WESTFIELD FIRE

Quick work by the Westfield Freezing Company staff and the Auckland Metropolitan Fire Brigade was instrumental in limiting the damage caused to the works, following the outbreak of a major fire in the engine room in July.

The fire was triggered off by what appears to have been a short circuit in the electrical switchboard and it spread quickly throughout the engine room putting all seven compressors and five boosters out of action.

The main electrical transformer supplying power to the plant was also affected resulting in a complete loss of power to most sections for two days until connections were restored.

Seventeen Auckland fire appliances and seven St John Ambulances together with their mobile cafeteria were on the scene soon after the fire broke out at about 8 pm. and at least half of the fire appliances were still at the works at daybreak the following morning.

Company tradesmen and outside contractors put in a “goliath” effort in working continuous shifts round the clock to restore refrigeration within 70 hours of the outbreak of the fire.

It was a great relief that, after a quick inspection of the thousands of tonnes of meat in store, it was found that temperatures had held and there was no damage to the product in store.

Through the tremendous effort of all those involved the plant was killing again within a week of the outbreak but it will be between six and nine months before the engine room is fully restored.

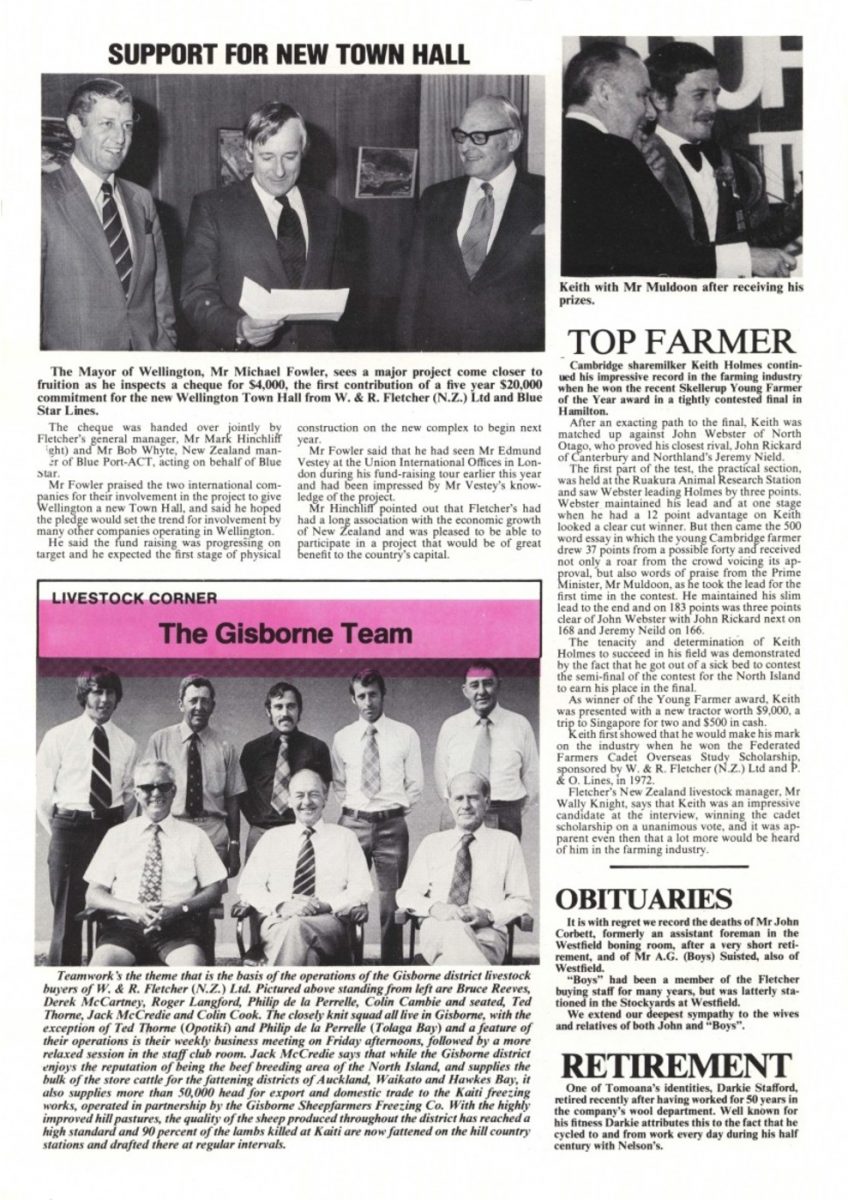

FAMILY TIES

Second year fitting and welding apprentice Gary Timms, pictured above being supervised by his father Reg Timms, leading welder at Nelsons N.Z. Ltd’s Tomoana works, is continuing a historical association of family service with the company.

