GISBORNE (cont’d)

and 30 Ministry of Agriculture inspectors, who also have offices on the floor.

Although at present there are no women working on the Kaiti chain, provision has been made for facilities for any women who will join the staff in the future.

The top floor comprises the three chains which are situated some four metres above the floor area with variable working levels as in beef operations to reduce the strain on employees performing different processes.

The sticking area for the new complex is just outside the stockyards and stock, once slaughtered, are conveyed up a ramp to the top floor during which the electric stimulation process for ageing and conditioning, is carried out.

The sticking operation will be carried out on a spreader conveyor rather than the traditional bleeding table and also incorporated is a stacking conveyor between the sticking and legging operations to cater for any minor delays.

A significant difference in the Kaiti and Tomoana operations is that at Gisborne lamb will go to a manual sorting area prior to entry into the freezing tunnel to provide the carcases with sufficient “dwell” time for the electrical stimulation process to comply with specifications for the conditioning phase. At Tomoana the carcases are held for an hour in the freezer area before the temperatures are brought down.

The freezer complex, which is being constructed by Robert Stone Ltd, comprises two blast freezer tunnels which work on a four tier system. The 24 hour process can handle some 9,000 sheep daily. Any excess in production will be either further processed for North American requirements or frozen in three extra freezer rooms. The freezing procedure for lambs for the North American market is different to standard methods as the temperatures are lowered in stages to the final freeze point.

In line with the Government’s present energy saving programme design changes have been incorporated to meet the projected targets put to industry. Perhaps the major of these as been a new lighting system using mercury vapour globes which require fewer fittings for a better light output. As the industry has a high level of lighting requirements this will result in a significant energy saving as the new system should result in up to a 30 percent reduction in lighting costs.

The plant’s existing engine room, boilers, hot water systems, rendering department and other facilities are also being upgraded to meet the increased production requirements.

