- Home

- Collections

- TUCK MP

- State Highway 5 - Tataarakina to Opepe

State Highway 5 – Tataarakina to Opepe

TUCK BROS LTD, Tataraakina Timber Co, Tarawera. (Hawke’s Bay).

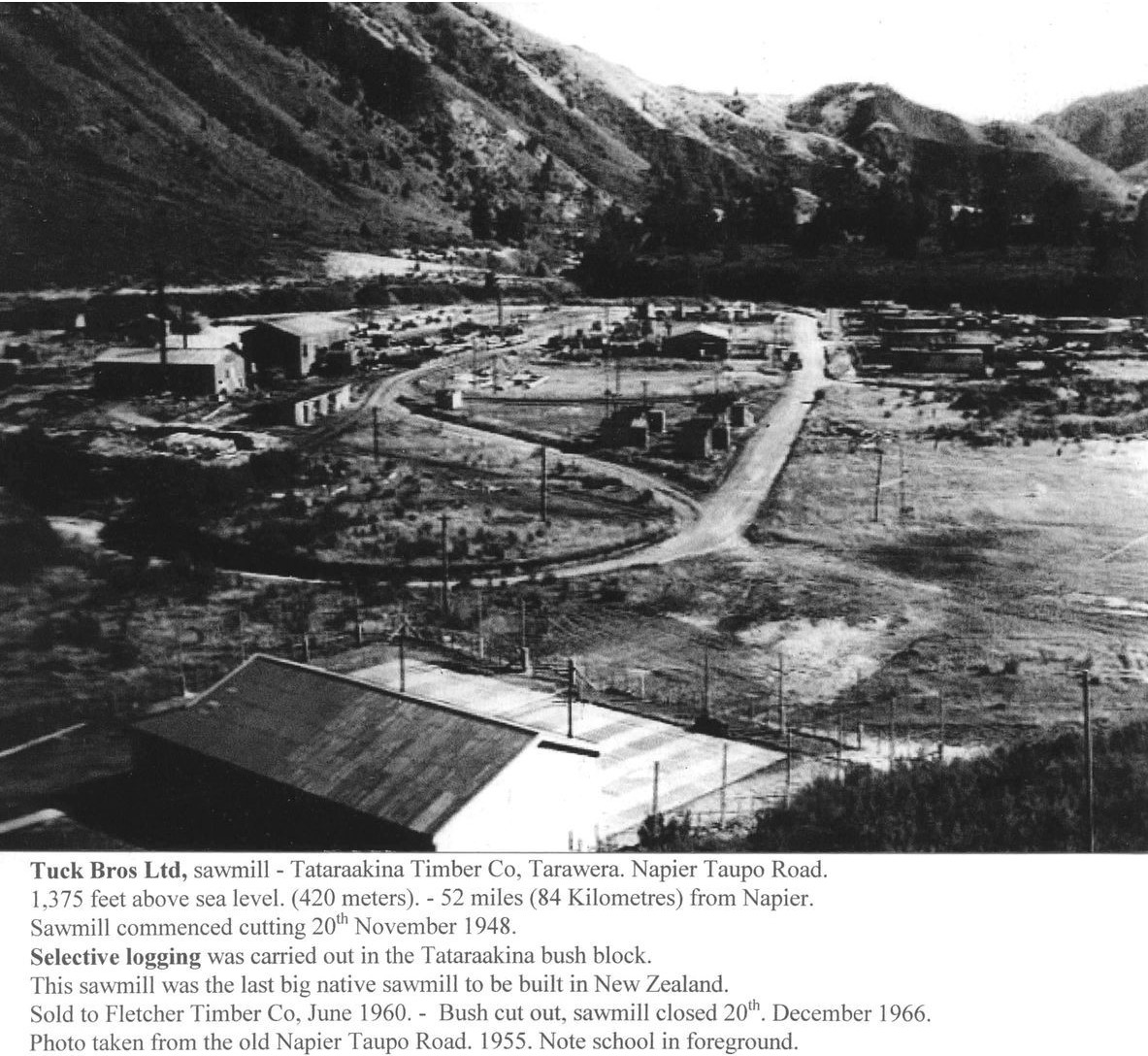

Stanley Palmer Tuck. (Stan) (Managing Director of Tuck Bros Ltd,) – 1947 designed, the sawmill to be built at Tarawera, on the flat 44 acre (18 hectares) site alongside the Napier Taupo Road. A Caterpillar D6 bulldozer from Tuck Bros Oruanui sawmill was dispatched late 1947 to construct roads and building sites.

Tuck Construction Ltd, a building company (Registered 27th February 1948) started building the sawmill, February 1948, cookhouse, and 10 single men’s unit’s. March 1949 the 11 staff houses were started and completed 10 months later. Tarawera School, relocated onto a site at the sawmill 1950/51 and enlarged. Company staff consisted of carpenters and a electrician, plumbing and painting was done by selected firms. Tuck Construction was well set up with on-site concrete batching plant, saws, planer, and sanding machine. Building operations were expertly managed by Eric Holmes Smith, (Smithy) who joined the company on 14th April 1948.

Eric was a Warrant Officer in the RNZAF Sawmill Unit commanded by Stan. Pacific Islands World War II. He was building in Gisborne, had heard that Stan Was building a sawmill and was keen to be involved.

Stan, a sawmiller and engineer soon had a section of the sawmill cutting its own building timber – temporarily powered by 120 H.P. 2 stroke GM diesel industrial motor. Two GMC war surplus 6 wheeler trucks were purchased, one used round the building site, while the other carted building materials, steel components and machinery from the company’s Taupo joinery factory, engineering workshop and from other sources. This truck later became the sawmills logging truck until replaced in November 1951 by a new International LF190. Tuck Bros Ltd, named and registered (27th February 1948) the sawmill Tataraakina Timber Co, after the native Tataraakina Block to which they had the cutting rights. Tataraakina sawmill cut it’s first production log under steam power on the 20th November 1948.

Completion was now concentrated on the Verticle [Vertical] saw (breaking down saw) to handle the larger logs. The first log to be cut was placed on the vertical saw’s carriage on 14th May 1949. The sawmill was built for an estimated life of 20 years to cut large native logs, of mainly Rimu, Kahikatea, Matai, Totara and Miro.

Selective logging:

Only trees marked with a number by the New Zealand Forest Service were logged. This promoted regeneration of bush. The Tataraakina block produced many large trees so the sawmill was designed to cut big logs and even then some logs were too wide for the vertical saw frame and had to be split on the mill skids by blasting.

Roading and Logging:

Road building, – A small bulldozer, Allis Chalmers HD5 followed Stan’s ‘Abony level’ survey trail (a mark by Machete slash) formed a rough track for the larger bulldozer to follow and work, where possible pushing downhill.

The company operated Caterpillar D7 3T and Allis Chalmers HD10. bulldozers. The first logging truck was a WWII war surplus GMC 6 X 6 (complete with gun turret). When government overseas purchasing restrictions were lifted in 1951. The GMC was replaced with an American built International LF 190 tandem drive 6 wheeler with a heavy duty logging trailer built at the company’s Taupo engineering workshop. Stan used a large aerial map of the bush area from which he planned, surveyed and supervised building bush roads and bridges. The main bush road established in this steep country with high annual rain fall was 19 miles (31 kms) in from the Napier Taupo Road, with easy gradients and many miles of side roads. Stan received many tributes from engineers and Forestry Ministers for his ability to construct roads in this steep, wet country.

Sawmill power and Electricity:

A horizontal steam engine – English ‘Tangye’ single cylinder – 14.5inch bore (36.8cm), 12 foot ( 3.6 meter) flywheel, powered the main saws and their connected machinery. The boiler, operating at 120 lbs per square inch pressure, fired with timber slabs (reject wood), feeding steam to the steam engine and log skids winch. Within the engine room, electricity was generated by one of two diesel engines driving generators, – one on stand-by. Electricity was used in the sawmill for lighting, and to power electric motors on the Goose saw, sawdust creepers, saw-doctors saw sharpening equipment, the village houses, single men’s quarters, cook house, school, street lighting, and water pump station. The water pump station also had a stand-by diesel motor.

Sawmill operations:

Logs arrived to the sawmill skids by logging truck, cut to length and as most logs were large they entered the mill via the breaking down saw – a large verticle saw that cut the log in half, (length wise)

Smaller logs, would by pass to go straight onto the pacific carriage. From the breaking down vertical saw, the half logs went to the pacific carriage to be cut into flitches (large timber pieces).

Next – to the breast bench cutting the flitches into boards, the waste going into the slab bin for boiler firing. The boards were then end trimmed by the goose saw (sometimes called docking saw) stacked onto a trolley on rails and taken out to the timber sorting skids, tallied (measured), and made up into loads ready for timber trucks to transport to the town retail timber yards. Some timber was stacked filleted (air flow round boards) in the sawmill timber yard for drying and later dispatched. This had the advantage that dry timber allowed more to be carted per truck load. The sawmill produced, on average about 12,000 board feet per day.

Tataraakina sawmill was the last large native sawmill built in New Zealand. It was well planned and constructed, incorporating modern labour saving machinery, much of it built at Tuck Bros Engineering workshop, Taupo.

Housing and school:

The company built 11 modern houses with fenced grounds and vehicle garaging. – 10 single men’s quarters, wash and drying rooms, a well appointed cook house, dinning room, and employed a cook.

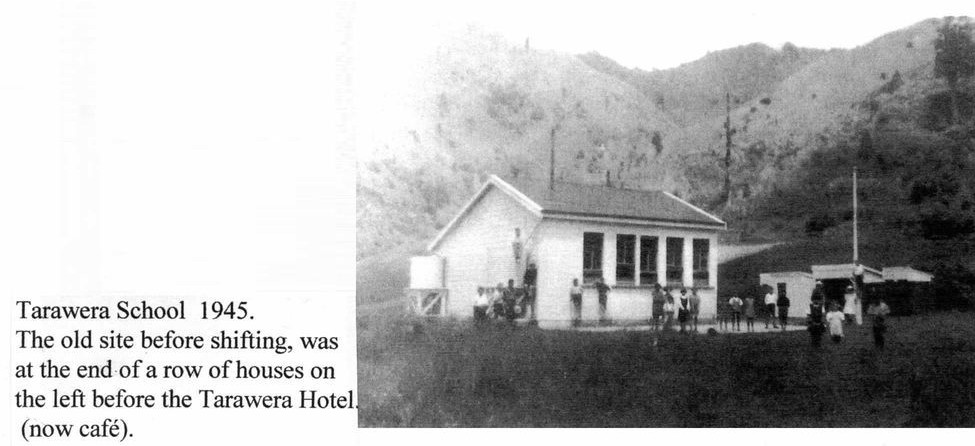

By arrangement with the Hawke’s Bay Education Board the Tarawera School was moved by volunteers using the company’s logging truck, from the site near the Tarawera Hotel to the sawmill grounds.

This was completed over the Christmas holiday break, 1950/51.

The school rooms were used for social events. The company gifted a film projector (films were drawn from the National Film Library), built concrete basketball and tennis courts in front of the school, and levelled sports grounds for cricket and football. The village was well lit at night with street lights.

Water supply:

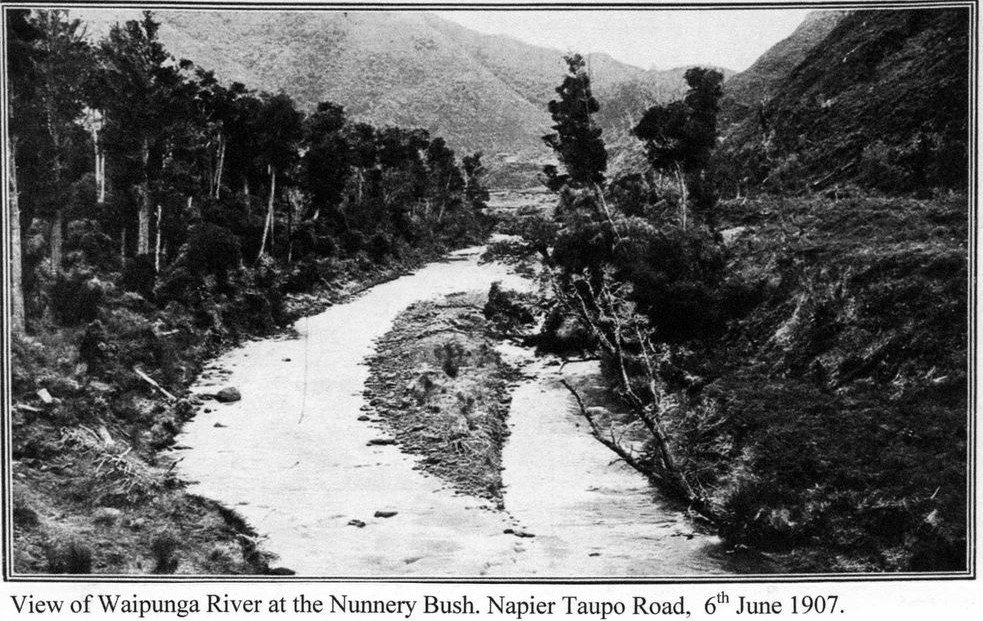

Originally pumped from the Waipunga River, was subjected to being muddied by floods –

Later water of a high quality from a spring in the valley above the mill site, was timber dammed, then pumped into two 7,000 gallon (31,822 Litres) wooden holding tanks manufactured at Tuck Bros Taupo joinery factory. One tank for mill use, the other for the houses, school, and fire hydrants that were set at intervals around the streets.

Employment : Sawmill and bush operations 18 – 20 men. Closed December 1966 after 19 years of operation.

State Highway 5 – now passes over the sawmill building site. – 2.5 Kilometres Napier side of Tarawera Café.

(Revised 25/01/2016. Michael Palmer Tuck).

Papers Past > New Zealand Herald > 9 June 1934 > Page 8 > PINUS INSIGNIS

PINUS INSIGNIS

New Zealand Herald, Volume LXXI, Issue 21822, 9 June 1934, Page 8

LARGE DIMENSIONS RECORDED

In view of the doubt prevailing in some quarters of the suitability of the pinus insignis for planting at high altitudes in the Dominion, some observations made recently by Mr. Hugh Corbin are of interest. During an extended tour made recently in the Taupo and Titiokura districts he made measurements of a number of older trees.

In the neighbourhood of the Terraces Hotel at Taupo, the elevation of which is 1400 feet above sea level, Mr. Corbin measured certain stalwart trees which were found to have a breast-high diameter of 3.8ft.and a height of well over 90ft. About 10 miles away, at an altitude of 2400ft., there were also some fine trees which had had no cultural treatment to force their growth.

