- Home

- Collections

- SANDERS MJ

- Weddel's World

- Weddel's World 1979 - January

Weddel’s World 1979 – January

Weddel’s World

WESTFIELD

TOMOANA

PATEA

KAITI – in conjunction with Gisborne Sheepfarmers Freezing Co. Ltd.

QUARTERLY NEWSLETTER

ISSUED BY

W. & R. FLETCHER (N.Z.) LTD

JANUARY 1979

TOMOANA PLANT A WORLD LEADER

Final work is now being carried out on the new $35 million mutton “super complex” at Nelson’s NZ Limited’s Tomoana plant at Hastings, which when commissioning starts in April will be one of the world’s leading operations.

The new complex includes a six chain mutton slaughterhouse connected to a mechanised blast freezer and the adjacent cool store which came into operation about 12 months ago.

The complex incorporates all the latest mechanical and scientific developments available to the industry and features hyugiene [hygiene], safety and space to give workers on the chain the best operating conditions in New Zealand.

The complex meets all the newly introduced international hygiene regulations and provision has been made for the incorporation of any likely additions to these in the future.

A clinic has been built to monitor worker health standards and provide health care. Site engineers, the safety officer and a consultant doctor were involved in the development of the first aid facilities and the clinic. Study was also undertaken into safety conditions throughout the whole operation.

The slaughterhouse, which is nearly 180 metres long by 36 metres wide, is a three floor building capable of processing about 100,000 lambs a week.

It introduces a revolutionary new process for the chain by staggering the working levels, as is common in beef operations, to reduce the strain on workers performing different operations. For example the second spreader operation has four operating levels for headwork and final trim, trotter removal, skin removal and skin disposal.

The chain itself moves nearly four metres above ground level with the operating positions far more liberally spaced than is customary. Union personnel are liaising closely with management on working procedures for the new complex.

The building has also, been designed to minimise noise levels to provide better working conditions and to meet hygiene standards that are expected to be introduced in the future.

The capacity of the plant has been planned to cater for the foreseeable demand from the Hawke’s Bay area in the future.

The present lamb stockyards will have their flow reversed when the new complex comes into operation. Stock will enter the building up a ramp and after slaughter will be carried to the top level for processing. Here the accelerated conditioning process required by North America amongst other countries, is started with electrical stimulation. This process continues down the chain and is competed in the blast freezing chambers under controlled conditions.

Provision has also been made in the new operation to continue the domestic abattoir business for Napier and Hastings, which the Tomoana works has been operating for the past 50 years. The building has a chill room on the ground floor for the storage of the 3,000 lambs required for local distribution each week.

The ground floor also houses the casings and calibrating processes and the offal department. Pelts, slipe wool and material for rendering will be returned to the old complex by fluming or blowing for processing.

The middle floor of the new slaughterhouse contains an expansive amenities area and some offices. Two large dining rooms will meet the needs of the 850 workers at the peak of the season, and these are adjoined by separate spacious changing rooms, locker areas and shower rooms for men and women.

Similar smaller facilities are provided for foremen and the Ministry of Agriculture and Fisheries personnel also have their own dining area, changing and shower rooms. In addition they have been provided with a number of offices, a laboratory and a tutorial room for the training of meat inspectors.

The new freezer block, which is 50 metres long by just over 40 metres wide contains five two storey blast freezers which have the capacity to handle the projected peak daily kill of about 20,000 lambs in an overnight cess.

All carcases on entering the system can be identified throughout the process automatically. As the carcase progresses along the chain and into the freezers information is processed into a controlling computer. This information is relayed back to “read heads” at predetermined positions which dictate the freezer room the carcase is destined for.

As the information will include grade and weight details the carcases can be assembled in the required sequence so that all of one type can be assembled together.

Provision has also been made for the construction of another freezer unit on top of the fifth freezer should an increase in local production necessitate this or for any other production reason.

With the completion of building a major landscaping project will be carried out to improve the environmental aspect of the site. This will include the laying of grassed areas and the planting of trees and shrubs.

