- Home

- Collections

- POPPELWELL MD

- Various

- Hawke's Bay Constructs 1962

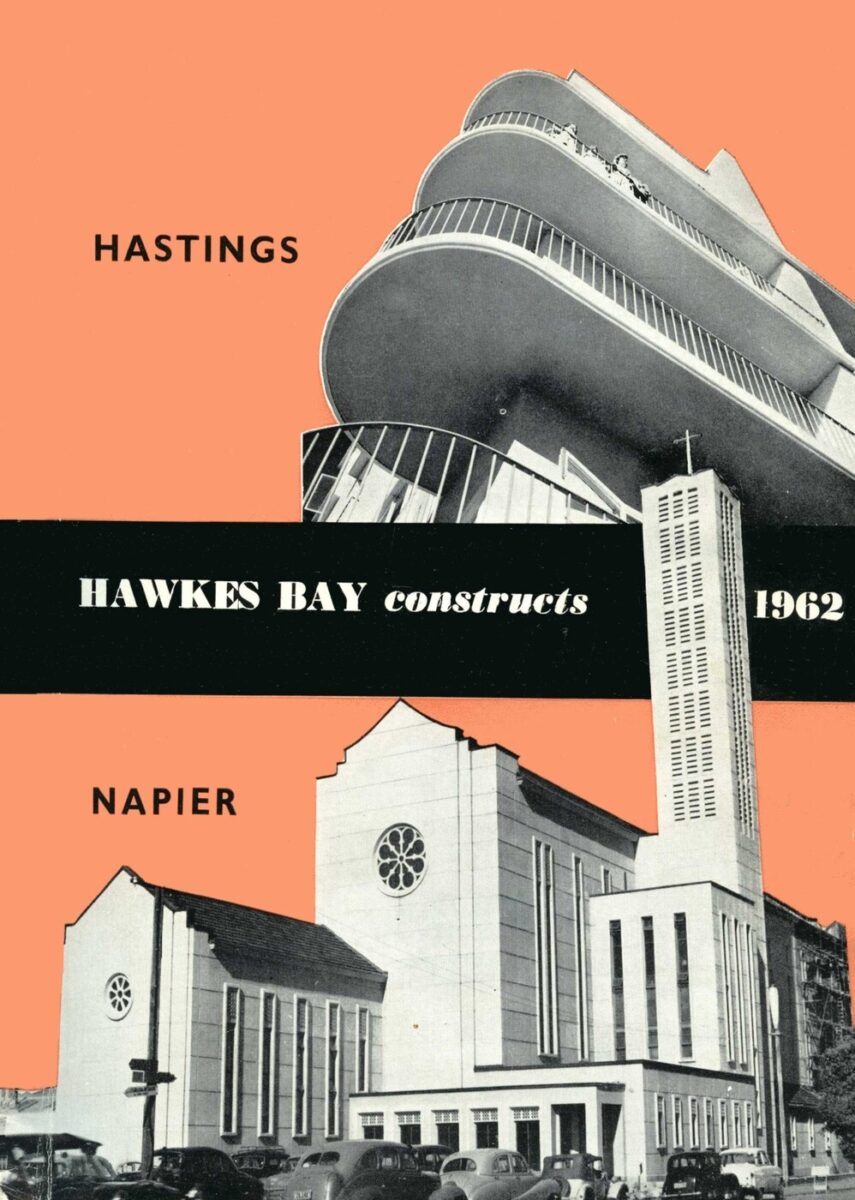

Hawke’s Bay Constructs 1962

[Advertisement]

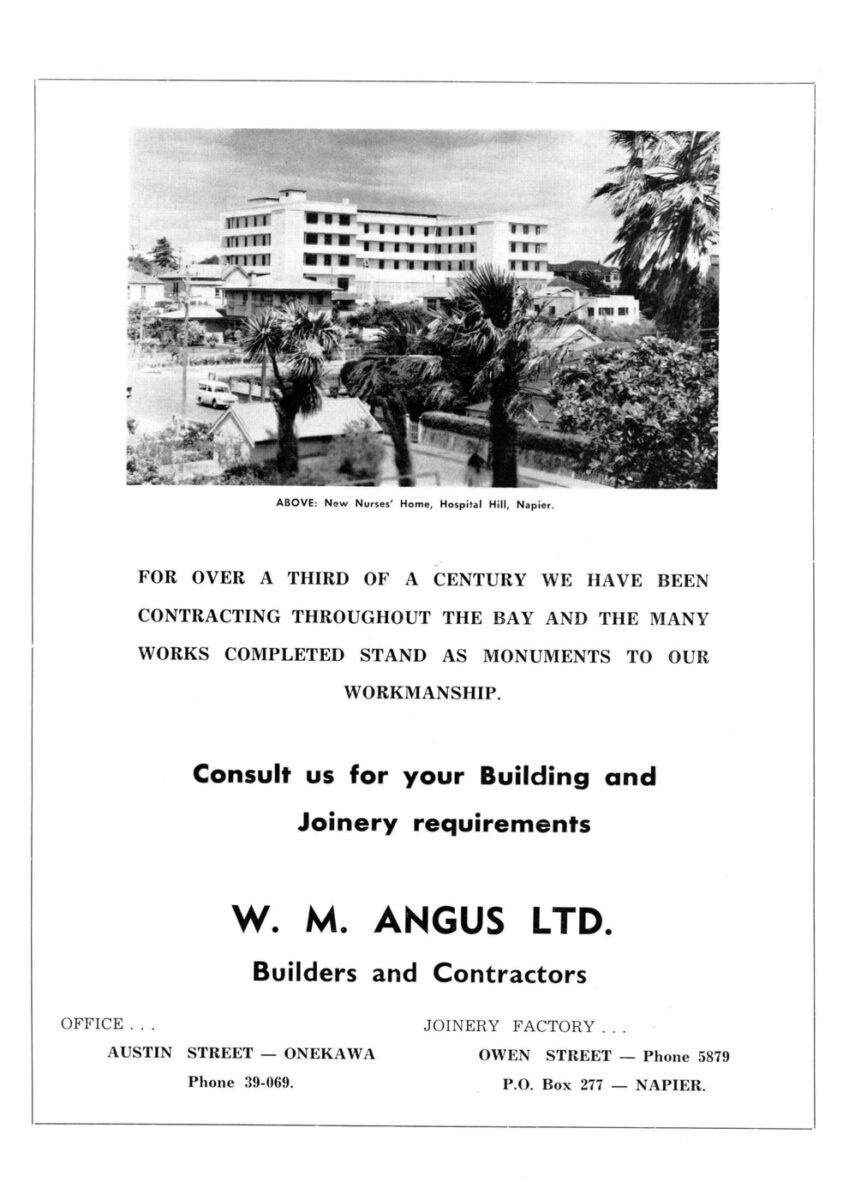

ABOVE: New Nurses’ Home, Hospital Hill, Napier.

FOR OVER A THIRD OF A CENTURY WE HAVE BEEN CONTRACTING THROUGHOUT THE BAY AND THE MANY WORKS COMPLETED STAND AS MONUMENTS TO OUR WORKMANSHIP.

Consult us for your Building and Joinery requirements

W. M. ANGUS LTD.

Builders and Contractors

OFFICE…

AUSTIN STREET – ONEKAWA

Phone 39-069.

JOINERY FACTORY…

OWEN STREET – Phone 5879

P.O. Box 277 – NAPIER.

HAWKES BAY CONSTRUCTS 1

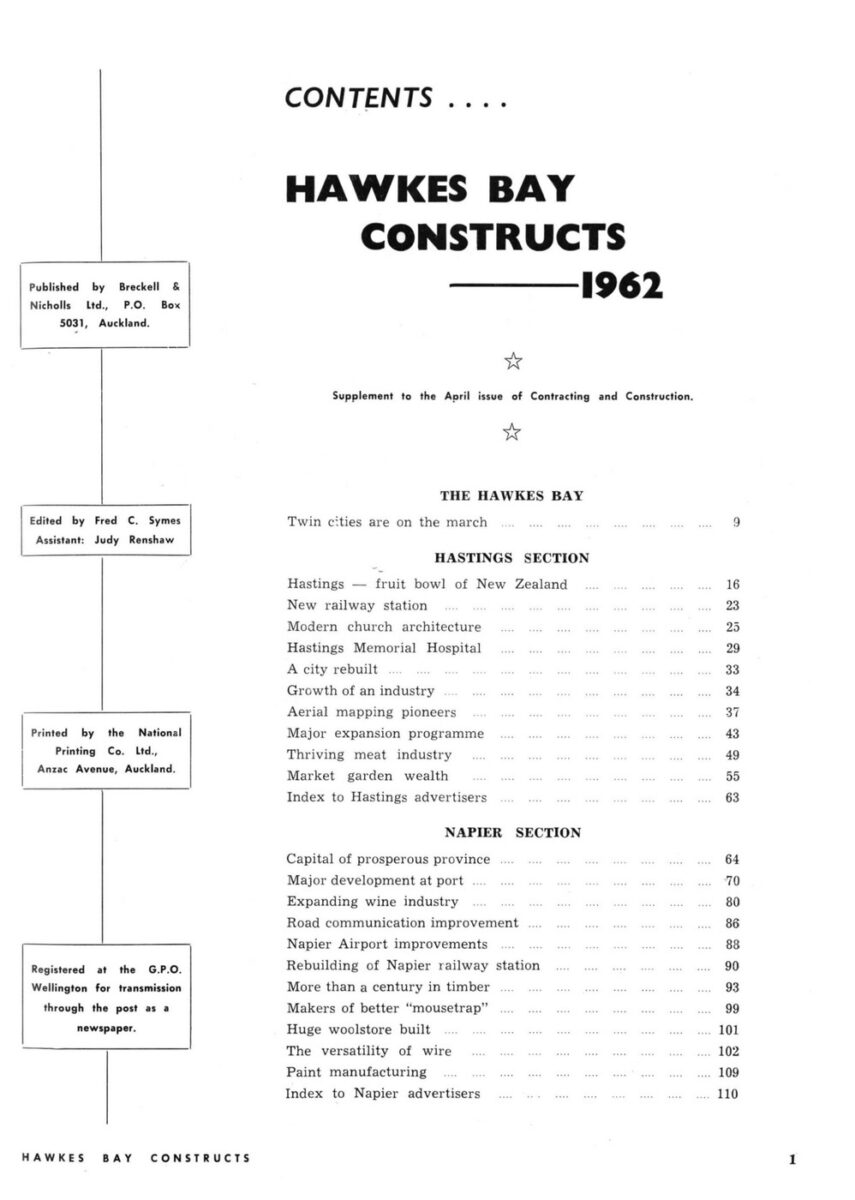

CONTENTS ….