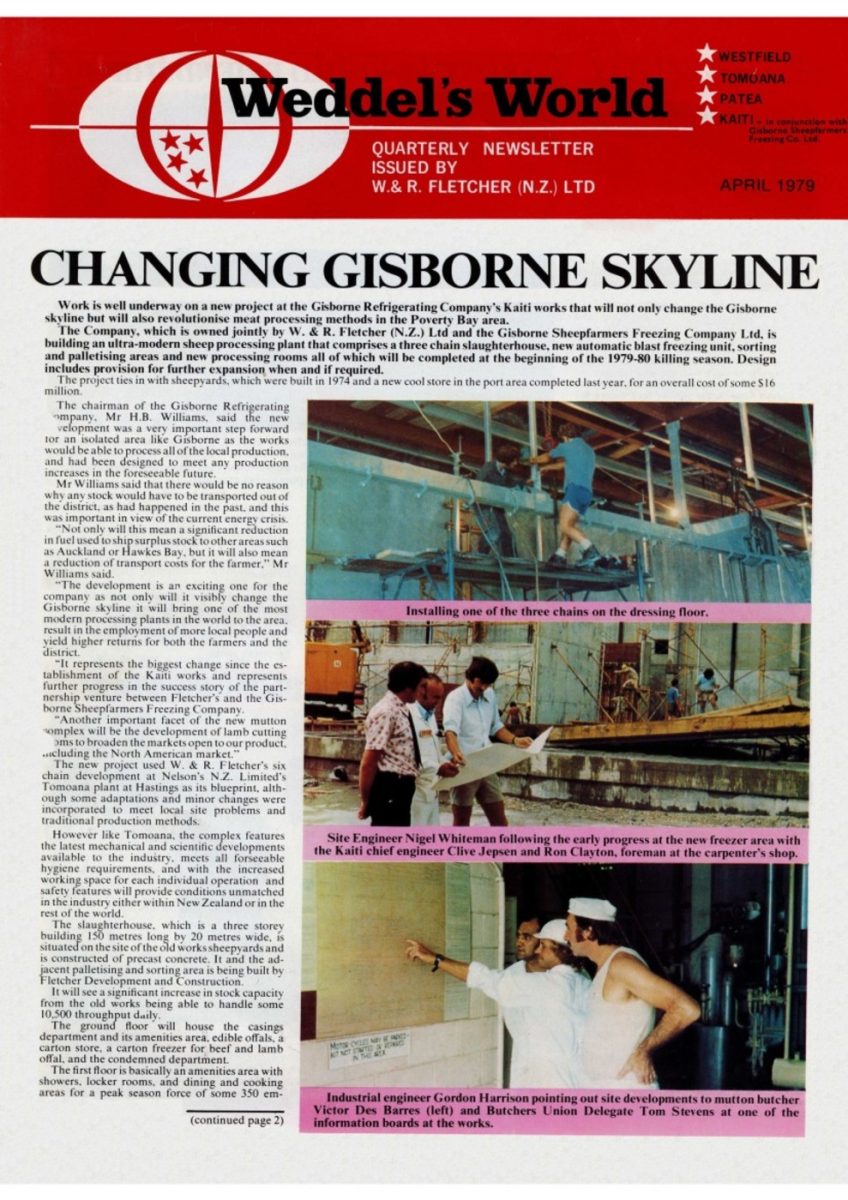

The entire project has been a successful exercise between management and personnel at the Kaiti works with all employees being kept up-to-date with developments on the site.

Notice boards have been placed in all departments showing plans of the buildings and giving written descriptions of work advances during the various stages of construction, and these have drawn much interest from the works staff. With the work areas beginning to take shape parties have been taken through the buildings and shown progress to date.

In addition some personnel representing union delegates, foremen and chain workers have been taken to Tomoana to be given a first hand chance to see how the project will look when complete. One union representative said he was greatly impressed with the Tomoana site and said that the new design features would substantially improve working conditions. “With everyone on the chain being placed no closer than a metre to his nearest workmate, improved ventilation and lighting, we will have probably the best of conditions.” he said.

The liaison has also led to some design changes with suggestions from the work floor on possible improvements to some amenities areas becoming a reality through the drawing boards.

Site Engineer Nigel Whiteman says this programme has led to he and his staff being stopped on site by many workers and asked to explain any new developments in the building area.

He says with Tomoana virtually complete and being used as the model for Kaiti, it has helped the engineers foresee problems in advance.

“We have been able to incorporate design changes made at the building stage at Tomoana in the drawing board stage here, which has in some cases led to valuable cost saving.

RENEWING OLD FRIENDSHIPS

A former general manager of W. & R. Fletcher (N.Z.) Ltd, Mr John Coleman, exchanged reminiscences with retired staff members during his visit to Wellington. With him are shown Miss A. Moxey, former senior typist, Mr Jack Kent, retired head of the stockfoods department, and Mr Colin Grant, who was the company s purchasing manager.

Mr Coleman was Fletcher’s general manager from 1951 until 1969 when he returned to England where he was appointed managing director of the British Beef Co. Ltd, (a member of the Vestey organisation) and a director of other associated companies in the United Kingdom and Europe. He retired last year after 48 years in the service of the group.

Mr and Mrs Coleman’s visit is part of a world tour embracing New Zealand, Australia, the United States and the Far East which is giving them the opportunity to meet again the people Mr Coleman had worked with and for them to meet friends in the various countries.

During his New Zealand tour Mr Coleman visited the Westfield, Kaiti and Tomoana works and described the new Tomoana mutton complex as “startling and impressive”.

“It is technically and hygienically far advanced of anything else I have seen in the world ” Mr Coleman said. “I think the staggered working positions on the mutton chain are a significant step forward.”

Mr Coleman said that in general the operations he had seen in New Zealand works were already well in advance of those in Europe. When the New Zealand works had completed their programme of meeting international hygiene requirements then they would greatly surpass standards existing in European works.

MAINTAINING COMMUNICATION

Tomoana management and staff have been holding regular communications meetings to discuss matters of interest outside normal department problems. Apart from dealing with problems in production, production forecasts to help in forward planning and company policy the meetings are also used as “sounding boards” for individual problems. The meetings are regarded as a valuable aid to improving liaison within Tomoana. Pictured above at a recent lunchtime meeting are (from left) David Bedford, industrial manager; Allan Tolley, by-products supervisor; Allan Edwards, works manager; Keith Taylor, casings foreman; David McLeod, yard foreman; Chris White and Len Love, meat graders.

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.