Although the new building dominates the Tomoana site it is not the sole product of the major development programme.

New cattle stockyards have also been built and a new unloading area has been constructed for sheep and lambs.

The amenities in the old mutton house will be upgraded and plans are underway for the building of a new cafeteria complex to service the whole works. In this provision will be made for separate areas for those working in food areas and those in non-food areas so future hygiene requirements can be met.

And the current building programme also allows for the possible extension of further processing for both lamb and beef products in the future.

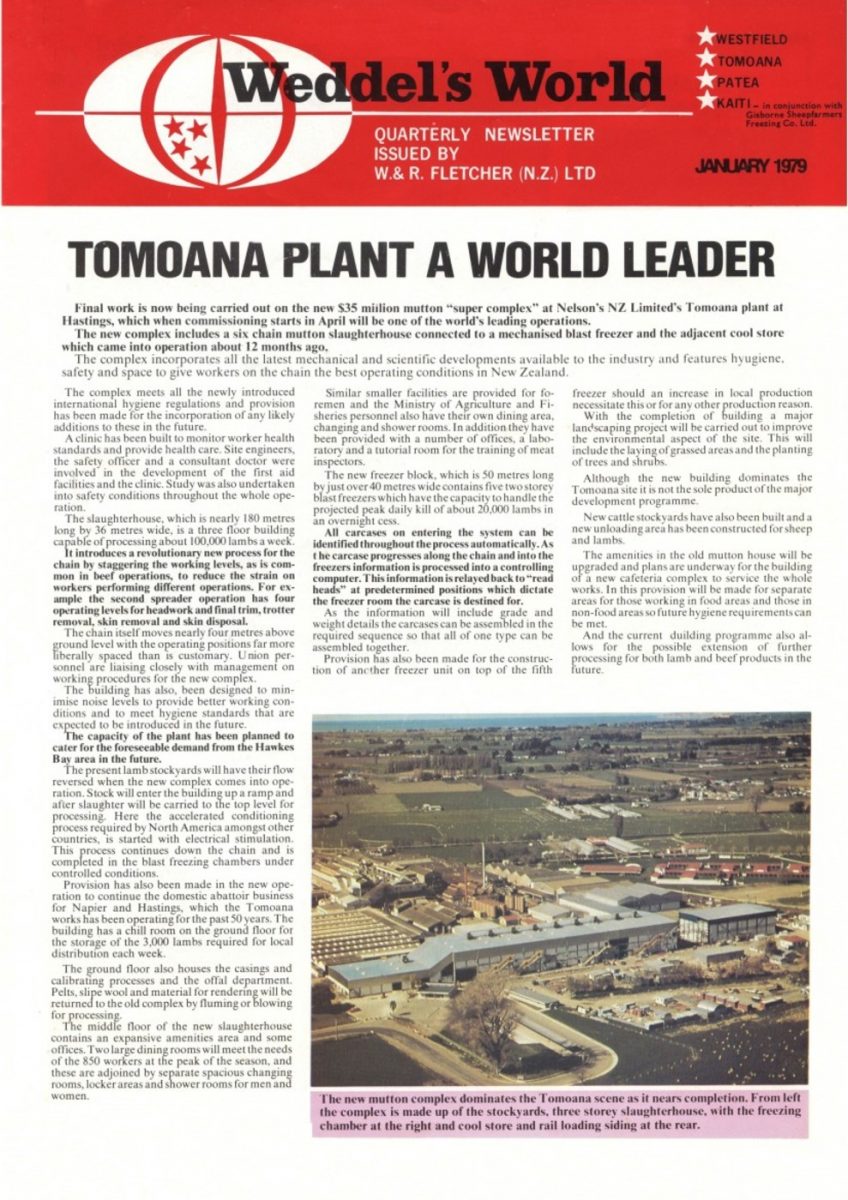

Photo caption – The new mutton complex dominates the Tomoana scene as it nears completion. From left the complex is made up of the stockyards, three storey slaughterhouse, with the freezing chamber at the right and cool store and rail loading siding at the rear.