HAWKES BAY CONSTRUCTS – 1962

Published by Breckell & Nicholls Ltd., P.O. Box 5031, Auckland.

Edited by Fred C. Symes

Assistant: Judy Renshaw

Printed by the National Printing Co. Ltd., Anzac Avenue, Auckland.

Registered at the G.P.O. Wellington for transmission through the post as a newspaper.

Supplement to the April issue of Contracting and Construction.

THE HAWKES BAY

Twin cities are on the march 9

HASTINGS SECTION

Hastings – fruit bowl of New Zealand 16

New railway station 23

Modern church architecture 25

Hastings Memorial Hospital 29

A city rebuilt 33

Growth of an industry 34

Aerial mapping pioneers 37

Major expansion programme 43

Thriving meat industry 49

Market garden wealth 55

Index to Hastings advertisers 63

NAPIER SECTION

Capital of prosperous province 64

Major development at port 70

Expanding wine industry 80

Road communication improvement 86

Napier Airport improvements 88

Rebuilding of Napier railway station 90

More than a century in timber 93

Makers of better “mousetrap” 99

Huge woolstore built 101

The versatility of wire 102

Paint manufacturing 109

Index to Napier advertisers 110

Page 2

[Advertisement]

A complete success

the

DUNCAN (ALL STEEL) HOSPITAL BED

This bed incorporates the very latest in manufacturing designs. Every thought has been given to ensure utmost comfort of patients.

Its mobility is a special feature and a pleasing factor to nursing staff.

AVAILABLE FOR

IMMEDIATE DELIVERY SINGLY OR IN QUANTITY TO

HOSPITAL BOARDS HOMES FOR AGED

INSTITUTIONS PRIVATE HOMES

Efficiency in Institutional Management depends on the equipment which is made available

THE BED PEOPLE of HAWKE’S BAY

The dun-can-rest

Pocket SPRING MATTRESS

INNERSPRUNG MATTRESSES

KING ARTHUR

DUNCAN-EZE

DUNCAN STANDARD FOLDING BED

Accept no substitute – Look for the Brand

“MADE BY DUNCAN’S”

DUNCAN U-BAR STEEL MATTRESSES

We also manufacture and distribute

DIVAN BEDS SWIVEL AND TILT CHAIR UNITS

RIMU BED ENDS UPHOLSTERY SPRINGS

WIRE WOVE MATTRESSES CHAIRS (All Types)

U-BAR MATTRESS SUPPORTS OFFICE DESKS

IRON BED RAILS AND BRACKETS MODERN FURNITURE

“FOR SERVICE, SATISFACTION AND DURABILITY YOU’LL FIND NONE BETTER THAN PRODUCTS FROM THE

DUNCAN FURNITURE MANUFACTURING Co. Ltd.

P.O. Box 143 HASTINGS

“All Duncan Quality Products are obtainable through leading Furniture Stores Everywhere”

HAWKES BAY CONSTRUCTS 3

[Advertisement]

For highest quality

Commercial and Residential

Building work

apply to

J. W. LINNELL

BUILDING CONTRACTOR

813A Caroline Road + Phone 86-699 + Hastings

Fine workmanship is apparent in their recent jobs…

Offices for Firth Concrete

Workshop for H. W. Louie Ltd.

Classroom Block for Girls’ High School

Warehouse for Skellerup Sales Ltd.

Intermezzo Coffee Lounge

Nic Nac Coffee Bar

Y.M.C.A. Sports Stadium (under construction)

Page 4

[Advertisement]

MOVING ON

The top picture shows the premises occupied by Hortop & Son Limited from 1935-1961.

Early last year the firm shifted into their new building (pictured below).

Hortop & Son Limited are stockists of Glass, Dowels, Putty, Plywoods, Hinges, Glue. Also large stocks of Foreign and Colonial Timbers are kept on hand.

For all your builder’s requirements such as Doors, Sashes, Frames, Shop Fronts, Counters,Showcases, etc. contact

HORTOP & SON LTD.

JOINERY MANUFACTURERS

CAROLINE ROAD

HASTINGS –

TELEPHONE 2895

HAWKES BAY CONSTRUCTS 5

[Advertisement]

J. C. MACKERSEY LTD.

BUILDERS AND CONTRACTORS

Hastings and District War Memorial Library.

SOME OF THE LARGER COMMERCIAL BUILDINGS UNDERTAKEN ARE: –

Waiapu House, Havelock North, Old Peoples’ Home

St. John Ambulance Hall

Hastings and District War Memorial Library (above)

Pre-stressed Concrete Reservoir for Havelock North Borough Council

3-Storey Office Block for H.B. Electric Power Board

At present under construction…Nelson Park Grandstand for Hastings City Council

REPAIRS and RENOVATIONS – SHOP and OFFICE FITTINGS

COMMERCIAL BUILDING – HOUSING CONSTRUCTION

– JOINERY MANUFACTURING –

Workshop: KAIAPO RD., HASTINGS.

Telephone 88-152.

Postal Address: P. O. Box 320.

J. C. MACKERSEY LTD.

Private Address:

Cnr. Kaiapo and Maraekakaho Roads.

Telephone 88-152.

Page 6

[Advertisement]

TOMOANA…

ONE OF THE PRINCIPAL INDUSTRIAL PLANTS IN THE COUNTRY

MODEST BEGINNING

The Tomoana Works were started in a very modest way by Messrs W. Nelson and J. N. Williams in the year 1880 for the manufacture of the Extract of Meat in connection with the “boiling down” of sheep. In the following year, Meat Preserving was added to the industry. From this modest beginning in 1880 the Tomoana Works have developed into one of the largest industrial plants in New Zealand. At the peak of the season upwards of 1,200 hands are employed. In 1882 the ship “Dunedin” arrived in London with the first shipment of frozen meat from the Dominion. The heavy demand for frozen meat from this country necessitated the building of new freezing works in the Dominion. Thus in 1883 Mr William Nelson founded the present company and erected the first works near Hastings, of Hawkes Bays, and introduced the necessary freezing machinery.

DESIGNED TO HANDLE 400 SHEEP

The works were originally designed to handle 400 sheep a day – capable of being increased to 800, plus 10 cattle per day. Now the works have a killing capacity of 16,000 sheep and lambs, and 500 cattle per day, with provision of all the necessary modern plant for handling chilled beef, packaged meat, and all other edible products.

HAWKES BAY CONSTRUCTS 7

[Advertisement]

TOMOANA FREEZING WORKS

PIONEERS

Tomoana was a pioneer in the development of the numerous byproducts of the industry, and the “Tomoana” brand of all stock foods and fertilizers is well known throughout New Zealand. Tomoana also operates a very successful commission “wool scouring business, the plant being amongst the most modern in New Zealand.

NELSON’S (N.Z.) LIMITED

‘PHONE: HASTINGS

85-069

TOMOANA

HAWKE’S BAY

P.O. Box 379, HASTINGS

Page 8

[Advertisement]

Leopard’s gone a long way in Hawke’s Bay

From humble beginnings, as long ago as 1883, Leopard Brewery is, today, one of the thriving Hawkes Bay industries that can view with pride, its expansion and the growing demand for its products over an increasingly wide area.

Leopard have introduced new ideas into New Zealand’s beer drinking air-conditioning in their hotels, and they were first to introduce canned beer.

The installation of new plant, concentration on expanding markets and successful efforts to improve the methods, and quality of production, have all played a part in the Leopard story.

Industry and application have been rewarded. Leopard now own four hotels in the North Island, including the 5-star plus Royal Oak Hotel in Wellington. They have built and are managing the contemporary, spacious Mayfair Hotel in Hastings & another new silhouette on the rapidly expanding Hawke’s Bay skyline. New buildings expanding industries growing population all these point to and underline Hawkes Bay’s

present prosperity and the potential of the prosperity to come.

Leopard are proud to have such a a long-standing association with Hawkes a Bay proud to be in the progress & centre of New Zealand.

Modern bar at the Mayfair Hotel

The automatic control panel of the brewhouse – one of the most modern in the Southern Hemisphere.

A section of the ultra-modern fermentation cellar.

LEOPARD BREWERY LTD.

HASTINGS

HAWKES BAY CONSTRUCTS 9

Twin Cities are on the MARCH!

Napier and Hastings are taking prominent part in the prosperity of N.Z.

POPULATION ESTIMATES

There is no doubt that the potential of the area is great. Projected population estimates put Napier at 36,000 and Hastings at 27,000 in 1981. Not very spectacular. But those figures are based on the assumption that boundaries will not change. Therefore the estimates for the urban areas more correctly show the possible increase. In 1981 it is estimated that the Napier urban area will have 55,000 people and that there will be 45,000 in the Hastings urban area. Added to this will be the 51,000 in Hawkes Bay county.

THE HAWKES BAY, bounded on the east by the Pacific, on the north by the Wairoa River and on the west and south by mountain ranges, is a compact and wealthy region which is gaining more and more prominence in the economic structure of New Zealand. Population wise it is one of the fastest growing areas in the country – though this increase is almost entirely confined to the twin cities of Napier and Hastings – and its productivity, both primary and secondary is growing rapidly.

THE MAJOR influence on the growth of Napier and Hastings has been the fertility of the Heretaunga Plains. This remarkable fertility has had most effect on Hastings while Napier has, to a great extent, had to rely on the port for its growth. The evolution of things has been that Hastings has become the centre of production while Napier has taken over the role of warehouse. Of course, Napier also has a large share of the area’s production within and near it boundaries.

