic feet.

Photo caption – MR I. D. CAMERON

[Advertisement]

We are proud to be entrusted with the insurance arrangements for The Hawke’s Bay Farmers’ Meat Co. Ltd and are confident of its contribution to the continued success of Hawke’s Bay.

C.T. Bowring and Burgess Ltd

Incorporated Insurance Brokers

Napier: Manchester Unity Building Emerson Street

PO Box 708 Telephone 53-249

Head Office: Bowring Burgess Building Boulcott Street, Wellington

P.O. Box 10145 Telephone 723-535.

Also at Auckland, Hamilton, Palmerston North, Christchurch, Dunedin, Fiji.

Page 2

Hygiene, care in handling of perishable foodstuffs

With its covered area of 5.684 acres the new Hawke’s Bay Farmers’ Meat Co. complex houses a number of innovations to meet the stringent requirements laid down by the Ministry of Agriculture and Fisheries.

Today’s emphasis placed upon hygiene and care in the handling of perishable foodstuffs such as those produced in a major freezing works makes the standards acceptable in a bygone age seem elementary and crude by comparison.

Even a casual glance at the interior of the company’s old wooden constructed freezer, it would seem, leads one to conclude the existing plant has done well indeed to keep pace with the progress made in servicing the province’s fat sheep and export lamb industry and in the preparation of beef cattle exports.

The Whakatu works leads the way in throughput figures, for in the last export season, for example, the sheep and lamb kill totalled 2,076,243 and the cattle kill 68,133 head. In the season before last the figures were not far behind – sheep and lambs 1,991,359 carcases, beef 61,626 bodies.

LOGICAL MOVE

The company directors were ever mindful of the need for change in updating the plant and facilities, so that in 1972 when the move was made, the decision to build a comprehensive freezer complex to replace the freezers and stores centrally situated in the works seemed logical.

The decision to rebuild was in line with the industry’s search for new and more hygienic ways to handle frozen meat in carcase and carton form.

The complex is virtually an oversize “fridg”. It is described as a forklift pallet store.

But what intrigues the visitor is the conveyor system that brings the carcases from the killing floors through the overhead tunnel above the roadway and railway lines into the complex.

There seem to be miles of this smooth working conveyor system, which grades and segregates the lambs.

BLAST FREEZERS

The store is arranged for loading in at one end and loading out at the other. Graded and segregated correctly, the carcases travel in an air conditioned temperature safely sustainable for 25 hours. They are admitted to the blast freezers of the degambrelling area, where they are placed in steel pallets. Forklifts take the pallets, full, into the store.

Forklifts take the pellets [pallets] to the loading – out platform. The carcases are packed into the containers on special railwagons. These are moved by a company tractor, fitted with a catalytic – type exhaust to prevent the contamination of the load-out area.

Photo caption – Linking the new complex with the main works is the raised connecting passage or “life-line”, as one works employee termed it. From the killing floor the carcases are funnelled on to two conveyor rails inside the air-conditioned passage and travel about 1.6km (one mile) to the marshalling floor.

Page 3

[Advertisement]

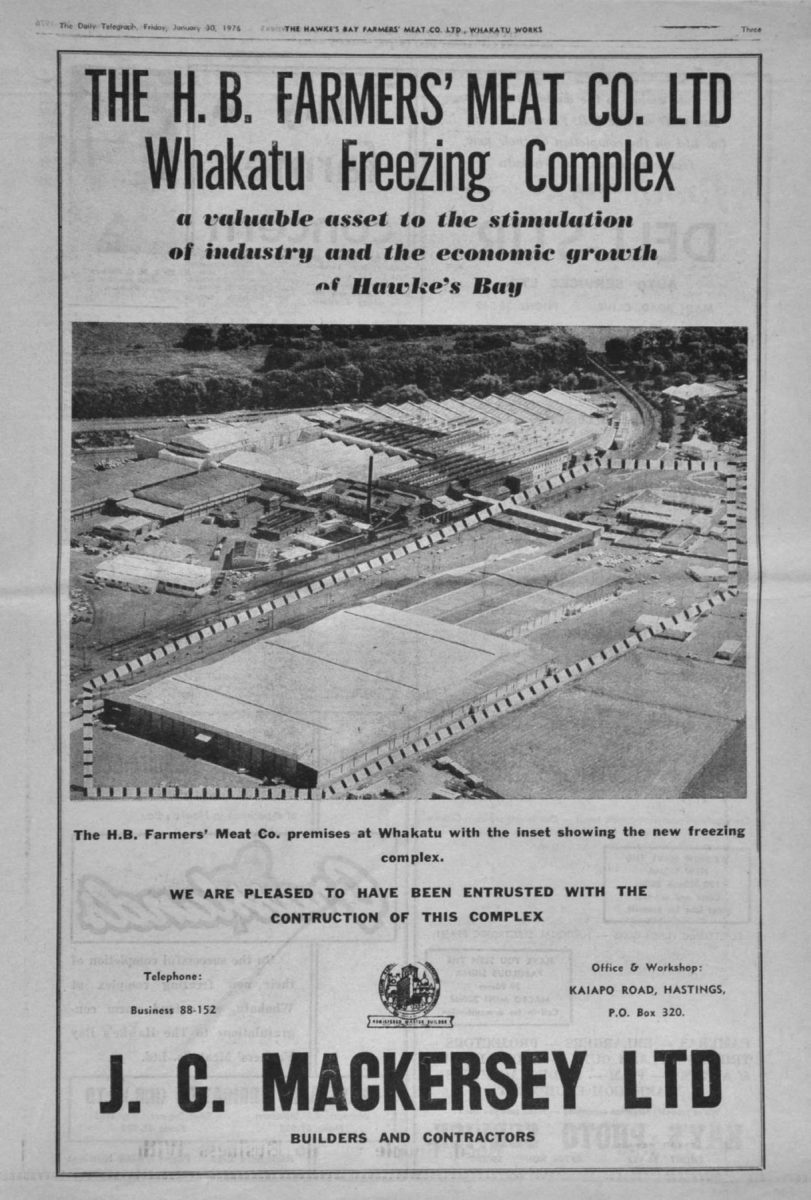

THE H.B. FARMERS’ MEAT CO. LTD

Whakatu Freezing Complex

a valuable asset to the stimulation of industry and the economic growth of Hawke’s Bay

The H.B. Farmers’ Meat Co. premises at Whakatu with the inset showing the new freezing complex.

WE ARE PLEASED TO HAVE BEEN ENTRUSTED WITH THE CONSTRUCTION OF THIS COMPLEX

Telephone:

Business 88-152

Office & Workshop:

KAIAPO ROAD, HASTINGS

P.O. Box 320.

J. C. MACKERSEY LTD

BUILDERS AND CONTRACTORS

Page 4

Model design

The economy of New Zealand still depends on the export earnings of agriculture. Exports from other sectors can only supplement agriculture, although the increasing contribution of manufacturing, forestry, and tourism ensures a healthier total national economy, says the Minister of Agriculture, Mr MacIntyre, in a special message on the opening of the new Whakatu complex.

Even last season, 1974-1975, in spite of a sharp decline in both meat and wool prices, agricultural exports earned 78 per cent of our overseas exchange – $1291 million out of a total $1658 million.

For the previous four seasons the figure averaged just over 85 per cent.

We start to get things in their proper perspective when we look at the figures in detail – agricultural exports $1291 million; timber, wood products, pulp and paper $146 million; manufactured goods $180 million.

Without wishing to minimise the very important part other industries play, and acknowledging that a broadened secondary industrial base is essential, it is a most salutary experience to ponder the utter dependence of New Zealand on its agricultural industry.

In spite of challenging developments in other sectors, agriculture continues to maintain its overwhelming predominance. Moreover, much of the secondary industrial development depends, and will continue to depend, for its establishment and continued growth on the earnings of agriculture.

Meat processing, including freezing, is our largest manufacturing industry and extends deeply into the realm of distribution. Yet it is often regarded purely as a farming industry.

Another distinction which is often overlooked is that agriculture in New Zealand has always been export orientated. In contrast, many other sectors produce for the local market and export only whatever product can be placed on markets developed aboard.

The sheer weight of the agricultural contribution justifies the need for a continued rate of expansion, and the Government is giving priority, within the framework of the national economy, to policies designed to stimulate investment in farming and to encourage expansion.

New Zealand has a reputation for producing high quality products to meet international standards. Our primary products compete successfully on world markets because they offer quality at competitive prices.

But we are not the only primary producers who are meeting these quality standards, and we must do everything possible to stay ahead.