G.M.’s MESSAGE

The W. & R. Fletcher group of companies enter the new year with a very optimistic outlook. The past year saw a major building programme at our works and in the coming year we will be undertaking a continuing rebuilding programme that will see our works to the fore in this competitive industry. As the cover story in this issue shows the massive new mutton complex at Tomoana is nearing completion and in addition, work is well underway with our partners, the Gisborne Sheepfarmers Freezing Company, on the construction of a new three chain mutton slaughterhouse at the Kaiti works in Gisborne. A major development has also begun at the Patea works.

The success of our operations has been the result of the hard work and co-operation of all of our staff within the works, out in the field and in the various administrative sections, and I would like personally to thank them all for their efforts. I would also like to wish all of them and their families a very happy new year and every success.

Finally, I am sure that you would all like to join me in wishing our retiring general manager, Mark Hinchliff, and his wife a long and happy retirement as they settle down to a well deserved “life of ease” in their Wellington home.

PETER JOHNSTON

General Manager

G.M.’s RETIRING MEETING

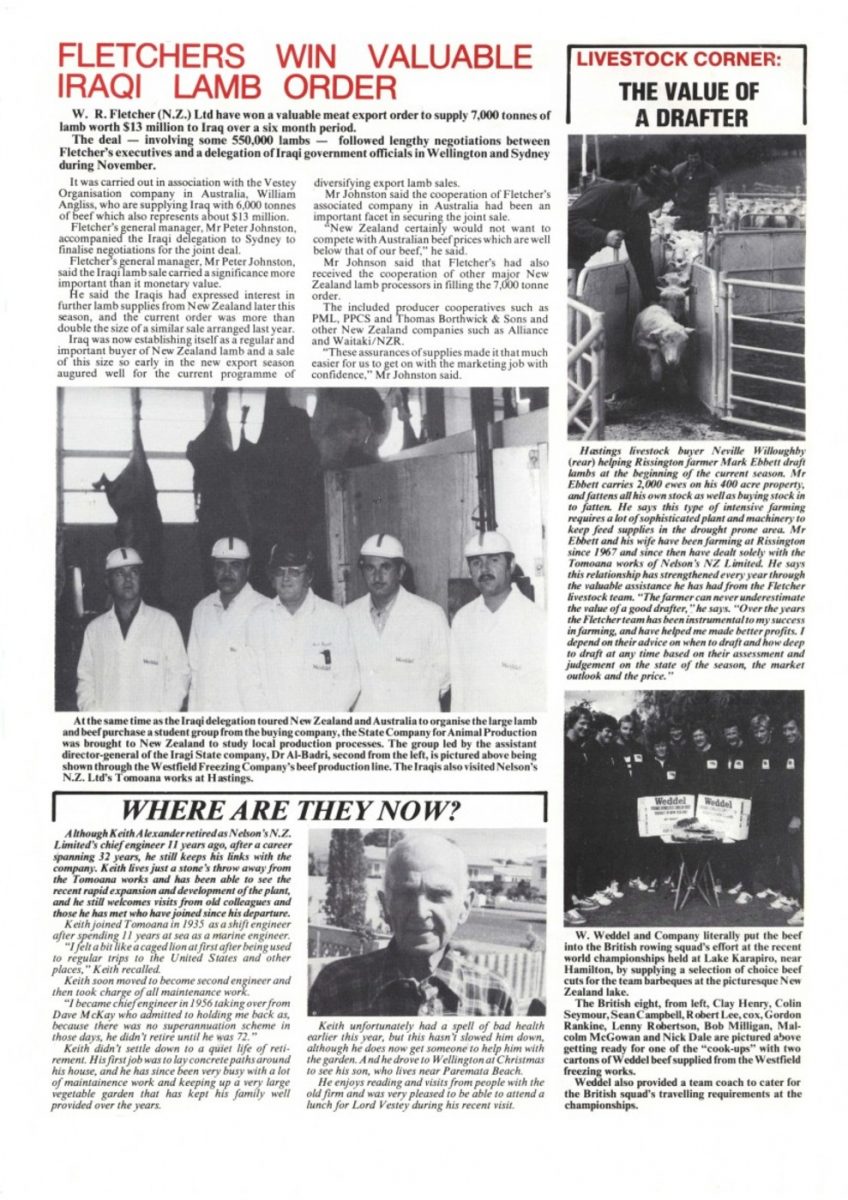

The retiring general manager of W. & R. Fletcher (NZ)Ltd., Mr Mark Hinchliff, recently presided over his last management meeting of group company executives in Wellington. The group took a moment away from the business agenda to pose for a farewell photograph and are : (Standing from left) Mr W. D. Jolly, general manager, Wanganui Mild Cure Bacon Co Ltd; Mr J. N. Baker, general manager, Gisborne Refrigerating Co. Ltd; Mr C. C. Greenough, general manager, Auckland Meat Company Ltd: Mr R. L. Stewart, general manager, Patea Freezing Company Ltd; Mr A. N. Byrne, group company secretary W. & R. Fletcher (NZ) Ltd; Mr D. N. Gusscott, general manager, New Zealand Stockfoods Company Ltd; (Seated from left) Mr G. T. Taylor, general manager, Westfield Freezing Company Ltd; Mr T. P. Jones, assistant general manager designate, W. &. R. Fletcher (NZ) Ltd; Mr M. Hinchliff; Mr P. H. Johnston, general manager designate, W. &. Fletcher (NZ) Ltd; and Mr M. J. Sanders, general manager Nelson’s (NZ) Ltd. Hastings.

Learning the trade – worldwide!

