- Home

- Collections

- HARRIS JA

- 60 Miles of Peach Trees

60 Miles of Peach Trees

Compiled in honour of J N Williams whose energy and foresight played a vital part in the growth of the food processing and orcharding industries in Hawke’s Bay, the Fruitbowl of New Zealand

Cover Picture

Contemporary postcard of the 60 mile Frimley orchard

ALL RIGHTS RESERVED

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any other form or by any means, electronic, mechanical, photocopying, recording, or otherwise without prior permission of the author.

D G Harris

13 Bishop’s Close,

NAPIER

ISBN: 978-0-473-22992-4

Printed by Fisher Print

[www].fisherprint.co.nz

Des Harris

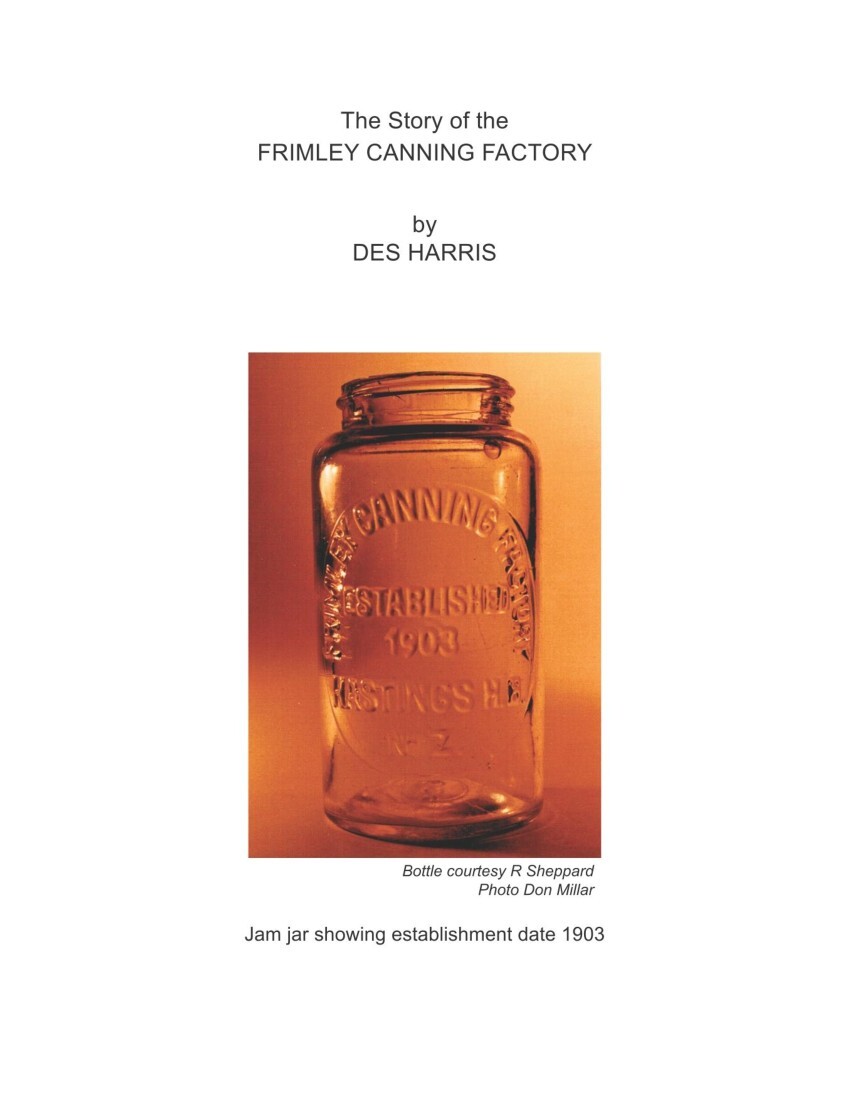

The jar pictured on the frontispiece contains the story of how this book came to be written.

Des Harris, an enthusiastic bottle collector, was attending a meeting of the local collectors’ group when a young man produced this jar and asked if others present had seen anything like it. There was a silence. No one knew the answer and Des determined to uncover the story. His journey of discovery resulted in this book, which features a few of the bottles which have formed part of his extensive collection.

Des was for many years a school teacher in Hawke’s Bay. It was while he was principal of Camberley School in Hastings that he compiled this book. It is significant that this school in fact stands on a site which once formed part of the 60 mile Frimley orchard.

Thanks are due to those who have now made publication possible, including descendants of J N Williams of Frimley.

Page 1

Part 1

JAMES NELSON WILLIAMS

of the Frimley Estate

James Nelson Williams was born at Waimate North in Northland near the Bay of Islands on 22 August 1837, a son of Revd William Williams, later Bishop of Waiapu. In 1840 the family moved to a new mission area near modern Gisborne, residing at Whakato, Kaupapa, and finally Waerenga-a-Hika in 1855.

While at Waerenga-a-Hika, J N was involved with the Mission farming venture. One of his tasks would have been the development of a new orchard with a variety of fruit trees which the family brought with them to the new mission.

In 1857 he came to Hawke’s Bay and worked for a time with Samuel Williams on the Te Aute farm. He eventually moved from this employment to take up the lease of Kereru Station where he farmed for a number of years before disposing of it in 1875.

In 1864 he took up the lease of two 1231 acre sections of the Heretaunga Block from the Maori chiefs Takamoana Karaitiana and Henare Tomoana. The lease became official in 1867 and finally freeholded in 1870. He acquired further land later, bringing the Frimley Station up to 3045 acres. This huge expanse of land covered much of what are today the Hastings suburbs of Camberley, Mahora and Frimley. The estate reached from the Ngaruroro River in the North to the Kaiapo Stream at Longlands in the South. In the West it ran along J D Ormond’s Karamu Station boundary, and along Thomas Tanner’s Riverslea Estate in the East.

When Williams settled the Frimley Block much of it was swampy, treeless, and very exposed to wind. It was not a very attractive proposition for anything but grazing. Over the years he drained the land, planted shelter belts and rye and clover pastures. In 1894 there were 200 acres in oats and barley, 90 acres in mangolds, plus another 40 acres in turnips. By 1872 he was running 9504 sheep on the property. This property was to become the Williams’ home and was named Frimley after his wife Mary’s family home at Frimley Hill, Surrey, England.

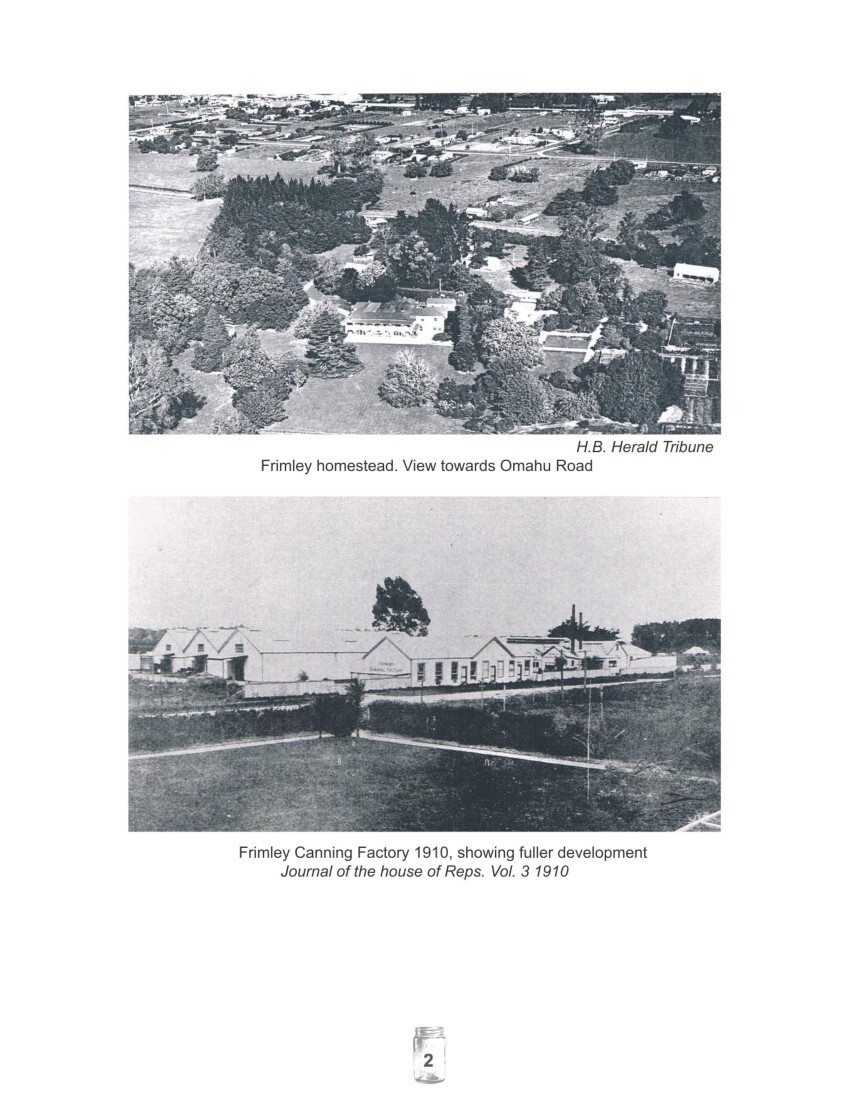

Williams built a large homestead of 22 rooms, erected by local builders from the finest heart native timbers. Two well known features of this homestead were the imported oak parquet floors and a magnificent staircase.

The homestead block grounds were planted with numerous specimen trees, many of which still stand today, forming the backbone of Frimley Park – a tribute to his foresight. After Williams died in 1914 the remainder of the property was split into small farm blocks and sold, while the 50 acre homestead site was retained by the family. In 1950 tragedy struck and this historic homestead was razed by fire. The land was later donated to the City of Hastings by the family in memory of J N Williams and his wife Mary. The area is now known as Frimley Park where the present sunken garden marks the site of the original homestead.

Page 3

FRIMLEY CANNING COMPANY HASTINGS

The history of the fruit growing and canning industries and their subsequent development in the Hastings area is inextricably bound up with the J N Williams family and their land, the Frimley Estate. J N Williams’ most important contribution to Hastings and the future of Hawke’s Bay was his recognition of the area’s potential as a major fruit growing district, and the steps which he took to lay the foundations of the present vast fruit growing and canning industries.

J N Williams could well be called ‘Father of the fruit growing and canning industries in Hawke’s Bay’. Were it possible for him to see how his original dreams and ideas had developed, he would be well pleased.