The cost of maintaining our position is enormous, as the new freezer and storage complex of the Hawke’s Bay Farmers’ Meat Co. illustrates. But it is a cost that has to be met if we are to ensure the entry of our meat products, not only to the established and traditional markets, but also to the many new ones that are opening up.

I extend my warmest congratulations to the directors of the company for their foresight and their business acumen in going ahead with this new complex.

It can be considered a model design for the meat processing industry in New Zealand and places Whakatu in the forefront of North Island freezing works.

Photo caption – Mr MacIntyre… who today opened the new complex at Whakatu.

[Advertisement]

for all

ELECTRICAL CONTRACTS

large and small consult

JOHN CROOK & CO. LTD

ELECTRICAL CONTRACTORS

918 SOUTHLAND ROAD, HASTINGS

PHONE 84-417 P.O. BOX 1063.

[Advertisement]

CONGRATULATIONS TO THE H.B. FARMERS. MEAT CO. LTD ON THE COMPLETION OF THE NEW FREEZING COMPLEX AT WHAKATU

from the

KAIAPO CONCRETE PUMPING LTD

HASTINGS – TELEPHONE 88-152

Page 5

HOW WHAKATU COPED DURING SLUMP YEARS

No record of the Hawke’s Bay Farmers’ Meat Co. would be complete without reference to the fate of Whakatu in the slump years.

The cost factor loomed large during this period. The cost of killing and freezing a carcase rose from 28.27d in 1935-36 to 39.91d in 1937-38. This represented a total increase of 22,000 pounds in two years.

By the outbreak of the Second World War the company was able to cope, thanks largely to the extra storage that had been provided. The entry into the chilled beef trade was a forward step.

KILL DOUBLED

In 10 years the sheep kill had been almost doubled. There were losses during the depression years, but the company was strong enough to withstand losses over a succession of seasons.

Hawke’s Bay historian T. K. Fallwell records the company was able to declare a dividend each year, to place appreciable sums to reserves and, with one exception, to continue the payment of rebates.

Fallwell’s history of the frozen meat industry in Hawke’s Bay deals only with the early period, ending with the outbreak of the Second World War in 1939. But his summary, as well as being authoritative, seems to set the pattern for the company’s development up to the present. He comments a significant reason for the company’s promotion was the farmers’ desire to have the opportunity of killing and shipping on consignment.

“By becoming an exporter himself,” Fallwell says, “the farmer hoped to eliminate the profits of the middle man – whom he felt was exploiting him – and to obtain what he believed to be the true value of his stock. The directors have recognised this need right from the inception of the company; indeed, they have encouraged this practice, for it fitted in neatly with the company’s non-buying policy.

“It has been important,” Fallwell adds, “that the farmer should have the opportunity of consigning his own stock, for it has enabled him to test the London market for himself. Moreover, while this avenue remains open to the farmer, there is little chance of meat exporters establishing a ‘price ring’.”

SOLID MEN

Fallwell strikes the right note when he mentions that the company’s success was in some measure due to sound management and efficient service. With three exceptions, Cranby, Stratton and Ebbett, the company’s directors until 1939, he says, were practical farmers “solid men with an abundance of common sense, and keenly aware of both the producers’ and the company’s needs”.

It took the company a quarter of a century to compete on equal terms with its rivals. At the end of that period the company was handling at least one-third of the province’s exportable fat stock.

Fallwell’s final comment is that the Hawke’s Bay Farmers’ Meat Co, to a large extent, preserved its original character. It had managed without the importation of “outside” capital which alone had saved a number of farmer-owned co-operatives.

The company had played an important role in the development of the province’s farming industry since 1912. Its success and its influence had more than justified the labours of its founders, for even the most optimistic of its promoters could scarcely have visualised that in time it would become “one of the soundest and best administered concerns of its class in the Dominion”.

In 1975 there would be general endorsement of this comment. Details of the company’s landmarks in progress are printed under a separate heading. The increase in the kill is the most eloquent testimonial of all. In the record season 1969-70, for instance, the sheep kill totalled 2,147,672. Two seasons later the company had a record cattle kill of 81,651 head.

KILLING METHODS

The original method of killing at Whakatu was under the old system of solo butchering, but progress demanded change as the years passed. The next significant change in killing methods came in 1964 when the works discontinued the old bed dressing system for cattle and changed to the present rail system.

At this time beef was exported in quarters and the company began a gradual conversion to boning and primal cutting, the method now in use.

To cater for all this activity the company built a new beef boning building and plant in 1969, the first of its kind in New Zealand for this particular purpose. It also started a rebuilding programme of freezer stores which featured high-level stores and pallet handling.

This was the forerunner of the present project which has more than doubled the available amount of space and involved the use of steel-framed self-supporting pallets.

Page 6

PROVISIONAL DIRECTORS’ EARLY TRIALS

The first definite step towards the establishment of a farmers’ freezing works in Hawke’s Bay was a meeting called by Central Hawke’s Bay personality, Mr J. D. Canning, on July 2, 1912, in the social hall of the Waipukurau Public Library.

The attendance included 50 interested farmers. A committee was appointed to gather information. Mr G. E. Merriken addressed the meeting.

This committee appears to have been a very active one. It met frequently, and among major decisions was, on the motion of Mr Canning and Mr J. D. Todd, that “the proposed company be a non-buying concern.” This was subsequently incorporated in the company’s articles of association.

The account by the Hawke’s Bay historian, T. K. Fallwell, of the step-by-tep [step] development of the proposed company can not be traced in detail here. There were moves to “marry” into established meat companies, for the promoters’ greatest need was capital.

Negotiations with the Wellington Meat Company (owners of the Waingawa works, near Masterton) broke down. Fallwell comments that this was a blessing in disguise.

We next read of the appointment of provisional directors in September 1912.

They were J. D. Canning, T. E. Whelch [Welch], A. C. Prentice, J. O’Neill, J. C. Parker, J. D. Todd and G. E Merriken.

SUPPORT SOUGHT

Meantime, of course, there had been much canvassing for financial support. One who refused financial support but offered 200 acres as a site for the freezing works, was S. Johnstone, of “Oruawharo”, Takapau.

One who succeeded as a canvasser was M. J. Corrigan, “an Irishman of genial manner and rich brogue who had kissed the Blarney Stone seven times over”.

According to Fallwell, the support promised in the Hatuma and Otane districts was considerable. One mentions the point because in these districts there was strong pressure to have the proposed works sited at Waipukurau, or at least in the district.

The provisional directors decided to enlist the support of the wealthier landowners. People like J. B. A’Deane, Ashcott, were quite definite in their refusal. Mr A’Deane intimated he had no faith in the success of another works in the province, for Nelsons were established and flourishing.

The provisional directors had been busy with the selection and purchase of a property suitable for the works. A site at Whakatu of seven acres and an adjoining paddock of 6¾ acres, known as Tuckers, were eventually purchased.

The time came for the statutory meeting to appoint directors, all other formalities having been attended to. The articles made provision for nine directors. There were eight nominations, Messrs Canning, Whelch [Welch], Parker, Todd, J. A. Macfarlane, W. J. Stratton, H. H. Glazebrook and G. H. Cranby. M. J. O’Neil [O’Neill] was subsequently appointed to fill the ninth position.

Stratton was a Napier accountant with an alert and practical mind. He had been closely in touch with the farming community. Cranby was a genial man with a pleasant personality, prominent in local body affairs and the proprietor of the well known merchants and commission agents, Cranby and Co., Napier. Glazebrook and Macfarlane were comparatively large landowners, being fatteners of large numbers of sheep and cattle.

BOARD BALANCE

These four men, according to Fallwell, “with their specialised knowledge in business and finance”, made the board more evenly balanced.

Tendering for the erection of the works and plant proceeded apace and the successful establishment of the company became a reality.

But there were rocks ahead for the directors. The trouble was that they had raised the initial capital by signing up shareholders on the memorandum of association.

While this method of floating the company had its advantages, it also had serious disadvantages until the memorandum was registered. It meant that any of the signatories could legally repudiate all responsibility merely by notifying the company in writing. Some did.

So, while the directors had been trying to get the company operating concurrently with the disabilities imposed by the First World War, secession was in the making.

As Fallwell says, the movement began quietly and modestly enough but gathered speed until it threatened the very existence of the project, and finally culminated in the institution of legal proceedings against the company.

Page 7

Four managers, four chairmen in 63 years

The Hawke’s Bay Farmers’ Meat Co has been well served administratively. A succession of four general managers and four chairmen of directors has aided constancy of purpose and policy throughout the company’s 63-year history.

Its four general managers all graduated the hard way and none of them were strangers to the frozen meat industry on their appointment to the general managership at Whakatu.