The best in a group at Tarawera, growing at 1700ft., had a breast-high circumference of nearly 20ft. and a height of over 116ft. Higher still, at Te Horoto [Haroto], there were trees 3.65ft. in diameter and 100ft. high, and there were also a number of stands of healthy younger trees. Young trees on the summit of Titiokura were growing well at 2300ft., some of them being 40ft. high.

Mr. Corbin states that in South Australia, where there are greater areas of pinus insignia plantations than in all the rest of the Commonwealth put together, the highest tree recorded by measurement was 109ft. The larger tree mentioned at Tarawera growing at 1700ft. would therefore probably be a record. Mr. Corbin estimates that it would contain somewhere in the neighbourhood of 10,000 super feet of timber in log measurement.

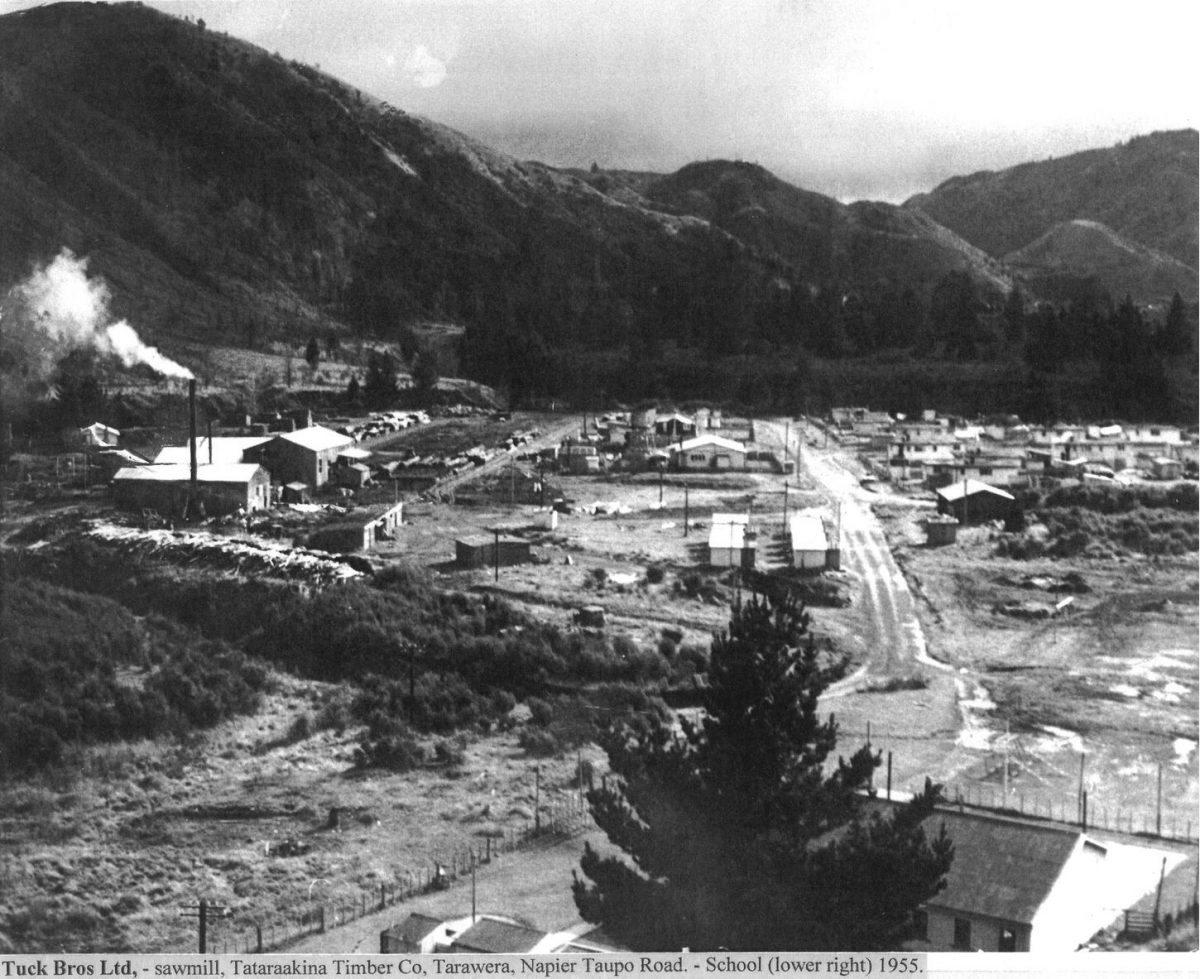

TARAWERA VALLEY, Napier Taupo Road. – (Foreground) Tuck Bros Ltd, sawmill & staff houses. Tataraakina Timber Co, Tarawera. (1948 – 1966). (Taupo District Council. Archives photo 1955). : History researched by Michael Palmer Tuck. 5th December 2015.

Tarawera Mineral Hot Springs

Highway 5, Taupo

Hotel No 3 (1907-1965)

Tarawera Tavern (1966)/Café. 2009

Hotel No 1 (1872-1973)

Hotel No 2 (1897-1906)

Ministry of Works Depot.

Deviation opened 1980.

Logging road to sawmill.

Tarawera School.

Old Napier Taupo Road.

Entrance to sawmill.

Tuck Bros Ltd, logging roads.

TARAWERA VALLEY. (Napier Taupo Road).

87 kilometres. (54 miles old road) from Napier. – Altitude 420 meters (1,375 feet).

Note: The three Hotel sites. 1872-1965. Café built 1966. First as a Tavern. (Hawke’s Bay’s first Tavern.

Mount Tataraakina – height. 1,130 meters. (3,708 feet).

Tarawera Mineral Hot Springs

Hotel No 3. /now Café.

State Highway 5.

TARAWERA VALLEY.

Hotel No 1.

Hotel No 2.

Ministry of Works Depot.

Old Napier Taupo Road.

Tuck Bros Ltd, Tataarakina Sawmill.

Tarawera School.

Tuck Bros Ltd, logging road

Wharangi

Mt. Tataarakina

Stoney Creek

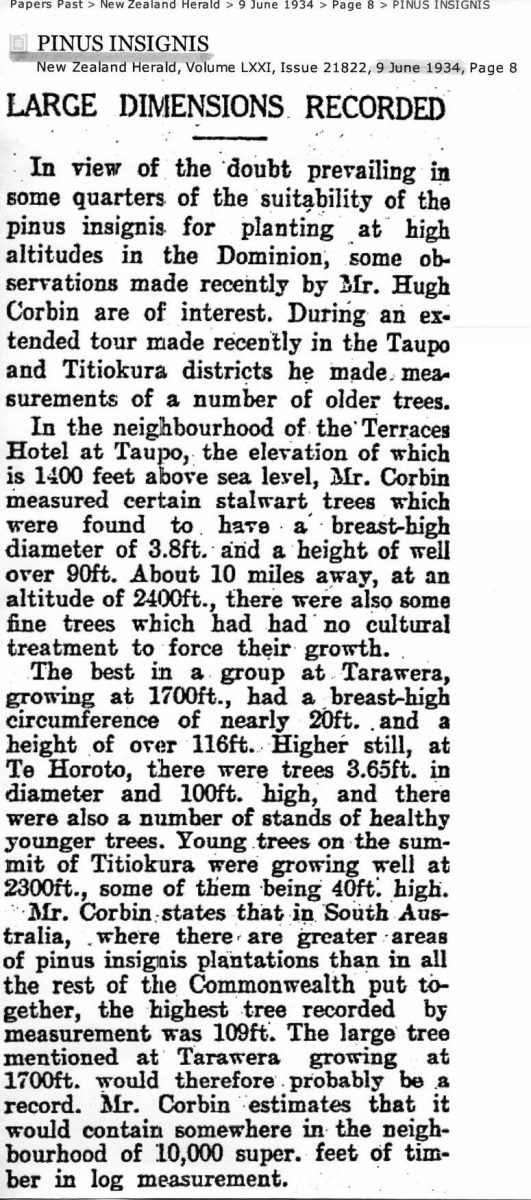

Tuck Bros Ltd, sawmill – Tataraakina Timber Co, Tarawera. Napier Taupo Road.

1,375 feet above sea level. (420 meters). – 52 miles (84 Kilometres) from Napier.

Sawmill commenced cutting 20th November 1948.

Selective logging was carried out in the Tataraakina bush block.

This sawmill was the last big native sawmill to be built in New Zealand.

Sold to Fletcher Timber Co, June 1960. – Bush cut out, sawmill closed 20th. December 1966.

Photo taken from the old Napier Taupo Road. 1955. Note school in foreground.

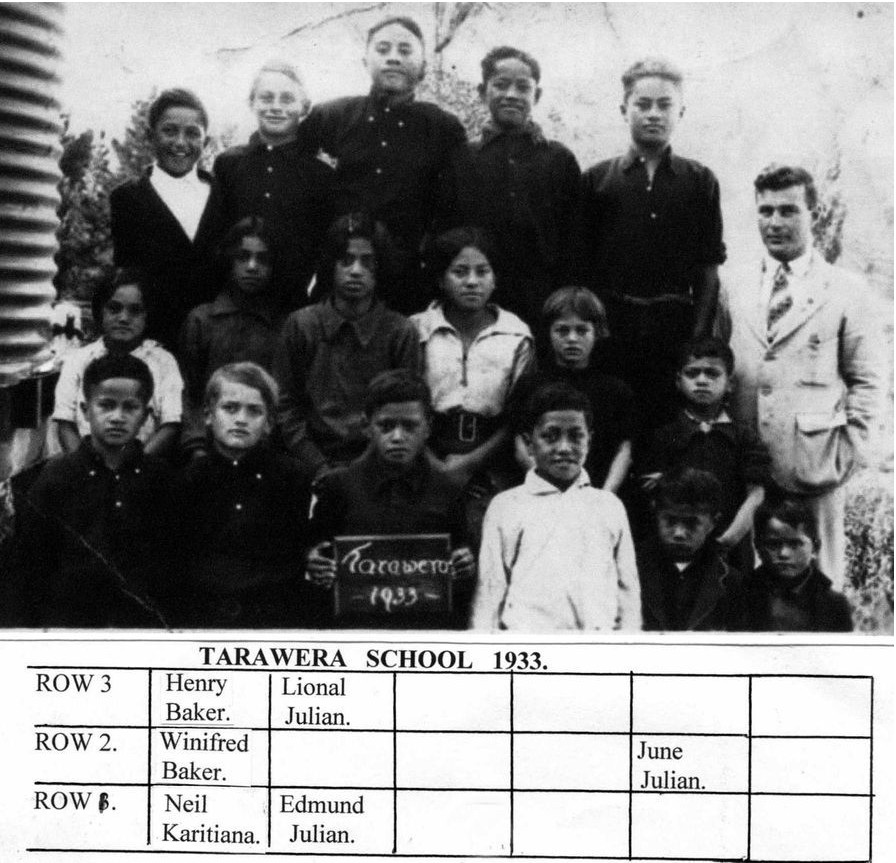

The Tarawera Native School reopened 26th October 1926 in a small building near the Tarawera Hotel. This building was let by J .T. Harvey manager Hawke’s Bay Motor Co.

First teacher was Miss. I. Merson.

The next teacher starting the new year on 1st February 1927 was M.A. Fimms who left on 29th June 1928. Tarawera Native School’s own newly built, building was built on land Napier side, on the left just before Tarawera Hotel.

The first teaching day in this new school building was 11th June 1928.

Teacher : M.A. Fimms.

Pupils.

Gwenda Donald.

David Baker.

Lena Raihania.

William Baker.

Joy Lynch.

Robert Cooper.

Mary Baker.

Margaret Baker.

Jessie Baker.

Melvia Hubbard and Bill Hubbard

Tarawera School Pupils from 1948

My name is Melvia. Our family moved from Rotorua to Tarawera when l was nine years old. It was a big shock moving to the bush after living in Rotorua. Our father was a truck driver. He got a job at the Bottom Mill. I have two sisters, Margaret and Carol. Bill is the youngest child in our family.

The school was near the pub. Peter Edwards was a lovely teacher and so was Mr Reed. The school was later moved closer to Tucks Mill, also known as Tataraakina Mill. There were sports days, pictures, and dances which were supported by all the mills in the district.

My name is Bill Hubbard. We didn’t have any lessons when it snowed. Sometimes the snow was about five or six foot deep. We mucked around a lot in the snow.

We had a school bus and if we missed it, it was a long walk to school. We lived at the Bottom Mill near the Crawford family. We had a lot of fun playing with the local kids. The girls were brought up rough. Bull Rush was one of the games we all played.

Photo taken at new school site at Tuck Bros Ltd, Sawmill Tataraakina Timber Co. School shifted 1951.