SECONDARY industry in the region is, however, of a relatively minor nature with metal and heavy industries being almost non-existent. Napier does appear to be the logical situation for this type of development and there is an abundance of good, level land close to the city but far enough away not to be a nuisance to residents. As Napier’s port develops – and there are big plans for the next few years this secondary industry should not be long in coming. Even now at Onekawa factories are mushrooming and one firm has recently purchased a 10-acre site for expansion.

HASTINGS, on the other hand, is very closely allied to the primary industries of food processing; meat, vegetables and fruit. However, it does have the Bay’s largest industrial concern which has recently announced its entry into the bicycle and scooter manufacturing field.

FIRST and foremost Hawkes Bay is a sheep farming area. This can be broken down into two sections which, in order of extent, are wool and store sheep, and fat lamb. There are also extensive areas of dairying and cattle farming. The sheep population is about six million and the cattle number just over 500,000 including 465,000 beef cattle.

Page 10

These vast numbers of sheep and cattle are the reason for the three big freezing works in the Bay. One is at Wairoa and the other two just outside the Hastings city boundary. These last two works between them killed well in excess of two million sheep and lambs this season and also accounted for 75,000 head of cattle for the chiller beef trade.

The fruit industry is quite a vast undertaking and has attracted to Hastings the largest food processing organizations in New Zealand. The largest, Watties Canneries Ltd., last season processed and packed for local and overseas consumption 20,000 tons of produce – more than 50 million units of 88 varieties, canned and quick frozen.

Three big quick freeze factories also handle vast amounts of vegetables freshly picked from the market gardens in the area surrounding Hastings. In fact, the introduction to the area of canning and quick freezing has probably meant more to the growth of Hastings than any other single factor.

Sheep and cattle numbers have increased steadily in the last 30 years even though the occupied land has decreased slightly. This increase is due mainly to the use of fertilizer, especially by aerial top dressing, and by mechanization. The use of more suitable grasses has also helped considerably. Now Hawkes Bay carries about 10 per cent of New Zealand’s sheep, but comprises only 5 per cent of occupied land.

Allied industries are the freezing works, abbatoirs [abattoirs], dairy factories and fertilizer works. There are three freezing works at Wairoa and at Tomoana and Whakatu near Hastings. Abbatoirs are sited at Wairoa and Tomoana. The 15 dairy factories are quite small as dairying is a minor part of the Bay’s farming industry. There are seven agricultural lime works at Hastings, Havelock North, Hatuma, Takapau, Porongahau [Porangahau] and two at Waipawa. Their combined output is nearly 100,000 tons. The new chemical fertilizer works at Awatoto produced 163,000 tons in 1960.

The vegetable growing industry has had a remarkable growth. Forty years ago there were only 150 acres under commercial vegetable cultivation. In 1939 this had expanded to 580 acres and by 1955 there were 4,000 acres. In 1961 7,000 acres were planted in peas alone and the total acreage under vegetable cultivation was 13,000. This expansion has, of course, been caused by the demand created by the establishment and growth of the canning and freezing industry in the area. By far the greatest portion of New Zealand’s export of canned and frozen vegetables goes through the port of Napier.

The acreages and yields for some

Photo caption – The busy heart of Napier’s commercial area seen from above Marine Parade. Much of the business area of the city had to be rebuilt after the tragic earthquake of 1931. Napier is the provincial capital and commercial heart of the Hawkes Bay.

– Whites Aviation picture.

HAWKES BAY CONSTRUCTS 11

of these vegetables and small fruits is worth noting.

Peas: 7,000 acres – 10,000 tons – average yield per acre, 1½ tons.

Asparagus: 1,500 acres – 1000 tons – average yield per acre, 2/3 ton.

Tomatoes: 1,000 acres – 12,500 tons – average yield per acre, 12½ tons.

Grapes: 500 acres – 3000 tons – average yield per acre, 6 tons.

Beans: 560 acres – 1,734 tons – average yield per acre, 3½ tons.

Potatoes: 1,700 acres – 13,600 tons – average yield per acre, 8 tons.

Sweet corn: 110 acres – 372 tons – average yield per acre, 3 tons.

Carrots: 34 acres – 408 tons – average yield per acre, 11 tons.

Berry fruits: 65 acres – 80 tons – average yield per acre 1½ tons.

Onions: 300 acres – 300 tons – average yield per acre, 1 ton.

Hawkes Bay, more particularly the area on the Heretaunga Plains, proudly calls itself the “Fruit Bowl of New Zealand”. This is no idle boast because the area, quite minute geographically, accounts for 17 per cent of the country’s apple trees, 36 per cent of the pear trees and 31 per cent of stone fruit trees. And the production from these orchards is higher than in any other area in New Zealand. The yield averages 1,000 bushels to the acre compared with an average 300-500 bushels in the South Island. Production is increasing far greater than the tree population, especially in the peach and pear orchards. Recent extensive apple tree plantings suggest that this fruit should soon show a corresponding increase.

Land development in the Bay is nowhere near as spectacular as in other New Zealand regions but, still, there are about 500,000 acres which will eventually be made productive. Aerial topdressing will help bring this about.

Another industry which means quite a lot to the economy of the area is the wine industry. The warm, dry climate around Hastings and Napier is ideal for the cultivation of European grape varieties which are particularly suited to the production of high quality wines. Latest venture in the Hawkes Bay wine industry is the plan to produce semi- sparkling wines. Consumption of New Zealand wines has greatly increased and is due in no small way to the fine product of this region. For many years Hawkes Bay has been regarded as timber deficient. This, however, will no longer be true when the major exotic plantings undertaken during the last few years reach the millable stage. And with New Zealand’s rapid growing record for exotics this day is not so many years away. There is plenty

[Continued on page 13]

Photo caption – This aerial picture shows part of the reason for the growing prosperity of Hastings, chief production centre of the Hawkes Bay. Market gardens and orchards spread around the city boundary and keep New Zealand’s biggest concentration of fruit and vegetable processing plants in action. Hastings also has two large meat freezing works.

– Whites Aviation picture.

Page 12

[Advertisements]

DESOUTTER

ELECTRIC AND PNEUMATIC PORTABLE TOOLS

DRILLS

GRINDERS

TAPPERS

SCREWGUNS

NUTRUNNERS

CORNER DRILLS

etc.

THE TOOLS THAT ARE SUPPORTED BY SERVICE AND SPARES

N.Z. AGENTS

de PELICHET, McLEOD & CO. LTD.

P.O. BOX 205 HASTINGS

BALLUSTRADING [BALUSTRADING]

FENCES

GATES

ORNAMENTAL SCREEN DOORS

TERRACE STAUNTIONS

SHOP FITTINGS

STEEL FARM GATES

STRUCTURAL STEELWORK

STEELCRAFTS (HASTINGS) LTD.

SPECIALISTS IN ALL TYPES OF WROUGHT

– IRON WORK –

POSTAL ADDRESS: 1001 SOUTHLAND ROAD

FACTORY: OMAHU ROAD (opp. Nurses’ Home)

Telephone 88-143

HASTINGS

HAWKES BAY CONSTRUCTS 13

[Continued from page 11]

of ideal forestry land available and markets are assurred [assured] within the region itself and in Manawatu, Taranaki and Wellington. Export of timber through Napier is also a distinct possibility. Timber has done wonders for the Bay of Plenty and that boom story could be repeated in Hawkes Bay when the forests mature.

In recent months fisheries experts have stated that the New Zealand fishing industry is only scratching the surface of the great harvest available from the sea. All these statements are borne out by the armadas of Japanese fishing fleets which we now know for certain are fishing around and off the coasts of New Zealand. The New Zealand fishing industry is not geared for the type of fishing the Japanese carry out, but more and more fishermen are realizing that they must change their fishing habits if they are to get their share of the harvest.

The Hawkes Bay region is ideally situated for this intensified fishing and it is well known that the local industry is keen to tackle this new type of fishing. Watties Canneries were first in the field when they sent their tuna boat to sea a few months ago. Catches have not been brilliant, but each time the boat goes out more and more is being learnt about tuna fishing on a commercial scale. Watties is set up for the canning of this fish and no doubt the other canning and freezing companies are prepared, too.

Food and beverages, as might be expected, are the major manufacturing activities in the Napier and Hastings employment districts. Napier also has one of New Zealand’s largest tobacco companies. Furniture manufacturing in Napier and Hastings is well established but metal industries are almost non-existent. The one major exception is Morrison Industries in Hastings. This firm has expanded rapidly since the war and will soon begin manufacturing bicycles and scooters.

It is hard to understand why the metal and heavy industries have not moved in to the area because there is a good labour force and the port at Napier is ideal for distribution. Both cities are also serviced by first class roads and railway. Both Napier and Hastings are trying to entice industry and both have large areas of land zoned for industry. Recent purchases of land for industrial purposes suggest that perhaps industries are at last realizing the very great advantages of establishing businesses in the area.

Photo captions –

On Napier’s beautiful and relaxing Marine Parade visitors can get all the information they need to ensure a pleasant holiday from this modern information centre.

– Russell Orr picture.

Hastings people are very proud of the recently completed additions to the Hastings Memorial Hospital. The graceful lines of this building have made it very popular with amateur photographers.

– Russell Orr pictures.

14 HAWKES BAY CONSTRUCTS 15

[Advertisement]

A. Miller

(Director)

R. W. F. Gurnsey

(Managing Director)

A. D. Oulaghan

(Secretary)

D. F. Fuller

(Accountant)

A. R. Holder

(Quantity Surveyor)

MILLER AND GURNSEY LTD.