The first general manager, Mr F. S. Candy, received his early training with the Canterbury Meat Co. The story has it that at the time the directors became interested in a man in the South Island who had nine or 10 sons. The man was a great cricketing enthusiast and with his 10 sons was able to, and did, field a cricket side.

SERVED ABLY

The Whakatu directors were not particularly keen to import a cricket side, so they chose Mr F. S. Candy who had been the first general manager of the Pareora freezing works, Timaru. He was appointed manager at Whakatu, holding the post till 1938.

This was the year Mr H. Brenton-Rule was appointed general manager. He had been well briefed for the post as an executive at the Gear Meat Co, Wellington, where he also held an important private secretaryship.

Mr Brenton-Rule served the company ably through a difficult wartime period, with resultant heavy pressures on the staff. Mr Brenton-Rule was succeeded in 1944 by Mr D. R. Little, who began his career with the company as office boy.

Mr Little left behind him a record of loyal and discreet service when he gave up the post in 1973 to live in retirement in Hastings. He was succeeded by the present general manager, Mr I. D. Cameron, a member of a well known Hastings family.

The second chairman of directors was Mr R. S. Chadwick, who joined the company as a director in 1915. He acted as chairman while the then chairman, Mr Stratton, a Napier accountant, was in England. Mr Chadwick was appointed chairman in 1921 when Mr Stratton resigned. He remained chairman until 1956. Mr Chadwick had a distinguished record in local body activity in the Dannevirke district. He was among the most knowledgeable of those who had made a study of the frozen meat trade.

A Yorkshireman, he settled with a brother and his parents in 1895, knocking down bush at Whetakura to clear land for farming. He took the property over in 1903. He was a staunch supporter of the old Farmers’ Union Movement. It is recorded of him that he was disheartened by the general apathy shown by sheepfarmers towards presenting a united front. In fact, it was their lethargy which prompted his association with the Hawke’s Bay Farmers’ Meat Co., for in the company he saw the realisation of his ideal of a group of farmers co-operating in a given enterprise.

QUIET STRENGTH

Mr Chadwick was active in the administration of the Mortgagor Relief Act of the period. He rose to Appeal Court status, being appointed to assist the late Sir Harold Johnstone.

Mr Chadwick was succeeded by the late Mr R. H. Whyte, a man of quiet strength and high principled dealing. Mr White [Whyte] served until 1960.

As well as being a sound farmer in the Patangata district, Mr White had enjoyed a conspicuous local body career. He was kindly remembered, too, for his sympathetic handling of his duties as a chairman of one of the Hawke’s Bay commissions hearing applications under the Mortgagor Relief Act brought in by the Government of the day in the depths of the slump. Mr White was chairman of directors of the Hawke’s Bay Farmers’ Co-operative Association for many years. The present chairman of directors, is Mr T. S. Ellingham, a member of a pioneering family, the branches of which are scattered over a wide area in Hawke’s Bay.

A man of wide farming and business experience, Mr Ellingham has been associated with the board of directors for the past 20 or so years. He is chairman of directors of the Hawke’s Bay Farmers Co-operative Association Ltd.

[Advertisement]

Congratulations to The Hawke’s Bay Farmers’ Meat Co. Ltd

from

W. BARRETT

BRICK AND BLOCK CONTRACTORS

TELEPHONE 778-710

BROOKVALE ROAD HAVELOCK NORTH

[Advertisement]

BEST WISHES

from

MANAGEMENT & STAFF

OF

STEINER’S SHINGLE CO. LTD

3 McKENZIE AVENUE,

PHONE 446-104 NAPIER.

Page 8

WAR PUT COMPANY ON FEET

A well-known Hawke’s Bay landowner is alleged to have once said that any one of the shareholders, early in the life of the Whakatu freezing works, could be bought out with a pint of beer.

The remark was indicative of the early contempt in which the “Establishment” held the small farmers who had subscribed the lion’s share of the foundation capital for the Hawke’s Bay Farmers’ Meat Co’s project.

But it didn’t stop there, for there was a concerted effort to crush the company out of existence before it got started. Hawke’s Bay historian T. K. Fallwell, writing of the year 1913, the most critical year in the company’s existence, says: “There is little doubt that if the discontented elements had had their way the company would have collapsed.”

PAINFUL TIMES

It was a painful episode, maybe best forgotten, best not dwelt upon. Fallwell goes on to detail the company’s operations during the war period, 1914-18, the days of the “commandeer”.

He contends the war put the company on its feet – it had $40,000 equivalent invested in Government inscribed stock and a further $30,000 on fixed deposit in the bank. By 1920 the kill had risen to 216,694 sheep and lambs.

The war gave the works the opportunity to prove itself to the province. Additional killing and storage space became available when it was vitally needed.

The company’s directors possibly did not welcome the lifting of the comandeer [commandeer] in 1920, but as Fallwell says, they “could at least face the resumption of normal trading with confidence – the company’s reputation was high.”

The next 10 years was a period of steady progress. The works were enlarged. The kill was increased. Substantial reserves began to accumulate, but progress in this period, of course, was bugged by disquieting industrial trouble, particularly antagonism over the employment of non-union labour.

Post-war depression created problems, too. There were attempts to prune out uneconomic freezing works. The word “merger” became both a popular and a dirty word.

The Hawke’s Bay farmers had the consolation of knowing that at least they owned their own freezing works, which is what the argument was all about. A giant take-over with producer control had been visualised. Neither the Meat Board nor the Government were enthusiastic about it.

Next crisis in the company’s affairs was caused by the earthquake and a controversy of a deep-seated nature, the point being that the quake had completely destroyed Bothwicks’ works at Paki Paki and brought gains to Whakatu which quite outweighed the company’s losses in the quake. The gains arose from the negotiations that Borthwicks entered with the company for killing space at Whakatu in lieu of rebuilding the Pakipaki works [Paki Paki].

Among the repercussions caused by the earthquake were moves to bring about certain desirable economies. Take-over proposals – they failed – offended the Wairoa people and there came about what could be regarded as heresy – a proposal for the amalgamation of Tomoana and Whakatu. Other takeover proposals were mooted.

Fallwell says the Whakatu directors found themselves in hot water. There were stormy meetings. The main point at issue involved fierce criticism of individual directors at the board table and in the correspondence columns of the Press.

A period was entered of long dispute about the company’s administration. It was even considered necessary to appoint a sub-committee of the board to act with what amounted to power to examine the whole well-being of the company.

It would seem at this stage unimportant, but in the 1930s such a statement would be challenged. Men like G. A. Maddison, G. J. Parker and J. D. Tod, holding to one line of thought were opposed by the grand old stalwartS, R. S. Chadwick, Edward Averill and George Ebbett. There were many personal exchanges, but at this distance it would seem the real trouble was lack of communication between the directors and the shareholders.

But the passage of time clearly shows the motivating thought behind the dissension was the welfare of the company.

Photo caption –

THREE AUTOMATIC BOOSTER PUMPS have been installed in the new complex to help supplement the main engine room across the road in the main works in the operation of the refrigeration cycle. These pumps are controlled from the main engine room.

Page 9

MORE SHEEP AT ONE TIME THAN PEOPLE

For the first 40 years of European settlement, New Zealand’s sheep were grown only for their wool. Flocks multiplied rapidly until by 1871 the sheep population had risen TO nearly 1 million (the people population to only a quarter of a million).

By 1880, however, experiments had begun with refrigeration and William Davidson, the manager of the New Zealand and Australia Land Company, persuaded his company to make a trial shipment of meat from New Zealand to Britain. The ship, Dunedin, sailed from Port Chalmers on February 11, 1882, with 4908 frozen sheep and lamb carcases aboard.

DOUBLE VALUE

Those first carcases, of which only one was rejected on arrival, sold within a fortnight for $8000, double their value on the New Zealand market, paving the way for the rapid growth of a New Zealand freezing industry.

The importance in value of the industry to the economy is illustrated by the fact that in the 1974 season New Zealand’s meat industry exported:- Lamb, 579,906 tonnes; mutton 110,817 tonnes; beef and veal, 167,528 tonnes.

As a further illustration, it was responsible for the export of hides, skins and meat by-products in the 11 months ended May 30, 1975 (provisional): Sausage casings, 5,700,163 hanks; cattle and calf skins, 2,488,938; sheep and lamb skins, 27,681, 210; inedible tallow, 57,808 tonnes.

These exports go to 90 countries from American Samoa to Austria, from Canada to Chile, from Malaysia to Muscat, from Panama to Portugal, and from Yugoslavia to Zambia.

LANDSCAPING A MAJOR TASK

For the last decade industrial concerns have become aware of the need to erect new buildings with some emphasis on landscaping – the Hawke’s Bay Farmers Meat Co Ltd is no exception.