Tarawera School 1956 Photo – Phylis Parkes

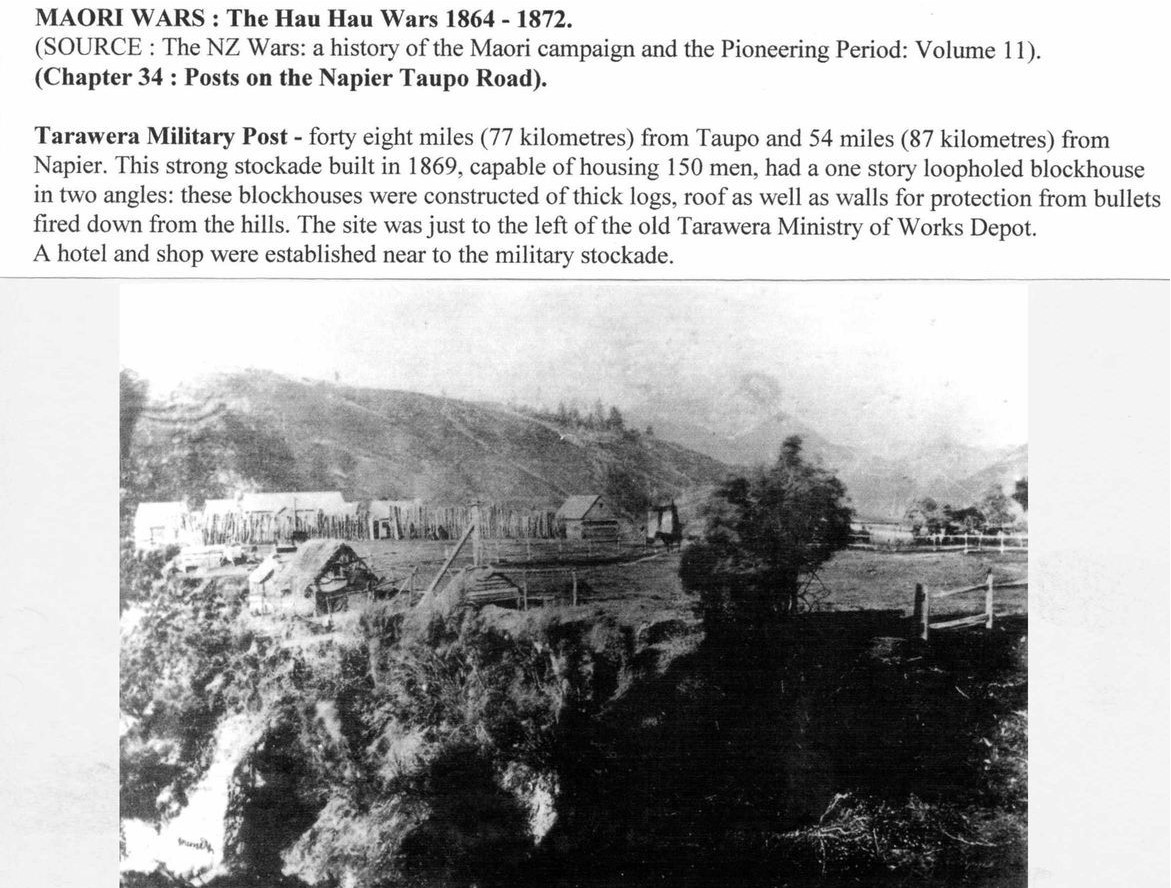

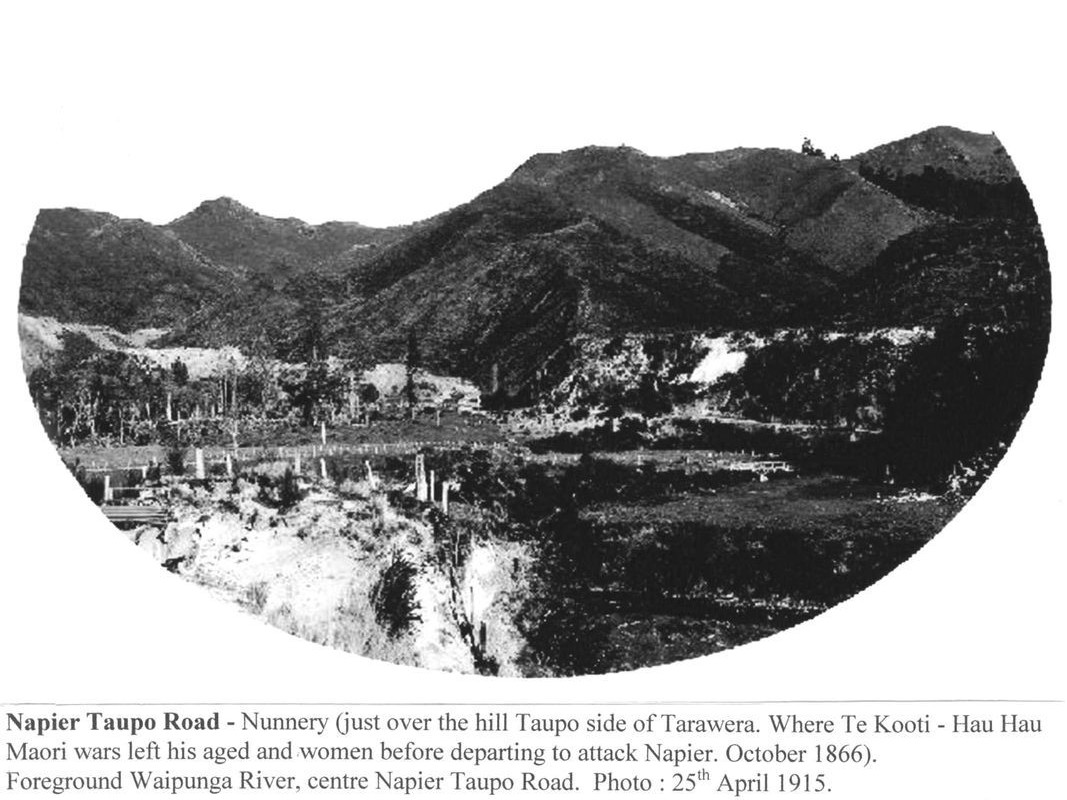

MAORI WARS : The Hau Hau Wars 1864 – 1872.

(SOURCE : The NZ Wars: a history of the Maori campaign and the Pioneering Period: Volume II).

(Chapter 34 : Posts on the Napier Taupo Road).

Tarawera Military Post – forty eight miles (77 kilometres) from Taupo and 54 miles (87 kilometres) from Napier. This strong stockade built in 1869, capable of housing 150 men, had a one story loopholed blockhouse in two angles: these blockhouses were constructed of thick logs, roof as well as walls for protection from bullets fired down from the hills. The site was just to the left of the old Tarawera Ministry of Works Depot. A hotel and shop were established near to the military stockade.

TARAWERA HOTEL – Owners / Licensees. (Researched by Michael Palmer Tuck. Nov 2015).

Region – HAWKE’S BAY.

1872 JOHNSON, J. Tarawera Hotel.

1873 13th April PEACOCK’S Tarawera Hotel. Burnt down. (Hotel No 1)

Coach passengers then stayed at the store owned by the Stage Coach Co.

1877 PEACOCK’S Tarawera Hotel.

1878 SUTHERLAND, Donald. Tarawera Hotel & store.

1882 FALVEY, Duncan. Tarawera Hotel.

1883 15th Sept. BRILL, Thorwald Emelius. Tarawera Hotel.

1891 8th June CRANE, John Fredrick. Tarawera Hotel.

1894 January. CRANE, John Fredrick. Tarawera Hotel. (Financial trouble. Disappeared leaving family).

1894 January. GREENWOOD, C.W. Tarawera Hotel. (Took charge & licensed to manage hotel).

1894. 1st June. HERRIES, Frederick William. Tarawera Hotel.

1896. 5th June HERRIES, Frederick William. Tarawera Hotel.

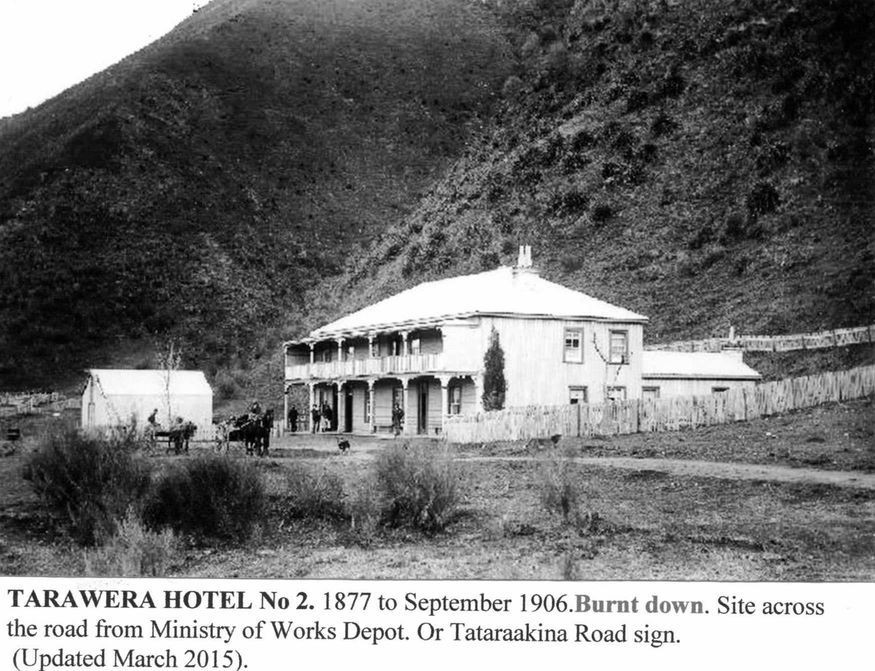

1897 2nd June HEBBERLEY, James William. Tarawera Hotel. – Building new Hotel No 2. (died 1898).

1898. 25th July Estate of James W Herbberley, Tarawera Hotel – for Sale & lease of 1,727 acre sheep run.

1899 January. MACKAY, Duncan. The Coach & Horses Hotel. (7th June 1899 name changed).

1906. 25th Sept. MACKAY, Duncan. The Coach & Horses Hotel. Burnt down. (Hotel No 2)

1907. Hotel No 3. MACKAY, Duncan. Hotel opened, – built nearer to the hot mineral springs.Hotel named – Hot Springs Hotel. Tarawera.

1910. 29th Nov. Duncan MACKAY Shot himself. Hot Springs Hotel. Tarawera.

1910. 2nd Dec. MACKAY, Mary. (Widow) applied for leave to carry on running hotel till next meeting.

1911. 12th May. MACKAY, Donald John. Hot Springs Hotel. Tarawera. – Applied for licence

1911. 1st Dec. MACKAY, John Alexander transferred hotel licence to George Edward Raymond KIRK.

1911 KIRK, George Edward Raymond. Hot Springs Hotel. Tarawera.

George. E.R. Kirk conscripted for Military Service. World War 1. (His future – unknown).

1916 10th June. LAMBERT, Reginald Woolridge. Hot Springs Hotel. Tarawera. (ASHTON, Squire & Lambert)

1919 3rd Dec. FOWLER, Claude Newton. Hot Springs Hotel. Tarawera.

1920 4th June. CARGILL, Benjamin Fleetwood. Hot Springs Hotel. Tarawera.

1923 WELLS, Jack & Ada Tarawera Hotel. – Name changed : Tarawera Hotel.

1926 HILL, Walter. Tarawera Hotel.

1931 YULES, Frederick Elizabeth. Tarawera Hotel.

1935 MEIKLE, J. Tarawera Hotel.

1937 January O’REILLY, J. Tarawera Hotel.

1938 READING, Bob & Elaine. Tarawera Hotel.

1941 DEAKIN, George & Jean. Tarawera Hotel.

1945 11th July SCOTT, Jim. Tarawera Hotel.

1946 HASLAR, Brian. Tarawera Hotel.

1949 CABLE, Dick. Tarawera Hotel.

1951 ORLOWSKI, Stan & Joyce Tarawera Hotel. – (Stanislaus Ivan Orlowski).

1952 – Lloyd & Betty Mathews. Lloyd hotel manager. Joyce Orlowski & Lloyd joint licensees.

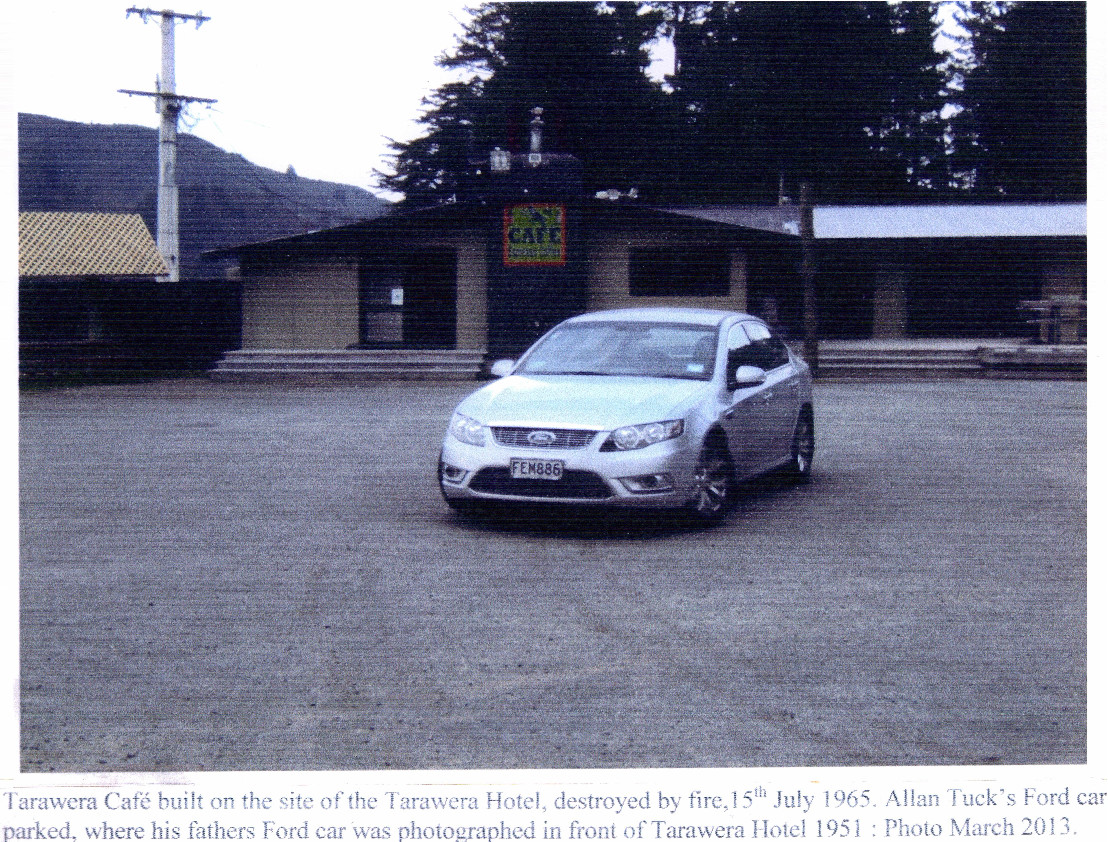

1965 15th July ORLOWSKI / MATHEWS Tarawera Hotel. Burnt down. (Hotel No 3)

1965 Stan Orlowski -Temporary; public bar established – licensee Lloyd Mathews to March 1966.

1966 Joyce Orlowski – Licensee April 1966 to December 1966. – Lockwood Tavern built & sold to –

1966 15th Dec. HENSLEIGH, Roger & Leslie. Tarawera Tavern. – (Opened – Hawke’s Bay’s first Tavern)

1974 30th Aug. WAIKATO BREWERIES Ltd. Tarawera Tavern, – Purchased – Manager appointed.

1974 HENERY, Robert. Tarawera Tavern. – Manager for Waikato Breweries Ltd.

1974 Waikato Breweries Ltd, taken over by New Zealand Breweries Ltd.

1975 ADAM, Hector James. Tarawera Tavern. Manager for NZ Breweries.

1977 Sept. New Zealand Breweries Ltd, name changed to Lion Breweries.

1977 31st Oct. BENJAMIN, P.G. & P Tarawera Tavern. – Manager for Lion Breweries.

1981 28th Feb. BATCHELOR, Anthony. Tarawera Tavern. – Manager for Lion Breweries.

1982 BAILEY, Victor Joseph & Jennifer Lynn BAILEY. Tarawera Tavern. – Managers for Lion Breweries.

1982 9th July. BAILEY, Victor Joseph & Jennifer Lynn BAILEY. Tarawera Tavern. – Purchased from Lion Breweries.

1988 25th July. HALL, David Graham & Moeaoa. Tarawera Tavern. – Leased from V. & J. Bailey.

