Slipe Wool – A Vital New Zealand Industry

The production of lamb and mutton for export had a valuable subsidiary industry in wool and pelts that are often overlooked in a full appraisal of the industry.

W. and R. Fletcher (N.Z.) Ltd’s wool department is a success story in the company’s extensive operations in New Zealand and is a prime example of its market research aimed at getting the best returns for the country’s primary produce.

The wool returns from the national kill form about 15 percent of the total annual clip, a formidable total considering the wool taken from stock killed is significantly lower than the fleece cut from fully grown sheep.

And the financial returns are also high as the wool and pelts earn on average about 30 percent of the yield from lambs, obviously fluctuating with variances in the international markets for meat and wool.

The wool department is supervised from the Wellington head office which controls stocks and shipments, estimates forward production – a major and time consuming facet of the organisation – supervises distribution of type samples which is the basis of the method of selling and finally supervises the scouring and blending done from samples sent in from the works.

A very tight watch is also kept on quality control with an extensive back-up library of type samples on hand as a reference for buyers’ needs and a method of recording changes in production styles. This library covers the past three seasons of production and involves about 2,700 tinned samples of the various blends of wool produced.

W. and R. Fletcher produces between 40,000 and 45,000 bales of wool annually from the lamb kill. That’s approximately 6.5 million kilograms, of which at least 90 percent is earmarked for export. Of this a minimum of 40 percent is used in carpet yarns with the rest spread through the woollen trades ending up as weaving and hand knitting yarns, knitwear and hosiery etc.

The marketing operation overseas is conducted mainly on a direct sales basis to the end users, such as mills, and ties in with Weddel International’s extensive world-wide marketing operation and expertise, rather than using brokers as middle men in the operation.

The company is the only freezing company in the world trading in “slipe” wool that has trained wool salesmen and outlets throughout the world, backed by extensive marketing knowledge and experience.

The slipe wool, or wool that is chemically removed from pelts after killing rather than by shearing, is handled basically in two ways.

Larger consignments are baled in job lots, while the smaller lots which are more difficult to market are scoured and blended to achieve a uniform result.

The process of treating the wool, whilst being a relatively simple one, involves much expertise to achieve the top class end product.

When the skin is taken from the carcase it is washed to get it clean and reduce the body heat to preserve the pelt, which is as valuable as the wool, for use as leather.

The skin is then put through a centrifuge, or spin drying process, to remove the excess moisture after which it is then bulk classed. In the next stage of process the skins are placed on a conveyor belt where a team of men trim and flatten them in preparation for the “painting” process. This involves the pelts being sprayed with a mixture of lime and sulphide which works its way through the pelt and loosens the wool for easy removal.

The skins are hung for 24 hours after which a team of pullers, who are in effect skilled wool classers, literally pull off the wool and class it. The pullers can process up to 100 skins an hour, sorting the wool on each pelt in to anything up to six grades. The pelt is then sent for processing and the wool is mechanically dried and goes into conditioning bins which allow it to regain its true normal moisture content before being baled prior to its despatch to wool stores.

Nine years ago Fletcher’s became totally involved in scouring wool in New Zealand for the dual reason of blending oddments and treating the wool for developing markets which were not used to handling raw slipe wool.

The principal agent for the processing of the wool is the Independent Wool Commission scouring plant at Tomoana, which not only handles the full production from the company’s four North Island plants, but also processes wool for other brokers on a commission basis.

The task is not an easy one with the vast variance in wool quality from area to area with up to 20 different breeds of lamb being processed.

However, in the first six years, sales doubled every year to its present day secure position in an industry vital to the New Zealand economy in foreign exchange earnings.

Those years of expansion saw a significant increase in sales of slipe wool to the then developing markets of Japan and other Far Eastern countries, and coincided with the opening of the Weddel office in Japan, the first representing any New Zealand freezing company in that country.

The head of the wool department, Alan Chapman, says the company’s development of the slipe wool trade was anything but a hit or miss venture.

“We have highly qualified wool salesmen around the world and this, combined with the ability to get a uniform product, vastly increased our markets.

“For example smaller lots of say three bales are as costly to sell as large consignments and in addition the seller is in the disadvantageous position of having to accept a discounted price for his product because of the small size of the order.”

Mr Chapman often visits Far East manufacturers to keep up to date with their needs and ensure they are getting the wool product that they want.

He says one drawback in slipe wool is the remnants of chemicals from the treating process and their effect on dyes but modern neutralising processes have combatted this effectively.

However the product has many advantages over traditional shorn wool because of the methods of production. With a widespread kill of lambs of a constant age the wool quality and length is constant giving a far more uniform product, thus requiring less blending than shorn wool.

In fact slipe wool is usually so uniform that manufacturers can buy it with confidence knowing that the quality and length of the blend is virtually guaranteed.

Britain still remains the largest customer of slipe wool, though heavy competition is now coming from European markets, principally Germany, Belgium and France.