When plans were completed for the company’s new freezer and storage complex, landscaping the site was already being considered.

A lot of money has since been used to beautify the site with the use of free-flow gardens, lawn areas and the planting of trees.

This work was undertaken by company staff in conjunction with a Hastings horticulturist, Mr Don Escort.

Included in the development of the site has been an extension of parking areas for works employees. Space has been provided for an extra 120 car park sites.

To keep an open area between the new building and the company’s office block, management decided at the beginning of development to leave the tennis courts and bowling green behind the offices untouched.

There had been some suggestion at first to include this area within the building site.

Photo caption – FIRST STOP for sheep carcases after the killing floor is in the new complex’s fully air-conditioned marshalling floor. Here they are sorted out into their respective grades in readiness to be frozen in the blast freezers. The marshalling area is capable of holding 8000 carcases and holding them in good condition overnight if needed.

[Advertisement]

GARY AUGUSTINE LTD

REGISTERED MASTER PAINTERS

PAINTING CONTRACTORS

Are pleased to be associated with

J.C. MACKERSEY LTD DULUX

BUILDING CONTRACTORS

401 N. WILLOWPOARK ROAD, HASTINGS PHONE 85-297

Page 10

Challenge for the contractor

Building the multi-million-dollar Whakatu freezer and storage complex was a challenge for the principal contractor, J. C. Mackersey Ltd, of Hastings – it was their biggest contract to date and the building programme was planned for speed.

With the completion of the third and final store this month, the success of the firm’s work is evident – the main sections completed well within the final contract completion dates.

Apart from the refrigeration work which was done by Ellis Hardy Symington Ltd, Wellington, and the meat rails (a sub-contractor was employed by the owners), the complex, including the railway siding, has been Mackersey’s “baby”.

When the firm arrived early in 1973 the site had already been cleared, top soil removed and backfilled with river metal.

The project manager, Mr A. M. Hartley, said work on the first freezer store began almost immediately with foundation work beginning on February 19, 1973.

During the three years of construction work, the firm had some 60 men at work on the site – this number swelling at times to well over 100 when the 30-odd sub-contractors were in operation.

LOCAL LABOUR

Mr Hartley said the policy was to use local labour and facilities wherever possible. Most of the sub-contractors were local firms and all material, including the concrete and steel-work, was bought within the Hawke’s Bay district.

The sheer size of the complex meant a quick and easy method of construction was of paramount importance if the job was to be done on time.

Once the concrete floor slabs were down and the steel framing in place, precut wall panels were installed and the roof added.

INSULATION NEEDS

Insulating the stores required combining a number of latest building techniques.

“Sandwich-type” floors were laid for each store. Between the first or “sub-floor”, which contains heating cables, and the next layer of concrete are several applications of vapour insulation mixture and also cork insulation.

The insulated ceiling was constructed from sandwich panels with a polystyrene core. The platforms at each end of the stores are completely enclosed with a 14-foot-high insulated ceiling and walls built from insulated panels.

These areas are regarded as having an environment suitable for the passage of carcases or cartons without causing a significant rise in their temperature.

To co-ordinate the work the contract required a close liaison between owners, contractor, sub-contractor, consulting engineers, quantity surveyors and management representatives.

This was achieved to a large degree by regular meetings between those involved. Every second Thursday throughout the three years a site meeting was held to discuss progress and other points of work.

Mr Hartley said the successful building programme was the result of team work, both among his own staff and others on the site.

Photo caption – Mr A. M. Hartley …Project manager for the principal contractor. J. C. Mackersey Ltd.

WHAKATU LANDMARKS

Production landmarks in the history of the Whakatu freezing works include a series of record throughputs in both sheep and cattle.

In outline the landmarks from the 1914-1915 opening season are stark. The record is as follows:-

Season Sheep, Lambs Beef Cattle

1914-1915 123,900 3,190

1927-1928 509,924 11,038

1939-1940 807,695 25,345

1958-1959 1,056,668 44,305

1966-1967 1,581,203 51,450

Record Day’s Kill: Sheep and lambs, 20,197 (December 22, 1970); cattle, 782 (February 14, 1973).

Record Week: Sheep and lambs, 102,837 (December 13, 1975); cattle, 3914 (March 3, 1974).

Record Season: Sheep and lambs, 2,147,572 (1969-1970); cattle, 81,651 (1972-1973).

[Advertisement]

THE COMPLETE STORE

Come in and use our services to YOUR advantage

Agents for Timex Watches

State Insurance Agents

Lube Bay – Europa Oil

Tyres and Batteries

General Repairs

G.H.B. STORE

OPEN EVERY DAY

The Management and Staff extend best wishes to The H.B. Farmers’ Meat Co. Ltd

WHAKATU STORE LTD

(OPPOSITE FREEZING WORKS)

Page 11

Former stalwarts

Co-operative affair

Planning for the multi-million-dollar complex at the Whakatu freezing works began five years ago when a proposal to extend the capacity of freezer storage was first decided.

The company’s chief engineer, Mr A. H. Waterhouse, said many plans were submitted from the firm’s own drawing room until the present plan was accepted in 1972.

Because of the nature of the building planning was a co-operative affair between the company staff and the refrigeration contractors.

Once building approval had been given by the Hawke’s Bay County Council approvals were sought from the New Zealand Railways and council to erect the connecting bridge across the Wellington-Napier main trunk line.

Approval also had to be sought to bring a main power cable underneath the railway lines from the main works. This work was done by New Zealand Electricity Department staff.

(See story page 7).

Photo captions –

– Mr R. S. Chadwick, second chairman of directors.

– Mr R. H. White, served the company until 1960.

– Mr H. Brenton-Rule, company manager in First War years.

– Mr A. H. Waterhouse, chief engineer to the company.

– Mr W. J. Stratton, resigned as chairman in 1921.

[Advertisement]

BEST WISHES TO THE H.B. FARMERS’ MEAT CO. LTD FROM –

Bob Anderson & Staff

OF

PRECISION SAW DOCTOR

A COMPLETE SERVICE FOR ALL SAWS & PLANER KNIVES

SETTING – HAMMERING – RETOOTHING

WELDING – SHARPENING – BAND SAWS MADE UP

SPECIALISTS IN GUILLOTINE BLADES

SAME DAY SERVICE

HERETAUNGA ST. W., HASTINGS PHONE 67552

[Advertisement]

P.O. Box 1154 Phone 85-200

817 CAROLINE ROAD

HASTINGS

SHERRATT DEMOLITION LTD

All types of demolition carried out.

Page 12

Truly a farmer concern

In its origin the Hawke’s Bay Farmers’ Meat Co Ltd was a genuine farmers’ concern – to all intents and purposes wholly a farmers’ concern.

Of those who signed the memorandum of association and supplied the initial share capital only four were non-farmers.

In February 1914, when the first call on shares was made, the subscribed share capital stood at the equivalent of $80,550. The shareholders totalled 327.

T. K. Fallwell, who wrote a thesis for his MA degree at the Napier Boys’ High School is the authority for this article. In his thesis, he makes the point that the shareholding was mostly in the hands of working farmers, or “cockies” as they were called.

“While there was a sprinkling of big sheep farmers among the company’s original shareholders, their numbers were relatively insignificant and their share of the capital even more so,” Mr Fallwell Writes.

APATHETIC

“Generally speaking, these farmers either remained apathetic or treated the project with disdain. Their attitude sprang directly from the favourable circumstances of their social background.”

The outstanding exception, according to Mr Fallwell, was the late Mr J. Davis Canning, the son of the pioneer owner of the famous “Oakbourne” Station in Central Hawke’s Bay.

“Canning championed the cause of the small farmers. He was criticised for his association with the movement and was warned that it would jeopardise his reputation,” Mr Fallwell wrote.

Mr Fallwell’s treatise could be described as a book of character studies, for it is clear that the Hawke’s Bay Farmers’ Meat Co is the product of a clash of personalities.

The author deals with the entire history of the frozen meat industry in Hawke’s Bay, mentioning, inter alia, a character who did much towards waking Hawke’s Bay up to the province’s potential, Mr G. E. Merriken, a farmer of Hatuma, “an Englishman with a univesity [university] education and a blasphemous tongue”. He had roughed it on estancios in the Argentine and sheep stations in Hawke’s Bay. We first hear of him urging a conference of Farmers’ Union supporters. His complaint was that the Canterbury farmers were getting two to three shillings a head more for their fat lambs than Hawke’s Bay were for theirs.”

COMMOTION

Merriken did not believe that freezing and shipping on owner’s account was a solution for the small farmer. His solution to the farmers’ problems was the establishment of a farmers’ co-operative freezing works.