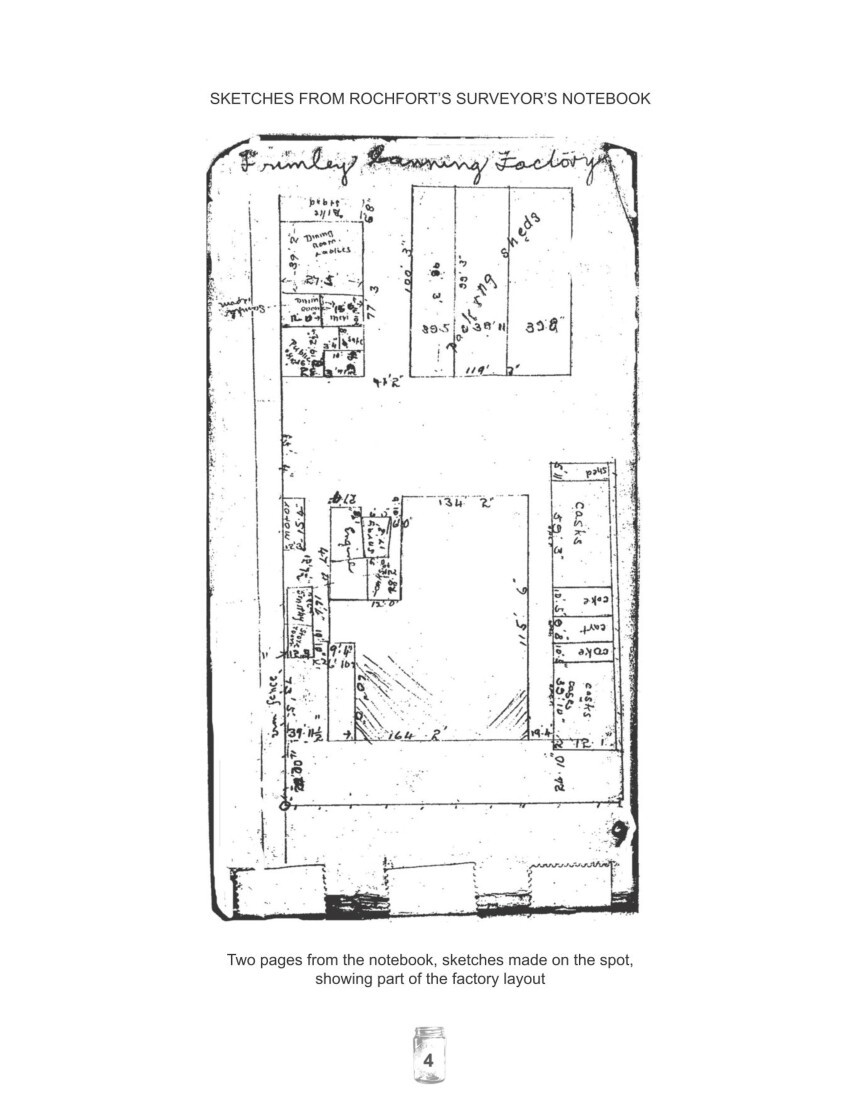

Hastings and the surrounding area of the Heretaunga Plains has become known throughout the country as the Fruit Bowl of New Zealand. Its rise to this status can be traced directly back to the 1890’s and J N Williams’ establishment of the first large commercial orchards and the allied Frimley Canning Factory which began production in 1903, though not officially opened until January 1904. Today Hawke’s Bay produces and processes more fruit and vegetables for the domestic and export markets than any other region of New Zealand.

The operations of this first cannery and its local significance have only been referred to briefly in various publications concerning the development of Hastings and the Heretaunga Plains, and no attempt has been made to deal purely with the story of Williams’ venture. Little has been recorded officially, apart from a few contemporary newspaper reports concerning the factory’s setting up and the development of the orchard complex. The people who were actually involved in the Cannery’s development and operations, and who could have cast much light on its daily life as well as the reasons for its eventual failure in 1913, are long dead and gone. Even the actual factory site has been a matter for debate.

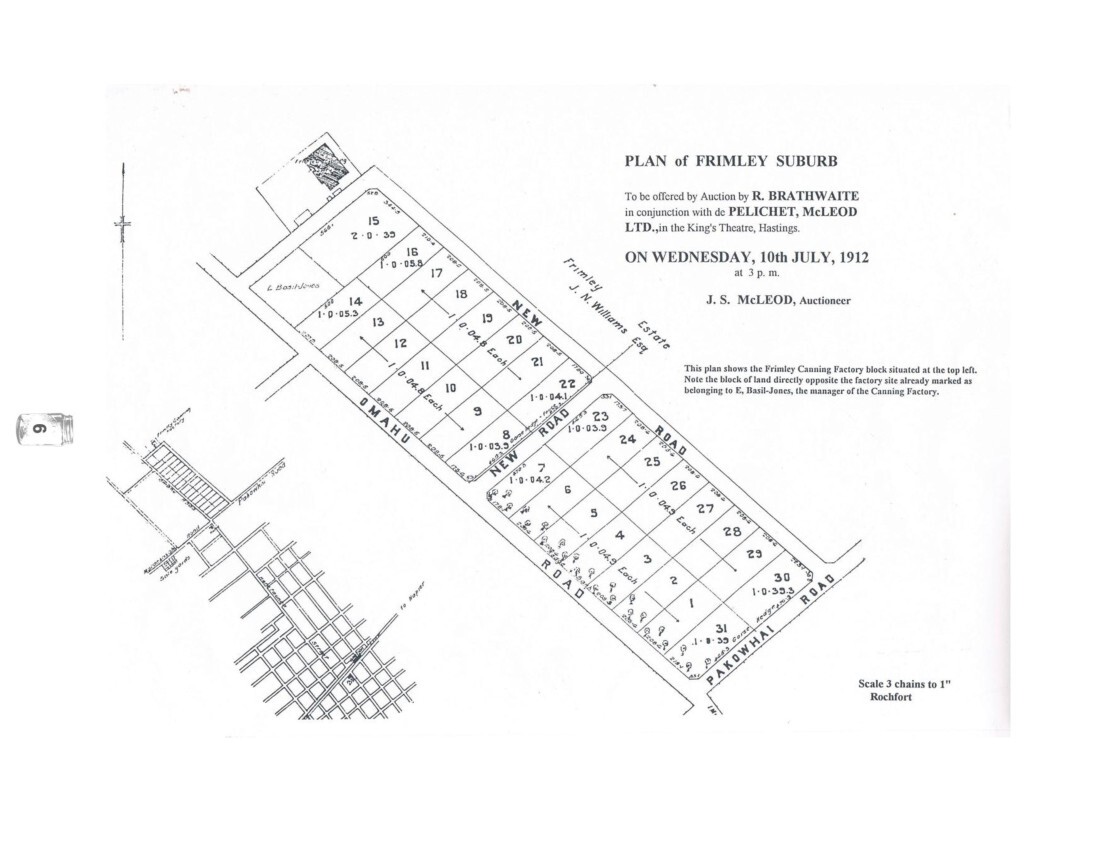

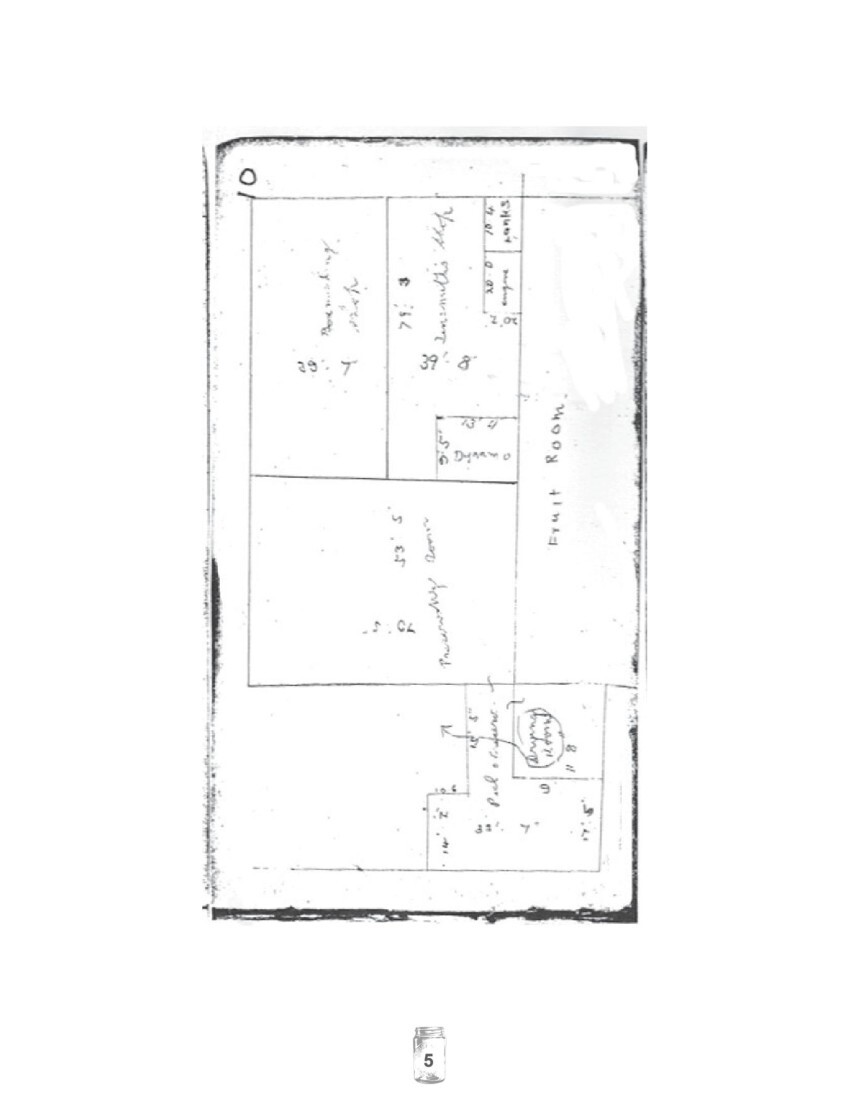

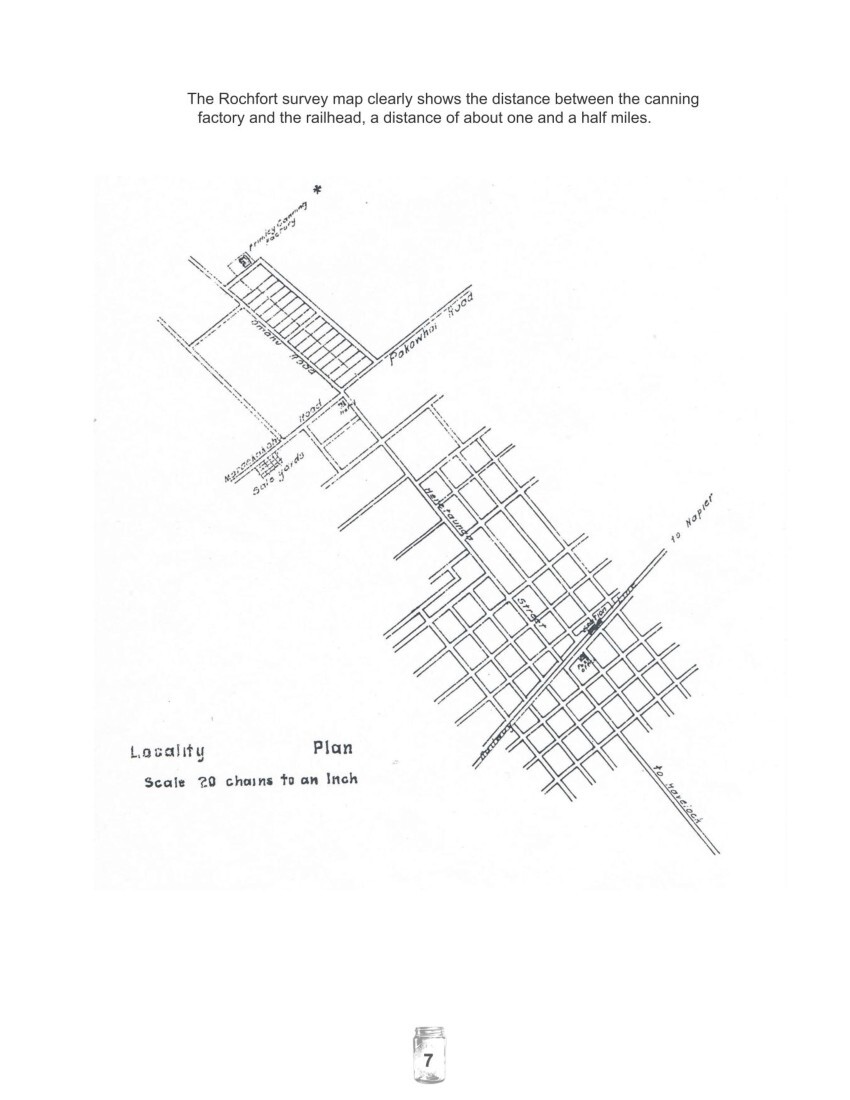

Mr Rochfort, a prominent surveyor in the Hastings District, was commissioned by Williams to carry out a survey of the factory grounds and buildings. He was also employed to carry out a great deal of survey work involved with the splitting up of the Frimley Estate into small farmlets and town sections, which were sold into private ownership over the years. By using Rochfort’s actual surveyor’s field notebooks alongside other relevant material provided by Lands and Survey staff it has been possible to identify the exact location of the factory beyond all doubt.

Page 6

PLAN OF FRIMLEY SUBURB

To be offered by Auction by R. BRATHWAITE in conjunction with de PELICHET, McLEOD LTD., in the King’s Theatre, Hastings.