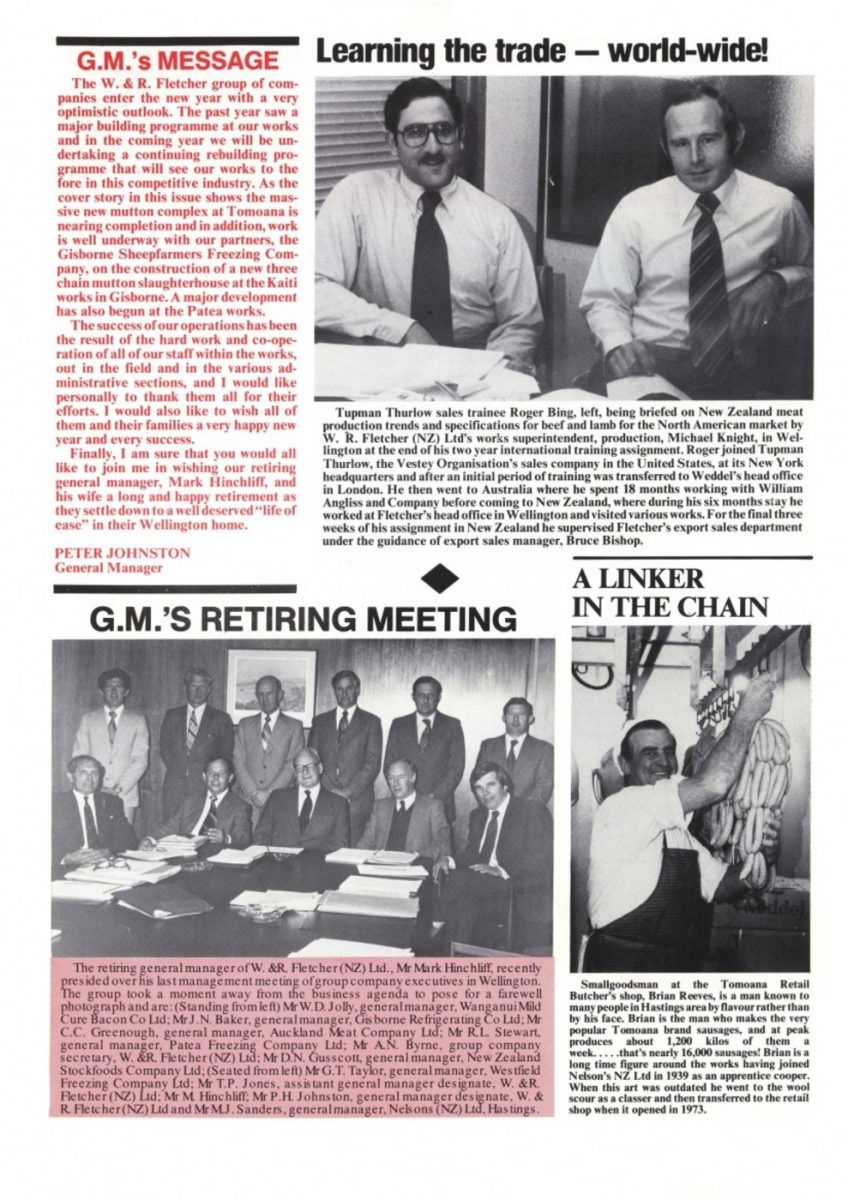

Tupman Thurlow sales trainee Roger Bing, left, being briefed on New Zealand meat production trends and specifications for beef and lamb for the North American market by W. R. Fletcher (NZ) Ltd’s works superintendent, production, Michael Knight, in Wellington at the end of his two year international training assignment. Roger joined Tupman Thurlow, the Vestey Organisation’s sales company in the United States, at its New York headquarters and after an initial period of training was transferred to Weddel’s head office in London. He then went to Australia where he spent 18 months working with William Angliss and Company before coming to New Zealand, where during his six months stay he worked at Fletcher’s head office in Wellington and visited various works. For the final three weeks of his assignment in New Zealand be supervised Fletcher’s export sales department under the guidance of export sales manager, Bruce Bishop.

A LINKER IN THE CHAIN

Smallgoodsman at the Tomoana Retail Butcher’s shop, Brian Reeves, is a man known to many people in Hastings area by flavour rather than by his face. Brian is the man who makes the very popular Tomoana brand sausages, and at peak produces about 1,200 kilos of them a week ….. that’s nearly 16,000 sausages! Brian is a long time figure around the works having joined Nelson’s NZ Ltd in 1939 as an apprentice cooper. When this art was outdated he went to the wool scour as a classer and then transferred to the retail shop when it opened in 1973.

FLETCHERS WIN VALUABLE IRAQI LAMB ORDER

W. R. Fletcher (N.Z.) Ltd have won a valuable meat export order to supply 7,000 tonnes of lamb worth $13 million to Iraq over a six month period.