Gary’s great grandfather, Thomas Timms, was the original foreman fitter when Tomoana was established in 1880 and did the first welding on the plant. He was engaged by Mr William Nelson, founder of Nelson Bros. Ltd, in England when he was 15 years old and later transferred to New Zealand during the construction of Tomoana. Some years later he suffered the loss of his left eye as a result of an explosion in the blacksmith’s forge.

Gary’s grandfather, Jack, was the “boss welder” at Nelson’s before his father, but the family connection is much broader than that.

George Timms, brother of Jack, also worked in the fitting shop for a time and his sons Ernie, Tom jnr., and Arthur were also on the staff for many years. Another son, John, also worked with the company, but for a shorter period. And Ernie’s son Colin, has been employed in the cooperage and latterly in the transport section of the yard department for the past 34 years.

With such a proud record the name of Timms has probably had longer associations and greater representation with the Tomoana works than any other family!

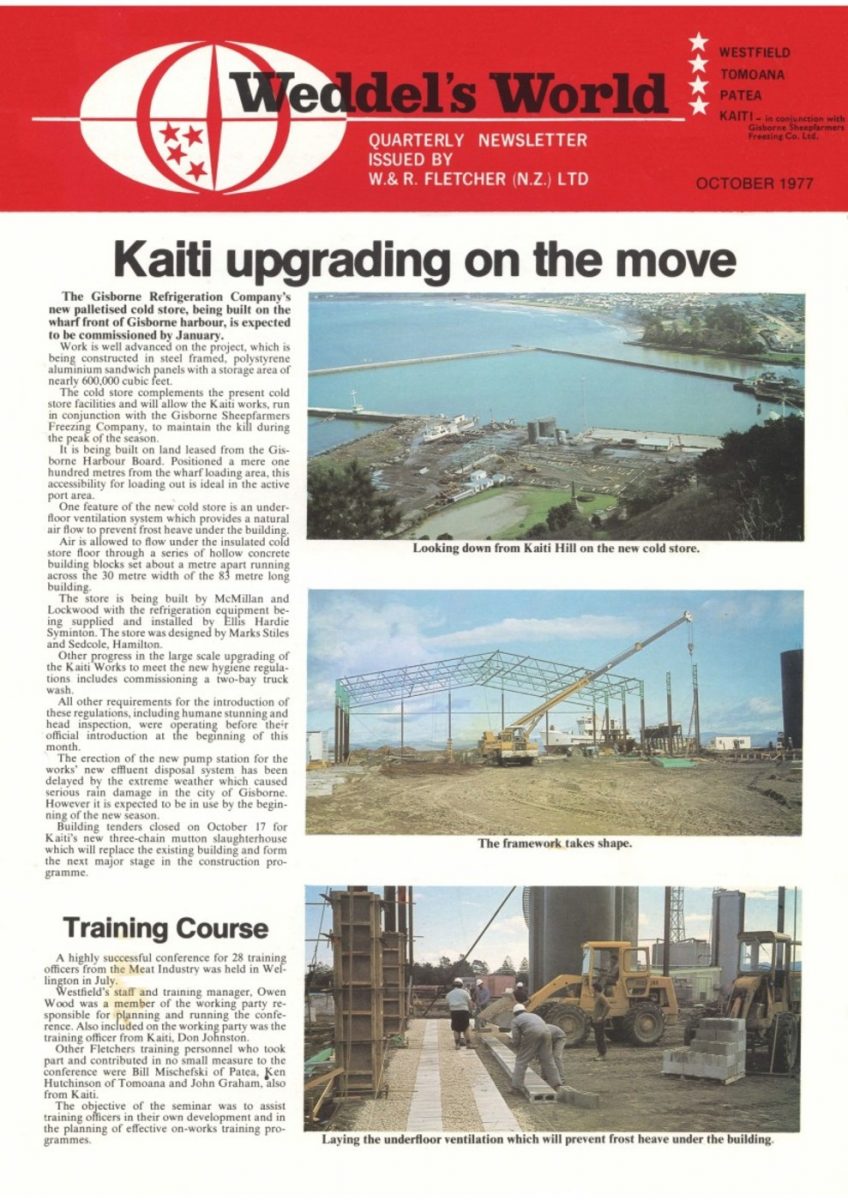

One of Westfield’s assistant foremen in the boning department, Mr Bob Craig, (pictured centre front row) with some of his workmates before a farewell function to mark his retirement after 26 years with the company.

Bob, who was farewelled by his colleagues at a luncheon function, will spend his retirement at his beach bach at Raglan.

Another recent Westfield retirement was Mr Jim Wayby, who had held various clerical positions with the company during his 22 years’ service.

Weddel’s World wishes Bob, Jim and their wives a long and happy retirement.

Where are they now?

When Mr A. G. Brebner (“Breb”) retired as W. & R. Fletcher’s Chief Engineer in New Zealand in November 1972 he didn’t realise it was purely a temporary move!

Shortly afterwards he accepted an offer to go to Brazil for the Vestey Organisation to finalise the design and ultimately supervise the construction of a new beef killing and packing plant Goiania, a project that took two years.

He and his wife spent the first five months in Sao Paulo at the group’s head office before moving north to the small city of Goiania for the construction stage.

The new Goiania works was designed for a daily killing capacity of 400 beef, and last year the plant had a throughput of 96,000 head according to its general manager Roger Beasley who visited New Zealand recently (see story page 2).

“Breb” says that one of the highlights of his visit was watching from a safe distance the antics of the small Brazilian monkeys, snakes, anteaters and other animals as they were disturbed by the bulldozer clearing the site for the new plant.