ON WEDNESDAY, 10th JULY, 1912

at 3 p.m.

J.S. McLEOD, Auctioneer

This plan shows the Frimley Canning Factory block situated at the top left. Note the block of land directly opposite the factory site already marked as belonging to E. Basil-Jones, the manager of the Canning Factory.

Page 8

J N WILLIAMS ENTREPRENEUR

This keen minded farmer and industrialist was involved with many business ventures during his lifetime, and his name appears on practically every list of shareholders in schemes for the progress of Hawke’s Bay Province. He bought and sold or had interests in several well known early Hawke’s Bay stations, namely the Apley Block of Rissington Station which he subdivided and sold again as smaller holdings: Mangakuri Station, Kereru Station, and Edenham. Later in 1883 he took up leases on the East Coast which were amalgamated and called the Waipiro Lease, developing this huge landholding, and eventually passing it back to the Maori owners. This venture is a story in its own right.

Interest in the development of a deepwater harbour at Clifton, a steamship company, woollen mills, and gold mining were among some of his less successful ventures.

The Hawke’s Bay Investment Company, and his partnership with James Nelson in establishing Tomoana Freezing Works, were two of his more successful projects. He was also involved in timber milling ventures near Taumarunui and in the Dandenong Mountains of Australia.

His intense ongoing interest in the future of the Heretaunga Plains, and the provision of employment opportunities for people living in the region, led to the diversification of farming from purely pastoral to include agricultural. This change led to the establishment of yet another of his commercial ventures – the Frimley Canning Company. This factory was planned to process the fruit and vegetables produced on orchards and farms developed by him and later sold into private ownership, as well as from others established in the area.

In 1892 a group of Napier entrepreneurs attempted to set up a dried fruit business using a Spawn’s evaporator. The syndicate members were G H Swan, J Neal, Mr Close, Mr McVay, Henry Williams, H S Tiffen, and J N Williams. The venture evidently failed.

J N Williams assisted any person interested in fruit growing by allowing them to purchase part of his peach orchard, and in 1899 the Mahora section of Frimley was subdivided for orchards and small farms.

In 1890, while on an overseas trip, Williams travelled to North America and Europe where he visited peach, apple and pear orchards around Buffalo and in California, gathering all the relevant information that he could concerning the growing, canning and marketing of fruit and vegetables. He also visited vineyards in the Bordeaux region of France where he gathered information about viticulture and winemaking, seeking how these could be applied to the Heretaunga Plains which he considered to be very similar to the Bordeaux topography and climate.

During a train journey through California he met an Englishman with similar interests who invited Williams to join him on a visit to a town which was supported by the fruit growing industry. He was most impressed by this town of some 30,000 people which seemed to be entirely supported by fruit growing and processing. At this time New Zealand was importing considerable quantities of American tinned fruit and Williams could not see why fruit could not be canned at Hastings which would save overseas funds as well as provide vital employment for local people. The land form,

Page 9

soil and climatic conditions of the Pacific slope of California were, in his opinion, very similar to those of the Heretaunga Plains. This served to firm his resolve to go home and start a fruit growing and processing industry.

Enthusiastic, and armed with all the information he could obtain, he returned to Hastings and began the planting of a 10 acre experimental orchard block on the Frimley Estate. This orchard was managed by his head gardener, David MacNamara. However, the venture was not as successful as first hoped, mainly due to inadequate pruning – also spraying was made difficult because the varieties were scattered throughout the block and each needed different treatment. Despite the problems the orchard cleared 420 pounds profit in its first season. Much was learned from this experiment and these lessons were applied with good results when the main orchard was planted.

The first part of the orchard and vineyard referred to earlier was planted close to the homestead which stood on higher ground and faced eastwards in the lee of a plantation shelter. The varieties in this 10 acre block were mainly plums, greengages and peaches.

During the 1890’s the Liberal Government was espousing a ‘land for settlements’ policy and was keen to break up the large land holdings for closer settlement and a more equitable sharing of farming land. Williams decided to offer around 1800 acres of Frimley and to retain some 400 acres to develop his own orchard. Of the land offered he proposed to put 300 acres into fruit trees and vines and to keep them under his control for several years. All development and running expenses were to be met by him. When the trees were bearing and the orchard in peak order, he would then hand it over to the Government for subdivision into smaller lots which would be sold into private ownership. He also proposed to put some 2000 pounds into the establishment of a factory to preserve the fruits, make jam, and manufacture wine so that growers would have no problem in finding a market for their produce.

When elaborating on his plans for this subdivision Williams advocated that they should not be too small. Each block must be able to support a man and his family, and to this end he wanted to plant and develop the area so that every new owner would have a viable property right from the start. He was also sure that there was a ready market in Wellington and Taranaki for all the fruit that they could grow and that, although they would be in competition with imported fruit from Sydney and Hobart, the current duties on imported fruit would make local produce competitive.

To bring his plans to reality a prospectus was issued for the Frimley Fruit Growing Company Ltd with 15,000 pounds capital in one pound shares. Williams was to take up 5000 shares and supervise and manage the whole property for four years from 1 July 1898. Most of the property was south of the Frimley homestead. To avoid delays, and to have the trees planted during the optimum planting season of winter, he purchased trees locally as well as from Auckland and Australia. The main peach variety was Kalamazoo which was considered to be one of the most suitable for canning. A quantity of the Australian trees evidently arrived unnamed. When these trees bore fruit the canning supervisor, a Mary Grant, is reputed to have commented that they were the best peaches that had come in for canning. Evidently these unnamed peaches were dubbed ‘Mary’s Choice’ and are still a popular preserving variety today.

Thomas Horton of the Premier Nurseries in Pahiatua came to Hastings in the late 1890’s with a view to establishing an agency for his comprehensive stock of fruit

Page 10

and shelter trees. Williams encouraged him to establish a nursery in Hastings and many of the trees eventually planted in the orchards came from Horton’s Nurseries. The increasing acreage under fruit trees convinced Horton that there was a big future in Hastings for the development of a nursery to supply fruit growers with young trees. In 1905 he bought 20 acres of the Frimley Estate in the Pakowhai/Lyndhurst Road area and opened a nursery. The following year he purchased another 15 acres to cope with the increasing demand for nursery stock. In 1909 he converted his business into a limited liability company under the name of ‘Thos. Horton Ltd’, the first directors being Messrs J N Williams, W H Hartgill, T Horton and E J Watt. The office of the business was established at Hastings, but the Pahiatua nursery continued as well.

By September Williams had planted some 80 acres with 12,000 peach, prune and plum trees. During this planting period the Land Purchase Commissioner visited Frimley to acquaint himself first hand with the development of the area which would be offered for sale. In that September Williams accepted an offer from the Board to purchase 1134 acres, about 600 acres on the north side of Omahu Road, and 500 on the south side, beyond the cemetery. Excluded from this sale were the 200 acres of the Frimley Fruit Growing Company, and 400 acres which were subject to periodic flooding.

Once again representations were made to the Minister of Lands advising against subdivisions that would be too small to be economic. Local farmers suggested that the blocks be 4 to 10 acre road sections for workers and 15 to 20 acre back sections for horticulture and dairying. The Lands Department duly produced a subdivision plan and advertised it for selection, receiving 181 applications in the Napier Office for 24 of the 35 sections which varied in size from 10 to 71 acres. Half yearly rentals ranged from five pounds to 49 pounds, 12 shillings and 11 pence.

The proposed Frimley Fruit Growing Company float in 1898 evidently failed through lack of capital offered, so the embryo company was never floated. Williams had received 31,178 pounds for the sale of the 1134 acres which was over double the share capital proposed for the company. He returned the money that had been subscribed and decided to develop the orchard and cannery which he ran on his own account. In later years, when the orchard and cannery were extended, he took others into partnership, including his managers, local businessmen and farmers.

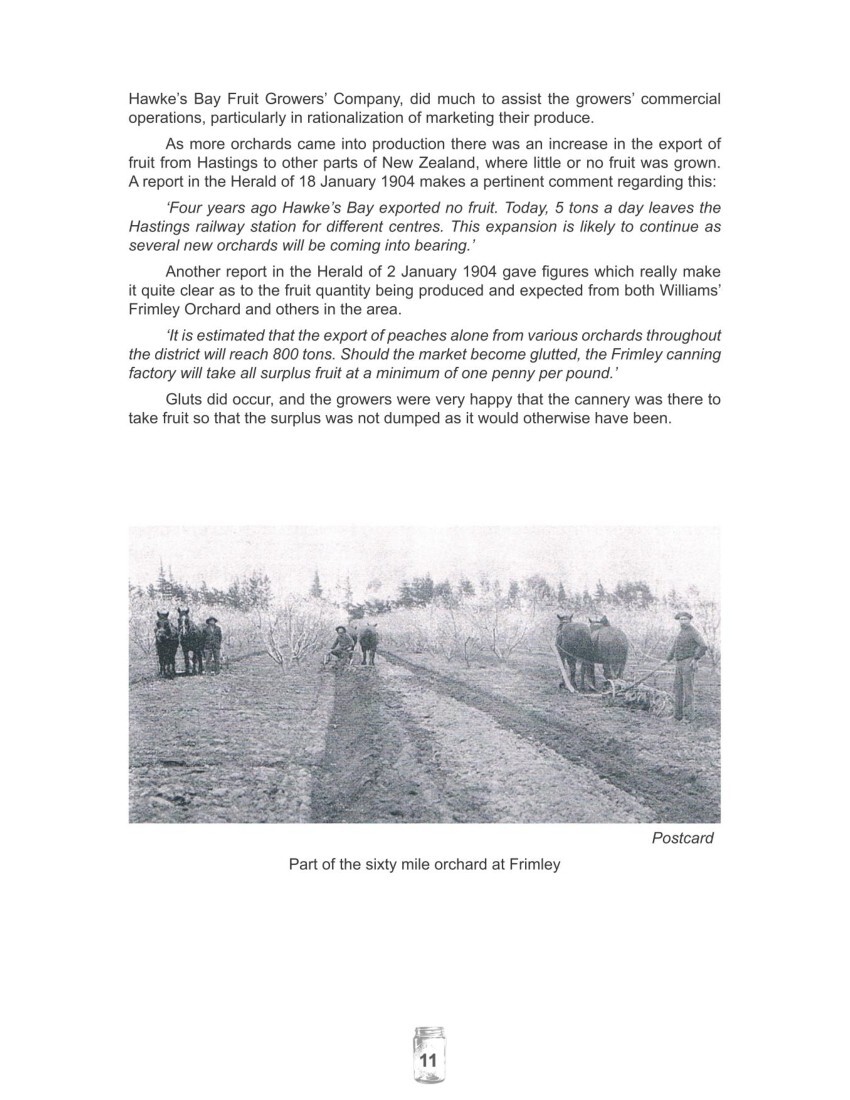

Williams increased the extent of his orchards so that the vast area was planted as 60 rows of trees, each a mile long. These 60 miles of peach trees in full bloom created a breathtaking feathery vista – a sight never seen in the district before. Over the years springtime brought many people from outside the area to Hastings to view this spectacle. Visiting dignitaries were also taken on a special tour to see the orchards.

In 1899 fruit growers in the district held meetings to discuss how they could co-operate with Williams in the establishment of a cannery and to decide what moves should be made to help make Hastings a flourishing fruit growing centre. A committee was formed and, from this body’s deliberations, the Hawke’s Bay Fruit Growers’ Association was born. The aims and objectives of this organization were to promote growers’ interests; facilitate discussion of common problems; arrange seminars with various Department of Agriculture experts; arrange for bulk supplies of sprays of consistent quality, fruit boxes and other orchard requisites at lower costs to the growers. Williams was the Chairman of the Association with W H Smith, the manager of Frimley Orchard, as secretary. This Association, and the formation in 1902 of the

Page 11

Hawke’s Bay Fruit Growers’ Company, did much to assist the growers’ commercial operations, particularly in rationalization of marketing their produce.