The campaign instigated by Merriken raised a commotion for the Establishment took notice and tried hard but failed to subdue him.

Mr Fallwell covers it well in his remark that there was little doubt Merriken’s arguments and his championship of the small farmers’ cause convinced many of the desirability and need for a farmers’ freezing works in the province.

Merriken, then, sowed the seeds of an idea. There was general sympathy for it. The pot simmered for two years. All that was needed was leadership. That eventuated in 1912 at Waipukurau where the history of Whakatu and all it means today began.

Whakatu one of 39

The number of freezing works in New Zealand contributing to the export trade is 39, but there are 125 companies or individuals holding meat export licences, with 25 meat packing houses licensed to operate.

The 39 works are owned by 22 companies. These range in ownership from farmer co-operatives to companies owned by New Zealand shareholding and subsidiaries of overseas-owned interests. Of the 39 works, 28 are controlled by New Zealand shareholding and 11 by overseas interests. Seven companies publicly listed on the Stock Exchange operate freezing works, either directly or through subsidiaries.

Photo caption – Mr E. M. C. Sullivan…office manager at Whakatu.

Page 13

SKILL WITH KNIFE AND HAND

To be placed high in the accomplishments of the frozen meat trade are the skills of the knife hands and those who prepare meat for export in package form.

This is one of many impressions to be formed on a tour of inspection at the Hawke’s Bay Farmers’ Meat Co’s works at Whakatu.

The deft manner in which a side of beef, for instance, was boned out left the onlooker very impressed.

The knife was seen to make a stroke best described as a wriggle deep into the flesh, but the knife-thrust and turning of the blade, of course, merely followed the outline of the leg construction of the animal.

In less time than it takes to remove a splinter from one’s finger, one saw the leg joints begin to emerge and very soon indeed out came the bones and knuckled joints, the bones white and bare of flesh.

DARTING KNIFE

Or again, in fascination one watched the deribbing of a mature bullock. In and out, up and down the ribs darted the knife, steered dexterously. A slash or two several well directed cuts with the knife, and the knife-hand was holding in his hand the skeletoned side of the animal, the rib construction intact.

Like some part from an abandoned motor vehicle in a junk heap he dropped it on to a metal platform, where it clanged and bumped rather sharply against a worker doing another job. He picked it up and threw it on to a conveyor which took it to regions below, there to be ground into bone dust as an aid to good viticulture or horticulture in Hawke’s Bay.

“MR SLICK”

Yet another impression was the extreme cold in those blast freezing chambers. Fifteen degrees. It seemed just inordinately cold, reminding one of Dunedin at the height of the ice-skating season. The day was overcast, yet to emerge into the daylight gave the feeling of brilliant sunshine. “This product must be kept frozen” read the printing on the cartons. That seemed to be rubbing in the obvious.

The man on the bandsaw was worth watching. At one time butchers halved a sheep carcase with a cleaver, the carcase suspended vertically. A series of blows along the spinal cord severed the body neatly in two.

“Mr Slick” on the bandsaw made that look all old hat. With deceptive speed reminding one of a conjurer, he halved the carcase, quartered it, and jointing the quarters, his hands, one felt, much too close to that whirling saw blade.

The “bits” went on to the conveyer [conveyor], and women packed them into cartons, marked and labelled for such sources as DEVCO.

Here was to be seen the reality of the talk and what one read about the search for markets, the potential in the American market, why did not the Germans or the Swiss eat more lamb? The skills – and there were many in that chamber – suggested the buyers of the product would be well rewarded with the quality of the product and the workmanship. Both were excellent.

Photo caption – FROM THE MARSHALLING FLOOR in the new complex, conveyers carry the carcases to the 10 blast freezer rooms. Each of these rooms is capable of freezing 2000 carcases in 14 hours. From the blast freezers the frozen carcases are conveyed out to be loaded on to the steel post bins ready for storage.

[Advertisement]

FARNDON FOODMARKET

CLIVE’S DISCOUNT GROCER

“THE HAPPY SHOP”

EXTENDS BEST WISHES TO THE MANAGEMENT & STAFF OF THE H.B. FARMERS’ MEAT CO. LTD. AND WELCOMES ALL

TO SHOP AND SAVE AT THE

FARNDON FOODMARKET

MAIN ROAD

CLIVE

Page 14

THE HAWKE’S BAY FARMERS’ MEAT CO., LTD.

NEW $11m BUILDING COMPLEX OPENED TODAY!

The Company was established in 1912 to provide processing facilities for Hawke’s Bay stock.

This service has been developed over the past 61 years to meet the changing requirements of both the farmer producers and the markets of the world.

In continuation of this policy the Company embarked on this major project, opened today by the Minister of Agriculture and Fisheries, The Honourable Duncan MacIntyre.

It is designed to efficiently process the stock raised on the fertile lands of Hawke’s Bay.

The completion of this project has involved a large number of people including staff, contractors, sub-contractors and suppliers. The company is grateful for all their efforts and co-operation over the past three years.

Photo caption – Pictured above is our complete Meat Processing Works at Whakatu…. covering an area of approximately 20 acres. This Works is one of the largest in New Zealand, with a season’s kill exceeding 2 million sheep and lambs and 80,000 cattle.

At the top left corner is shown the new complex.

At Right – A close-up of the new complex

The overhead structure is the access way from the killing floor to the marshalling area and remainder of the new complex.

THE HAWKE’S BAY FARMERS’ MEAT CO., LTD.

WHAKATU WORKS

[No Page 15]

Page 16

PORT LINKS WORLD’S MARKETS

The Port of Napier has played a significant role in handling the meat exports of the province during the last 100 years.

Before the breakwater harbour was established and refrigerated freighters were loaded in the roadstead from lighters, meat – beef, mutton and lamb – was one of the main items of trade handled by the port.

This trend has continued through the developing years, although it has been arrested to some degree with the establishment of containerisation.

Napier, however, is still one of the leading export ports of meat in New Zealand.

The main meat trade has been between the port and the United Kingdom, New Zealand’s biggest customer over the years.

The port has saved farmers an immeasurable amount of money in costs, mainly because of the short-haul railage.

The actual costs of handling meat at the port have traditionally been lower than any other New Zealand port, giving farmers a double saving.

The efficiency in the turnround of shipping and the lower costs, has also had the effect of drawing meat from outside Hawke’s Bay for export.

Stevedores, harbour board employees and watersiders have all played an important part in gaining the port a reputation for efficiency.

This has been emphasised by the fact that ships are often queued up waiting for berths.

MORE ECONOMIES

Napier also featured in the two-port loading system for United Kingdom meat, and latterly the single-port system, providing more economies for the farmer.

As far as the Hawke’s Bay Harbour Board has been concerned, the needs of the meat trade have been accorded the highest priority.

Today the port has a trade turnover exceeding one million tonnes a year and of this last year the total meat exports amounted to 101,594 tonnes, compared with 75,324 tonnes in 1974.

Last year 1978 tonnes of beef, 29,451 tonnes of cartoned meat 17,823 tonnes of mutton and 52,342 tonnes of lamb were shipped out of Napier.

MAJOR ROLE

Conference Lines refrigerated freighters have played the major role in taking the United Kingdom meat, but significant inroads have been made into this trade, as new markets have been developed, by the Dutch and the Japanese.

Photo caption – THIS IS A TYPICAL SCENE at the Port of Napier – refrigerated freighters loading meat for overseas consumption. The vessel loading at the far side, Kirkpatrick Wharf, is a reefer-type vessel, while the two ships in the centre are conventional freighters.

[Advertisement]

Best wishes to The H.B. Farmers’ Meat Co. Ltd with their new Freezer Complex at Whakatu

“YOU’RE IN GOOD HANDS”

WITH

Hawke’s Bay SECURITY SERVICES LTD

HOME & INDUSTRIAL SECURITY – FIRE PROTECTION & SAFETY ENGINEERS – COURIER SERVICES – ARMED ESCORTS

WEDDINGS, SOCIALS, PRIVATE FUNCTIONS, STORE DETECTIVES

P.O. BOX 662 NAPIER

PHONE 56-315 After Hours 439-774

Page 17

[Advertisement]

The National Bank of New Zealand Limited congratulate The Hawkes Bay Farmers’ Meat Company on completion of its new freezer complex at Whakatu

As bankers to the Company since its inception in 1913, we have watched it grow to a national asset and we look forward to supporting it as it provides an expanded service to Hawke’s Bay and to New Zealand.

The National Bank

OF NEW ZEALAND LIMITED

– YOUR FRIENDLY BANK

Page 18

BOARD DOES NOT “FLY BLIND”

Members of the board of directors of the Hawke’s Bay Farmers’ Meat co. are not just front men, and in that respect the company is well served.