OUR PART IN BUILDING GREATER HASTINGS

HASTINGS AUTOMATIC TELEPHONE EXCHANGE

WAIPUKURAU SEWAGE TREATMENT PLANT

CLIFF PRESS PRINTING HOUSE

NATIONAL MUTUAL LIFE BUILDING

J. R. SETON AND CO. WAREHOUSE

ELECTRICITY DEPT. STORE. NAPIER

CALTEX OIL CO. OFFICE BLOCK, NAPIER

NEW HERETAUNGA INTERMEDIATE SCHOOL

DE LUXE CAR SALES AUTOCOURT

MONARCH MOTORS LTD., CONTRACTS Nos. 1, 2, 3

BUTLAND INDUSTRIES NEW FACTORY, 1958

BUTLAND INDUSTRIES EXTENSION, 1959

BUTLAND INDUSTRIES STORE 1960

BRIMMER AND CRABTREE JOINERY FACTORY

A. R. CHRISTIAN FACTORY

HARRIS FOOD MARKET

F. C. HORTOP LTD. JOINERY FACTORY

H. B. ELECTRIC POWER BOARD STORE

MOTOR SPECIALTIES LTD. NEW WAREHOUSE

MURRAY ROBERTS WOOL STORE

HERETAUNGA INTERMEDIATE SCHOOL CLASSROOM BLOCK

FURNITURE AND WOODWARE LTD. STORE

N.Z.R. GOODS OFFICE

N.Z.R. GOODS SHED

HASTINGS HOSPITAL REFUSE DISPOSAL

AND NUMEROUS SMALLER CONTRACTS.

“STAR” FLATS CONTRACT – HASTINGS

COMMERCIAL WORK

HOUSING

ALTERATIONS

BUILDERS and CONTRACTORS

HASTINGS

HAWKES BAY CONSTRUCTS 17

Home of the FROZEN FOOD industry

THE development of Hastings has been somewhat like the life of a rebel. Almost none of the things it was supposed to be have eventuated. First off it was intended to be a suburb of Havelock North, then expected to become a major centre. Within a short time Hastings had outstripped Havelock North and the positions had been reversed. As the town grew it was expected that Hastings would become a dormitory town of Napier. But no, Hastings just grew and grew and now is almost level pegging with Napier on a population basis.

While Napier was becoming a town of some proportion Hastings was still a rather motley collection of frame houses clustered around the swamp which today is the thriving business area. A town board was established in 1886, 22 years after the first settlement, and Hastings began to grow. The opening of the railway between Hastings and Napier was the impetus that has since marked the rather remarkable growth of Hastings.

After World War I Hastings began to increase at a faster rate than did Napier and this trend has continued right to the present day However, projected population estimates show that Hastings will eventually be overtaken by Napier unless of course, boundary change: are made to bring parts of the heavily-populated Hawkes Bay county into the city.

Hastings was given a population boost during the early ’20’s when orchard development around the then borough was substantial. This brought about residential development resulting in a significant increase in the population of the Heretaunga Plains.

During 1926-36 there was a big increase in the Hastings urban area despite there being a severe depression in the country for several of those 10 years. The increase for the Hastings urban population was 25.6 per cent against 13.1 per cent for the Napier urban area.

During this period, of course, was the earthquake of 1931. Napier, as a port town, was feeling the depression more than Hastings because of the drastic falling-off in trade and when the earthquake shoaled up the harbour Napier lost a lot more of its business. Meanwhile, Hastings was experiencing rapid growth despite these disasters. And it must be remembered that though the earthquake is referred to as the Napier earthquake, Hastings was just as hard hit. Many buildings were wrecked and damaged and 93 people killed.

The period 1936-45 again saw Hastings growing at a more rapid rate than Napier, but the expansion had slowed somewhat. For the first time Havelock North – of which Hastings was originally destined to be a suburb – increased at a faster rate than Hastings. It became clear in this decade that Napier had completely recovered from the earthquake and depressions of the 30’s. By 1945 the urban areas of the two cities were almost identical with Napier having the slight edge of eight people with a population of 20,334.

This trend has been a continuing

[Continued on page 19]

Photo caption – The growth of Hastings during the last few years has been quite astounding and new suburbs have been growing round the fringes of the city. This growth has called for new schools and below is a recently opened intermediate school.

– Russell Orr picture.

Page 18

[Advertisement]

HAWKE’S BAY DISTRIBUTORS

OF

SINGER

GAZELLE and VOGUE

SALOONS OR STATION WAGONS

BACKED BY COMPLETE MOTORING SERVICE AND SPARE PARTS ORGANISATIONS.

AGENTS FOR

JAGUAR and DAIMLER

ROSS, DYSART & McLEAN Ltd

LICENSED MOTOR VEHICLE DEALERS

200 KARAMU RD. STH. HASTINGS Tel.: Day 87-029; Night 87-494

LET US ARRANGE QUICKER DELIVERY OF A NEW MODEL UNDER THE NO REMITTANCE SCHEME

THE GENERAL HAULAGE CO. LTD.

Suppliers of READY MIX CONCRETE for Hastings and surrounding district.

HASTINGS

Est. 1928

Illustration shows one of the Units delivering material to a Bridge Job.

We also supply –

SHINGLE

ALL GRADES

SAND

CHIPS

FOR SEALING

SPOIL

FOR FILLING

Works: Pakowhai Bridge.

P.O. Box 287.

Telephone 83-515.

HAWKES BAY CONSTRUCTS 19

Buildings under construction

[Continued from page 17]

feature of the two cities with Hastings always showing a larger percentage increase.

There can be no doubt that the market garden and orchard industries have helped Hastings expand. This and the establishment of huge processing plants for the produce of these industries. As well as this Hastings is the main centre for the slaughter of sheep and cattle and also the site of New Zealand’s second largest stockyards. As production of fruit, vegetables and live stock increases so the processing plants are expanding their premises so that the future of Hastings is assured on this score alone.

But Hastings is more than a place to grow and process food. Already it has a fairly well established industrial side to it. Largest of the industrial concerns is Morrison Industries who have recently expanded into a very large factory addition. And there is plenty of land for factory expansion or, better still, the establishment of new industries in this young city. The lively city council, like that of Napier, is offering many inducements to foreign capital to start businesses in Hastings. Because of the seasonal nature of the food processing industry Hastings certainly needs other industry to take up the large labour force which is available in the off season.

Another industry that Hastings is pushing hard is tourism. This is mainly in the capable hands of Greater Hastings whose public relations officer, Mr Ken Sparks, is possibly the most efficient any city or town in New Zealand has. With his annual Blossom Festival each spring he has tempted as many as 80,000 people to the city for the festivities. And these people come from all over the North Island and the South Island, too. The Easter highland games are another great attraction in Hastings and draw almost as many people as the Blossom Festival.

It is certainly no idle boast that Hastings is, in the words of Ken Sparks, “a grand place to live, to work, to start industry, or to just relax”.

Photo captions –

Another addition to the fine cultural and institutional buildings in Hastings is seen during construction in the picture above.

– Russell Orr pictures.

The largest fruit receiving depot in New Zealand The Apple and Pear Marketing Board’s building has an area of 60,000 sq. ft., there being cool storage space for 250,009 cases of fruit. During the 1961 season 850,000 cases of apples and 245,000 cases of pears were handled of which 480,000 were exported.

– Russell Orr picture.

Page 20

[Advertisement]

H. H. Campbell & Sons Ltd.

TIMBER

HARDWARE

GLASS

OIL and COLOUR MERCHANTS

DIRECT IMPORTERS

A corner view of H. H. Campbell & Sons Ltd’s hardware department.

H. H. Campbell & Sons Ltd. was established in 1893 by H. H. Campbell, and was converted to a partnership in 1919, as H. H. Campbell & Sons.

In 1919 the business occupied the corner of Karamu Road and Albert Street only. … NOW it occupies the block bounded by Karamu Read, Albert Street, Warren Street, and Victoria Street.

The business comprises Timber yard, and Planing mill, Joinery factory, heavy Hardware warehouse, builders’ Hardware department, paint, class [glass] and wallpaper department and Ship Chandlery department. The company is also a direct importer of all builders’ heavy and light Hardware and wallpapers, etc.

An outside view of the premises of H. H. Campbell & Sons Ltd.

602 KARAMU ROAD NTH,

HASTINGS, HB.

P.O. BOX 389.

PHONE 85-024

NIGHT 82-624

HAWKES BAY CONSTRUCTS 21

[Advertisement]

No matter how large or small, our vehicles will

undertake any job…

Earthmoving

Excavation

Cranage

Drainage

Metal Supplies

Heavy Haulage

Our earthmoving MACHINERY, CRANES, METAL TRUCKS and EXCAVATORS have been first on the job in most of the major construction works in Hastings. In recent years these have included.

HASTINGS MEMORIAL HOSPITAL

HAWKES BAY ELECTRIC POWER BOARD BUILDING

KARAMU HIGH SCHOOL

HASTINGS RAILWAY YARDS

EXTENSIVE DRAINAGE WORKS – including both Cartage and Laying of Concrete Pipes from 6 in. to 6 ft. in diameter.

Contact –

JOHN FRASER & SONS, CONTRACTORS, LTD.

Omahu Road Hastings ‘Phone 89-196

Page 22

[Advertisement]

Travellers…

Here is a hotel with comfort

friendliness

attractive decor

service

This was purchased by the Buchanan family in 1953 and has been transformed from an old ’boozer’ to the leading establishment, by careful thought and planning and thanks to the local support we have a programme out for the future additions

STORTFORD LODGE HOTEL

Hastings Phone 89-039

The modern Novalite roof gives a soft, soothing light.

HAWKES BAY CONSTRUCTS 23

NEW STATION FOR CITY THAT GREW AROUND THE RAILWAY

HASTINGS, like a number of other cities and towns, developed from its earliest days around its railway station. As in the case of those other centres, the city’s growth resulted in the cramping of station expansion, with attendant delays to the flow of road traffic by shunting activities across the busy streets.

When the city of Hastings became due for increased and improved railway facilities, it therefore became necessary to remove the entire station facilities to a less restricted area from a quarter to half a mile away from their existing site. This entailed the purchase of additional land and the construction of a new marshalling yard, a new station building, and office block, and a goods shed on the new site. The main railway line also had to be rebuilt some 25 yd. east of the existing line to allow adequate room for the new yard. This constituted one of the largest railway construction projects ever put into operation in Hawkes Bay.