The deal – involving some 550,000 lambs – followed lengthy negotiations between Fletcher’s executives and a delegation of Iraqi government officials in Wellington and Sydney during November.

It was carried out in association with the Vestey Organisation company in Australia, William Angliss, who are supplying Iraq with 6,000 tonnes of beef which also represents about $13 million.

Fletcher’s general manager, Mr Peter Johnston, accompanied the Iraqi delegation to Sydney to finalise negotiations for the joint deal.

Fletcher’s general manager, Mr Peter Johnston, said the Iraqi lamb sale carried a significance more important than it monetary value.

He said the Iraqis had expressed interest in further lamb supplies from New Zealand later this season, and the current order was more than double the size of a similar sale arranged last year.

Iraq was now establishing itself as a regular and important buyer of New Zealand lamb and a sale of this size so early in the new export season augured well for the current programme of diversifying export lamb sales.

Mr Johnston said the cooperation of Fletcher’s associated company in Australia had been an important facet in securing the joint sale.

“New Zealand certainly would not want to compete with Australian beef prices which are well below that of our beef,” he said.

Mr Johnson said that Fletcher’s had also received the cooperation of other major New Zealand lamb processors in filling the 7,000 tonne order.

The included producer cooperatives such as PML, PPCS and Thomas Borthwick & Sons and other New Zealand companies such as Alliance and Waitaki/NZR.