One of them, unnamed by choice, puts it differently. “On the board”, he said, “we just don’t fly blind under the surveillance of the executives.

“The board meets once a month, and it’s not just a procedure of sitting all day round a table and being served with morning and afternoon tea,” he said.

The members kept abreast of all that went on at Whakatu and a close look indeed was invariably taken at all projects that involved financial outlay. Frequently there were gaps in the board room attendance, with individual members making a tour of inspection to report back.

The present chairman of the board, Mr T. S. Ellingham is a nephew of the late Mr R. S. Chadwick and the former board member, Mr J. W. Ellingham.

Mr Ellingham carries an honoured name in Hawke’s Bay, for he is of pioneering stock. His father was Mr T. W. Ellingham, of Whetakura, where Mr Searle Ellingham was born.

He attended the old Heretaunga School and is an old boy of Wanganui Collegiate School. As a schoolboy he was a steward of the Dannevirke A and P Society and in later life he joined the society’s general committee. He was an original member of the now defunct Southern Hawke’s Bay Rabbit Board.

SPORTS INTERESTS

Mr Ellingham was vice-captain for rowing and football at secondary school, and he played representative football for Southern Hawke’s Bay. He was made a JP in 1952.

As well as holding the chairmanship at Whakatu, Mr Ellingham is chairman of directors for the Hawke’s Bay Farmers Co-operative Association Ltd. As chairman of the Associated Farmers Co-ops, Mr Ellingham visited Britain last year. He is a director of Baillie Farmers Motors Ltd.

There have been only three representatives of the Poukawa Riding in the history of the Hawke’s Bay County Council, and all three have filled the council’s chairmanship. They are Messrs H. M. Campbell, Robert Harding and M. G. Groome, the present chairman.

Mr Groome joined the board of directors at Whakatu in 1959. He is a third generation member of one of Hawke’s Bay’s best known families of the Onepu district, his grandfather having taken up the property in the late 1870s.

SHOW SUPPORTED

An old boy of Wanganui Collegiate School, Mr Groome served 17 years on the general committee of the Hawke’s Bay A and P Society and he was an active supporter of the Federated Farmers movement. He has represented the Poukawa Riding since 1956. Mr Groome is a JP.

As do his colleagues on the board, Mr Groome leads an active life, largely owing to the demands made upon him by the county council. Allied with his duties as chairman Mr Groome represents Hawke’s Bay on the Counties Association Insurance Co.

A past president of the Waipukurau Jockey Club for 17 years, Mr H. W. Smith, Omakere, joined the board in 1946.

Mr Smith is a member of a well known Wellington family, the owners of James Smith and Co, the large departmental store in Lower Cuba Street, Wellington. He was educated at Scots College. He and an elder brother went farming, two of his brothers, as third generation directors, staying on with the firm.

Mr Smith arrived in Central Hawke’s Bay in 1933, taking over from the late Mr Lachlan McKenzie the historic Te Manuiri property, one of the outstations of the original Pourerere Station.

Mr Smith served two terms as a member of the Central Hawke’s Bay Electric Power Board. He is an enthusiastic dog trialist. He is president of the dog trial club. He owns a dog and still takes part at the smaller meetings.

BEEF ENTHUSIAST

After leaving Christ’s College, Mr S. T. Belcher was initiated into sheep-farming by cadeting on his father’s extensive holdings in Canterbury. He came to Hawke’s Bay as a stock agent and after three years went to Marlborough, where he was appointed a stock auctioneer, stationed on Kaikoura. He returned to Hawke’s Bay and took up the property at Waimarama, which he has farmed on his own account for the past 43 years.

For 10 years Mr Belcher served on the Electoral College of the Meat and Wool Boards and in 1960 he was elected to the board of directors at Whakatu.

At all times an enthusiast for beef cattle, Mr Belcher was among those associated in the first export of chiller beef from Hawke’s Bay by arrangement with Thos Borthwick and Son. That was in 1934. He was also one of the first producers in Hawke’s Bay to use the carton method in the export of beef.

A breeder of purebred Angus cattle for many years, Mr Belcher has regularly supported both the Central Hawke’s Bay and the Hawke’s Bay chiller beef championship as an exhibitor and donor of cash prizes. He has won the competition himself on occasions.

Sharing the board-room

(Continued on Page 19)

Photo captions –

– MR T. S. ELLINGHAM

– MR M. G. GROOME

– MR H. W. SMITH

– MR T. S. BELCHER

– MR I.A. BARNETT

[Advertisement]

EVERY FLAMING SECOND COUNTS!

RELIANCE FIRE FIGHTING EQUIPMENT LTD

CAN PROTECT YOUR PROPERTY

– SPRINKLER SYSTEMS

– FIRE EXTINGUISHERS

– HEAT AND SMOKE DETECTORS

– FIRE HOSE AND FITTINGS

– ALARM SYSTEMS

– HOSE REELS

FREE QUOTATIONS.

We will service all types of Extinguishers and Systems. Phone us and discuss your Fire Protection problems.

93 GAVIN ST., PENROSE. P.O. Box 12133 Penrose.

Telephones – 592-262 593-162 597-792 592-263

[Advertisement]

Metal Import Company

(Hawke’s Bay) Ltd.

A MICO./WAKEFIELD GROUP COMPANY

Suppliers to The Hawke’s Bay Farmers’ Meat Co. Ltd

We take this opportunity to extend congratulations and best wishes to The H.B. Farmers’ Meat Co. Ltd on the completion of the Freezing Complex at Whakatu

LEYLAND STREET, ONEKAWA

P.O. BOX 521, NAPIER PHONE 436-002

[Advertisement]

THE SOLID PLASTERING WORK

On The Hawke’s Bay Farmers’ new Blast Freezer Complex at Whakatu

WAS SUCCESSFULLY CONCLUDED BY

R.N. FERGUSSON PLASTERING CO. LTD.

WE WILL BE HAPPY TO QUOTE FOR ANY JOB, LARGE OR SMALL, DOMESTIC OR COMMERCIAL.

THIS IS A SPECIALISED TRADE AND WE HAVE SPECIALISED TRADESMEN.

R.N. FERGUSSON PLASTERING CO. LTD

LEYLAND STREET, ONEKAWA PHONE 437-124

Page 19

(continued from Page 18)

table with Mr Belcher is a very popular rival breeder of stud beef cattle. Mr I. A. Barnett, of Oringi, Dannevirke. Mr Barnett, as a stud herd owner, is an executive member and on the council of the New Zealand Hereford Breeders’ Association. He takes a keen interest in Royal Agricultural Society affairs. He has exhibited at various A and P shows successfully as a breeder of Hereford cattle, and is a past president of the Dannevirke A and P Society.

For several periods Mr Barnett served as a Dannevirke county councillor.

Mr Barnett is well known as a sportsman. He has played tennis and golf with distinction all his life. He still plays tennis and his present golf handicap is eight. He has figured in representative tennis, also in Hawke cup cricket. In his youth he also played Rugby.

GRASSLAND RESEARCH

Mr J. A. H. Inglis is a young man perhaps best known for his expert knowledge in grassland management. Having made a hobby of it as a private study, he has put that research knowledge to effective commercial use in the administration of a 540-acre sheep farm lying under the famous Wharite Peak, in the lower Ruahine Ranges on the north side of the Manawatu Gorge.

By no means easy country to farm, the property earned distinction, among several reasons, for the unique brother and sister relationship at its helm.

Miss Helen Inglis, now Mrs R. A. Soundy, of Kaeo, North Auckland, took her full share of the shepherding and other manual work on the farm, sharing her brother’s enthusiasm and contributing much with her own special knowledge, in flock and pasture management.

Mr Inglis was educated at the Wanganui Collegiate School. In 1974 he led a party of 11 New Zealanders to the 12th International Grassland conference in Moscow, as well as on a tour of central Asian and European countries.

He is a past chairman of the Manawatu Agriculture Club. He has been an active Federated Farmers supporter and treasurer of the National Party organisation in the Pahiatua electorate.

Mr Inglis is one of 100 people able to write the letters ACIS after his name, as a chartered administrator (Institute of Chartered Secretaries).

Mr Inglis has been a member of the Whakatu board of directors since 1965. He is a Justice of the Peace.

FARMING LIFE

A man with a lifetime farming background, Mr L. E. Hardy needs no introduction to the farming community in Hawke’s Bay. He has been a member of the board since 1962.

Born at Tikokino, he farmed at Elsthorpe on his own account until some 12 years ago, when he moved to the Takapau district, where his farm runs both sheep and cattle.