By May, 1959, platelaying was in progress on the new line between St. Aubyn and Frederick Streets, so that ultimately shunting could be eliminated across St. Aubyn and Heretaunga Streets. Work was also in progress on the new marshalling yard, situated almost half a mile north of the existing station. This yard comprises several long sidings and a crossing loop capable of accommodating a train more than 600 yd. long without encroaching on Frederick Street (which crosses the yard’s northern approach). The new yard was completed and brought into operation in May, 1960.

In the following February a start was made on the new station platform, with a crane swinging the first of 21 10 ft. long, 243-ton concrete blocks into position to form the front of the 210-ft. platform. A contract was let in October, 1961, to the Hastings firm of Miller and Gurnsey Ltd. for the construction of a new goods shed and an administrative and goods office block. The office block was to be partly two – storeyed, with a floor space of 2,000 sq. ft. The adjoining 200 ft. by 40 ft. goods shed would have 18,000 sq. ft. of floor space and would have a steel portal frame sheathed with corrugated asbestos and concrete blocks.

Work was begun almost immediately on the laying of foundations for these buildings, 33 piles being sunk to a depth of 20 ft. on the site of the new goods shed.

In the same month tenders were called for the construction of the new station building on a site about a quarter of a mile north of the existing station. The building is to have floor space of 2,700 sq. ft. and will comprise timber framing, steel columns and verandah supports, roofing of corrugated asbestos, and concrete block veneer walls. The verandah area is to approximate 1,100 sq. ft.

The new station will measure approximately 101 ft. by 264 ft., with a 210 ft. platform. It will incorporate a stationmaster’s office, a combined waiting room and booking office with a modern-type open counter, a luggage room opening on to the waiting room, toilet rooms, and rooms for communications and other station equipment. In keeping with modern New Zealand railway station design, extensive use is to be made of glass to achieve a well-lit interior.

A contract for the construction of the new building was let in November last to S. E. Morgan and Sons Ltd., of Hastings. Construction work on the building is at present proceeding and the station is expected to be completed about the middle of 1962. More compact than the old-fashioned wooden building which it will replace, the neat and attractive new station, with its modern facilities, should serve the expanding city of Hastings well for many years to come.

Page 24

Hastings uses block system for numbering streets

VISITORS to Hastings sometimes find the house numbering system somewhat confusing, because of the fact that the lowest numbered house in any street is 100. The numbering is on the American block system, and Hastings is reputed to be the only city in New Zealand which adopts this system. Actually, it is a very simple one, and for directional purposes very easy to follow – provided the compass direction of the number sought is known.

The whole system is based on the four points of the compass, with the railway line as the division between east and west and Heretaunga Street as the division between north and south. The first block north, south, east or west of these division points, carries the number 100. The second is numbered 200, the third 300, and so on, so that all houses in the first block are numbered from 100 and those in the second block from 200. In some cases, where the blocks are unusually long, an imaginary line is fixed to divide the block for numbering purposes.

By means of this block system, which can only be applied where cities and towns are flat and laid out in blocks, it is easy to direct a person to find any house again provided it is known whether the house is north, south, east or west.

For instance, in the event of a person wishing to find, say 305 Queen Street west, the first direction is that the street runs west from the railway line the dividing point. The fact that the house is in the 300 numbering, indicates that it is in the third block west of the railway line. The usual odd and even numbering is used, with odd numbers on the right hand side and even numbers on the left, so that 305 Queen Street west would be the third house on the right-hand side of the third block west from the railway line.

Postal officials especially consider it has a great advantage over the usual numbering system.

[Advertisement]

SHEARING PLANT EXPERTS – PUMP INSTALLATIONS

HYDRAULIC TRACTOR EQUIPMENT – BOILER

REPAIRS – SAW BENCHES – WIRE ROPE

– BELTING – ENGINES – ETC.

THE H.B. MACHINERY & ENGINEERING CO., LTD.

GENERAL ENGINEERS

P.O. Box 643 HASTINGS 406 Karamu Road

Telephone 85 405

HAWKES BAY CONSTRUCTS 25

MODERN OUTLOOK OF HASTINGS AREA IS REFLECTED IN THIS NEW CHURCH

Throughout New Zealand new church architecture is among the most modern and while retaining many of the traditional features of church construction church design is much more dramatic than what had become the orthodox design of the first 50 years of this century. Among the most striking small church recently built is this Catholic church at Havelock. While it looks unmistakeably like a church it has none of the orthodox lines with which church buildings have become associated. The architect was the brilliant Maori, John Scott, of Haumoana, Hastings.

– Russell Orr picture.

Page 26

[Advertisement]

ODLIN’S – the

BUILDING

SUPPLIES

SPECIALISTS

are proud to have served the

BUILDING INDUSTRY IN HAWKE’S BAY

for over 30 years

WE CARRY A COMPLETE RANGE OF TIMBER and HARDWARE SUPPLIES

THE C. & A. ODLIN TIMBER & HARDWARE CO. LTD.

HERETAUNGA ST. WEST

HASTINGS

Phone 88-003

BRANCHES THROUGHOUT N.Z.

Kennedy Road

Napier

Phone 4668

HAWKES BAY CONSTRUCTS 27

[Advertisement]

Build in Steel –

for

Strength

and

Durability

The photograph illustrates the Steel Fabrication of the additions to the Steward Stand at Hastings being erected for the Hawkes Bay Jockey Club.

Today in building construction the emphasis is on strength with the minimum of weight and this can only be achieved through fabricated steel…Our skilled staff over the past few years have been entrusted with many major contracts … these are located throughout the “Bay” and include a wide coverage of construction work.

SOME OF THE MAJOR CONTRACTS COMPLETED INCLUDE: –

Extension of Cable-Price Lid. (Steel Division) Steel Store, Napier.

Hastings Memorial Hospital, new block, four storey building, Hastings.

Little Sisters of the Poor, Hastings.

Wairoa Centennial Library, Wairoa.

Wattie Canneries Ltd., additions.

WE SPECIALIZE IN THE MANUFACTURE OF: –

Front and rear hydraulic Forklifts, fit all tractors.

Tanks of all descriptions.

Rotary Screen, Blood Cookers for Freezing Works.

Universal Beams done by Submerged Arc Process.

Combination Sheep and Cattle Crates.

WELDERS & ENGINEERS (HASTINGS) LTD.

GENERAL AND STRUCTURAL ENGINEERS

409 N. King St. – HASTINGS – Phone 83-303

HASTINGS

MEMORIAL

HOSPITAL

A comment on an earlier page that the design if the Hastings Memorial Hospital made it popular photographers is fully supported by these pictures in which full play has been made of design, light and shade to produce graceful and interesting pattern pictures. In both, straight lines and curves harmonize beautifully.

– Russell Orr picture.

HAWKES BAY CONSTRUCTS 31

[Advertisement]

Plan number 17, 945 sq. ft.

Basic Price: £2,598.

For the luxury features you’ve always wanted – see

exclusive

homes

Plan number 18,

956 sq. ft. Basic Price: £2,655.

Phone or call for a FREE Illustrated Brochure

…They’re Architect designed for modern living

Exclusive Homes cost no more than conventional type homes … yet you get a whole host of luxury features like french doors, flower boxes and terraces that you can include when you build or add later when you choose.

What’s more include a range of house plans of 2, 3 and 4 bedroom homes that start a £2,300 … fully approved by State Advances, too.

Designed and construction arranged by

K. G. LETT Ltd.

HERETAUNGA ST., HASTINGS. PHONE 84-149.

Member Read [Real] Estate Institute of New Zealand.

Page 32

[Advertisements]

Our motto…

SALES & SERVICE

Bennett & Redfern Ltd.

DOMESTIC COMMERCIAL INDUSTRIAL

REFRIGERATION ENGINEERS

Agents for: PRESTCOLD and McALPINE

24-HOUR SERVICE FOR ALL TYPES OF REFRIGERATION …

PHONE 88-932 AFTER HOURS SERVICE PHONE 84-419.

804 W. Heretaunga Street HASTINGS P.O. Box 791.

BARCLAY MOTORS LTD.

(MEMBER OF THE WRIGHT, STEPHENSON GROUP)

Licensed Motor Vehicle Dealers

BUSINESS BUILT ON SERVICE TO THE COMMUNITY

NAPIER

HASTINGS

WAIPUKURAU

VOLKSWAGEN SALES AND SERVICE

MASSEY – FERGUSON TRACTORS AND IMPLEMENTS

WRIGHTSON IRRIGATION

HOMELITE CHAIN SAWS

SUNBEAM SHEARING PLANTS

BEAN ORCHARD SPRAYERS

HAYTER TRACTOR MOWERS

HONDA POWER CYCLES

MARIN [MARINE] OUTBOARDS

PLYLITE BOATS

USED CARS AND TRUCKS

MORRISON MOWERS AND MULTIHOE CULTIVATORS

HAWKES BAY CONSTRUCTS 33

1931 EARTHQUAKE TOOK A TERRIBLE TOLL OF HASTINGS –

New city a tribute to faith of inhabitants.

IN THE gay atmosphere which prevailed during the recent Hastings highland games, the well-stocked shops and splendidly displayed windows, the fine buildings, and modern homes and motor vehicles, visitors to Hastings probably saw nothing to recall that just over 30 years ago, the business area of Hastings was in a heap of ruins as a result of the disastrous earthquake on 3rd February, 1931. Like its sister city, Napier, Hastings has risen from debris, and today it is in a truly flourishing condition.

It was the vision, courage and determination which were displayed in that period immediately following the disaster, that have been largely responsible for the progress which has enabled city status to be reached.

In the six months from 3rd February, 1931, temporary building permits for no fewer than 192 business premises were issued, these permits providing for temporary shops which were to be replaced within one to two years. In addition 704 permits were issued for repairs to other shops and houses, and it is worthy of note that most of the promises to have the temporary places replaced by permanent structures were redeemed within the specified period.

The greatest of the immediate post-quake undertakings was the reconstruction of the stage of the Municipal Theatre. This was undertaken at a cost of £11,000 and was completed within 12 months.