As more orchards came into production there was an increase in the export of fruit from Hastings to other parts of New Zealand, where little or no fruit was grown. A report in the Herald of 18 January 1904 makes a pertinent comment regarding this:

‘Four years ago Hawke’s Bay exported no fruit. Today, 5 tons a day leaves the Hastings railway station for different centres. This expansion is likely to continue as several new orchards will be coming into bearing.’

Another report in the Herald of 2 January 1904 gave figures which really make it quite clear as to the fruit quantity being produced and expected from both Williams’ Frimley Orchard and others in the area.

‘It is estimated that the export of peaches alone from various orchards throughout the district will reach 800 tons. Should the market become glutted, the Frimley canning factory will take all surplus fruit at a minimum of one penny per pound.’

Gluts did occur, and the growers were very happy that the cannery was there to take fruit so that the surplus was not dumped as it would otherwise have been.

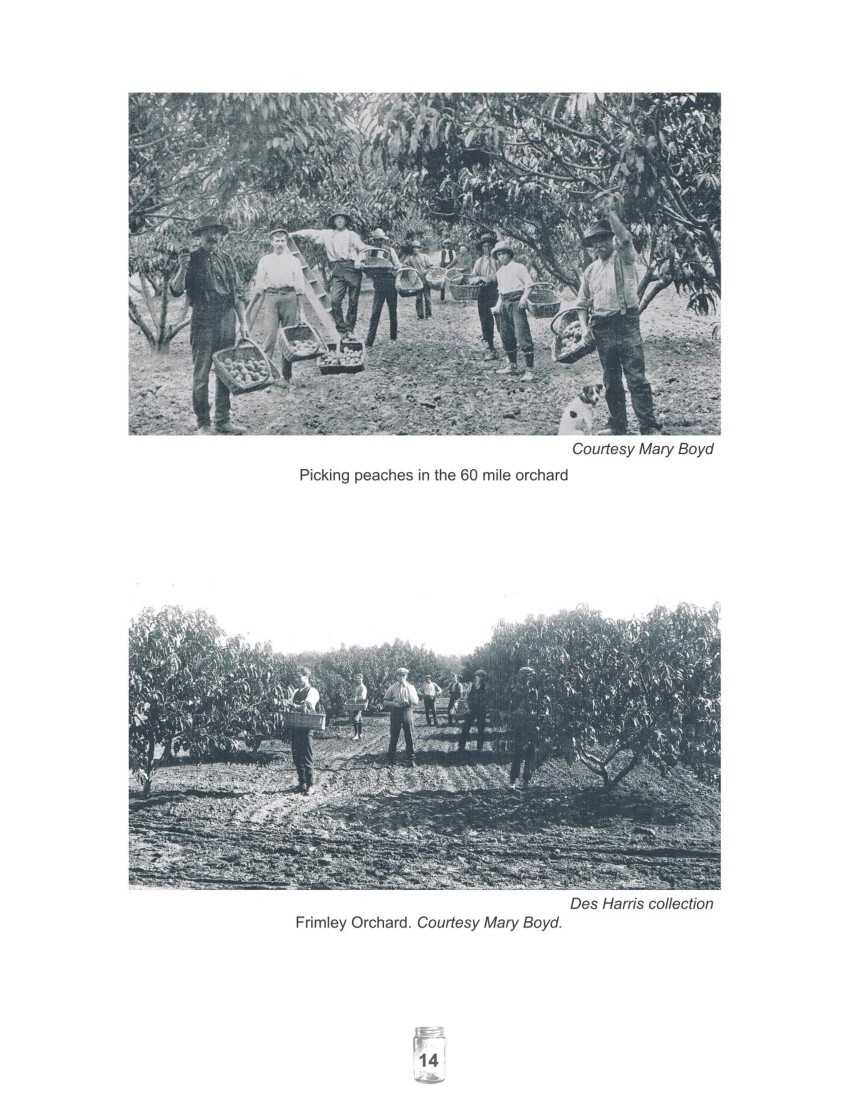

Part of the sixty mile orchard at Frimley

Postcard

Page 12

Part II

SIXTY MILES OF FRUIT TREES

The Frimley Orchards

On his return from America J N Williams began to put his orchard plans into operation. After the trial orchard, which had been planted near the homestead, had provided experience for Williams’ orchardist, Mr D MacNamara, work was put in train to plant what was to become the famous Frimley Orchard. Williams had made up his mind to grow the best fruits which would not only be suitable for dessert use but for canning purposes as well. The final result was 120 acres of peach trees planted in 60 rows – each a mile in length. There were also 12 acres of plums and 17 acres of grapes The vineyard eventually increased to 40 acres by the turn of the century and was producing 4000 gallons of Hock. All these were planted on the south side of Omahu Road. On the north side of Omahu Road there was another section of the orchard which contained an extensive area of WBC pears, 60 acres in peas, and more acres in tomatoes. Many of the trees were supplied by Hortons of Pahiatua, who eventually set up a huge nursery in Hastings on land purchased from the Frimley Estate.

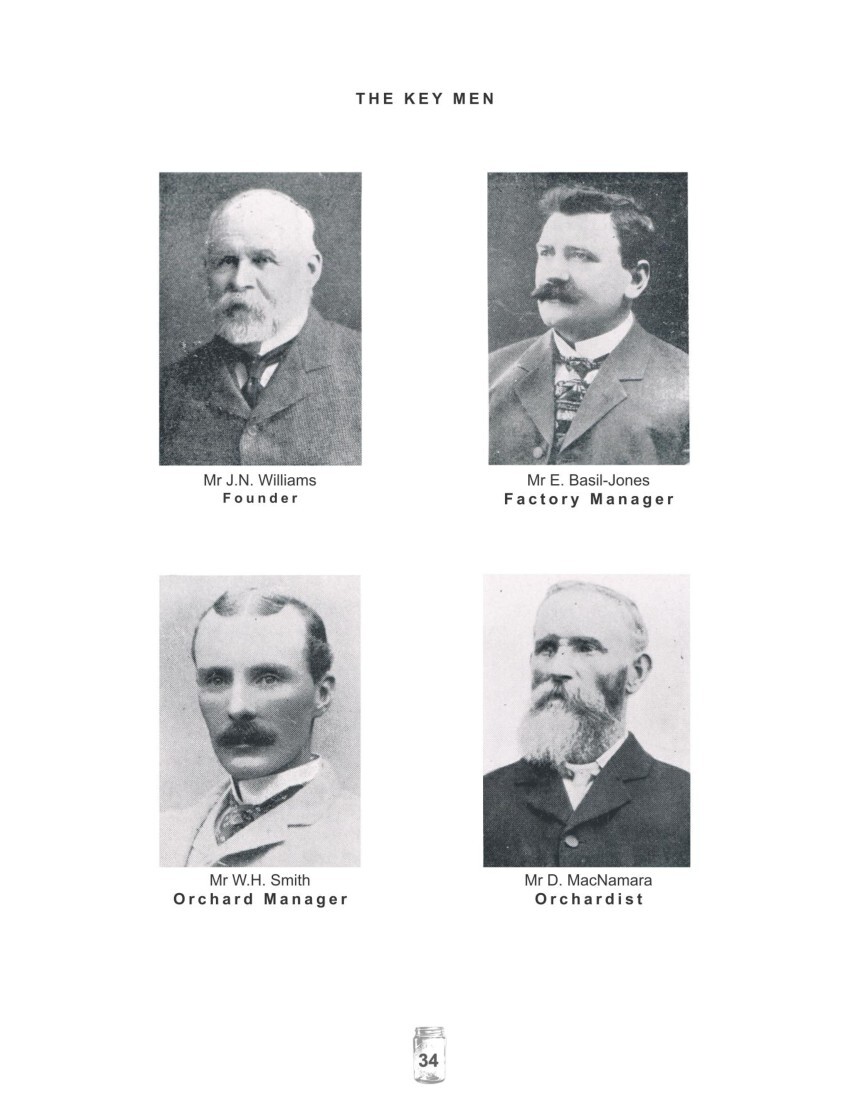

Mr MacNamara looked after the actual horticultural management of the orchard, while W H Smith was the overall manager of the orchard complex.

When 60,000 more trees were planted two groups were formed, the Kaiapo group and the Frimley group. The Kaiapo group consisted of 10 owners: Smith and MacNamara who were in charge of operations, plus two owners who worked for wages, and six sleeping partners of whom C L Mackersey, C Douglas and W Purvis were three. The orchard was worked as one entity with no dividing fences. The staff working this block consisted of 60 in the summer and 22 in the winter months. In the Frimley group which had 75 acres were J N Williams, Basil-Jones in charge of the cannery and orchard, and Mr Hennessy who was the orchard manager. There were other working hands similar to the Kaiapo group.

The scale of operations was so great that men worked in gangs to carry out the tasks of grafting, spraying and pruning. Spraying was a massive operation and very tedious, as it was all done with hand pump sprayers. Picking was carried out by gangs with the fruit being picked into special baskets. The logistics of ensuring a constant supply of baskets to the pickers and the delivery of these to the cannery was a very exacting task which was entrusted to Mr George Porter.

Williams needed a capable manager for the Cannery, one with a sound practical knowledge of the business. The position was offered to E Basil-Jones, who was at the time Manager for Messrs E H Crease and Sons of Wellington, in September 1903. Mr Basil-Jones was originally in business in England, and was very much impressed at that time by the advances made in the canning of fruit by the Americans. He went to America and spent five years in Washington, Philadelphia and Baltimore acquiring knowledge of the very latest methods and machinery used in the canning business.

Recognising this wealth of background knowledge and experience Williams authorized Mr Basil-Jones to procure whatever machinery was required to properly equip an up to date factory. This he did, and the result was the most modern canning plant in New Zealand.

Page 13

Fruit was picked and put into cases for transport to the general market as well as for the cannery. A report in the Hawke’s Bay Herald of 2 January 1904 mentions quantities of cases required.

‘To show the magnitude of the operation at the Frimley Orchard, it may be stated that, at the beginning of the season; 10,000 fruit cases were ordered. These cases contained 50,000 feet of white pine and, when delivered, occupied a space 60 feet long, 40 feet wide, and 16 feet high.’

Children were employed as pickers and received about 3¼ d a pound which could almost be regarded as slave labour. In the 1909-10 season some of the pickers went on strike for a penny more and were successful.

There was an enormous amount of interest both locally and throughout New Zealand in the Frimley Orchard and Cannery. It even became a tourist mecca in the season. The following report in the Hastings Standard of 1908 bears this out.

‘The Frimley Orchards are being visited by people from all parts of the Colony, and have been escorted through them by the Head Orchardist, Mr D MacNamara. The visitors have expressed themselves as being astounded at the magnitude of the orchards, and the quantity of fruit grown. The trees are bearing very heavily this year, in fact this season’s crop of peaches, prunes and plums far exceeds past years. Mr McNamara estimates the output of peaches will be 300 tons, and prunes and plums another 50 tons. The grape vines have never looked better and give promise of an abundant crop. During the last five working days at the Frimley Orchards 2277 cases of peaches passed through the packing sheds representing 22 ¾ tons weight’

Another report from the Standard of 10 February 1906 states:

‘Arrangements have been made by the Mayor to send a motor car to Napier tomorrow to convey the Governor to Flaxmere. His Excellency will be received by the Hastings Borough Council and will be introduced to the councillors, and presented with an illuminated address. He then visits a State School and afterwards proceeds to Frimley and lunches with Mr J N Williams. In the afternoon he will be shown around the canning factory and orchards.’

15 February Hastings Standard: ‘The Premier, accompanied by Miss Seddon, Messrs Dill, MHR, and Dennett (Mayor) drove off amidst cheers to the Frimley Canning Factory and Mr Seddon expressed himself as highly impressed with the fruit industry.’

The Frimley orchards were also prone to being raided by members of the local community and this fact was obviously of great concern to the owners. The loss of fruit was probably minimal, but the damage done to trees by these raiders caused lasting damage. The 17 March Hastings Standard reports on this matter as follows: `The Frimley Orchard authorities have been troubled a good deal lately by people visiting the gardens and helping themselves to fruit, and they have decided to take legal proceedings against anybody found trespassing.’