Mr Hardy, as he puts it, “did his turn” as an active supporter of Federated Farmers at branch level, and also took an active interest in school committee affairs. His association with the Hawke’s Bay Farmers’ Meat Co, though he does not say so, is an abiding and absorbing interest.

WASTE INTO FARM

Mr W. D. Mouat, well known for his association with Mangaorapa Station, near Porangahau, came on to the board in 1970. Mangaorapa, a 5600-acre holding, was once a scrub-covered and rabbit-infested waste. It has been converted into a unit of high production in the ownership of the Mouat family over three generations, for the station is currently farmed by Mr Mouat in partnership with his two sons, Messrs W. M. and B. D. Mouat.

Mr Mouat served on the Patangata County Council at one stage being deputy chairman. He has been a supporter of Federated Farmers, is on the board of directors of Williams and Kettle Ltd and is chairman of the Lindisfarne College Board of Governors. Mr Mouat is a Justice of the Peace. He is president of the Porangahau Country Club, a novel country folk organisation with few if any parallels in this country.

Photo caption –

– MR J. A. H. INGLIS

– MR L. E. HARDY

– MR W. D. MOUATT [MOUAT]

[Advertisement]

WE ARE PLEASED TO HAVE BEEN ASSOCIATED WITH SOME OF THE ELECTRICAL WORK ON THE HAWKE’S BAY FARMERS MEAT CO LTD NEW FREEZING COMPLEX AT WHAKATU.

NEVILLE RODGERS LTD

ELECTRICAL CONTRACTOR & ELECTRICIANS

305 ALEXANDRA STREET, HASTINGS

TELEPHONE 88-392

[Advertisement]

WRIGHTSON PLANT HIRE

OUR SPECIALISED EQUIPMENT HELPS KEEP HAWKE’S BAY’S ROADS, STREETS AND INDUSTRIAL SITES FREE FROM LITTER, FLYING STONES, METALLIC OBJECTS AND FLOOD WATER.

PHONE 56-256

After Hours 418 BV

for service and machines including:

ROAD SUCTION SWEEPERS SUMP CLEANERS MAGNETIC PICK-UP UNIT WEED SPRAYING UNIT WATER CART STREET WASHING EQUIPMENT

WRIGHTSON CLEANERS LTD.

P.O. BOX 378, NAPIER

Page 20

Whakatu personnel

MR D. BAWDEN, chief accountant.

MR R. STAYT, stock superintendent.

MR B. MURPHY, production supervisor.

MR B. JENKINSON, production manager.

MR R. A. WHARTON, works manager, labour and by-products.

[Advertisement]

CRAIG BROS.

REFRIGERATION & ENGINEERING CO LTD

STONEYCROFT STREET, HASTINGS

CONGRATULATIONS TO THE H.B. FARMERS’ MEAT CO. LTD ON THE COMPLETION OF THE NEW FREEZING COMPLEX AT WHAKATU.

– INSTALLATION OF ALL REFRIGERATION PLANT & REPAIR WORK.

– STRUCTURAL STEEL AND METAL WORK.

– STEAM, AIR, GAS, OIL and WATER PIPE WORK.

– MANUFACTURERS OF FRAME SCAFFOLDING

TELEPHONE 83-135 BUS. P.O. BOX 1064

PRIVATE 68-680. HASTINGS.

[Advertisement]

ORSBORN ROADMARKERS LTD

ROAD MARKING & SPRAYPAINTING CONTRACTORS

P.O. BOX 262,

HAVELOCK NORTH

TELEPHONE 777-597

Page 21

“CHAIN” INTRODUCED IN EARLY THIRTIES

To visit a modern freezing works and watch the butchers at work on the chain provides a contrast with the solo butchering method adopted on the farm and elsewhere.

Although the knife skills are real, it seems to the onlooker that on the chain there are as many men as there are carcases being prepared for the freezing chambers.

The “chain” method is of comparative recent vintage, for at Whakatu, anyway, the chain was not introduced until the thirties.

KEY TRADE

The system was introduced during the depression in a bid to insulate the industry from labour disputes arising out of the prevailing hard times.

Before this, slaughtering was conducted under the solo system, whereby each butcher was responsible for the killing and dressing of a single sheep at a time. It was a highly skilled trade and a key trade at that!

If slaughtermen went on strike or were not available for work, the works came to a standstill. It was in these circumstances that certain freezing works adopted the chain system about 1929 or 1930. The virtue of the system was that it enabled killing to proceed using unskilled labour, each man being responsible for only one facet of the task.

The directors of the Hawke’s Bay Farmers’ Meat Company saw the advantages of the chain system, and in 1932, they placed $2000 in a special reserve for the installation of the system at Whakatu “should circumstances render it necessary”.

It so happened it became necessary that very year, for there was a strike on at both Whakatu and Tomoana.

TWO UNIONS

Tomoana installed the chain system immediately the trouble broke out, but it was not plain sailing at Whakatu, no matter how desirable the chain system might seem.

Whakatu’s difficulty was that there were two butchers’ unions functioning. Members of one of the unions decided to carry on under the old system in the belief that the remaining butchers would follow suit.

The dispute continued however, but by the end of the season alterations to the slaughterhouse enabled four chains to be engaged. The throughput was 9000 to 10,000 lambs a day.

T. K. Fallwell, in his book, “The Freezing Industry of Hastings”, says that while the introduction of the chain at Whakatu was the outcome of the depression, in particular the slaughtermen’s strike of 1933, the system aided the company’s recovery from the slump.

“Indeed, after the initial experimental period,” Mr Fallwell writes, “it quickly became an indispensable feature of the freezing industry, for, by accelerating the rate of killing and lowering overall labour charges, it reduced overhead costs significantly.”

[Advertisement]

Angus Inn MOTOR HOTEL

Bruce & Audrey Menzies

WELCOME YOU

To the “Family Hotel” where you can enjoy top quality service and cuisine in the Black Bull Restaurant with our chef, David Barron, and take advantage of the other services offered.

CONFERENCE ROOM SPACIOUS REFRESHMENT BARS

FORTY FULLY-SERVICED ROOMS COLOUR Tv

SECLUDED HEATED SWIMMING POOL

Between races relax in comfort in the “BIRDCAGE”

JOIN US SOON – OUR BUSINESS IS YOUR PLEASURE

We congratulate The Hawke’s Bay Farmers’ Meat Co. Ltd on the completion of their new freezing complex at Whakatu.

Angus Inn

RAILWAY ROAD, HASTINGS PHONE 88-177

[Advertisement]

NAPIER SAND BLASTING CO. LTD

128 Guppy Road Phone 442-881 Napier

We are pleased to have assisted The H.B. Farmers’ Meat Co. Ltd with their Whakatu Freezing Complex

Page 22

Planning further expansion

The next major undertaking for the board of directors of the Hawke’s Bay Farmers’ Meat Co. is a new fellmongery.

The site will be behind the present new freezer and storage complex. The project is on the urgent list.

The decision for the moment is understood to be a little complex, for the board awaits the pleasure of the Meat Board in the granting of a licence enabling work to proceed with the preparations for the new abattoirs and freezing works at Takapau.

COMPLEMENTARY

Indeed, there is a tie-up between the Takapau project and the construction of the new fellmongery at Whakatu. One is complementary to the other in the sense that the present fellmongery does not cope with the hides from the beef kill at Whakatu.

The pressure on the existing fellmongery is becoming greater and greater as the throughput at Whakatu increases.

The hides from the beef kill are “farmed out” at present. Moreover, the motivation in the Takapau move is the need and opportunity to greatly increase the cattle kill. With a works flourishing at Takapau, full-scale fellmongery plant and processing equipment would be more than justified.

SHAREHOLDER

The Hawke’s Bay Farmers Meat Co. is a shareholder in a Napier company that handles the hides, but the pelts from the sheep kill at Whakatu are handled by the company’s present fellmongery.

The board is expecting to receive the Meat Board’s approval next month.

No figure has as yet been released for the cost of building the new fellmongery at Whakatu.

PROJECT HISTORY

Since the Whakatu company’s decision to build the multi-million dollar complex in 1972 work has proceeded apace.

The first freezer store was brought into use in March 1974. This was followed by the second freezer floor in February last year.

Eight months later, in October, the bridge linking the new complex with the main works was completed together with the marshalling floor, blast freezers and staff amenities.

The completion of the third freezer store this month brings the complex into full working capacity.

Secretary at works

Mr R. H. George, secretary of the Hawke’s Bay Farmers’ Meat Co, is a former pupil of the Napier Boys’ High School. He was appointed at the end of 1970. He received his earlier business training in the employ of Richardson and Co. Ltd, Napier, the well known coastal shipping firm.