The one feature concerning the future in which it is generally agreed that little vision was shown when the reconstruction programme got under way, was that of the failure to widen Heretaunga Street. At the time of the earthquake it was realized that as a main thoroughfare of Hastings, Heretaunga Street, was too narrow. When it was found that so many business places were destroyed, there was a half-hearted move towards a rebuilding plan which would make Heretaunga Street at least 10 to 14 ft. wider. In fact, one or two new buildings were actually sited on the set-back building line, but universal support was absent.

It is interesting to recall that in the main area of the town, only one building came through the earthquake without damage. This was the Hawkes Bay Farmers’ building in Market Street. The Public Trust building and the Salvation Army Citadel in Warren Street also stood up to the battering but both were cracked in places. Apart from the wooden hotels, the Pacific, Carlton Club and Albert (all of which have since been modernized), the only pre-quake building still standing in Heretaunga Street is the National Bank at the corner of Karamu Road and Heretaunga Street; but it was scarred by fire and had to be considerably strengthened.

Visitors to Hastings for the first time usually remark on two things – the fact that most buildings are of only one storey and the high chimneys which one sees in other towns and cities are conspicuous by their absence. The reason, of course, is not hard to find. So many of the tall chimneys came down and did so much damage in the earthquake, that all re-building plans provided for small chimneys, which are less liable to topple over and which, if they did fall, would not do so much damage.

The one-storey building was an immediate reaction to the earthquake. With the passage of time, however, the earthquake becomes more and more a memory a memory of something which, in spite of the loss of life and limb it brought with it, had its compensations. In the re-building the past was linked with the future, for provision was made to withstand shocks of great magnitude, and today, Hastings can rank with Napier as the safest city in New Zealand.

34 HAWKES BAY CONSTRUCTS 35

Growth of an industry

IN 27 YEARS THE NAME OF WATTIES HAS BECOME SYNONYMOUS WITH THE BEST IN FOOD

THE STORY of the foundation and growth of J. Wattie Canneries Limited is a romance of the industrial development of New Zealand. With the country just emerging from a world-wide depression in 1934, the firm of Watties was first established in a small wooden building, where it stands today on its original site. The initial capital of £1,250 was subscribed by 28 members. In the first season there were 25 on the pay roll.

The dramatic development in the short space of 27 years from the small beginnings is evident when viewing the present flourishing industry with its two large factories. The Hastings factory, warehouses and head office has more than nine acres under roof, while the Gisborne factory has six acres under roof.

Both factories combined have an output of 68 million units or approximately 26,000 tons. During the processing season, Watties employ over 1,200 men and women and in addition a further 650 supply fruit and vegetables under contract to the factory.

The first operation of the company was the pulping of fruit for jam makers, but it was not long before a programme was commenced of widening the scope and range of products handled and utilizing to the full the great variety of fruit and vegetables grown in the fertile Heretaunga Plains. This policy has been pursued through the years until the present impressive array of not less than 88 varieties of canned, bottled and frozen foods on the market.

Technical superiority

The spectacular success of Watties can be traced in part to emphasis on up-to-date efficient methods and mechanization both in field and factory, which has been maintained a very high level. All the new overseas developments in food processing are studied and where practicable, adapted to New Zealand conditions and installed. In the field Watties employs the largest fleet mechanical harvesters in this hemisphere. These mechanical robots attend to most of the harvesting thereby eliminating to a very great degree the slow and inefficient hand picking methods of yesteryear.

Mobile pea harvesters move into fields of peas picking up vines shelling the peas as they go, and delivering the podded peas in bins at a rate of 7-8 tons in a working day for each harvester. Giant mobile bean harvesters are each capable of doing the work of 200 hand pickers.

Mobile sweet corn harvesters speed up operations and reduce the huge labour force previously required for manual work to a bare minimum. Another important factor is that employing mechanical means, harvesting continues right through the night at the height of the season. This was impossible with manual harvesting.

In the factory plant, the same high degree of mechanization is evident with machines doing much of the work done manually a few years ago.

All cans used at Watties are manufactured at the Hastings factory by their own plant, and this venture could well be considered as an industry within an industry. Recently a new plant was installed to manufacture beer cannisters for a large brewery company. Beer cannister making is a highly technical and very exacting procedure, and very few such machines are in existence.

Besides canning, bottling, and freezing foods, Watties are major growers of fruit and vegetables for their factories. At present, 350 acres are planted with asparagus, Wattie’s orchards, the largest in the Dominion, cover approximately 235 acres and contain upwards of 18,000 trees of all kinds, mainly peaches and pears.

Baby foods and junior foods offer a varied choice of varieties and Wattie’s Felix and Fido pet foods are also well known throughout the Dominion.

Scientific research

Fully qualified staff of agricultural field officers and food technologists have a programme of scientific research into soil and crop improvement, spray materials, new varieties of fruit and vegetables, and better seeds. While in the laboratory, new recipes and new products are constantly being tested.

The success of Watties can be put down to the policy of producing and maintaining a wholesome, home cooked flavour, and appearance. All the resources of the company are growing from year to year and a vigilant 24-hour watch is maintained on all aspects of quality control and hygiene by the large laboratory staff.

The great part of Wattie’s output goes to satisfy home demands. Nevertheless overseas markets are growing from year to year and a tremendous potential exists for expansion in this direction.

New ventures

The latest experimental venture undertaken by Watties, is investigation into tuna fishing with a view to opening up a new New Zealand enterprise. Early results are very promising and the company’s vessel, “Olwyn”, operating from Gisborne under an American with many years of experience in the tuna industry, is fully occupied testing fishing grounds on the East Coast of New Zealand. Early indications are that there is every reason for optimism and that before long, tuna will be canned in this country by Watties.

Photo caption – The giant food processing plant and headquarters of Watties Canneries Ltd. which has done so much for the wealth of Hastings and the surrounding district.

– Whites Aviation picture.

Page 36

[Advertisement]

It’s SOUND BUSINESS to

consult the SPECIALISTS

when PLANNING for the FUTURE

For years AGNEW REFRIGERATION LTD. has enjoyed the privilege of supplying the requirements of Architects, Builders and Contractors. Through the completeness of our staff from Design to Service and because we are in the privileged position of being suppliers of Nationally recognized equipment, you can have every confidence in dealing with AGNEWS.

AIR CONDITIONING Air Conditioning, a relatively new venture in New Zealand, is rapidly gaining popularity. Most major buildings are designed today with either the inclusion of Air Conditioning or the necessary requirements so that it can be installed later. Air Conditioning for the home is now possible and easily installed by means of packaged type conditioners.

AGNEW REFRIGERATION LTD. have installed some important Air Conditioning installations and will be pleased to discuss features of design and installation with you.

ROOM CONDITIONERS

COMMERCIAL INSTALLATIONS

OFFICE INSTALLATIONS

COMMERCIAL REFRIGERATION

for 24 years AGNEW REFRIGERATION LTD. have enjoyed the confidence of business firms in the supplies of Commercial Refrigeration. Our Company was founded to promote the sale of Commercial Refrigeration and has prospered over the years because of our ability to advise, design, install and service from the simplest to the most complicated installations.

Why not consult our engineers who will be only to happy to advise you on all matters of design construction and supply of Commercial Refrigeration.

COOL STORES

FREEZING CHAMBERS

SHOP REFRIGERATION

ELECTRICAL APPLIANCES FOR HOME

Builders, are you recognised for the completeness of the Homes you build? Are they fitted out with Recognised Home Appliances?

Builders who equipped the Homes they are building with Appliances from Agnew Refrigeration Ltd. have a distinct advantage, because you have the privilege of choosing your requirements from a wide range of popular and competitively priced Appliances.

In purchasing your customers Appliances through Agnews, your responsibilities are few as we deliver and service. Most important as a Recognised Builder, Plumber or Electrician you are entitled to a Contractors’ Discount.

KELVINATOR Refrigerators

BENDIX Home Laundries

WHITEWAY Washing Machines

WHITEWAY Clothes Driers

WHITEWAY Dish Washers

SHACKLOCK Electric Stoves

WATER CONTROL BY PUMPING

Water plays a big part in the Economy and productivity of our land. In no small way AGNEW REFRIGERATION LTD. has contributed to this prosperity by specialising in WATER CONTROL.

Every installation is carefully designed and correctly installed to give the maximum efficiency and your Clients can be assured of First Class after sale service.

HOME PUMPING SYSTEMS

FARM RETICULATION

CONTRACTOR PUMPS

INDUSTRIAL PUMPS

IRRIGATION

SWIMMING BATH FILTRATION

SPECIAL PRICES TO THE TRADE

AGNEW’S

SPECIALISTS IN DESIGN & INSTALLATION OF REFRIGERATION & PUMPING.

NAPIER – HASTINGS – PALMERSTON NORTH – LEVIN

HAWKES BAY CONSTRUCTS 37

New Zealand Leader ….

Hastings firm pioneers of aerial mapping in this country

IN THE industrial progress of Hawkes Bay and, in fact, New Zealand, Hastings can claim a unique distinction. It is the head-quarters of the N.Z. Aerial Mapping Co, an organization which has played an important part in “plotting” not only Hawkes Bay but also most of New Zealand. For this reason, the industry is playing an important part in the economy of the country as a whole.

Pioneered by Mr Piet van Asch, the industry of exploring possibilities from the air became a commercial undertaking in 1936 when Mr van Asch started operations with a monospan aircraft which had a ceiling of 12,000 ft. So quickly did the business grow, however, that it was not long before Mr van Asch had to import a Beechcraft machine with a ceiling of 20,000 ft.

The two-storeyed building at the corner of Warren Street and Avenue Road, Hastings, is further evidence of the growth of this unique industry, for which there is an ever increasing need.

Photographs taken from the firm’s aircraft are used extensively by the Lands and Survey Department, the Soil Survey Department and the State Forest Department, among others. By means of the pictures it is possible to detail topography, ascertain ravages of erosion and pin-point weak spots in river control and bridge construction.

The company’s photographs can best be described as “photographic maps” plotted to the national grid and carrying all the information required. With the advent of topdressing by air, the work of aerial mapping became even more important. In fact, the application of aerial photography is so comprehensive that it is almost impossible to cover all avenues of its usefulness.

[Advertisement]

STEEL BUILDERS & E. L. WHITE LTD.