Whether or not prosecutions were made is unclear. The vineyard section of the orchard produced excellent wine which was sold mainly throughout New Zealand. The Frimley Exhibit at the International Exhibition in Christchurch in 1906 included wine from the Frimley Estate and was awarded two Gold Medals in the Claret section. A surviving vine from this vineyard is still bearing fruit at the Elms’ house in Orchard Road.

Page 15

Part III

THE FRIMLEY CANNING FACTORY

THE OFFICIAL OPENING Hawke’s Bay Herald, 18 January 1904

‘The Frimley Canning Works were officially opened on Saturday afternoon, establishing another industry for Hawke’s Bay, which is certain to bring wealth to the people besides widely advertising our district as a fruit producing area of first rank. Until recently it was made a reproach to our early settlers that they carried all their eggs in the wool and meat baskets. Gradually and surely, however, changes are occurring, and new industries are springing up in our midst that are finding healthful occupation for a large number of persons, and adding other permanent sources of wealth to Hawke’s Bay. Mr J N Williams is the instigator of the latest of our industries. While on a visit to California some 13 years ago, he was so much taken with the similarity of the climate and surroundings to those existing here that he decided on his return to test the district and laid down an orchard. This had gradually been extended until Frimley can claim60 miles in length of peach trees alone, besides the large areas of apples, plums, apricots, pears, vines etc.

A description of the orchard appeared in the Herald about three months ago and will be fresh in the minds of our readers. Its great extent and the large area of land which at present is being put into orchards, has emphasized the necessity for an up to date canning factory. This Mr Williams has supplied by putting down a plant of the latest machinery, capable of treating over 20,000 cases, or half a million 2 pound tins of preserved fruit, besides dealing with the big quantities of different fruit pulps. It was no surprise therefore, that fully 200 persons found their way to Frimley on Saturday afternoon, to take a share in wishing the success to industry which is full of possibilities for the district.

In the absence of Sir William Russell, MHR, who is indisposed, and Mr A L D Fraser, MHR, who is assisting the Wairoa promotion of a harbour loan, the ceremony was performed by Mr W Y Dennett, Mayor of Hastings. Among others present were noticed; Lady Russell, Messrs F W Williams, Mayor of Napier, A Loudon, Manager of HB Farmers’ Cooperative Association, R Hansard of Murray Roberts, A H Russell, C A Fitzroy, E P A Platford, E Newbigin, Geo White of Raureka, and nearly all the fruit growers of the district, besides a large number of ladies.

Mr Dennett, before formally opening the factory, apologized for the absence of Sir William Russell and Mr A L D Fraser. The former was too unwell to attend and the latter was bar bound in Wairoa. The cannery he said was erected for dealing with surplus fruit grown in the district and for preparing the same in such a manner as to be able to compete successfully with the American article. In New Zealand alone 24,000 cases of mixed tinned fruits were consigned annually at a cost of 17,000 pounds.

This enormous quantity was nearly all imported from America and the speaker thought it was ridiculous that 17, 000 pounds should go out of the Colony for an article that could be provided locally just as cheaply and as of good quality. Most of the American tinned fruits coming into this country were put up in sweet waters, while the Frimley factory would employ only the best syrups. The factory he said, has cost for buildings up to the present, the sum of 800 pounds, while another 800 pounds had

Page 16

been put into machinery. The bulk of the machinery had not yet been erected but sufficient plant was on hand to treat the output of tomatoes and fruit that was coming forward. The estimated cost of running the factory for a year was roughly,

Wages 2000 pounds Tin Plate 2,000 pounds Fruit 5,000 pounds Sundries 2,000 pounds.

The estimated output was 10,000 cases of 2 dozen cans each of preserved fruit, or roughly 250,000 tins, besides raspberry pulp, and other preserves in large quantities.

Mr J N Williams, the enterprising proprietor of the factory had spent a large amount of money on the Frimley orchard and in establishing the factory. He had secured the best manager procurable in the person of Mr E Basil-Jones, and he (Mr Dennett) considered that Mr Williams was deserving of the gratitude and support of the community for the manner in which he had brought the fruit growing industry to its present state in Hawke’s Bay. The factory, Mr Dennett said in conclusion, would employ 80 men, women, boys and girls and he would leave his hearers to imagine what this would mean to the district. (applause) He called for three hearty cheers for Mr Williams, which were heartily given.

Mr J N Williams, who was received with applause, said that he deeply regretted the absence of Sir William Russell and Mr Fraser, but he was glad to say that Mr Dennett had done his subject full justice. He said that he would explain some of the reasons why he was able to speak in front of a canning factory in Hawkes Bay that day. While in California 13 years ago, he visited a district which was considered the most suitable on the Pacific Slope for fruit growing. The area in fruit was surrounded by hills, the climate was similar and conditions generally closely resembled those ruling in our own district. The town in the centre of the district he visited was twice as large as Napier and Hastings combined, and he was assured that fruit and fruit alone was responsible for the signs of prosperity to be seen everywhere. On inspecting the district he realized he had not seen an orchard before, and he thought that there was no reason why we should not have one of a similar kind in Hawkes Bay. He had come back to New Zealand and planted the Frimley Orchard and vines and was satisfied with the result. He would impress on orchardists however, that they should endeavour to grow only the best fruits. If they persisted in growing inferior fruits, they had better cut down their trees and leave fruit growing alone. He concluded in saying that in one American factory which he visited there were 700 women and girls employed and 250 men and boys. The output from this particular factory was 250,000 cases and the other factories were run on an equally large scale.

Mr Dennett then declared the factory duly open and intimated that Mr Jones and his staff would be happy to show any of the visitors around the factory. Afternoon tea and other refreshments including choice fruits were provided for the visitors, Miss Heath, Mrs E Basil-Jones assisted by a bevy of young ladies being assiduous in attending the visitors. Full justice was done to the beautiful display of fruit that was evident in every form.

DESCRIPTION OF THE FACTORY – continuation of Herald report –

Both before and after the ceremony the public were much interested in the different processes brought into use from the time the fruit is received until it is ready for the market. The different departments were crowded with spectators anxious to get information. The staff were most courteous and explained the various methods of handling the fruit in a manner that showed thorough knowledge of their business.

Page 17

The buildings stand on two acres of land and contain all the most modern conveniences. They are well lighted and airy, and consist of offices, luncheon room, sorting room, packaging room as well as a storage department. With the exception of the offices and luncheon rooms the floors are all concrete, and there are ample supplies of hot and cold water for cleaning purposes. Steam and hot water are supplied by a 23hp boiler. A 9hp Brown & May engine provides the driving power for the tinsmiths’ shop and workshop. Steam is also conducted from the boiler to the cooking pans and an exhaust pipe is fitted to every pan.

The tinsmiths’ shop is fitted with various machines for the quick dispatch of the raw material until the finished article is produced. Here is a power press made by J Heine of Redfern, Sydney, a solid machine for the purpose of cutting the lids and bottoms of the tins at a rate of 1800 per hour. Another machine standing alongside is for the purpose of rounding the sheet into shape. It is then handed over to the solderer, who in turn sends it along to an upright automatic crimping machine where the tops and bottoms are brought into position in one operation, the side being pressed in at high speed. The soldering machine and bath completes the operation, as the projecting rims revolve in a bath of liquid solder. Mr Jones stated that this machine was capable of turning out 5000 complete cans per day. There are also machines for making square tins of almost any size required. The soldering irons are kept heated by a powerful gas generated from kerosene by the aid of an air blast.

The tins are cleaned and then are ready for use, after which they find their way into the sorting room. Here the fruit such as pears is sorted out and peeled, one girl being able, with the aid of the machine, to keep her five companions busy filling. After the peeling process the fruit is submitted to a bath of cold water and then put into tins. The water is now drained off and the fruit is handed to operators at the syrup tanks, of which there are three, containing different grades of syrup suitable to the fruit under manipulation. From here they are sent along a trolley to the capping machine and are finally sealed in double quick time.

The next we see the article is when it is making its way to two large cooking tanks. Here the tins are stacked on a round table and then lifted by steam power to the top of the tanks, in which they are shortly afterwards immersed. The times allowed for plums and soft fruit is usually about 15 minutes, while pears take the full hour.

After sufficient immersion they are transferred to the cooling tanks which are the same size as the cooking tanks, after which the tins are carefully wiped and are ready to receive the different labels, which are got up in the most artistic style.

In the same room are two steam jacket pans which are used for the manufacture of pulp for jam making. Thus the fruit which is not suitable for canning is dealt with. The time occupied to reduce the fruit to pulp is 15 minutes, and it is then put into 7lb and 40lb tins and is ready for export. In fact on Saturday morning no fewer than 50 40lb tins of apricot pulp were treated.

Every modem convenience has been introduced for the comfort and convenience of the workers. A large luncheon room has been erected for them. It contains spacious table accommodation, luncheon cupboards, hat and clothes pegs and a plentiful supply of wash basins and water. Hot water is supplied for those wishing to brew the cup that cheers. The office is completely fitted with telephone, typewriter and all articles necessary for the conduct of business on up to date lines.

Page 18

In a storage room over the sorting department are 75,000 tins completed ready for filling, and everywhere is exhibited a determination to push the business and to make the produce of Frimley Canning Factory a commodity known for choiceness and excellent flavour.

As before stated Mr E Basil-Jones is the manager, Mr G Sage, a gentleman of large experience in Australia, is the foreman of works, while Mr J McLean has charge of the Power department.

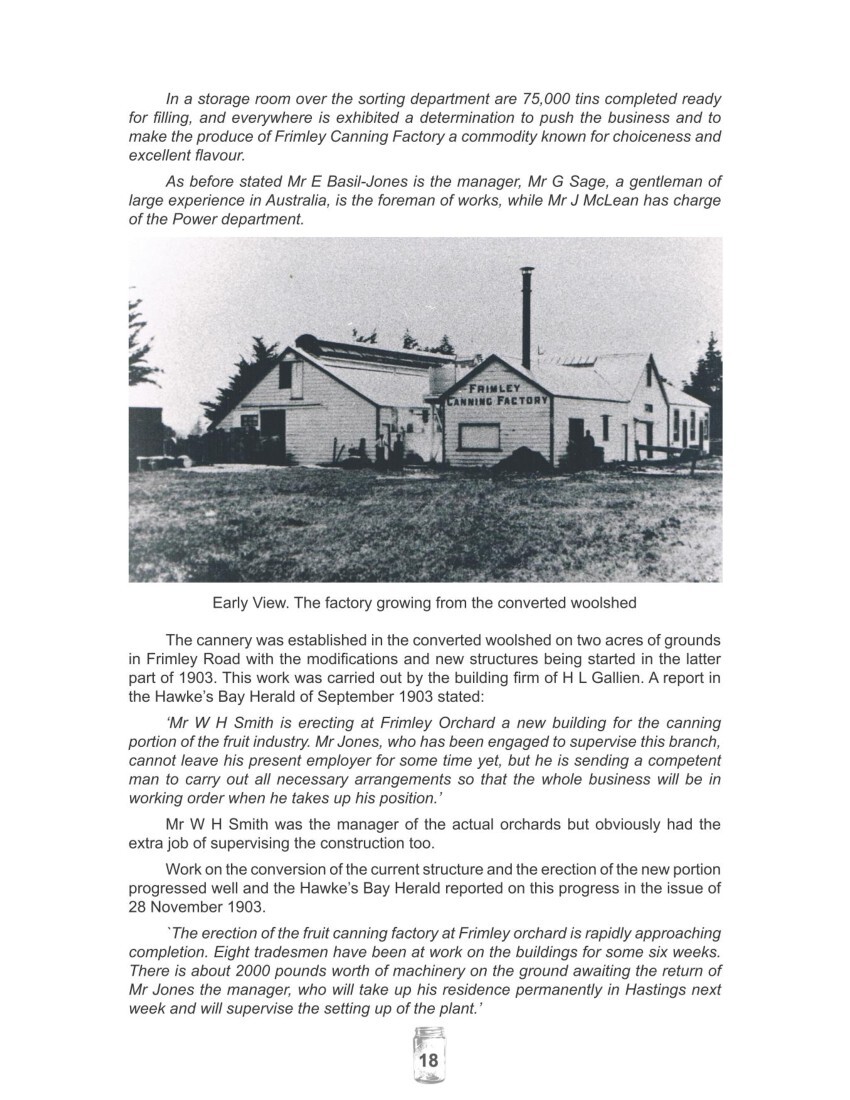

The cannery was established in the converted woolshed on two acres of grounds in Frimley Road with the modifications and new structures being started in the latter part of 1903. This work was carried out by the building firm of H L Gallien. A report in the Hawke’s Bay Herald of September 1903 stated:

‘Mr W H Smith is erecting at Frimley Orchard a new building for the canning portion of the fruit industry. Mr Jones, who has been engaged to supervise this branch, cannot leave his present employer for some time yet, but he is sending a competent man to carry out all necessary arrangements so that the whole business will be in working order when he takes up his position.’