“These assurances of supplies made it that much easier for us to get on with the marketing job with confidence,” Mr Johnston said.

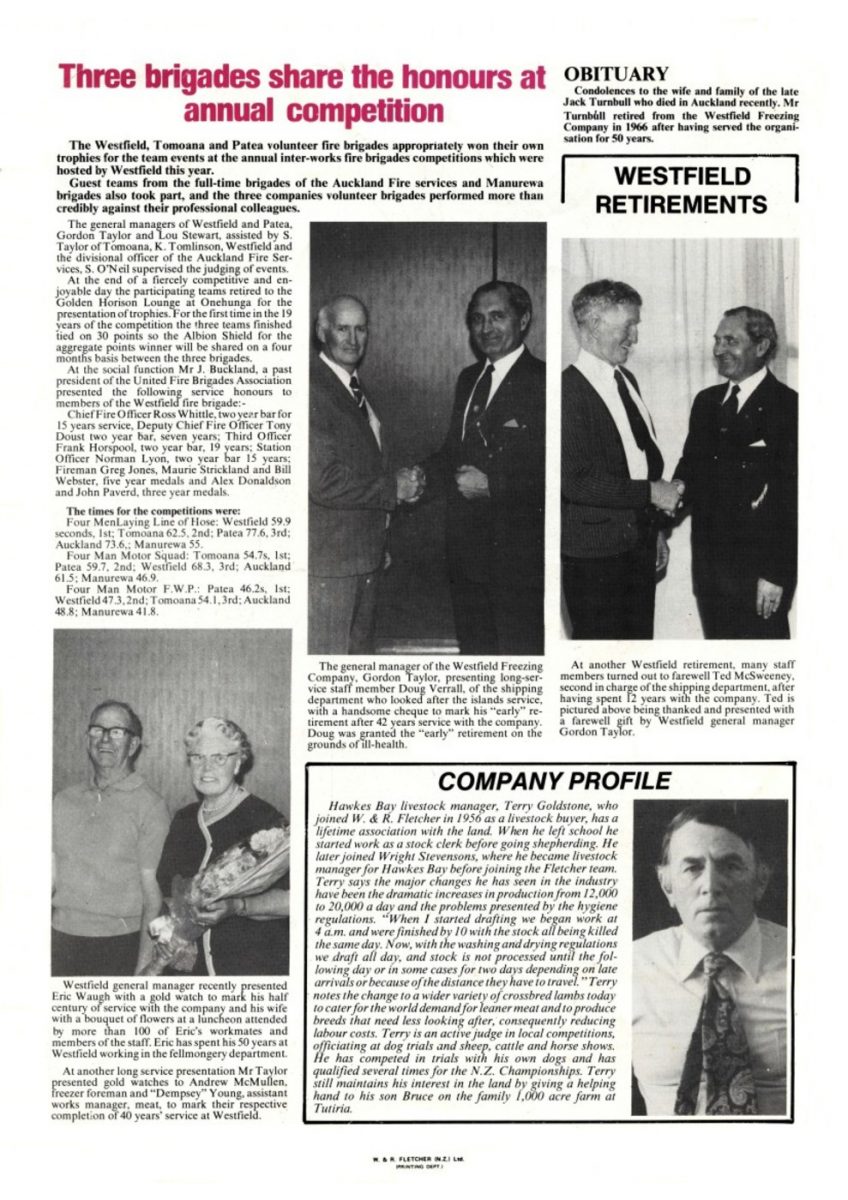

Photo caption – At the same time as the Iraqi delegation toured New Zealand and Australia to organise the large lamb and beef purchase a student group from the buying company, the State Company for Animal Production was brought to New Zealand to study local production processes. The group led by the assistant director-general of the Iragi [Iraqi] State company, Dr Al-Badri, second from the left, is pictured above being shown through the Westfield Freezing Company’s beef production line. The Iraqis also visited Nelson’s N. Z. Ltd’s Tomoana works at Hastings.

WHERE ARE THEY NOW?