Cnr. HERETAUNGA & BERESFORD STS.,

HASTINGS

MANUFACTURERS OF THE FAMOUS

“MASTER” STEEL FRAMED BUILDINGS

SHEARMASTER WOOLSHEDS

BALEMASTER HAYBARNS

SPACEMASTER IMPLEMENT SHEDS

Distributors of these popular, low-priced buildings are:-

WILLIAMS & KETTLE LTD.

H.B. FARMERS CO-OP. ASSN.

N.Z. FARMERS CO-OP. DIST. CO. LTD.

AGENTS FOR “EDBRO” TRUCK TIPPING EQUIPMENT … Full range of spares always in stock.

STEEL FRAMED TRUCK BODIES

Built-To-Order.

WELDING and GENERAL ENGINEERING Undertaken.

[Advertisement]

A proud record and a prominent place [in the] food processing industry

J. WATTIE CANNERIES

LIMITED

Aerial view of Hastings Factory and Head Office.

Size of Factory Buildings can be gauged by comparison with the two Football Fields in background.

The Hastings Factory has in excess of 9 acres under Roof and the Gisborne Factory 6 acres.

During the processing season, Watties two Factories employ upwards to 1,200 Men and Women. In addition to this, a further 450 growers supply Fruit and Vegetables by contract to the Factory.

Attractive and flavoursome dishes from Wattie’s 88 varieties.

Aerial view of Gisborne Factory.

[J] WATTIE CANNERIES

LIMITED

In the short space of a quarter of a century, Watties has emerged as the Premier Food Processing Establishment in New Zealand. Indeed, with no less than 88 varieties of canned and quick frozen foods on the market and an output of some 25,000 tons of canned and frozen foods, it is the largest establishment of its kind in the Southern Hemisphere.

By trying the latest overseas developments and adapting them to New Zealand conditions, Watties has a record of vision and enterprise which gives cause for pride.

First to use Mobile Pea, Bean, Beet, Carrot and Corn Harvesters, and by reducing to a minimum manpower and transportation charges.

First to employ Automatic Peach Stoners. First to can the delectable Asparagus Tips. Now greatly sought home and overseas.

First to utilize Mobile Bean Pickers which harvest 8-10 acres of Beans and do the work of 200 Pickers.

And now boldly exploring the possibilities of a Tuna Fishing and Canning in New Zealand.

Pea Harvester in action delivering shelled peas into bins on the move, at a rate of 8 tons a day per machine.

A moving stream of luscious Golden Queen peaches on their way into cans. Over 2,000 tons a season.

Watties

88

VARIETIES

WATTIE CANNERIES LTD.,

HASTINGS, GISBORNE, AUCKLAND, HAMILTON,

WELLINGTON, CHRISTCHURCH.

Page 40

[Advertisement]

THE LUXURY PLIX CORNER BATH

WB/8 BB/8

This can actually SAVE you £50 and more in planning costs. Providing spacious shower, 50 in. x 50 in. with built-in seating, the whole unit conveniently fits a bathroom 5 ft. 6 in. x 7 ft. 6 in. This can, however, be reduced to about 4 ft. 2 in. x 7 ft. 6 in. for even greater economy. Enquire carefully into the possibilities of this handsome, FULL SIZE Corner Bath before finalizing your plans.

OTHER LINES OF PLIX PERSPEX INCLUDE: –

BB/4 Standard Perspex Baths 5 ft. 6in. long

Perspex Washtubs

Baby Baths

Caravan components, etc.

A wide variety of Washhand basins, both vanity type and pedestal type designed for various fittings.

Soap Recesses

Shower bases

PLIX PERSPEX SIGNS

BRING YOU THE LATEST IN DAY OR NIGHT ADVERTISING

PLIX PRODUCTS LTD.

Auckland Provincial Representatives: –

MESSRS CAMPBELL LAURIE & CO LTD.

P.O. BOX 2247 – AUCKLAND C.1.

HASTINGS

P.O. BOX 247 – TEL 83-185

South Island Representatives: –

MESSRS SPECIALTY SALES LTD.

P.O. BOX – 471 DUNEDIN

HAWKES BAY CONSTRUCTS 41

[Advertisement]

Vidal’s

keep going on growing!

The climate in Hawke’s Bay favours growth and Vidal’s are growing all the time. As the popularity

of their white wines, table wines and Ports increases so does the service Vidal’s offer. This new Bottle Store in Hastings for instance is the most up-to-the-minute in Hawke’s Bay – you simply Drive-in for today’s top selection of wines and spirits. It’s smart, it’s modern, it’s typical of Vidal’s and typical of Hawke’s Bay.

Vidal’s

BOTTLE STORE

AVENUE ROAD EAST,

PHONE 84-720 HASTINGS

Page 42

[Advertisements]

JEPSON ENGINEERING CO.

MECHANICAL and DIESEL ENGINEERS

503 West Queen Street, Hastings Telephone 89-220 day or urgent night

OUR PRECISION workshop enables us to specialize in

DIESEL MAINTENANCE

G.M. DIESEL SALES and SERVICE for Gisborne and Hawkes Bay

Announcing the NEW ALL-PURPOSE POWER RANGE

20 to 1,650 h.p.

The popular engine for Industrial Application and Marine Use.

MAIN DISTRIBUTORS

FOR NORTH ISLAND…

CLYDE ENGINEERING LTD.

419-427 HUTT ROAD

Telephone 66-129

LOWER HUTT

PHONE 81-358

OMAHU ROAD,

R.D.5,

HASTINGS

H. B. DRIVEWAYS

ASPHALTING

METALLING

GENERAL CONTRACTORS

HAWKES BAY CONSTRUCTS 43

MAJOR INDUSTRIAL FIRM IS EXPANDING AT A RAPID PACE

Morrison Industries Ltd. moves to 180,000 sq. ft. building after small start in a shed in 1939.

AN OVERSEAS visitor, once gave his opinion of New Zealand as a land where the unearthly hush over business areas at the weekends is replaced by an almost continuous roar in suburbs from thousands of motor mowers. New Zealanders are finding these efficient little machines have climbed out of the luxury class. Now they have taken their place with radios, refrigerators and washing machines as standard domestic equipment.

Hastings is the home of the Morrison motor mower, the biggest manufacturer and assembly plant of its kind in the Dominion. It’s one the city’s major industries, although a young one for it was formed shortly before the outbreak the last war.

It has moved from shed to engineering shop to major factory until it last a dream for many of the staff has come true; a complete new factory is being built on the most up-to-date lines.

This fine new building is partly finished already and the total final size will be an area for production of 560 ft. by 320 ft. The first half of construction will cover 90,000 sq. ft. and the final area one of 180,000 sq. ft., the total area to be developed is 62 acres. In this new building, many new processes and plants will be used for the first time throughout New Zealand. In the paint shop, an automatic wash and dry-off spray paint booth, and an automatic oven, will be in operation. Air flow through the spray booth is 62,000 cu. ft. per minute and it is possible to do spray painting in evening dress without getting any paint on the clothing. The plant will be the most modern which is obtainable in the world today.

The hardening of the reels which form the work horse of each motor mower will be done by induction heating and it is understood this is the first type of its kind in New Zealand.

Electronically controlled lathes and other equipment are being installed together with the latest designs of press brakes and mechanical presses up to 300 tons. The weight of the latter press is 43 tons and the shipment of one case weighing 31 tons will be the heaviest lift ever undertaken in Hawkes Bay.

Staff amenities have been catered for on an up-to-date scale and will include a canteen with modern kitchen, swimming pool, and tennis courts. The whole front of the factory will be landscaped with lawns and gardens and it is hoped will become one of the beauty spots of the area.

The Morrison motor mower in its original form was the brain child of a Hastings engineer, Mr Sid Morrison, who before the war had an agency for an imported model. Import restrictions cut off his supply, so the engineer who previously made himself a motorized mower used parts of an old Model A Ford, experimented with his own designs for a powered mower.

First model

His model had many virtues. It was light but sturdy, easily handled, simple in operation and not excessively expensive and these principles have been carried on to the present day. And so Morrison Mowers Limited was formed and a new company went into production. Soon the company turned to power driven cultivators and when the war came these replaced mowers on the production chain as the Dominion’s market gardening system was expanded to meet the demand for foodstuffs.

In the immediate post-war boom, production climbed by leaps and bounds; over the past nine years the company has almost tripled its factory space until the present new factory was developed. Morrison Mowers Limited with their new plant and up-to-date equipment are at present in the process of developing new lines for manufacture. Many of these new products are still at the drawing board stage and not available for publication.

Rigorous tests

Design and development is a vital part of any industry. It is a key to improvement in products and the extension of a manufacturing programme. At Morrison Industries

Page 44

Giant press installed

A mobile crane moves a huge 300-ton press into position in the 180,000 sq. ft. factory addition of Morrison Industries Ltd. The press is the largest of its type in Hawkes Bay. To the left of the picture workmen can be seen installing other plant.

[Advertisement]

KEN GRANT LTD.

PHONE

86-623

HASTINGS

508 N. KARAMU ROAD

PHONE

86-623

AUTO ELECTRICIANS

AND

INSTRUMENT REPAIRERS

HAWKES BAY SALES AND SERVICE FOR –

“SMITHS” INSTRUMENTS and K. L. G. SPARK PLUGS

Hastings Sales and Service for: –

AC-DELCO, DELCO-REMY AUTO ELECTRICAL PARTS

SOLARC and VOLTEX BATTERIES

CLAUDET IGNITION REPLACEMENT PARTS

POLLAK SWITCHES

Ken Grant Ltd. new building.

HAWKES BAY CONSTRUCTS 45

MORRISON INDUSTRIES, Contd.

Test mowing is a full time occupation

Limited men are engaged full time in the company’s development section trying improvements for future models and testing all new designs under rigorous conditions before recommending them for production. Draughtsmen and engineers work in unison to plan and to put into effect new ideas. Some are adopted many are rejected.