Mr W H Smith was the manager of the actual orchards but obviously had the extra job of supervising the construction too.

Work on the conversion of the current structure and the erection of the new portion progressed well and the Hawke’s Bay Herald reported on this progress in the issue of 28 November 1903.

‘The erection of the fruit canning factory at Frimley orchard is rapidly approaching completion. Eight tradesmen have been at work on the buildings for some six weeks. There is about 2000 pounds worth of machinery on the ground awaiting the return of Mr Jones the manager, who will take up his residence permanently in Hastings next week and will supervise the setting up of the plant.’

Photo caption – Early View. The factory growing from the converted woolshed

Page 19

This was followed by another report in the 8 December 1903 paper. ‘The machinery at Frimley Canning Company is now in full working order and operations will commence this week Gooseberries will be the first fruit dealt with, after which other fruits will be handled as they come in.’

The machinery was set up by an expert in this field from Adelaide.

Later on, as production increased, a further three buildings were added to the cannery. These buildings housed sample rooms, a storage shed, and men’s and women’s dining rooms.

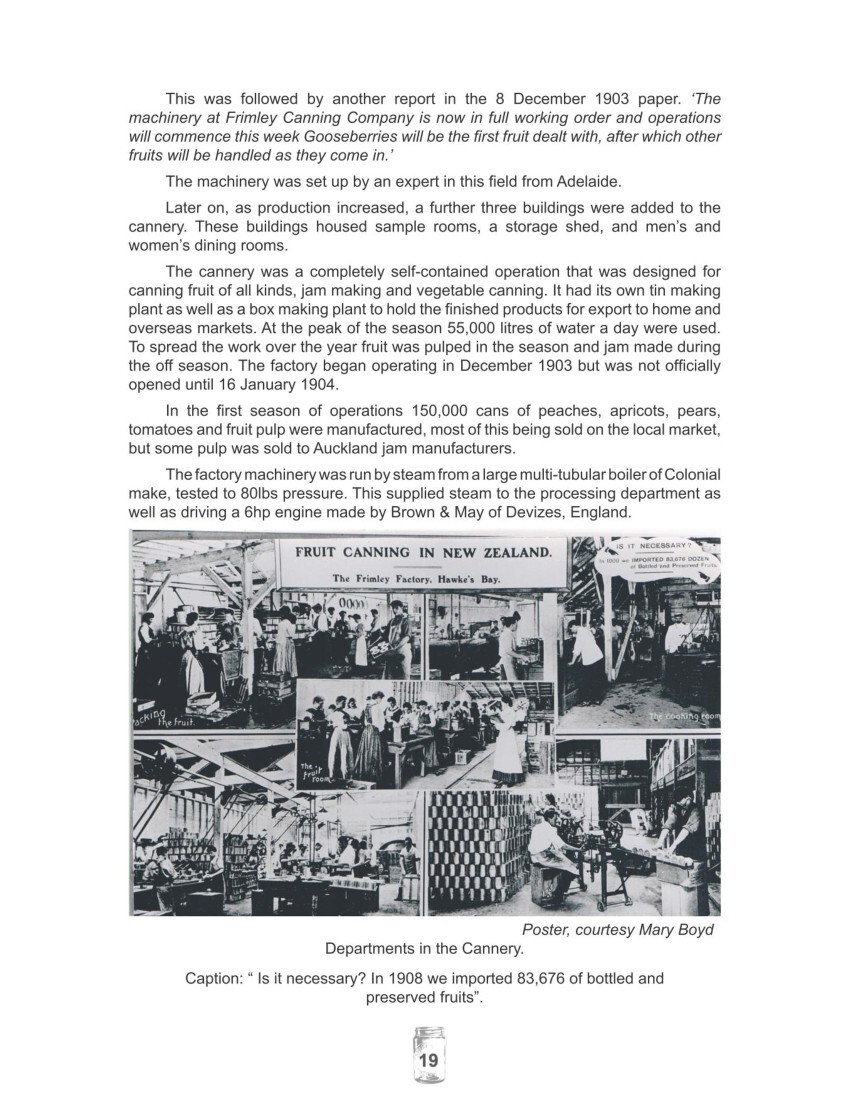

The cannery was a completely self-contained operation that was designed for canning fruit of all kinds, jam making and vegetable canning. It had its own tin making plant as well as a box making plant to hold the finished products for export to home and overseas markets. At the peak of the season 55,000 litres of water a day were used. To spread the work over the year fruit was pulped in the season and jam made during the off season. The factory began operating in December 1903 but was not officially opened until 16 January 1904.

In the first season of operations 150,000 cans of peaches, apricots, pears, tomatoes and fruit pulp were manufactured, most of this being sold on the local market, but some pulp was sold to Auckland jam manufacturers.

The factory machinery was run by steam from a large multi-tubular boiler of Colonial make, tested to 80lbs pressure. This supplied steam to the processing department as well as driving a 6hp engine made by Brown & May of Devizes, England.

Departments in the Cannery.

Poster, courtesy Mary Boyd

Caption: “ Is it necessary? In 1908 we imported 83,676 of bottled and preserved fruits”.

Page 20

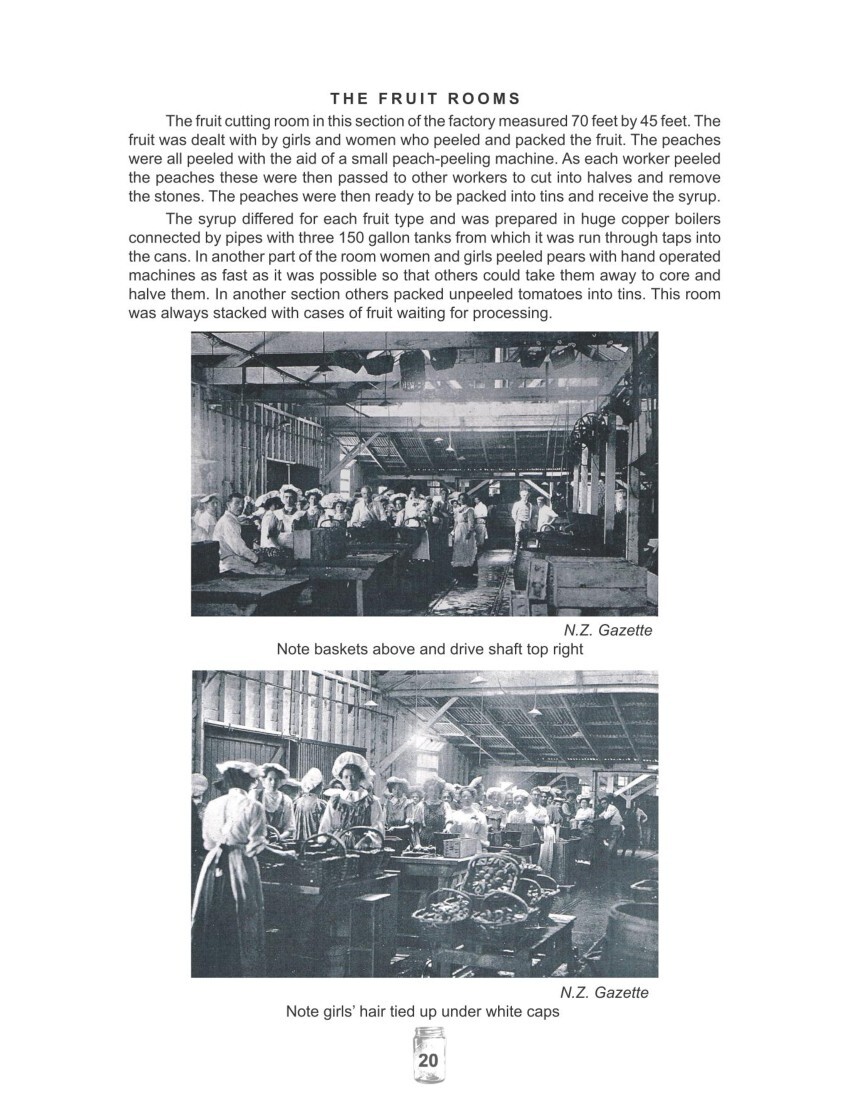

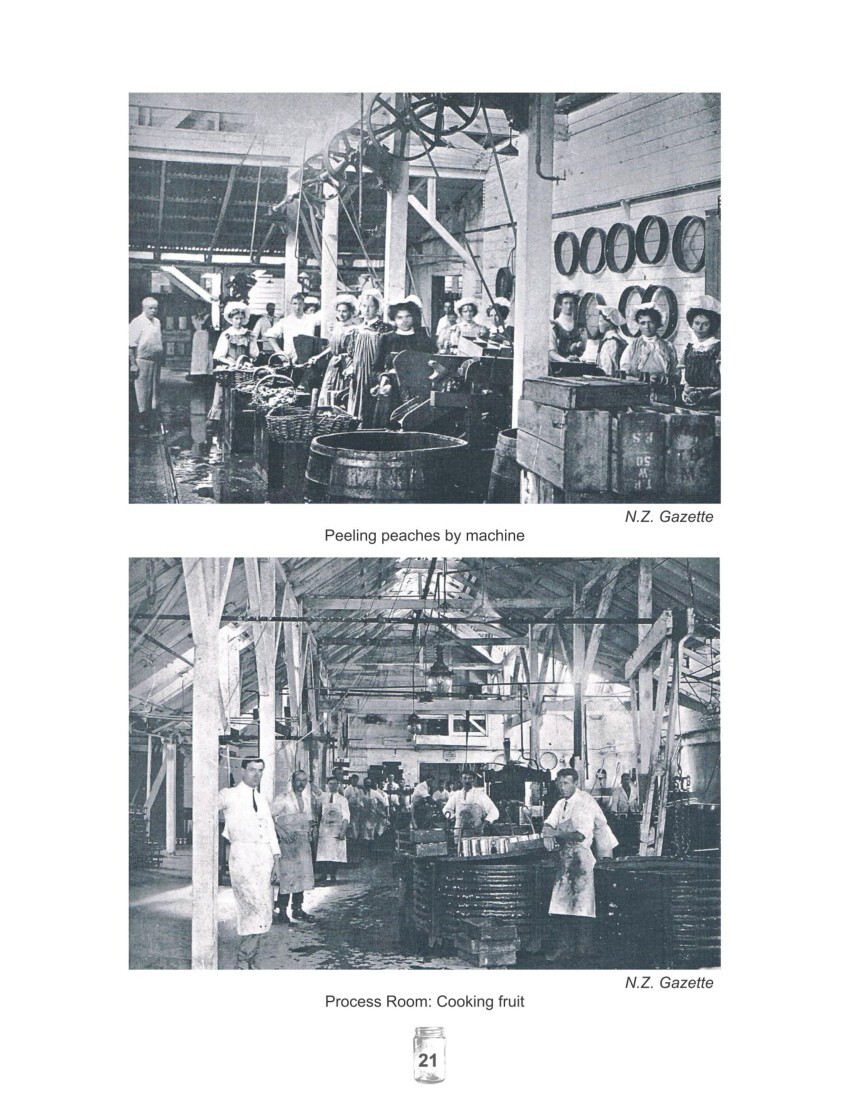

THE FRUIT ROOMS

The fruit cutting room in this section of the factory measured 70 feet by 45 feet. The fruit was dealt with by girls and women who peeled and packed the fruit. The peaches were all peeled with the aid of a small peach-peeling machine. As each worker peeled the peaches these were then passed to other workers to cut into halves and remove the stones. The peaches were then ready to be packed into tins and receive the syrup.