1994 19th Aug. TREZISE, Ronald & Caroline. Tarawera Tavern. – Leased from V. & J. Bailey.

1996 18th Jan. RYNEX, Frank Edward & Kay Patricia BELCHER Tarawera Tavern. – Leased from V. & J. Bailey

2002 18th July Frank Edward RYNEX died.

2003 13th Aug. BELCHER, Kay Patricia Tarawera Tavern. – Purchased freehold.

2004 7th May. BEASLEY, Rupert Douglas. & Ngaire Caro Lillian MIDGLEY. Tarawera Tavern. – Purchased.

2007 22 Feb. MIDGLEY, Ngaire Caro Lillian. Tarawera Tavern. – Purchased.

2008 October. ANDREW, James Robert & Marie Heather BUCKLEY. Tarawera Tavern. – Purchased.

2009 Sept. ANDREW, James Robert & Marie Heather BUCKLEY. Tarawera Café. – Changed from Tavern to Café.

2015 Nov. ANDREW, James Robert & Marie Heather BUCKLEY. Tarawera Café.

LATEST SOUTHERN NEWS. [From New Zealand Press Association.]

Daily Southern Cross, Volume XXIX, Issue 4877, 14 April 1873, Page 3

LATEST SOUTHERN NEWS.

[From New Zealand Press Association.]

NAPIER, Saturday.

Peacock’s Hotel, at Tarawera, situated halfway between Napier and Taupo, was burned down yesterday: the cause of the fire is unknown. The building and stock was insured for ₤400 in the South British.

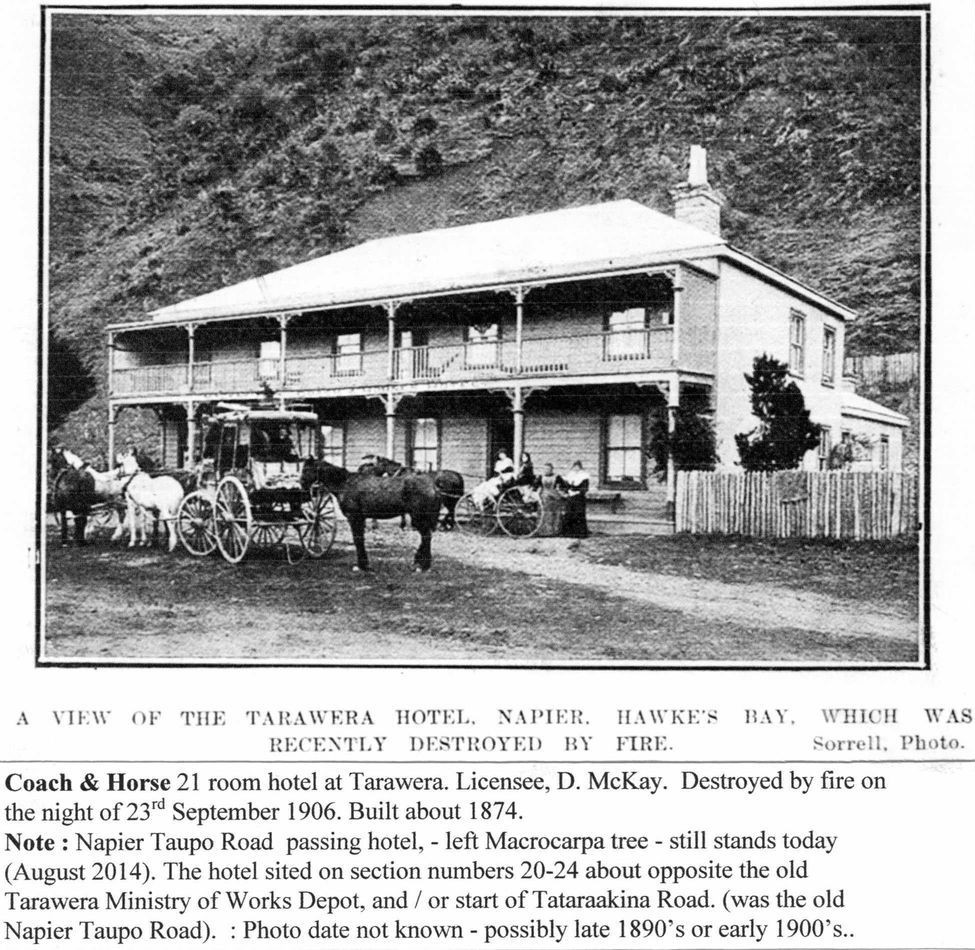

VIEW OF THE TARAWERA HOTEL. NAPIER, HAWKE’S BAY, WHICH WAS RECENTLY DESTROYED BY FIRE. Sorrell, Photo.

Coach & Horse 21 room hotel at Tarawera. Licensee, D. McKay [MacKay]. Destroyed by fire on the night of 23rd September 1906. Built about 1874.

Note : Napier Taupo Road passing hotel, – left Macrocarpa tree – still stands today (August 2014). The hotel sited on section numbers 20-24 about opposite the old Tarawera Ministry of Works Depot, and / or start of Tataraakina Road. (was the old Napier Taupo Road). : Photo date not known – possibly late 1890’s or early 1900’s.

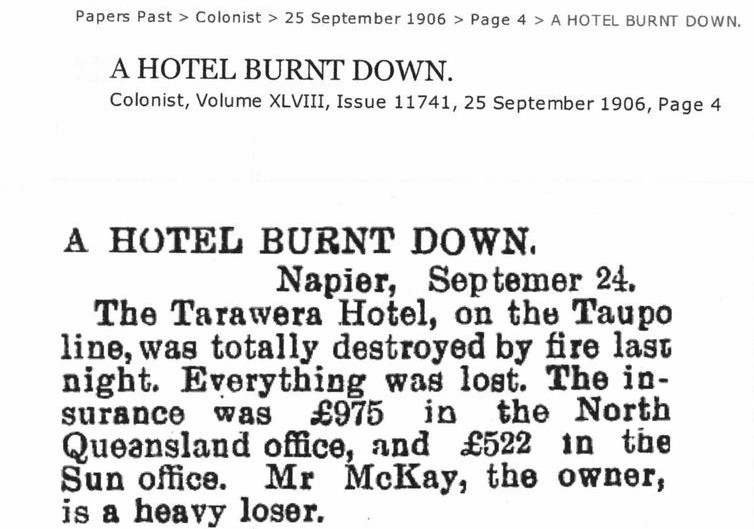

Papers Past > Colonist > 25 September 1906 > Page 4 > A HOTEL BURNT DOWN.

A HOTEL BURNT DOWN.

Colonist, Volume XLVIII, Issue 11741, 25 September 1906, Page 4.

A HOTEL BURNT DOWN.

Napier, September 24.

The Tarawera Hotel, on the Taupo line, was totally destroyed by fire last night. Everything was lost. The Insurance was £975 in the North Queensland office, and £522 in the Sun office. Mr McKay [MacKay], the owner, is a heavy loser.

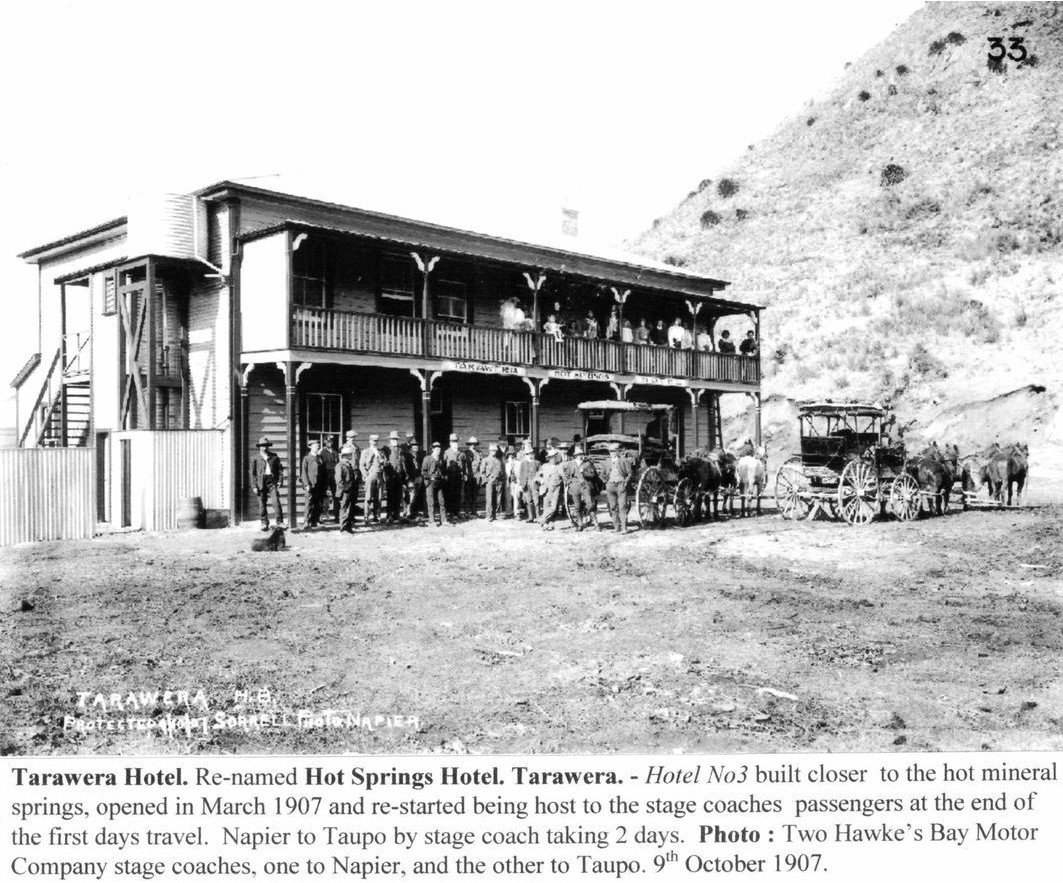

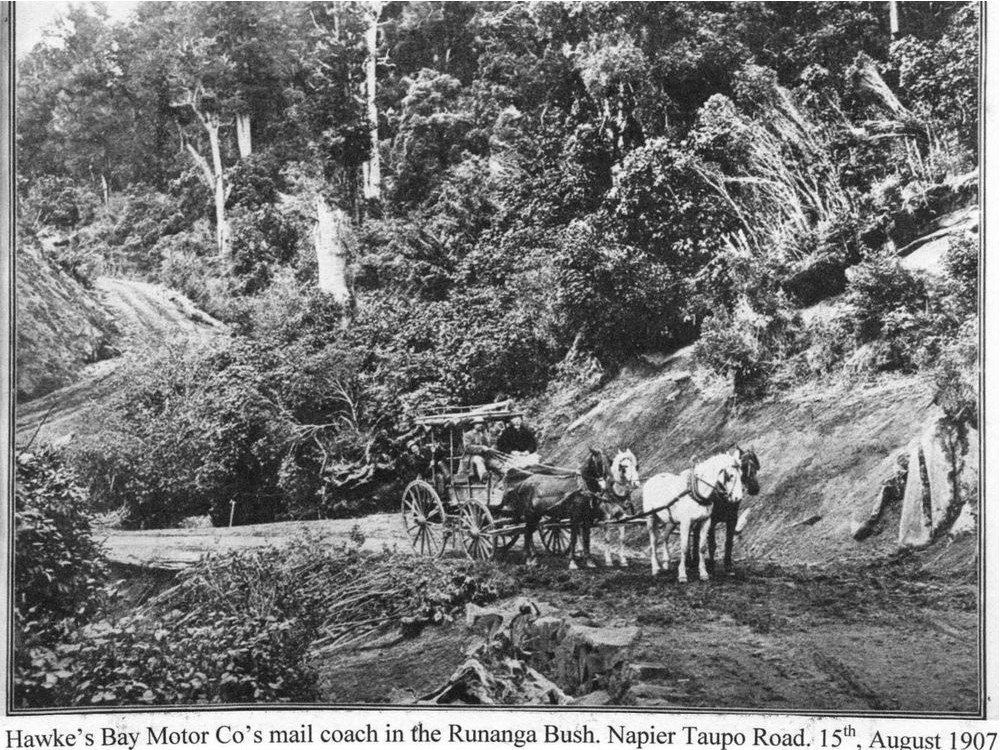

Tarawera Hotel. Re-named Hot Springs Hotel. Tarawera. – Hotel No 3 built closer to the hot mineral springs, opened in March 1907 and re-started being host to the stage coaches passengers at the end of the first days travel. Napier to Taupo by stage coach taking 2 days. Photo : Two Hawke’s Bay Motor Company stage coaches, one to Napier, and the other to Taupo. 9th October 1907.

TARAWERA H.B.PROTECTED 9/10/07 SORRELL PHOTOGRAPHER

HOTELKEEPER‘S DEATH.

Evening Post, Volume LXXX, Issue 130, 29 November 1910, Page 7

HOTELKEEPER’S DEATH

[By TELEGRAPH – PRESS ASSOCIATION.]

NAPIER, This Day.

The police have received information from Tarawera that Duncan Mackay, proprietor of the Hot-Springs Hotel, was found dead early this morning with a revolver beside him.

The Daily Telegraph. 15th July 1965.

Tarawera Hotel burn [burns] to ground

The two-storeyed wooden hotel at Tarawera – about 45 miles from Napier on the Napier-Taupo road – was burned to the ground early this morning.

Eleven persons escaped from the blazing building in their night attire. They included the owner, Mr S. Orlowski, his wife and three children, two guests and three regular boarders.

One man, Mr J. Fitzgerald, believed to come from Rotorua, received lacerations of the wrist and arm while escaping from the burning building.

He was brought by car to the Napier Public Hospital, treated at the outpatients’ department, and allowed to leave.

The 91-year-old hotel blazed furiously, sending a red glow over the surrounding forestry areas. The glow was seen some five miles away.

The licensee, Mr L.N. Matthews, was awakened by screams about 2.30 a.m. He rushed through the building waking guests.

SMOKE VICTIM

Mr Matthews had his hair and hands singed and had to drag out a Tarawera millhand, Mr W. Merrick, who had been overcome by the smoke.

People in the district accommodated the guests and staff. Some slept in the cookhouse of a nearby sawmill.

Very few personal belongings were saved, and this morning people of the district were busy finding clothes and catering for the ‘fire’ victims.

It is thought the fire started in an upstairs bedroom.

SOON DOOMED

[…] worker’s wife, Mrs V. Keen. This morning Mrs Keen minded the children while Mr and Mrs Orlowski and Mr Matthews travelled to Taupo to buy new clothes and personal effects.

COACH DAYS LINK

The hotel was a well-known landmark on the route between Napier and Taupo. The site was the first day stopping place for five-horse coaches from Napier in the early days.