Although Keith Alexander retired as Nelson ’s NZ. Limited ’s chief engineer 11 years ago, after a career spanning 32 years, he still keeps his links with the company. Keith lives just a stone’s throw away from the Tomoana works and has been able to see the recent rapid expansion and development of the plant, and he still welcomes visits from old colleagues and those he has met who have joined since his departure.

Keith joined Tomoana in 1935 as a shift engineer after spending 11 years at sea as a marine engineer.

“I felt a bit like a caged lion at first after being used to regular trips to the United States and other places,” Keith recalled .

Keith soon moved to become second engineer and then took charge of all maintenance work.

“I became chief engineer in 1956 taking over from Dave McKay who admitted to holding me back as, because there was no superannuation scheme in those days, he didn’t retire until he was 72.”

Keith didn’t settle down to a quiet life of retirement. His first job was to lay concrete paths around his house, and he has since been very busy with a lot of maintainance work and keeping up a very large vegetable garden that has kept his family well provided over the years.

Keith unfortunately had a spell of bad health earlier this year, but this hasn’t slowed him down, although he does now get someone to help him with the garden. And he drove to Wellington at Christmas to see his son, who lives near Paremata Beach.

He enjoys reading and visits from people with the old firm and was very pleased to be able to attend a lunch for Lord Vestey during his recent visit.

LIVESTOCK CORNER: THE VALUE OF A DRAFTER

Hastings livestock buyer Neville Willoughby (rear) helping Rissington farmer Mark Ebbett draft lambs at the beginning of the current season. Mr Ebbett carries 2,000 ewes on his 400 acre property, and fattens all his own stock as well as buying stock in to fatten. He says this type of intensive farming requires a lot of sophisticated plant and machinery to keep feed supplies in the drought prone area. Mr Ebbett and his wife have been farming at Rissington since 1967 and since then have dealt solely with the Tomoana works of Nelson’s NZ Limited. He says this relationship has strengthened every year through the valuable assistance he has had from the Fletcher livestock team. “The farmer can never underestimate the value of a good drafter,” he says. “Over the years the Fletcher team has been instrumental to my success in farming, and have helped me made better profits. I depend on their advice on when to draft and how deep to draft at any time based on their assessment and judgement on the state of the season, the market outlook and the price.”

W. Weddel and Company literally put the beef into the British rowing squad’s effort at the recent world championships held at Lake Karapiro, near Hamilton, by supplying a selection of choice beef cuts for the team barbeques at the picturesque New Zealand lake.

The British eight, from left, Clay Henry, Colin Seymour, Sean Campbell, Robert Lee, cox, Gordon Rankine, Lenny Robertson, Bob Milligan, Malcolm McGowan and Nick Dale are pictured above getting ready for one of the “cook-ups” with two cartons of Weddel beef supplied from the Westfield freezing works.

Weddel also provided a team coach to cater for the British squad’s travelling requirements at the championships.

Three brigades share the honours at annual competition

The Westfield, Tomoana and Patea volunteer fire brigades appropriately won their own trophies for the team events at the annual inter-works fire brigades competitions which were hosted by Westfield this year.

Guest teams from the full-time brigades of the Auckland Fire services and Manurewa brigades also took part, and the three companies volunteer brigades performed more than credibly against their professional colleagues.

The general managers of Westfield and Patea, Gordon Taylor and Lou Stewart, assisted by S. Taylor of Tomoana, K. Tomlinson, Westfield and the divisional officer of the Auckland Fire Services, S. O’Neil supervised the judging of events.

At the end of a fiercely competitive and enjoyable day the participating teams retired to the Golden Horison Lounge at Onehunga for the presentation of trophies. For the first time in the 19 years of the competition the three teams finished tied on 30 points so the Albion Shield for the aggregate points winner will be shared on a four months basis between the three brigades.