He and his wife returned to New Zealand in October 1975, but he has not severed his connections with the industry. Mr Brebner joined the firm of Refrigeration Engineering Co. Ltd in Auckland and in his new job continues to see many of his old friends in the meat industry, through the extensive countrywide upgrading work being carried out to meet the new international hygiene regulations.

On the mend

Kaiti chief engineer, John Grainger, is on the path to recovery after a recent operation in Auckland’s Greenlane Hospital.

LEAGUE SUCCESS

Tim Parry of the W. & R. Fletcher Export Sales staff was recently selected for the New Zealand Rugby League Southern Zone under 19 side. It was a memorable season for Tim, who plays Upper Hutt senior side in the Wellington League, as he was also selected as a reserve back for the Wellington Provincial team that met France, and he also played for the Wellington Under-19 side which beat two touring Australian sides.

COMPANY PROFILE

Mr Lewis W. Jagger became Fletcher’s Superintendent Scientist in 1965 after spending the years since he joined the company in 1947 at Westfield, learning the business of the group in New Zealand. This covered many diverse fields from meat killing and processing to the smallgoods and canning preparation and last but no means least the work of New Zealand Stockfoods situated at Westfield, and Fletchers other plants at Patea and Mataura.

Mr Jagger says that when he joined the company Westfield was virtually out in the country, and as such, operations and waste disposal programmes could be carried out without hindrance or harm to any of its neighbours. But the growth of Auckland city to the area has brought different restrictions to the operations and also different standards. “This means changes too for the scientist,” Mr Jagger says. “New skills must be grafted on to the old. Accumulation of knowledge is now so rapid and startling that an older hand finds it difficult to adapt easily to keep abreast of all the developments occurring in our own rapidly changing industry, but whatever they may be, it makes the days exciting and rewarding. Science has contributed greatly to the Company’s success over the past fifty years and I expect it will continue to do so to a greater degree in the future. I often wonder what further developments we will see in the next fifty years. Whatever they may be, we scientists will have had a large hand in their devising. It is not too far fetched to think that by then we could possibly be utilising non-edible meat by-products and other materials to manufacture synthetic foods.”

W. &. R. FLETCHER (N.Z.) Ltd.

(PRINTING DEPT.)

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.