The hotel was built in 1874 after the militia had established a stockade, which was sited near the present hotel. This followed military action against the Maoris in this area.

It is understood that architects were preparing plans for reconstruction of the hotel in accordance with directions issued recently by the Licensing Control Commission. Efforts are being made to set up a temporary bar.

The hotel was insured for £10,000.

ALL THAT REMAINS of the 91-year […] destroyed by fire early this morning […] to users of the […]

Papers Past > Manawatu Standard > 7 October 1907 > Page 5 > THE TARAWERA BATHS.

THE TARAWERA BATHS.

Manawatu Standard, Volume XLI, Issue 8408, 7 October 1907, Page 5

THE TARAWERA BATHS.

Per Press Association.

NAPIER, This Day

A new bathing-house, erected at Tarawera by the Government, was opened on Saturday by Mr J. Vigor-Brown, Mayor of Napier, in the presence of a. number of visitors. The springs here have been used for many years by a limited number of visitors; but their fame, especially as a curative agent in cases of rheumatism and sciatica, having spread, the Government has been compelled to provide more adequate accommodation. A large new hotel has been erected near the springs, which can be reached from Napier in half a day and from Wellington in a day and a half.

Tarawera Bathhouse, on the Napier Taupo Road. Opened by the Mayor of Napier 5th October 1907.Waipunga River below.

LOOKING BACK

We take a journey into the past, thanks to the Daily Telegraph’s photo files and caption details from Napier historian Russ Spiller

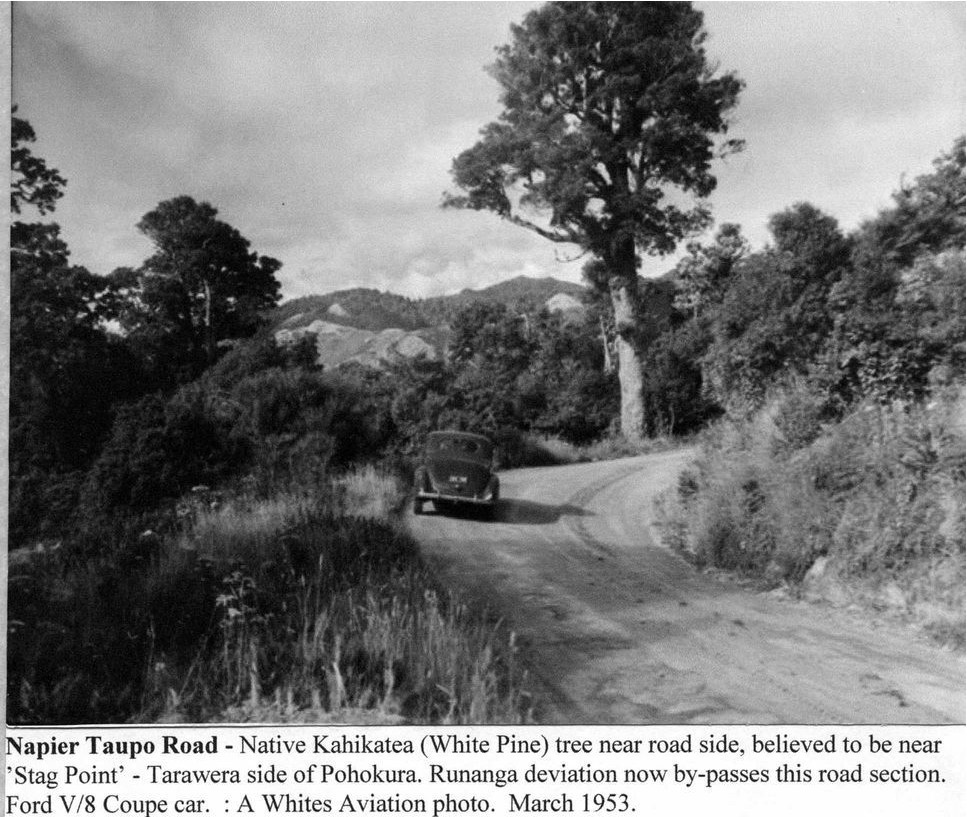

TIME TO REST: A stagecoach is pictured on the old Taupo Road, circa 1898. Russ believes this was taken at Pohurakura, [Pohokura] west of Tarawera, now bypassed by the Waipanga [Waipunga] deviation.

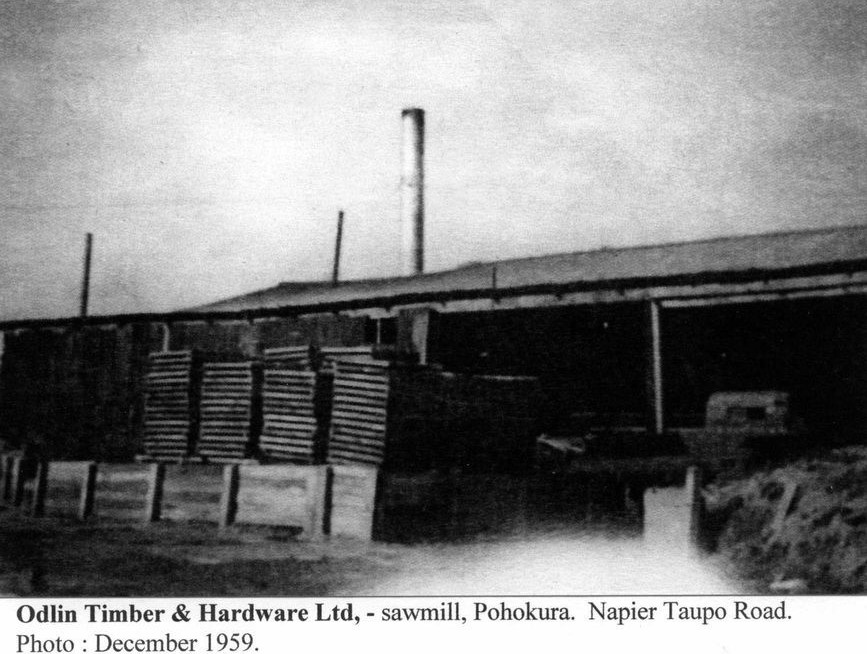

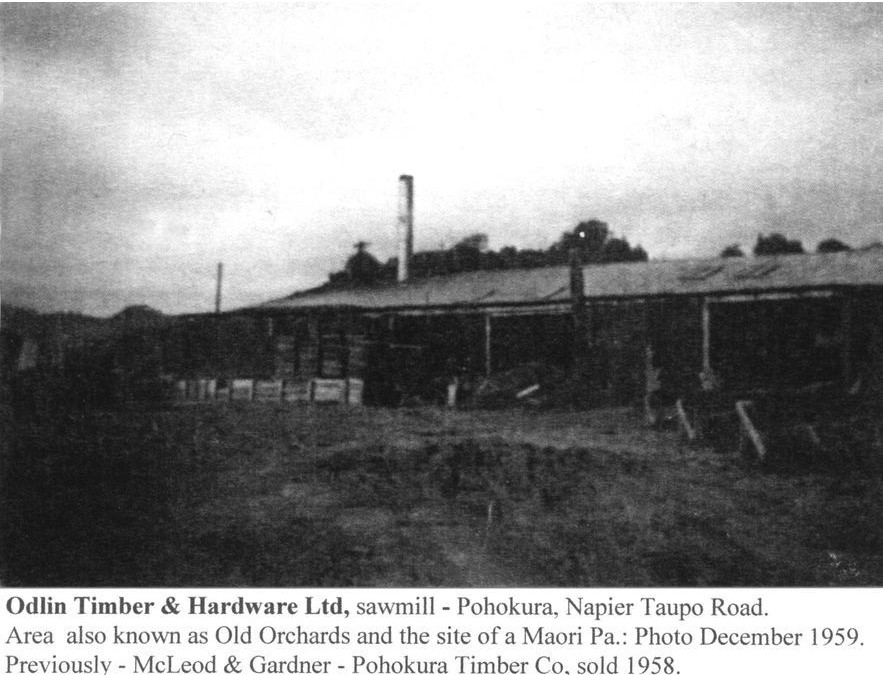

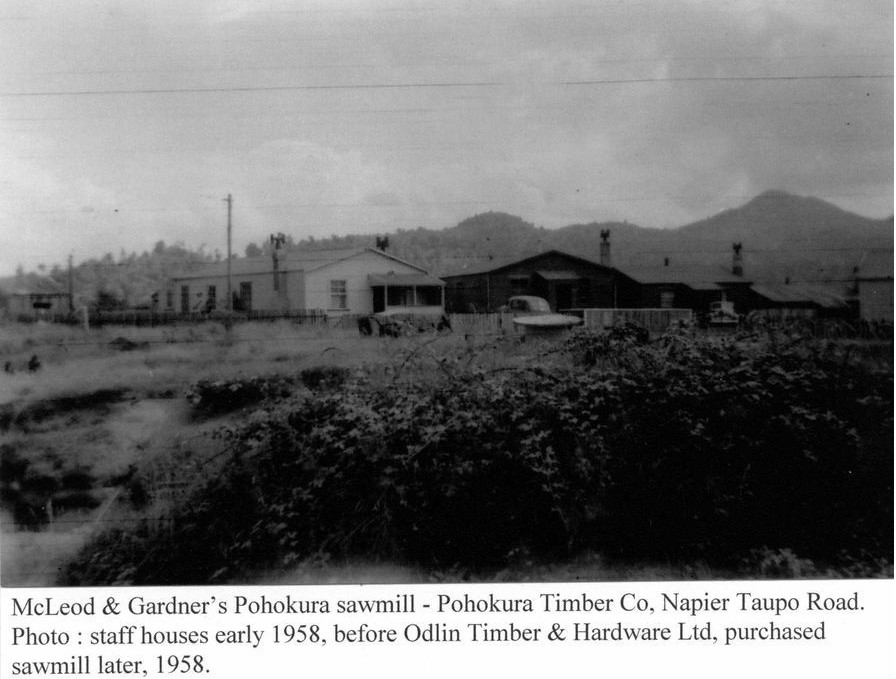

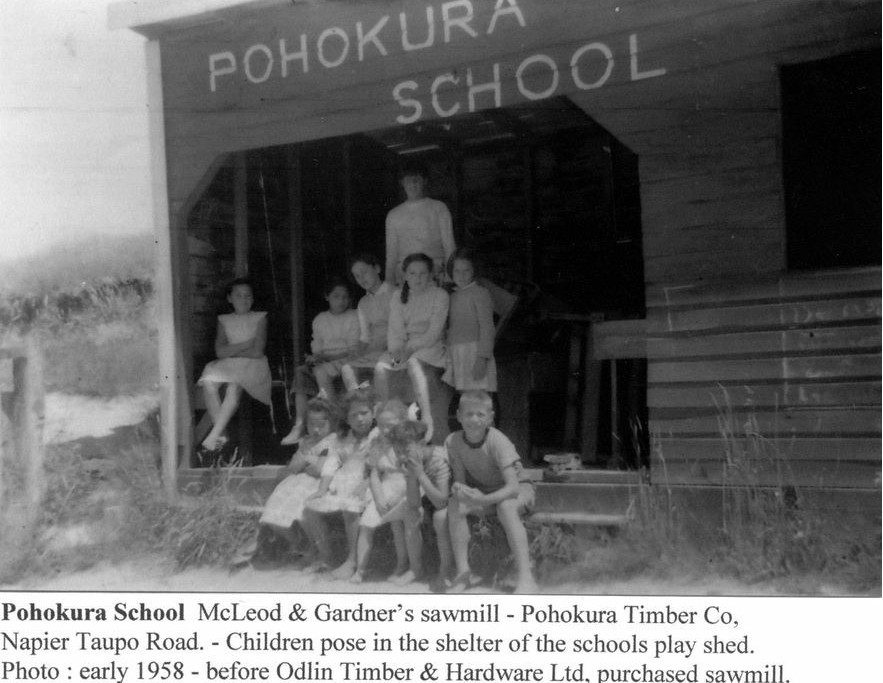

McLeod & Gardner – sawmill Pohukura [Pohokura]. (Area also known as Old Orchards). Napier Taupo Road. 60 miles (97kms) from Napier. – Elevation above sea level, 732 meters (2,400 feet).

McLeod & Gardner’s sawmill commenced cutting in 1941.

1958 sold to C & A Odlin Timber & Hardware Ltd,

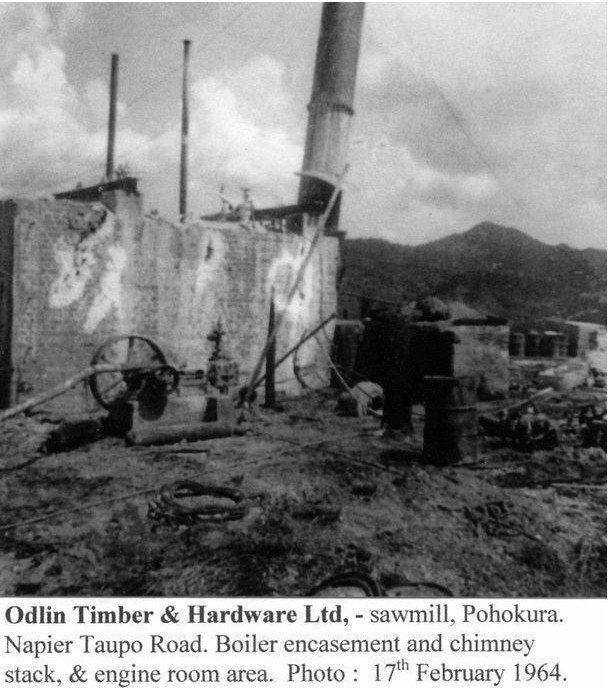

Odlin’s appointed Edie [Eddie] Batt, a well known sawmill manager, to manage the Pohukura sawmill. Destroyed by fire 13th February 1964. – Sawmill not rebuilt.

Odlin’s logged the area for about 2 years supplying the native logs to their Waikoau sawmill, near Tutira, in Hawke’s Bay.

Note : Napier Taupo Road passing between houses, (centre right), turning left before sawmill entrance (see timber skids), then down hill in front of houses to left, and on to Taupo.

Pohukura (Old Orchards) has been by-passed with the opening of the Runanga deviation on 24 May 1972.

[refers to previous page]

McLeod & Gardner Ltd, (1941-1958) sawmill – Pohokura Timber Co, Pohokura, ( also known as Old Orchards) Napier Taupo Road. Sold 1958.to C & A Odlin Timber & Hardware Ltd,

Aerial photograph flown 4th October 1966.

Note : bottom left, (from Taupo) – to right, the wider formed road was the main highway Napier Taupo Road.