Mr Customer

One of the backroom boys is the equivalent of “Mr Customer” who, when he buys a motor mower, expects it to give him trouble-free mowing year in and year out, often under rigorous conditions. “Mr Customer’s” task is to take experimental models into grassed areas of Hastings and simply mow them and keep on mowing day after day. It’s a full time job, but one calculated to find the bugs which do not show up on the drawing board or in the machine shop.

Production at the factory does not follow the mass chain system associated with many heavy industries. But each man and women, the metal workers, braziers, welders, painters, have their tasks and a carefully allocated plan of assembly. Into the Hastings factory flows a regular supply of sheet steel in 2-ton bundles.

Fed into hydraulic presses which punch out components with deceptive ease or moulded over steel dies, the metal is punched and shaped into mower components for later assembly to meet production orders. Speed of working, however, takes second place to accuracy and efficiency. Engineers are constantly checking components as they come from the presses and lathes to ensure that critical sizes are being adhered to. The smallest deviation would shorten the life of or prevent the correct operation of an assembled mower.

With the exception of engines which are imported from Britain and United States, the mowers are completely built in Hastings. At the final assembly point before despatch to retailers, each motor is run and tuned. When the machine reaches the customer it’s ready to cut its swath through the fastest growing spring grass.

Morrison history

Like many companies of national repute, this company started off with an idea to produce a sturdy precision product manufactured to give long and satisfactory service. The company was originally started by Mr S. Morrison in 1939 and the first model produced, which is still known as the 16 in. Morrison reel motor mower, was designed and manufactured under his guidance. This model had a high wooden handle whereas the present models are all steel construction. With the advent of the war in 1939, the production of motor mowers was interrupted and the factory engaged on all out war effort.

Prior to 1951, the only model manufactured was a 16 in. reel motor mower but since that date new models have been designed and improved. The company is fully aware that to give the public of New Zealand the finest motor mower of its kind, an ever watchful eye must be kept on current trends and to improve this design, simplify where practical the operation and pound for pound give the best value possible.

In 1951 the 20 in. reel mower was produced for those with larger areas of lawn to cut. In 1952 the 22 in. motor scythe was produced. In 1953 the Morrison cultivator, 1956 the rotary mower with catcher and side delivery, 1957 the 14 in. motor mower, a lighter machine for a smaller lawn. Morrisons were this year proud to announce the sale of their 50,000th 16 in. reel motor mower alone. Proof in itself that the foundation principles of manufacture have been followed precisely.

The whole process of designing, the making of machine tools, and every phase of manufacture is carried out in Hastings. Only parts not manufactured, being the power units which are imported from England, Canada, and the United States.

46 HAWKES BAY CONSTRUCTS

[Advertisement]

MORRISON INDUSTRIES LTD.

Private Bag HASTINGS

Manufacturers of the famous

Morrison range of

Reel Mowers

Rotary Mowers

and

Multihoes

Morrison’s new factory is being built on the most up-to-date lines. In this building many new processes and plant will be used for the first time in

An automatic wash and dry-off spray paint booth and an automatic oven, will be in operation. Air flow through the spray booth is 25,000 cu. ft. per minute and it is possible to do spray painting in evening dress without getting any paint on the clothing. The plant will be the most modern which is obtainable in the world today.

The hardening of the reels which form the work horse of each motor mower will be done by induction heating. It is the first type of its kind in New Zealand.

Photograph above shows the progress being made on Morrison’s new factory premises to cope with manufacture of existing products and their extension into the manufacturing and assembling of bicycles. This latter will be the first of its kind in New Zealand.

Recently completed for Morrison Industries Limited 60 ft. span portals covering 90,000 sq. ft. of floor area

Electronically controlled lathes and other equipment are being installed together with the latest designs of press brakes and mechanical presses up to 300 tons capacity.

The continued public demand for Morrison’ mowers has made this new factory and the extensions of facilities to take care of bicycle manufacture possible.

Morrison’s are indeed grateful to the New Zealand public for their appreciation of their High Quality Products and would assure everyone that future products will continue to be manufactured at the same high standard.

Page 48

[Advertisement]

Clayton

(DYNA-MOMETER)

VEHICLE

ANALYZER

Measures Engine Horse Power.

If it’s O. K. on the CLAYTON

it’s O. K. on the road !

COPY BOOK TUNING WITH THE CLAYTON DYNAMOMETER

This machine which copies the manufacturers’ specifications for engine tuning and performance has been installed in our Automotive Service Depot., in Hastings. The machine costing £2,500, is the Clayton Dynamometer, and is one of the only two of its type now installed in the country. Our Service Manager reports that: –

“It has taken the guesswork out of diagnosis and has the added advantage that road testing is now kept to a minimum. By carefully observing test instruments we get definite proof whether or not the vehicle corresponds to the standard values. The machine can simulate most kinds of road conditions at all speeds and in all gearings. It cuts out the sometimes long hours of road testing and other testing by a skilled man seeking faults “by ear” and experience.”

A car under inspection is driven on rollers with the engine and clutch engaged. Linking instruments show the action of individual components of the engine, output being transferred to a power-absorption unit via the driving gears and rollers.

As well as testing power and performance, speedometer accuracy can be checked at all speeds. It is quite true to say that –

“If it’s alright on the Clayton, it’s alright on the road”.

Used in conjunction with the Clayton Dynamometer is an Electronic Engine Tester, which supplies, on a cathode ray tube a trace for each cylinder indicating the actual performance of the spark plugs, condenser, contacts and dwell angle. Fault finding is thus reduced to a matter of minutes. A substantial saving in time and expense is thus accomplished.

This company, which was established in 1927 have always specialized in the field of Automotive Electricity and has kept their plant and their methods always in line with modern practice as adopted both in this and other countries.

JOHN HILL LTD.

P.O. Box 139, Hastings.

Telephone 89-093 (Two Lines)

HAWKES BAY CONSTRUCTS 49

MEAT FREEZING INDUSTRY

Two Hastings meat works kill 28,000 sheep and lambs daily; and annually export more than 100,000,000 lb. of the finest lamb and mutton overseas

Tomoana:

The Tomoana Freezing Works ranks with the largest in New Zealand and the name and the company’s products are famous throughout New Zealand. These works have a killing capacity of 16,000 sheep and lambs and 50 cattle per day – a big advance on the capacity in 1883 when the company first operated and handled 400 sheep and 10 cattle daily.

Page 50

Furniture

&

Woodware

Ltd.

HASTINGS

FURNWARE

THIS COMPANY, incorporated in 1935, is essentially a Hastings concern, built with local capital, and local effort and initiative. From a small beginnings trading in radios, with a capital of £675, it has grown to be the largest factory of its type in New Zealand with a capital of £160,000.

Its manufacturing activities received a boost in early years from Government war contracts, for such items as ammunition boxes, instrument stands, pegs, water bottle stoppers, as well as furniture for military organizations, all in quantity production.

Its transition from war to peace was not particularly happy and some lean years were experienced. However, in the late 1940’s it settled down and with a change in policy towards bulk manufacture of standard designs, notably in school furniture and kitchen fittings for State Houses, from which time it has made steady headway. Rather than be dependent almost exclusively upon the retail furniture trade, Furnware changed its policy in favour of diversification of markets in order to ensure continuity of demand and sustain volume output.

Concentration on mass-produced, standardized products using selected materials, skilled operative and efficient plant, yielded increasing returns, thus confirming the wisdom of the Company’s manufacturing and trading policy. From an output in 1950 of £90, to an output in 1960 of £278,000 is a very commendable expansion.

Earlier products were made entirely of wood, till about 1954, influenced by the Education authorities

HAWKES BAY CONSTRUCTS 51

changeover to tubular steel desks and chairs, the Company commenced manufacturing in this newer material. Many of the manufacturing principles involved were to be common to both materials and the conversion was made very smoothly. Today probably more than half the output involves tubular furniture of one kind or another.

School furniture, for which the Company has consistently secured large contracts all over New Zealand, is a specialty which has kept the Furnware trademark to the forefront in this department.

Increasing popularity of steel for use in seating for halls, clubs, restaurants, etc., has created such a demand that the Company has installed the latest plant to take care of its increased output. As a consequence, the Furnware brand takes a very prominent place as suppliers of such furniture in the Dominion.

The logical development from tubular furniture finished in stoved enamel, is chrome plating and this Company’s latest venture. By early 1962 it will be operating one of the largest and most efficient electro-plating plants in this country.

Main products include household furniture, school furniture, kitchen fittings, office desks, church pews, shop fittings and automatic turnery. These are supplied through various channels to consumers throughout both North and South Islands.

With a staff of 110 and approximately 60,000 sq. ft., Furnware is on its way to bigger things, as a local enterprise of which the Hastings community be proud.

CONTACT US FOR QUOTATIONS ON YOUR

REQUIREMENTS OF

SCHOOL FURNITURE

KITCHEN FITTINGS

SHOP FITTINGS

CHURCH PEWS

HALL FURNITURE

CAFETERIA FURNITURE

OFFICE FURNITURE

Page 52

[Advertisement]

For all

PLUMBING

and

DRAINAGE

REQUIREMENTS

Apply to –

J J. O’CONNOR LTD.

Alexandra Cres., Hastings

Phone – 86-746

Our Agent includes…

BROWNBUILT ROOFING

FILTERMASTER FILTRATION PLANTS

RENOWN PUMPS

PERNACRETE [PERMACRETE] CONCRETE TANKS

We also undertake all types of HEATING and BOILER installations

HAWKES BAY CONSTRUCTS 53

[Advertisement]

SYNONYMOUS with PROGRESS

throughout the ‘Bay

HBF

Unity is Strength – The Hawkes Bay Farmers’ Co-op. Assn. Ltd. is a member co-operative of the Farmers’ Co-operative Wholesale Federation (N.Z.) Ltd. Combined these co-operatives are the largest Stock and Station Agents in New Zealand.

Throughout Hawkes Bay the H.B.F. is recognised as a leader in the field in the providing all that’s best for Town and Country.

Approximately 29.4% of the total yards throughput in stock is sold by the H.B.F.

Approximately 25% of the total Greasy Wool and approximately 22.7 of the total Scoured Wool sold at auction in H.B. is sold by the H.B.F.