The syrup differed for each fruit type and was prepared in huge copper boilers connected by pipes with three 150 gallon tanks from which it was run through taps into the cans. In another part of the room women and girls peeled pears with hand operated machines as fast as it was possible so that others could take them away to core and halve them. In another section others packed unpeeled tomatoes into tins. This room was always stacked with cases of fruit waiting for processing.

Note baskets above and drive shaft top right

N.Z. Gazette

Note girls’ hair tied up under white caps

N.Z. Gazette

Page 22

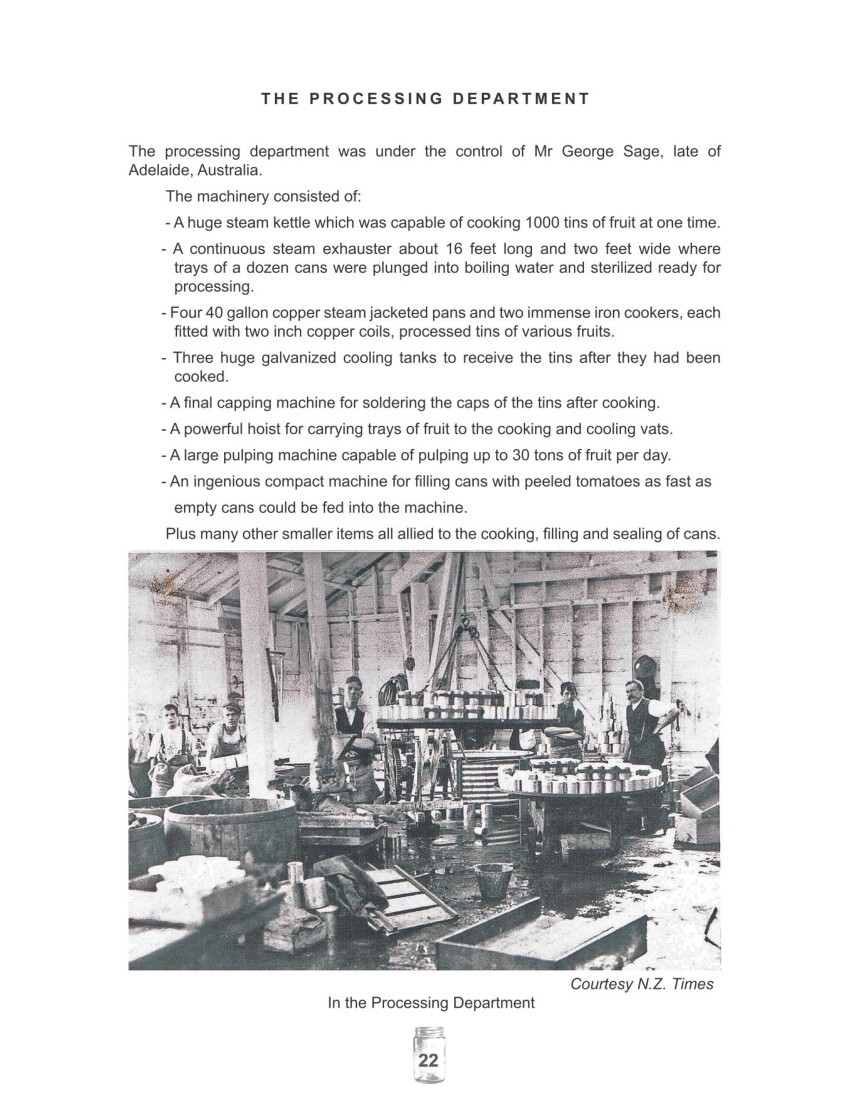

THE PROCESSING DEPARTMENT

The processing department was under the control of Mr George Sage, late of Adelaide, Australia.

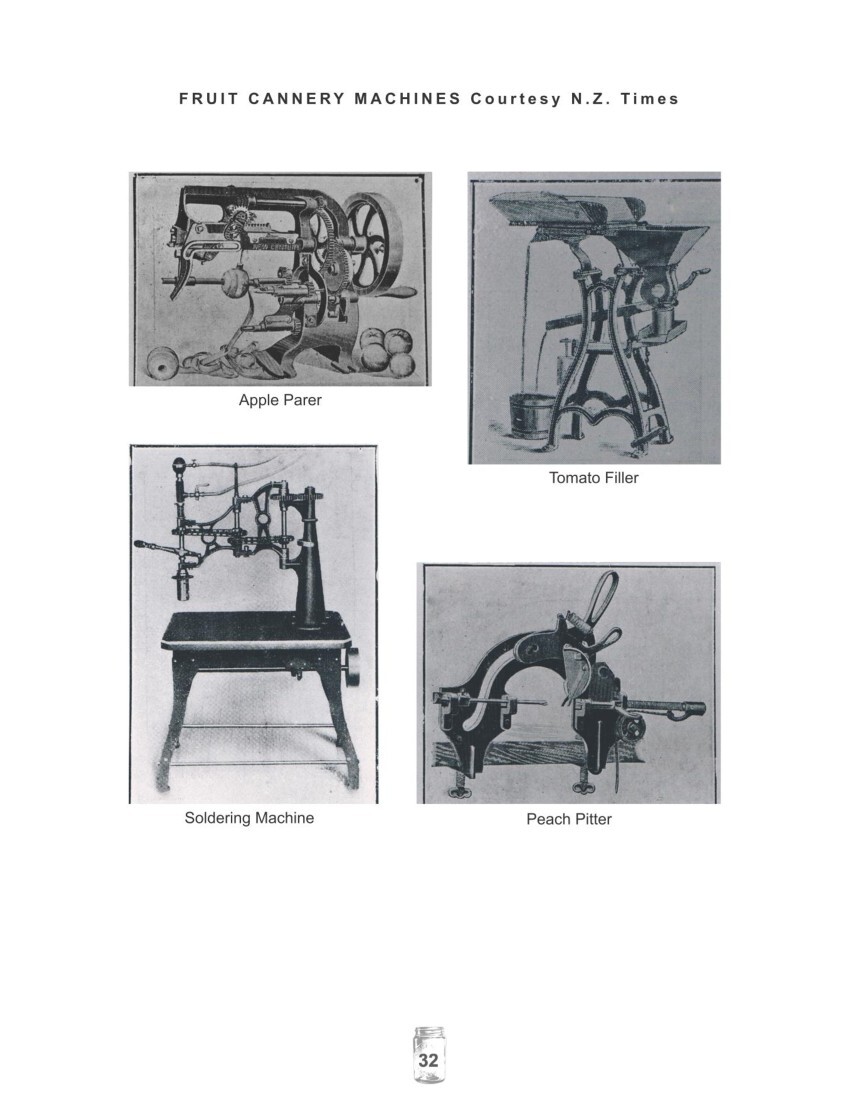

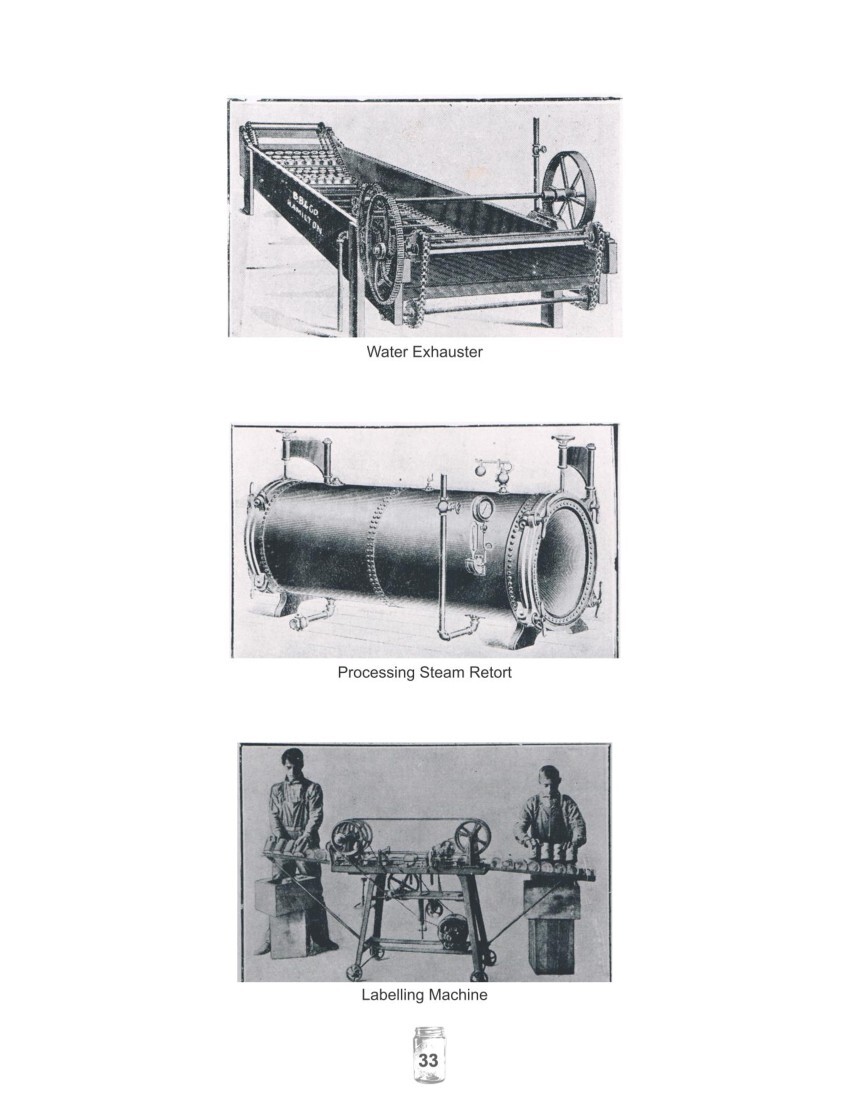

The machinery consisted of:

A huge steam kettle which was capable of cooking 1000 tins of fruit at one time.

A continuous steam exhauster about 16 feet long and two feet wide where trays of a dozen cans were plunged into boiling water and sterilized ready for processing.

Four 40 gallon copper steam jacketed pans and two immense iron cookers, each fitted with two inch copper coils, processed tins of various fruits.

Three huge galvanized cooling tanks to receive the tins after they had been cooked.

A final capping machine for soldering the caps of the tins after cooking.

A powerful hoist for carrying trays of fruit to the cooking and cooling vats.

A large pulping machine capable of pulping up to 30 tons of fruit per day.

An ingenious compact machine for filling cans with peeled tomatoes as fast as empty cans could be fed into the machine.

Plus many other smaller items all allied to the cooking, filling and sealing of cans.