The surface of the road was metal (gravel), regularly graded by the Public Works Dept, (renamed Ministry of Works). Pohokura, set on a ridge that widened further back, the Napier Taupo Road climbed quite steeply from both sides to peek opposite the houses and school. Other roads are sawmill logging roads.

Area lower middle right, where the sawmill was before totally destroyed by fire on the night of 13th February 1964.

Sawmill not rebuilt, logging continued to supply another sawmill, only about 2 years log supply was left.

The Daily Telegraph, Napier.

Monday. 17th February. 1964.

(Sawmill destroyed by fire. Thursday night. 13th. Feb 1964.)

Lost mill may not be rebuilt

The timber mill of C. and A. Odlin Ltd, at Pohokura, on the Napier-Taupo road, about, 60 miles north of Napier, which was destroyed by fire on Thursday night, may not be rebuilt, according to the branch secretary of the company, Mr F. Glover.

“The mill will be out of production for some time, and whether or not we rebuild will depend on the cost in comparison with transporting the logs to another mill,” Mr Glover said today

“However, the final say will have to come from our head office in Wellington.”

DISCOVERED FIRE

The mill manager, Mr E. L. Batt, left his home at 11.45 pm. on Thursday to look for the cause of a power failure.

“I saw flames shooting through the roof of the boiler-house, Mr Batt said. “It was obvious that there was nothing I could do to stop the fire, so I called the men out to confine it to the mill itself.

“The mill was like a natural funnel and the flames swept straight through it. Our fire-fighting gear was in good order but there was no water coming from the reservoir, as the pipes had burst near the boiler room.”

Stacked timber was removed from the danger zone and the men concentrated their efforts on keeping the fire away from nearby houses and buildings.

WIND HELPED

“Fortunately the wind was in the right direction and it carried the flames. away from the houses, Mr Batt said.

Odlins have a mill at Reporoa, Waikoau, and one at Hastings which is not operational.

The Napier showrooms of Odlins Ltd, were completely destroyed by fire on December 13 last year. Damage was estimated at £100,000.

Pohokura Mill

After making a few enquiries via Johnny Parks [Parkes] daughter Shona we have come up with a bit of info on the mill and village.

The mill opened approx 1942.

Mcleod/ Gardeners [McLeod & Gardner’s] were the owners before C & A Odlins took over.

Eddie and Hazel Batt {my parents} moved there in 1959 where he took on the role of mill manager.

My mum Hazel Batt operated the little telephone exchange called Hinekuku post office.

She took in telegrams, phone messages and sorted mail that was delivered each day on the service car.

She also held the first aide post.

The mill was operated by steam and I can remember the big boiler that was operated by Lou Hawkins.

My younger brother and I quite often went up to see him and he carried us over the hot boiler roof and sat us in the saw dust box.

There were big doors that he fed slab wood into the roaring fire but on top were 3 holes where he fed shovels of sawdust to keep the fire going at a certain temperature.

There were old gauges to keep an eye on how hot it was.

It is thought that a spark from the boiler was the cause of the fire that destroyed the mill.

And I will never forget that night. The fire just raged through the old building and there wasn’t any chance of saving it.

Looking at photos now it doesn’t seem as though it was all that big.

There was a GMC truck with a winch on it that was used to drag logs into the mill. This was sent down to the mill Odlins had at Waikoau

after the fire the other truck was an old Austin that used to take sawdust away. That one was lost in the fire though.

The mill employed approx. 12/15 workers plus a bush crew, all lived in the village.

Pohokura School. The day I started school 19 th aug 1959 we had to move from the smaller school room to the big hall next to the cook house.

The small school building became accomodation for some of the single men and there was a little prefab cottage placed on the school grounds for the teacher.

My 1st teacher was Mrs Tepohe [Te Pohe]. Her husband Patrick [Patika] worked over at the mill.

They also had a little shop at the front of their house but main supplies came out on the timber truck with Rex Brown.

Once a year we had an inspector visit from the education department just to make sure everything was running smoothly.

Eddie Batt was the school committee chairman and always got the village women together to help with xmas parties etc

Hazel took the girls into her home to teach cooking and Joy Gore took a group of the boys to her home to do the same.

There was always the end of year exams to get through.

In winter there were 2 pot belly stoves going with pots of hot cocoa heating for the kids.

There was also quite often a movie night planned and run by Eddie and whoever the teacher was at the time. And this was attended by the whole village.

We didn’t have tennis courts etc at school.

The grounds were all pumice. We had black rubber balls that would shoot in any direction if they hit a lump and there would be plenty over the bank behind where the school was.

We did a lot of bush walks and often would walk right down to the bridge near the Waipunga Falls.

Quite a hike for any kid. And it was also state h/way l at the time to.

We had to go to the school dentist at TeHaroto [Te Haroto] and sports days we to Tarawerea [Tarawera], TeHaroto, TePohue [Te Pohue] and Iwitahi.

The Village

The manager’s house was close to the mill also the office, petrol pump, generator shed etc.

The generator supplied power to all of the village and was turned off at a set time each night.

If there was a get together in the village it would be left on for a bit longer.

The Bushmen lived down the alley and single men’s quarters were by the old orchard.

Not too many men were turned down when they came up for a job.

It was winter 9 months of the year back then and had snow falls of around 18 inches.

And we quite often had to be piggy backed to school across the road by our father.

Some of the names we have remembered are:

Eddie & Hazel Batt

Barry & Joy Gore

Booths

Johnny & Camellia Parkes

Len Brown

Jim Brown

Dave Brown

Phil & Lovey Brown

Clotworthy

Ron Flight

Godfrey Budd

Leggets

Patrick & Monica Tepohe

Robin Schofield Teacher

Peter Kohing teacher

Solly Percell [Purcell] teacher??????????

Franf Vargher [Frank Varga]

Gary Mcrae

Bob Seymour

Rangi

Tairua

Keith Phillpot

Lou Hawkins

Johnson Karitiana [Karaitiana]

Eddie Kereopa

Hanz

Major Hauraki

Wi Hauraki

Tai Hauraki

Fred Rouse

Don Littlington

Roy & Lizzie Hunter

Paul Roia

Bobby Cooper

Dave Baigent

Ivan Martin

Hope you can get something from this.

Carolyn London

December 2013.

POHOKURA Saw Mill Odlins 1958-62.

Eddie Batt Mill Boss & Saw Doctor

Lou Hawkins Boiler man

Patika Te Pohe Brake down

Cedric Gundry Brake down

Billy Raiwania Bench man

Toko Rahui Tailer Out

Barry Gore Tailer Out

Johnson Karaitiana B/Bench & Tailer Out

Frank Varga Pin Boy, Goose Saw, Running Out Head Yard

Godfrey Budd Goose Saw, Mill hand

Danny Batt Goose Saw, slab truck

Danny Smith Mill Hand

John Parkes Head Yard man

Dave Brown Skids – and bushman

Garry McRae Mill hand

Ron Flight Carpenter

Pat Fitzegerald [Fitzgerald] Mill hand, slab truck

Major Hauraki Mill hand

Tai Hauraki Tailer Out

Ted Tairoa Mill hand

Bushmen

Len Brown Logging contractor, Dozer Driver

Jim Brown Truck driver

Ted Budd Cross cutter

Dave Brown Hauler Operator, (steam) cross cutter

Wee [Wi] Hauraki Dozer, Cross cutter

Robin Schofield School Teacher

Timber carters

Rex Brown

Doug Popperwell

Ron Willis

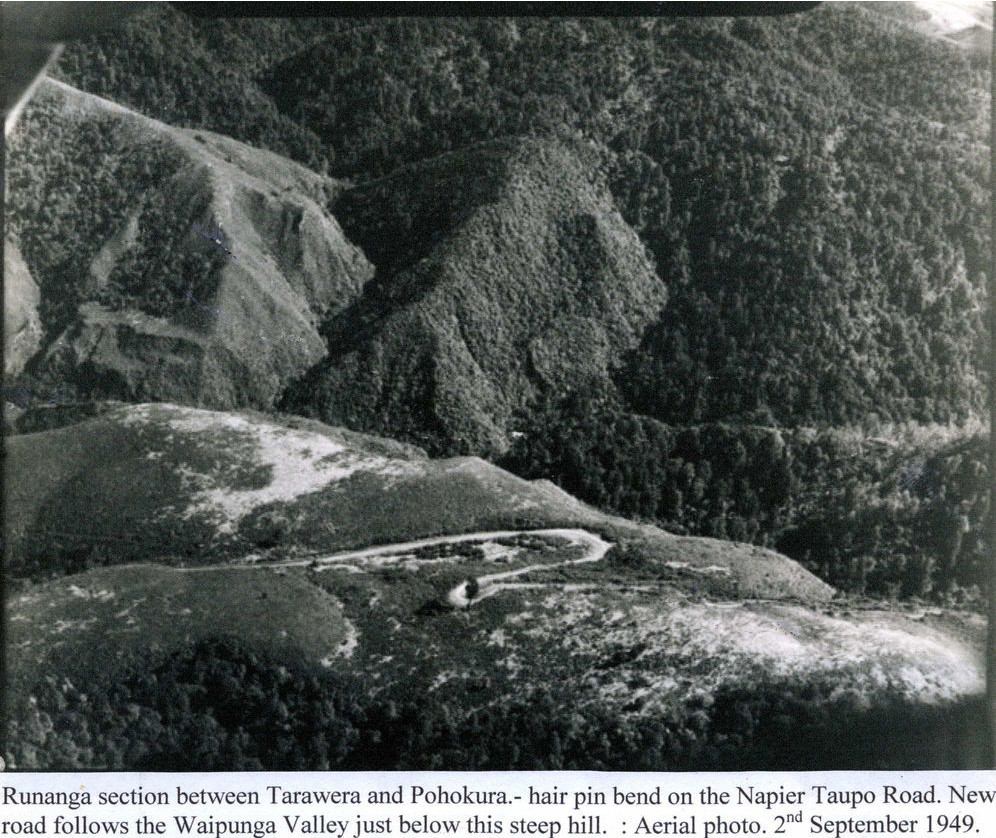

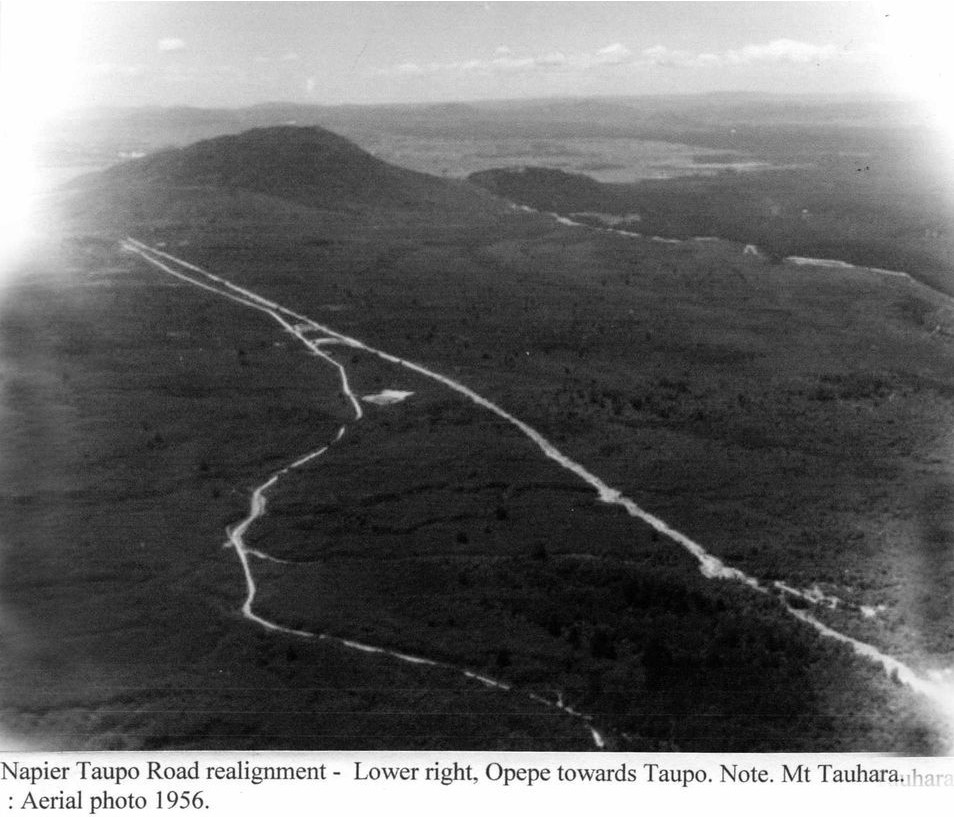

Runanga deviation looking south

Earth moving contractors : Green & McCahill Ltd. Auckland. Won the Runanga deviation contract – 26 July 1966, contract price 114,564 pounds.

More big Runanga contracts

Contracts worth more than £250,000 have been let to date on the 5.4-miles Runanga deviation on the Napier-Taupo highway.

Two major contracts were announced in Napier today by the District commissioner of Works, Mr D. U. White.

The second of three formation contracts in the Runanga deviation has been let to Earthmovers (Waikato) for about £74,500.

Green and McCahill (Auckland) have been awarded a £35,000 contract for the construction of two bridges over the Waipunga river.

Mr. White said it was fortunate that the deviation was well under way when the No. 5 Roads District’s allocation was cut by the National Roads Board.

PRIORITY WORKS

He said that priority would remain with the Runanga deviation, general maintenance, and the Frasertown bridge project near Wairoa.

The Earthmovers (Waikato) contract involves the formation of about 1½ miles of the deviation at the Taupo end.

The first formation contract was let last July to Green and McCahill for £114, 564. It involves 1½ miles at the Napier end.

The third and final formation contract is expected to be open for tender about next September.

The Waipunga river bridges are to be built in the area of Green and McCahill’s formation contract.

According to Mr. White, this firm is making excellent progress. Early in the New Year there should be a track right along the deviation.

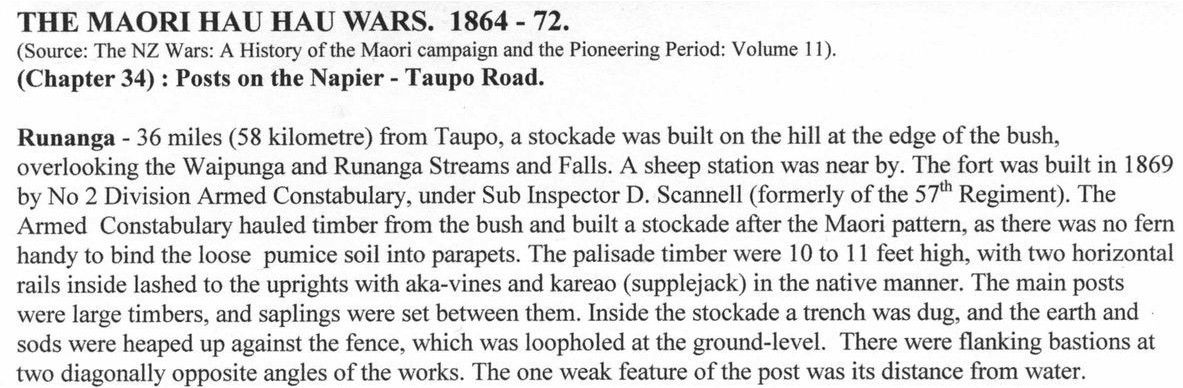

THE MAORI HAU HAU WARS. 1864 – 72

(Source: The NZ Wars: A History of the Maori campaign and the Pioneering Period: Volume II).