At the social function Mr J. Buckland, a past president of the United Fire Brigades Association presented the following service honours to members of the Westfield fire brigade:-

Chief Fire Officer Ross Whittle, two year bar for 15 years service, Deputy Chief Fire Officer Tony Doust two year bar, seven years; Third Officer Frank Horspool, two year bar, 19 years; Station Officer Norman Lyon, two year bar 15 years; Fireman Greg Jones, Maurie Strickland and Bill Webster, five year medals and Alex Donaldson and John Paverd, three year medals.

The times for the competitions were:

Four Men Laying Line of Hose: Westfield 59.9 seconds, 1st; Tomoana 62.5, 2nd; Patea 77.6, 3rd; Auckland 73.6,; Manurewa 55.

Four Man Motor Squad: Tomoana 54.7s, 1st; Patea 59.7, 2nd; Westfield 68.3, 3rd; Auckland 61.5; Manurewa 46.9.

Four Man Motor F. W. P Patea 46.2s, 1st; Westfield 47.3, 2nd; Tomoana 54.1, 3rd; Auckland 48.8; Manurewa 41.8.

Westfield general manager recently presented Eric Waugh with a gold watch to mark his half century of service with the company and his wife with a bouquet of flowers at a luncheon attended by more than 100 of Eric’s workmates and members of the staff. Eric has spent his 50 years at Westfield working in the fellmongery department.

At another long service presentation Mr Taylor presented gold watches to Andrew McMullen, freezer foreman and “Dempsey” Young, assistant works manager, meat, to mark their respective completion of 40 years’ service at Westfield.

OBITUARY

Condolences to the wife and family of the late Jack Turnbull who died in Auckland recently. Mr Turnbull retired from the Westfield Freezing Company in 1966 after having served the organisation for 50 years.

WESTFIELD RETIREMENTS

The general manager of the Westfield Freezing Company, Gordon Taylor, presenting long service staff member Doug Verrall, of the shipping department who looked after the islands service, with a handsome cheque to mark his “early” retirement after 42 years service with the company. Doug was granted the “early” retirement on the grounds of ill-health.

At another Westfield retirement, many staff members turned out to farewell Ted McSweeney, second in charge of the shipping department, after having spent 12 years with the company. Ted is pictured above being thanked and presented with a farewell gift by Westfield manager Gordon Taylor.

COMPANY PROFILE

Hawkes Bay livestock manager, Terry Goldstone, who joined W. & R. Fletcher in 1956 as a livestock buyer, has a lifetime association with the land. When he left school he started work as a stock clerk before going shepherding. He later joined Wright Stevensons, where he became livestock manager for Hawkes Bay before joining the Fletcher team. Terry says the major changes he has seen in the industry have been the dramatic increases in production from 12,000 to 20,000 a day and the problems presented by the hygiene regulations. “When I started drafting we began work at 4 am. and were finished by 10 with the stock all being killed the same day. Now, with the washing and drying regulations we draft all day, and stock is not processed until the following day or in some cases for two days depending on late arrivals or because of the distance they have to travel. ” Terry notes the change to a wider variety of crossbred lambs today to cater for the world demand for leaner meat and to produce breeds that need less looking after, consequently reducing labour costs. Terry is an active judge in local competitions, officiating at dog trials and sheep, cattle and horse shows. He has competed in trials with his own dogs and has qualified several times for the N. Z. Championships. Terry still maintains his interest in the land by giving a helping hand to his son Bruce on the family 1,000 acre farm at Tutiria [Tutira].

W. & R. FLETCHER (NZ) Ltd.

(PRINTING DEPT.)

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Description

Surnames in this newsletter –

Al-Badri, Alexander, Baker, Bing, Bishop, Buckland, Campbell, Dale, Donaldson, Doust, Ebbett, Goldstone, Greenough, Gusscott, Henry, Hinchliff, Horspool, Johnston, Jolly, Jones, Knight, Lee, Lyon, McGowan, McMullen, McSweeney, Milligan, O’Neil, Paverd, Rankine, Reeves, Robertson, Sanders, Seymour, Stewart, Strickland, Taylor, Taylor, Tomlinson, Turnbull, Verrall, Waugh, Webster, Whittle, Willoughby, Young

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.