Photo captions –

– Mr L. Schroder, freezer foreman.

– Mr S. Thompson, freezer foreman (marshalling).

[Advertisement]

J.J. O’Connor Ltd

HASTINGS

WE ARE PLEASED TO BE ASSOCIATED WITH THE HAWKE’S BAY FARMERS’ MEAT CO. LTD IN THE CONSTRUCTION OF THIS VAST COMPLEX.

– ROOFING

– CLADDING

– VENTILATION

– PLUMBING

– DRAINAGE

J.J. O’CONNOR LTD

Alexandra Cres., HASTINGS

PHONE 86-746

After Hours 69-993

The Daily Telegrah congratulates The Hawke’s Bay Farmers’ Meat Co. Ltd.

Page 23

Women at work

LEFT: Mrs Gillian Malone, courier for the Hawke’s Bay Farmers’ Meat Co.

BELOW: Mrs Helen Martin, receptionist at Whakatu.

[Advertisement]

Congratulations

THE H.B. FARMERS’ MEAT CO. LTD

from

STANTON BROS. (H.B.) LTD

Commercial Printers & Stationers

NAPIER & HASTINGS

SUPPLIERS OF:

– COMMERCIAL STATIONERY

– PRINTING FROM OUR OWN FACTORY (AT REAR OF OUR HASTINGS SHOP)

– OFFICE AND INDUSTRIAL STAPLING MACHINES.

LET THE FIRM WITH EXPERIENCE SUPPLY YOUR STATIONERY AND PRINTING STATIONERY. SINCE 1910.

[Advertisement]

Congratulations to the HAWKE’S BAY FARMERS’ MEAT CO…

THE Hawke’s Bay Electric Power Board was there from the beginning

The Hawke’s Bay Electric Power Board is pleased to be associated with the opening of the new Freezing and Storage complex at Whakatu.

Since the 1920’s The Hawke’s Bay Electric Power Board has been serving the needs of Industry and the community throughout the area.

HAWKES BAY ELECTRIC POWER BOARD

HERETAUNGA ST. EAST, HASTINGS

Page 24

Whakatu’s work force

One hundred and five employees of the Hawke’s Bay Farmers’ Meat Co Ltd are working in the new freezer and store complex.

Most of the men were simply transferred from their positions within the main works to the new building.

The freezing works at present has a total staff of 1768, including 148 maintenance staff and 220 permanent employees.

A recent report on staff employed at the works plant reveals:

– Percentage of staff age groups employed: Under 20 years, 19 per cent; 20-30, 33 per cent; 30-40, 18 percent; over 40, 30 per cent.

– Percentage of each sex: Male, 94 percent’ female, 6 percent.

– Percentage of married and single: Married, 60 percent; single, 40 percent.

– Percentage of years service: first season, 29 percent; one to five seasons, 32 per cent; one to five seasons, 32 per cent; Over five seasons, 39 per cent.

Meaning of Whakatu

The “assembly-line” style of killing operations at the Whakatu freezing works has a strange connection with the Maori meaning of the word Whakatu.

According to Mr Taanga Tomoana, who works at Whakatu, the name is not an ancient word. It comes from a shortening of the words Whakatutu Hoaia (an assembly of soldiers).

When Te Kooti and his band were plundering the Hawke’s Bay district in the early 1860s, local Maoris were being recruited to form a force to search for the elusive rebel.

It was at Whakatu that the recruits gathered – so it became known as the place of assembly for soldiers – Whakatuta Hoaia [Whakatutu].

According to Mr Tomoana, the usual Maori word for stop is etu!

Whakatu is said by some also to mean stop, or stop, look and listen!

“The one means stop with urgency, as in an emergency,” Mr Tomoana pointed out. “Etu means stop in the sense of finality. The other word means stop in a much looser sense – stop, or do what you like”.

Mr Tomoana said that within the precincts of the Whakatu freezing works there was once a pa. A cemetery not far from the main works is the burial place of the district’s first Anglican Maori minister, the Rev. Manahi, who preached in the area in the late 1800s.

The pa site was abandoned following the destructive 1897 flood.

Photo caption – A FEATURE of the new complex is the completely enclosed loading out platform and railway siding. Capable of holding 14 insulated railway wagons or 24 shipping containers, the siding can be sealed off at night by doors at either end of the freezer stores.

[Advertisement]

BAY-BRITE STAINLESS STEELS LTD

SHEETMETAL FABRICATORS & ENGINEERS

Catering Food Handling & Sterilizing Equipment Benches Tubs Shower Trays Filtered Exhaust Systems

We congratulate the members of The H.B. Farmers’ Meat Company on meeting the challenge to establish this major and impressive Blast Freezer Complex, and also all trades involved who co-ordinated to make it possible.

CONTACT US FOR ALL SHEETMETAL AND MECHANICAL ENGINEERING WORK AND STAINLESS STEEL EQUIPMENT

NOTE NEW ADDRESS:

P.O. Box 4024 MAYFAIR, HASTINGS

PHONE 67-039

BAY-BRITE Stainless Steel

Page 25

HB’s history on board’s walls

The board room of the Hawk’s Bay Farmers’ Meat Co. at Whakatu is a place of recollection. Photographs on the walls represent a fair slice of Hawke’s Bay contemporary history.

The first board of directors elected in January, 1913, for instance, revives memories for generations living today.

The list includes Messrs C. H. Cranby (1913-16), the chairman, Davis Canning (1913-18), H. J. H. Glazebrook (1913-22), J. A. Macfarlane, deputy-chairman (1913-16), J. C. Parker (1913-26), James O’Neill (1913), W. J. Stratton (1912-21), J. D. Todd (1913-14, 1934-46) and T E. Welch (1913-47).

Personalities of a later period follow in their footsteps, and all, like the first board of directors, were conspicuous in some field of farming and business, often both.

A glance at random identifies such people as Mr C. D. Buddo (1946), a member of a well-known Canterbury family, one of two brothers who farmed at Poukawa most successfully. Their farms today are carried on by their sons, both the export and domestic meat markets being well served.

FAMOUS PAKOWHAI

There is the name of R. (Dick) Tattersall, whose father farmed a part of world famous Pakowhai, one-time fattening land that established a reputation second to none for throughput of livestock and cropping. With its tremendous depth of river-formed top-soil.

In one season alone the 300-acre holding supplied one-seventh of the wether intake at Whakatu.

When the property was sold it made record figures at auction for farming land.

Next there is the name of L. R. Averill (1947), now living in retirement at Taupo but well remembered as a farmer at Maraekakaho. His father, the late Mr Edward Averill, was a member of the board in 1921.

The late Mr Averill managed two well-known estates, Mangatoro station (Dannevirke) and Olrig Station, at the time one of the largest sheep runs in the province, stretching as it did, from the environs of Salisbury Road over Maraekakaho and Mangatahi to the fringe of Kereru. Mr Averill also farmed his “Echills” property in the same locality and it is now farmed by his grandsons.

Mr H. M. Glazebrook, of Washpool fame, was a board member from 1932-35. And other board personnel of note included the late Mr O. M. Monckton (1913-47), a member of one of the best known North island pioneering families, and Mr L. H. McHardy (1916-28), of Blackhead fame on the coast south of Pourerere.

The earlier membership includes Mr C. Smith (1926-32), Mr J. W. Ellingham (1917), Mr S. Chadwick (1940), and Mr F. S. Candy, manager from 1914 till 1938 and elected to the board in 1944.

Would hold for week

With a refrigerator, no matter what the size, the main worry is a possible power failure.

What then is the situation at the Whakatu freezing works with their new $11 million “fridge” now in full operation?

The new freezer and storage complex does not even have a backup power system. The only emergency power supply is for a number of permanently lit lights and a couple of fans.

The works’ chief engineer, Mr A. H. Waterhouse, is not worried, however. He explains that the insulation of the stories is such that in the event of a complete power failure there would be no significant rise in temperature for at least one week.

He is pretty confident a power failure would not last that long.

[Advertisement]

“We are proud to be associated with the Hawke’s Bay Farmers Meat Company Ltd.

We know that containerisation and your private rail siding will keep you modern and on the move.”

NZ Railways.

[Advertisement]

MEMBER OF THE HALL THERMOTANK GROUP

EHS

REFRIGERATION – AIR CONDITIONING – and ABATTOIR SPECIALISTS

One of the three Howden 275 horsepower completely automatic ammonia screw booster compressor sets, and a large suction separator vessel in one corner of the unmanned new Freezing & Storage complex main engine room.

We take this opportunity of congratulating The Hawke’s Bay Farmers’ Meat Co. Ltd., on the completion of this major expansion programme.