(Chapter 34) : Posts on the Napier – Taupo Road.

Runanga – 36 miles (58 kilometre) from Taupo, a stockade was built on the hill at the edge of the bush, overlooking the Waipunga and Runanga Streams and Falls. A sheep station was near by. The fort was built in 1869 by No 2 Division Armed Constabulary, under Sub Inspector D. Scannell (formerly of the 57th Regiment). The Armed Constabulary hauled timber from the bush and built a stockade after the Maori pattern, as there was no fern handy to bind the loose pumice soil into parapets. The palisade timber were 10 to 11 feet high, with two horizontal rails inside lashed to the uprights with aka-vines and kareao (supplejack) in the native manner. The main posts were large timbers, and saplings were set between them. Inside the stockade a trench was dug and the earth and sods were heaped up against the fence, which was loopholed at the ground-level. There were flanking bastions at two diagonally opposite angles of the works. The one weak feature of the post was its distance from water.

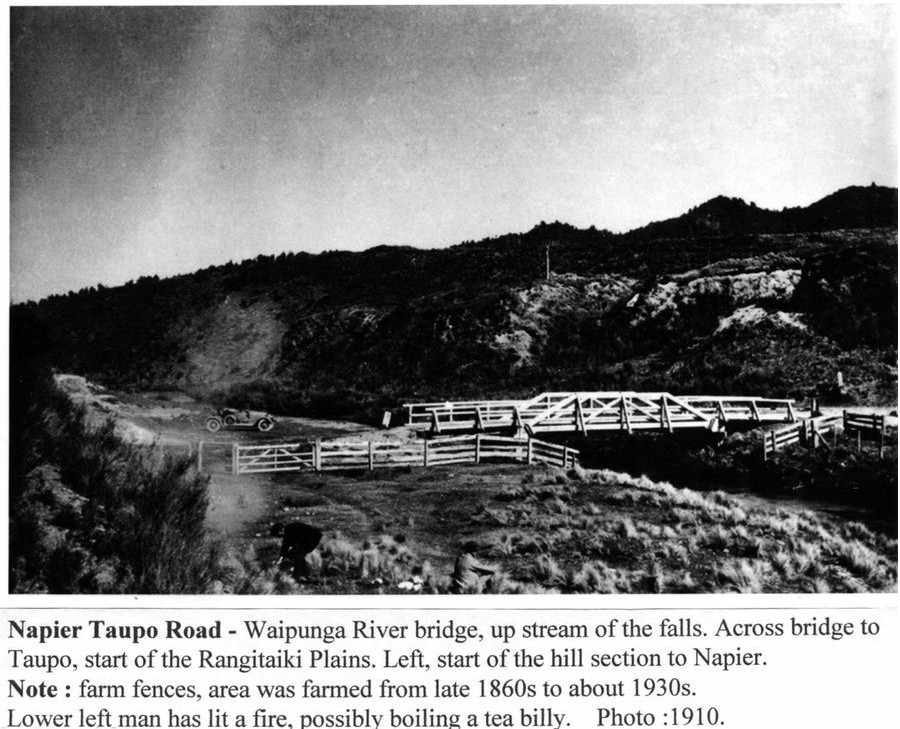

Napier Taupo Road – Waipunga River bridge, up stream of the falls. Across bridge to Taupo, start of the Rangitaiki Plains. Left, start of the hill section to Napier.

Note : farm fences, area was farmed from late 1860s to about 1930s.

Lower left man has lit a fire possibly boiling a tea billy. Photo : 1910.

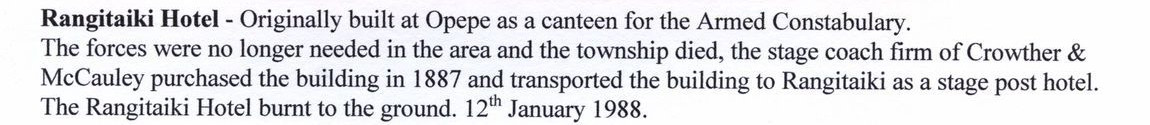

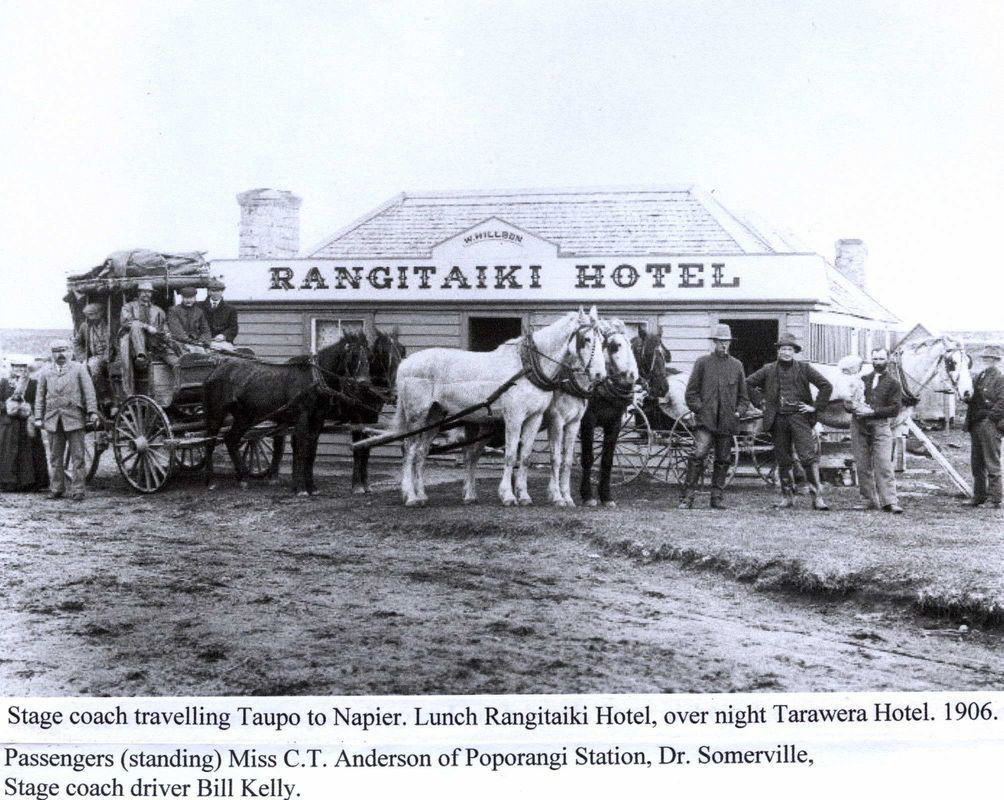

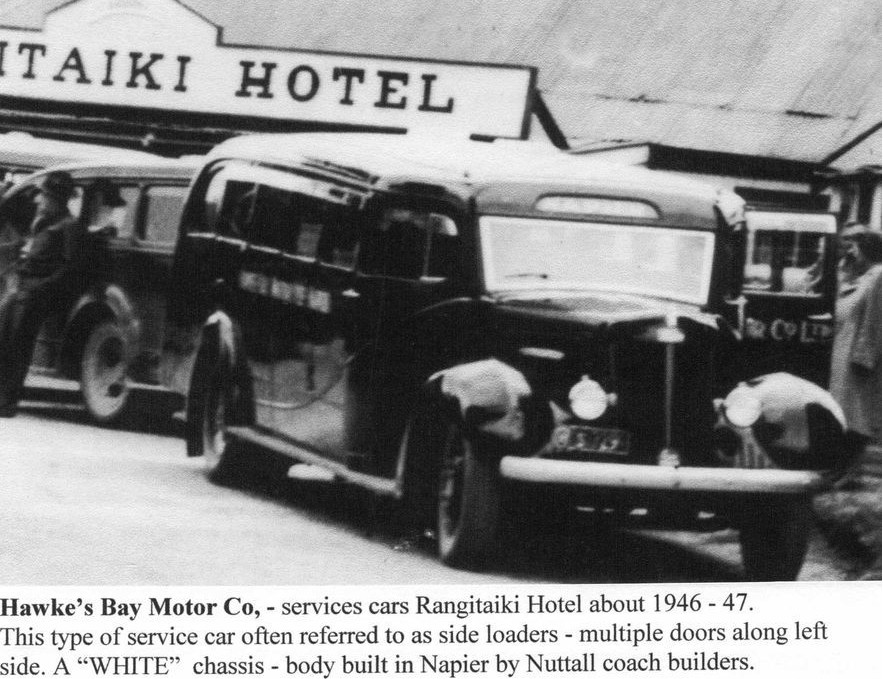

Rangitaiki Hotel – Originally built at Opepe as a canteen for the Armed Constabulary.

The forces were no longer needed in the area and the township died, the stage coach firm of Crowther & McCauley purchased the building in 1887 and transported the building to Rangitaiki as a stage post hotel.

The Rangitaiki Hotel burnt to the ground. 12th January 1988.

Fire destroys historic hotel

Daily Telegraph Napier. Tuesday 12th January 1988.

The historic Rangitaiki Hotel, about 40km from Taupo on the Napier-Taupo highway, was destroyed by fire last night.

Passing motorists noticed the fire soon after 8pm, informed residents and joined in the effort to save the building and priceless relics.

But little was able to be saved from the building which had been moved from its original site and renovated to form part of the Rangitaiki Lodge, owned by Wally Lippel and Mary Ruthe.

Firemen called from the fire services in Taupo, Timberlands camp at Iwitahi and Lochinver Station, arrived to find the 100-year-old building well alight.

Lodge employee, Nicolle Stone said today “The building’s completely had it.”

The building had been restored to reflect its earliest bar conditions, the only thing missing being the bearded clientele and their ale. Amongst items lost in the fire were original beer tags, cash till and telephone.

Ms Stone said Mr Lippel and Ms Ruthe were distressed about the fire, though warmed by the response from the Rangitaiki community. Some historic items, including photographs, were recovered.

The couple had operated the lodge for less than a year.

The hotel stopped operating in the liquor business in 1969 when the Rangitaiki Tavern was built.

The old building was then made a relic under the care of the Historic Places Trust.

Part of the building was once a barracks messroom for the Armed Constabulary based at Opepe, a few kilometres from Rangitaiki. In June 1969 [1869], Te Kooti’s advance guard surprised a group of Bay of Plenty cavalrymen in a clearing at Opepe and slew nine of its 14 members.

FLASHBACK the Rangitaiki Hotel in 1902

Briefly

Taupo Times

KEEPING TAUPO IN TOUCH

Taupo Times, Wednesday, January 13, 1988.

Fire cause investigated

The Fire Service believes the fire which almost destroyed the historic Rangitaiki Tavern on Tuesday night might have been caused when the owner burnt paint off the building early in the day.

Assistant fire commander Brian Jensen of Taupo said investigations were continuing, but the paint burning theory was a strong possibility.

A report on the fire should be completed in a week, he said.

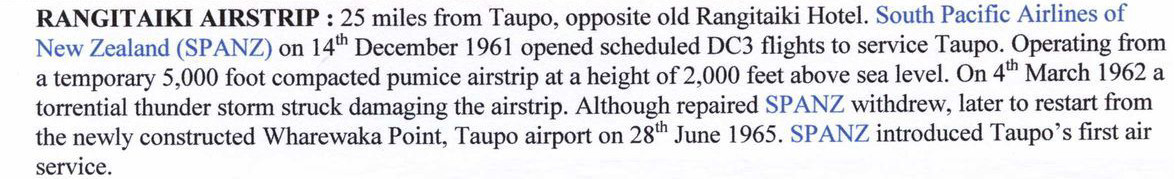

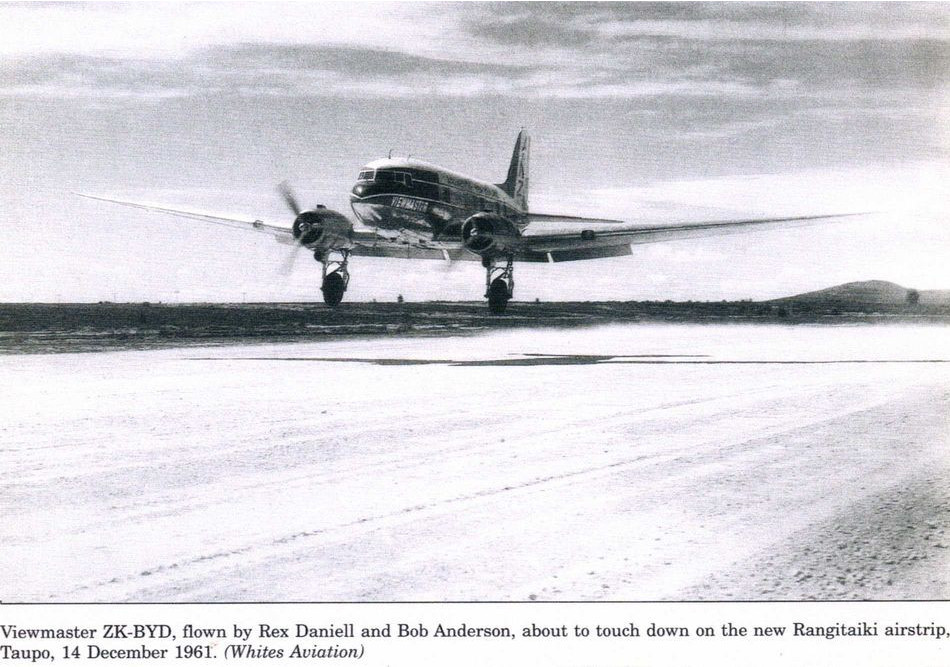

RANGITAIKI AIRSTRIP : 25 miles from Taupo, opposite old Rangitaiki Hotel. South Pacific Airlines of New Zealand (SPANZ) on 14th December 1961 opened scheduled DC3 flights to service Taupo. Operating from a temporary 5,000 foot compacted pumice airstrip at a height of 2,000 feet above sea level. On 4th March 1962 a torrential thunder storm struck damaging the airstrip. Although repaired SPANZ withdrew, later to restart from the newly constructed Wharewaka Point, Taupo airport on 28th June 1965. SPANZ introduced Taupo’s first air service.