With much of the sales done on a forward basis, an important facet of the wool department’s operations is to keep fully abreast of market and production trends, values and possible shortages of supply.

Fletcher’s also operate a well defined trainee system whereby new recruits to the department attend a wool course at Massey University and then spend training periods at the works where they get experience in all facets of wool production.

OBITUARY: Mr F. G. Knight

Mr F. G. [Frank] Knight, a previous General Manager of the Westfield Freezing Co. Ltd, has died in Auckland.

Mr Knight joined W. and R. Fletcher (NZ) Ltd in 1918 and rose through various positions to be Acting General Manager of the Group and General Manager of the Westfield Freezing Co., a position he held from 1944 until his retirement in 1965.

When Head Office was moved to Wellington in 1935 Mr Knight came down as chief of the Costing Department. On the outbreak of war in 1939 he was closely associated with the Government Marketing Department involving the control and bulk selling of New Zealand meat. He also assumed the position of Controller of Canneries and, as such, played a major part in ensuring the efficient flow of New Zealand meat to the United Kingdom.

For a long period Mr Knight was Chairman of the New Zealand Freezing Companies’ Labour Committee and his wide knowledge of the freezing industry gained him universal respect. He is survived by his wife.

Photo captions –

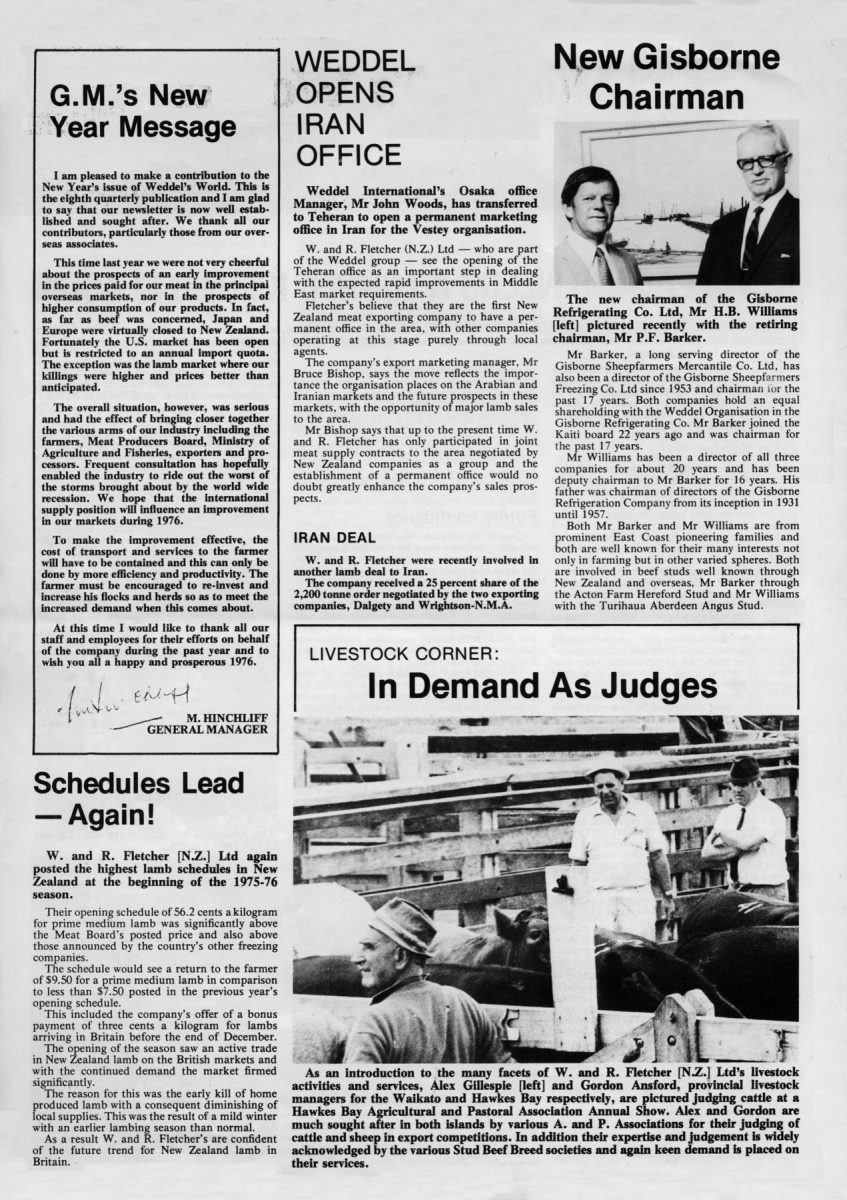

Alan and Roger checking a wool sample from the “library” to meet a customer’s demand.

The main scouring train at Tomoana showing the fork lift [at bottom] loading wool into the hopper.

Alan Chapman [right] and his assistant, Roger Paton, appraising varying slipe wool samples for quality control before scouring.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.