SPANZ pioneered airline services to Taupo on 17 December 1961 and ZK-CAW George Bolt is seen here at the Rangitaiki airstrip in early 1962. Note the staggered signwriting of ‘Airlines of New Zealand’ – different to the other two Viewmasters. ZK-CAW had a varied career in New Zealand, finally retiring from topdressing service on 29 October 1984, and survives on display at the McDonalds Restaurant in Taupo. (Des White via Bruce Gavin)

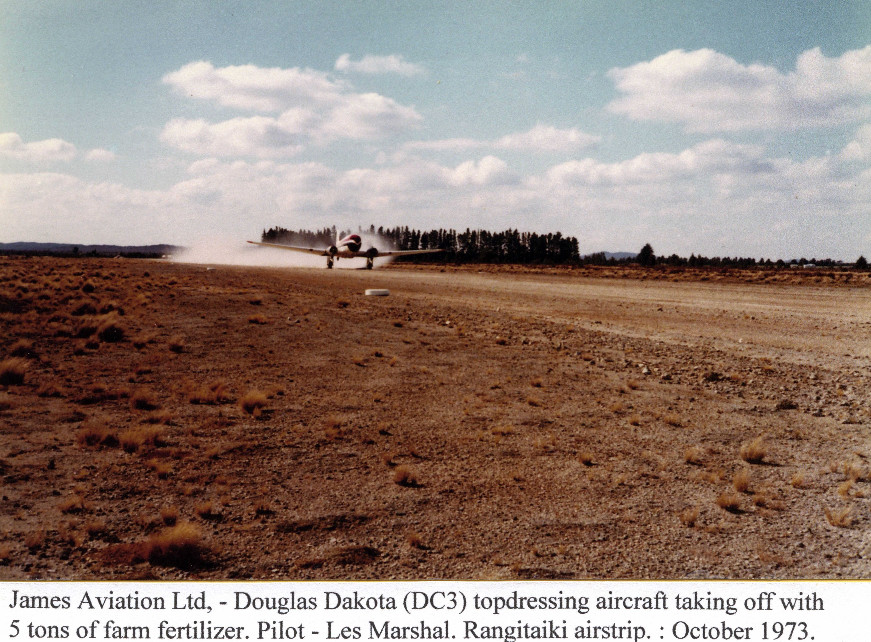

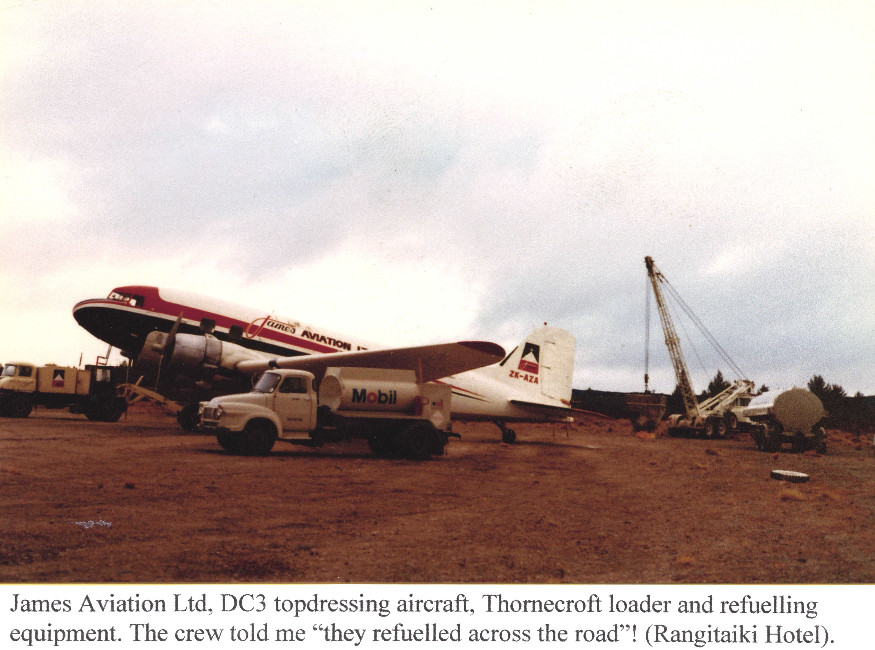

JAMES AVIATION DC 3. ZK-AZA. Topdressing aircraft. Pilot Les Marshal. Base Ardmore Auckland. Working off Rangitaiki airstrip on and off from 1st September to 24th October 1973.

One job for Ministry of Works (MOW) Napier was 6 loads (30 tons) of fertilizer with grass seed spread on the newly opened Runanga section, Napier Taupo road, to boost the road-side grass growth.

FOOT NOTE : Taumaranui [Taumarunui], October 26, 27, 28th 2012 Tiger Moth fly in . I, Michael Tuck teamed up with Les, to refuel the aircraft. Idly talking, Napier Taupo road mentioned. Les told me about topdressing a new road section. Les wondered who the MOW representative was, he did one flight to show where to spread fertilize [fertiliser]. Les did not get his name. I was able to contact Les later and supply the name. A friend of mine Bernie Kaye, we both current members of HB Aviation Heritage, and ex aero club.

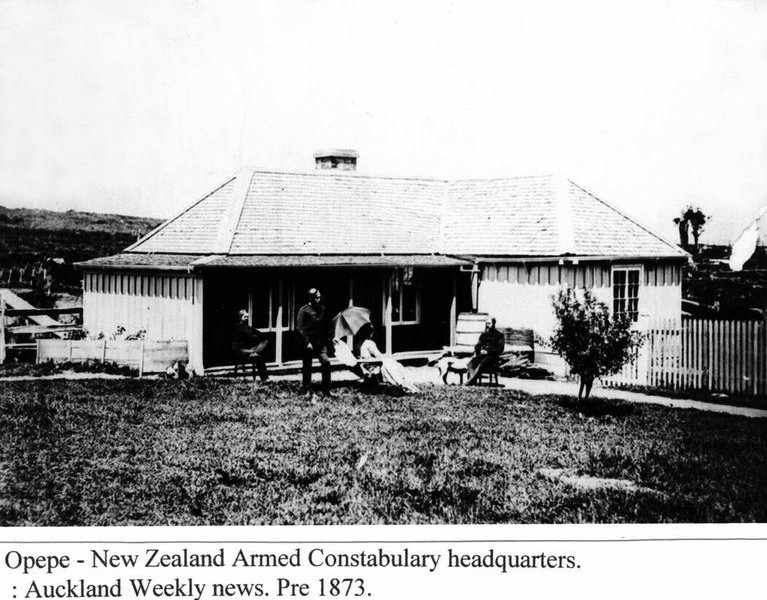

New Zealand Armed Constabulary garrison at Opepe

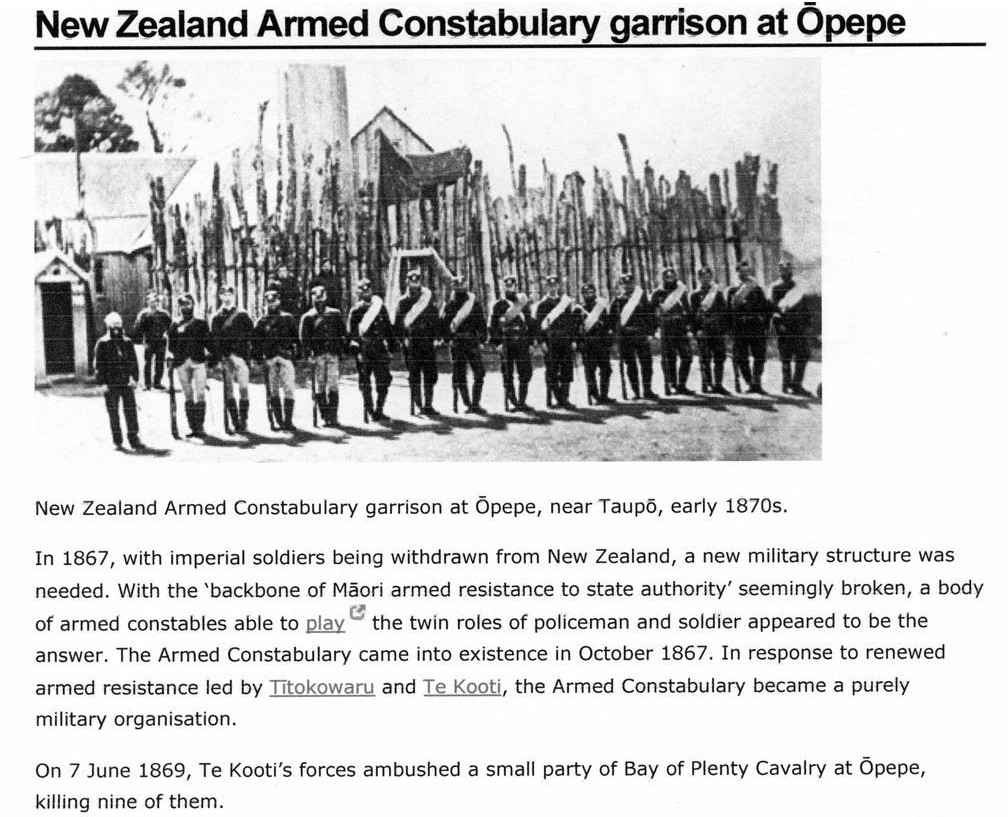

New Zealand Armed Constabulary garrison at Opepe, near Taupo, early 1870s.

In 1867, with imperial soldiers being withdrawn from New Zealand, a new military structure was needed. With the ‘backbone of Maori armed resistance to state authority’ seemingly broken, a body of armed constables able to play the twin roles of policeman and soldier appeared to be the answer. The Armed Constabulary came into existence in October 1867. In response to renewed armed resistance led by Titokowaru and Te Kooti, the Armed Constabulary became a purely military organisation.

On 7 June 1869, Te Kooti’s forces ambushed a small party of Bay of Plenty Cavalry at Opepe, killing nine of them.

MAORI WARS : THE HAU HAU WARS 1864 – 72.

(SOURCE: The NZ Wars: A History of the Maori Campaign and Pioneering Period: Volume II).

(Chapter 34) : Posts on the Napier – Taupo Road.

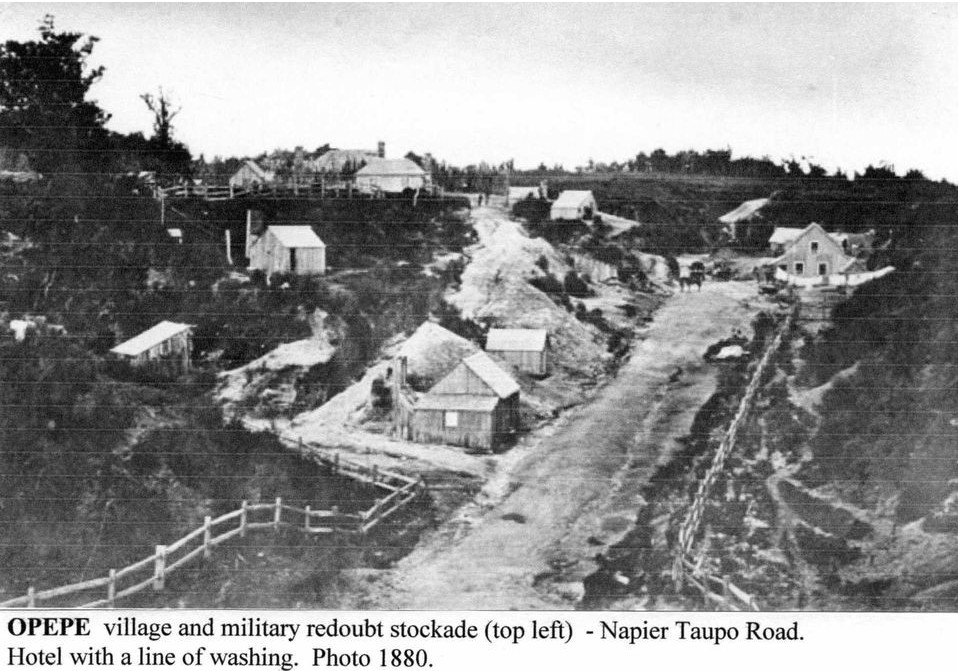

OPEPE twelve miles (19 kilometres) from Taupo. Te Kooti and his Hau Hau followers massacred 9 Armed Constabulary soldiers from the Bay of Plenty R camped at Opepe on the 7th June 1869. The graves may be Visited in off the Napier Taupo Road. (sign posted. )

1869 – 70 – Stockades built of strong timber were then established along the 100 mile (161 kilometre) length of the Napier Taupo Road.

Opepe stockade constructed in 1869 and maintained up to 1886, became a depot for the Armed Constabulary Field Force of up to 140 men and stabling for 50 horses. A large settlement grew up around the stockade and by the 1880’s Opepe had a population of about 600 people.

The town had several shops, a licensed hotel, dance hall, and a race course.

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Description

More items in this collection will be added in due course

Surnames in this folder –

Adam, Anderson, Andrew, Baigent, Bailey, Baker, Batchelor, Batt, Beasley, Belcher, Benjamin, Bolt, Booth, Brill, Brown, Buckley, Budd, Cable, Cargill, Cooper, Corbin, Crane, Crawford, Cross, Crowther, Daniell, Deakin, Donald, Duncan, Edwards, Falvey, Fimms, Fitzgerald, Flight, Fowler, Gavin, Glover, Gore, Greenwood, Gundry, Hall, Hanz, Haslar, Hauraki, Hawkins, Hayhow, Hebberley, Henery, Hensleigh, Herries, Hill, Hillson, Hubbard, Hunter, Jensen, Johnson, Julian, Karaitiana, Kaye, Keen, Kelly, Kereopa, Kirk, Kohing, Lambert, Legget, Leylan, Lippel, Littlington, London (nee Batt), Lynch, MacKay, Marshall, Martin, Matthews, McRae, Meikle, Merrick, Merson, Midgley, O’Reilly, Orlowski, Parkes, Phillpott, Poppelwell, Purcell, Rahui, Raihania, Raiwania, Rangi, Reading, Reed, Rezise, Roioa, Rouse, Ruthe, Rynex, Schofield, Scott, Seymour, Smith, Somerville, Spiller, Stone, Sullivan, Sutherland, Tairoa, Tairua, Te Kooti, Te Pohe, Tuck, Varga, Vigor-Brown, Wells, White, Willis, Yules

Tags

Format of the original

Folder of photocopied photos and typed textDate published

2016Creator / Author

- Michael Palmer Tuck

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.