In the Processing Department

Courtesy N.Z. Times

Page 24

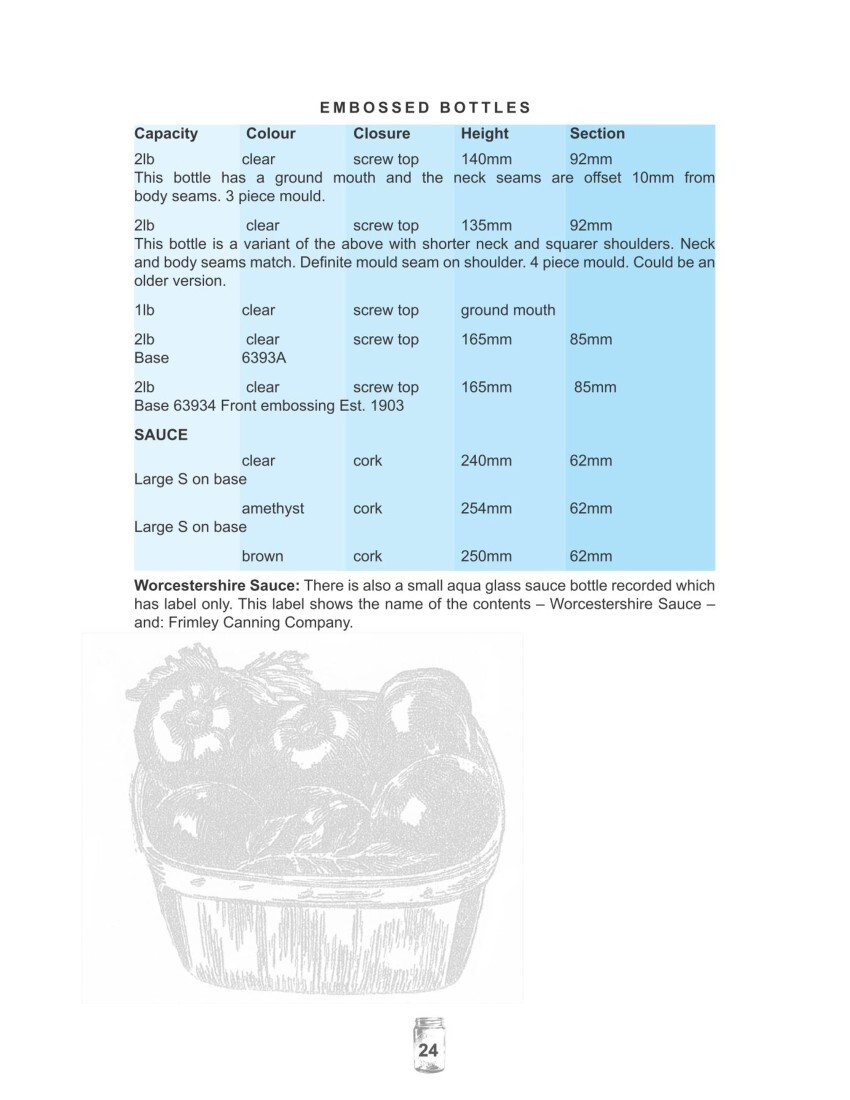

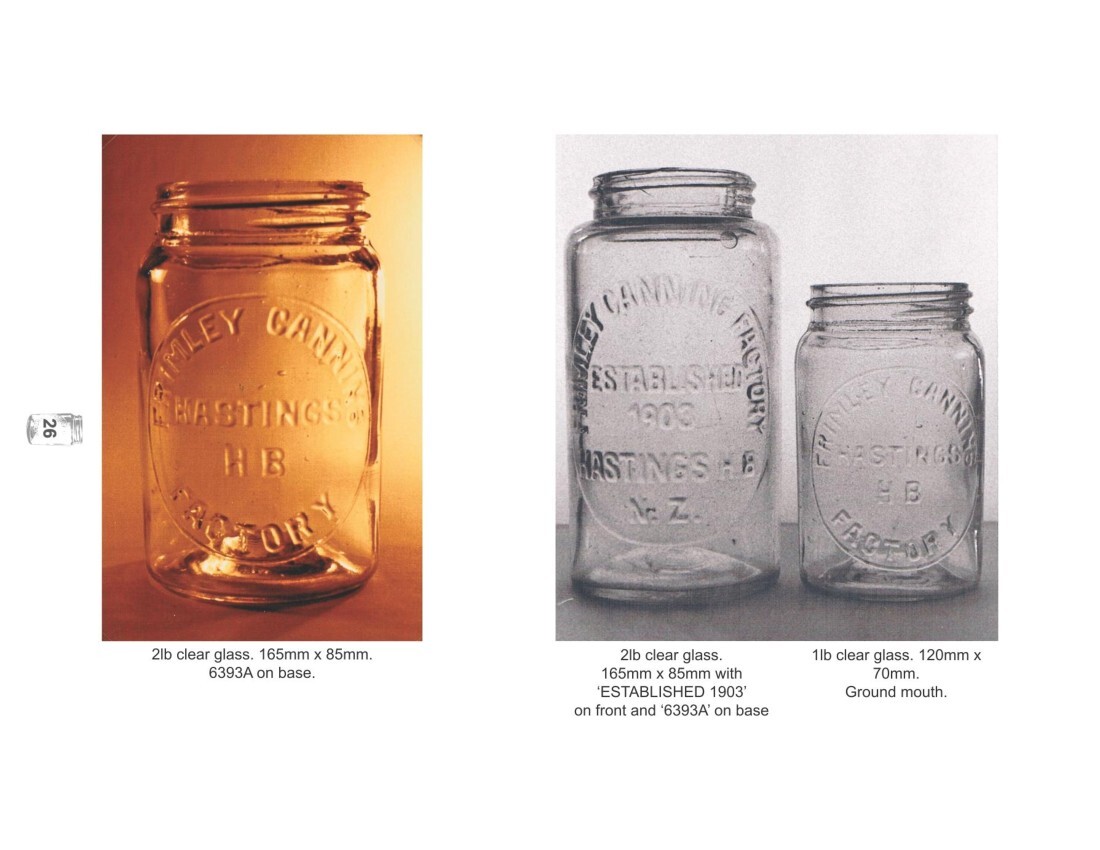

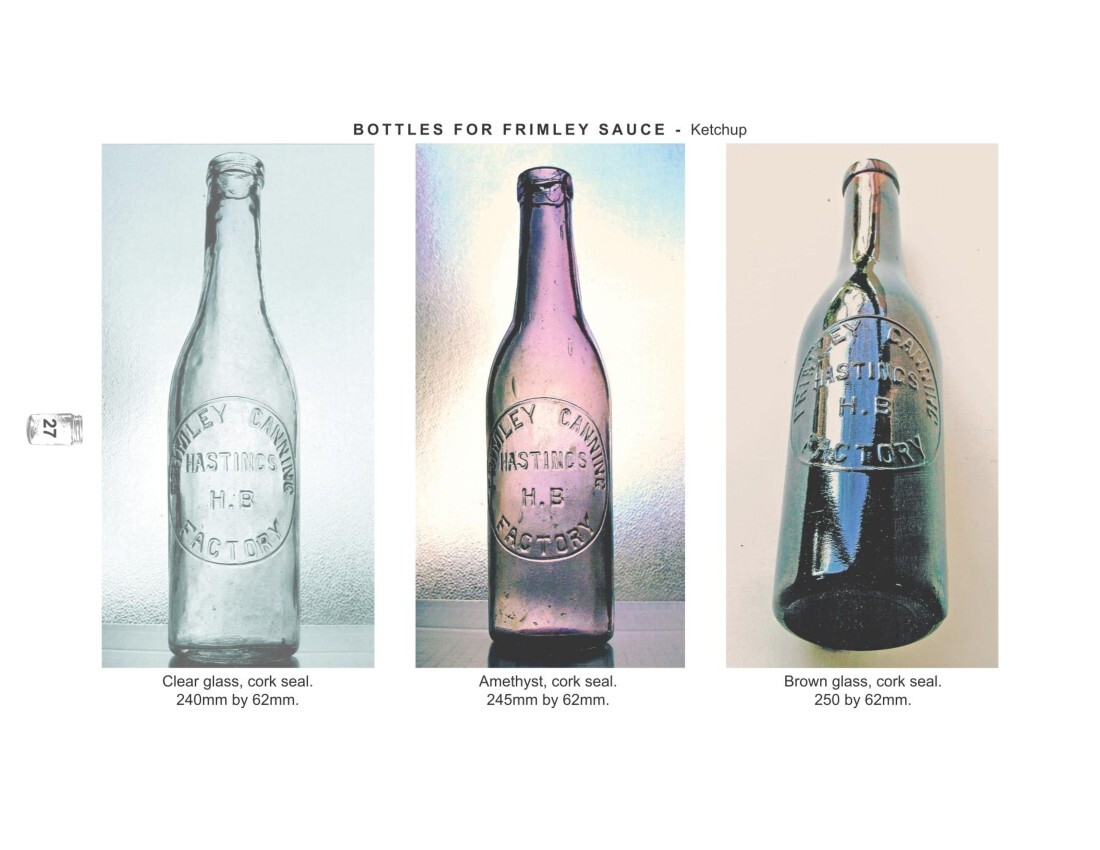

EMBOSSED BOTTLES

Capacity Colour Closure Height Section

2lb clear screw top 140mm 92mm

This bottle has a ground mouth and the neck seams are offset 10mm from body seams. 3 piece mould.

2lb clear screw top 135mm 92mm

This bottle is a variant of the above with shorter neck and squarer shoulders. Neck and body seams match. Definite mould seam on shoulder. 4 piece mould. Could be an older version.

1lb clear screw top ground mouth

2lb clear screw top 165mm 85mm

Base 6393A

2lb clear screw top 165mm 85mm

Base 63934 Front embossing Est. 1903

SAUCE

clear cork 240mm 62mm

Large S on base

amethyst cork 254mm 62mm

Large S on base

brown cork 250mm 62mm

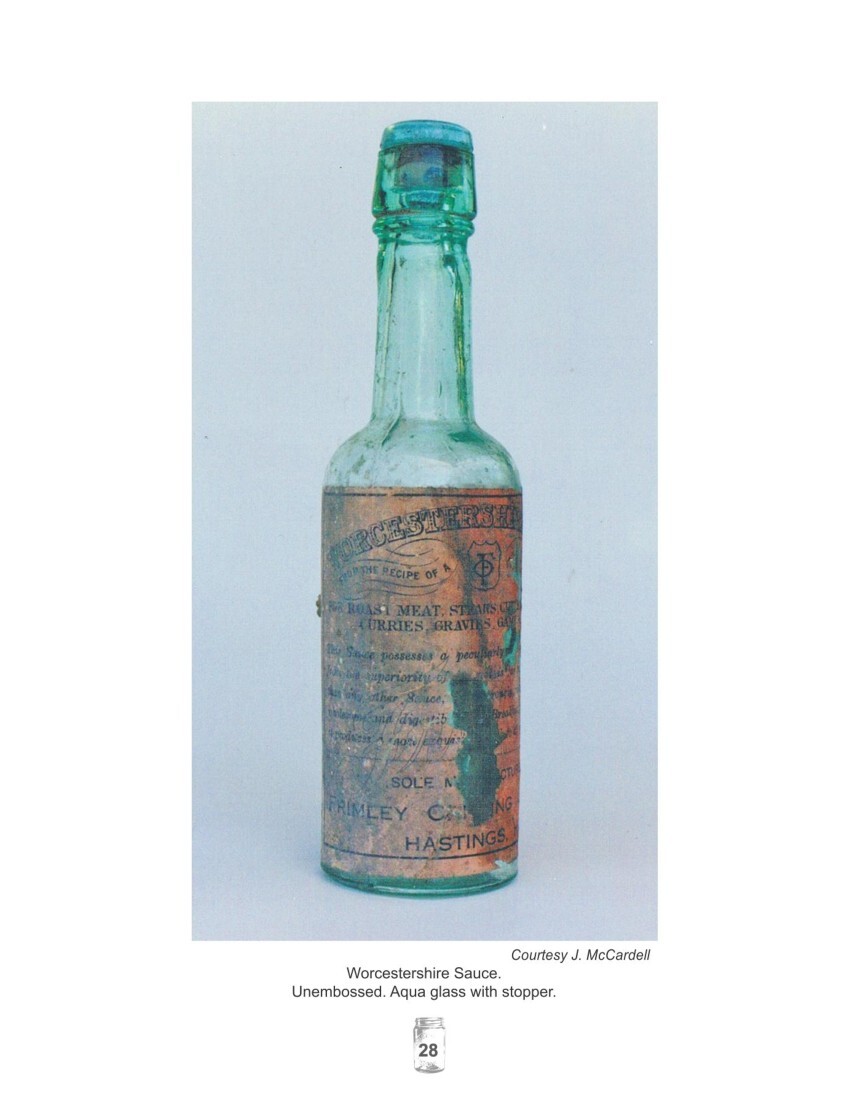

Worcestershire Sauce: There is also a small aqua glass sauce bottle recorded which has label only. This label shows the name of the contents – Worcestershire Sauce – and: Frimley Canning Company.

Page 25

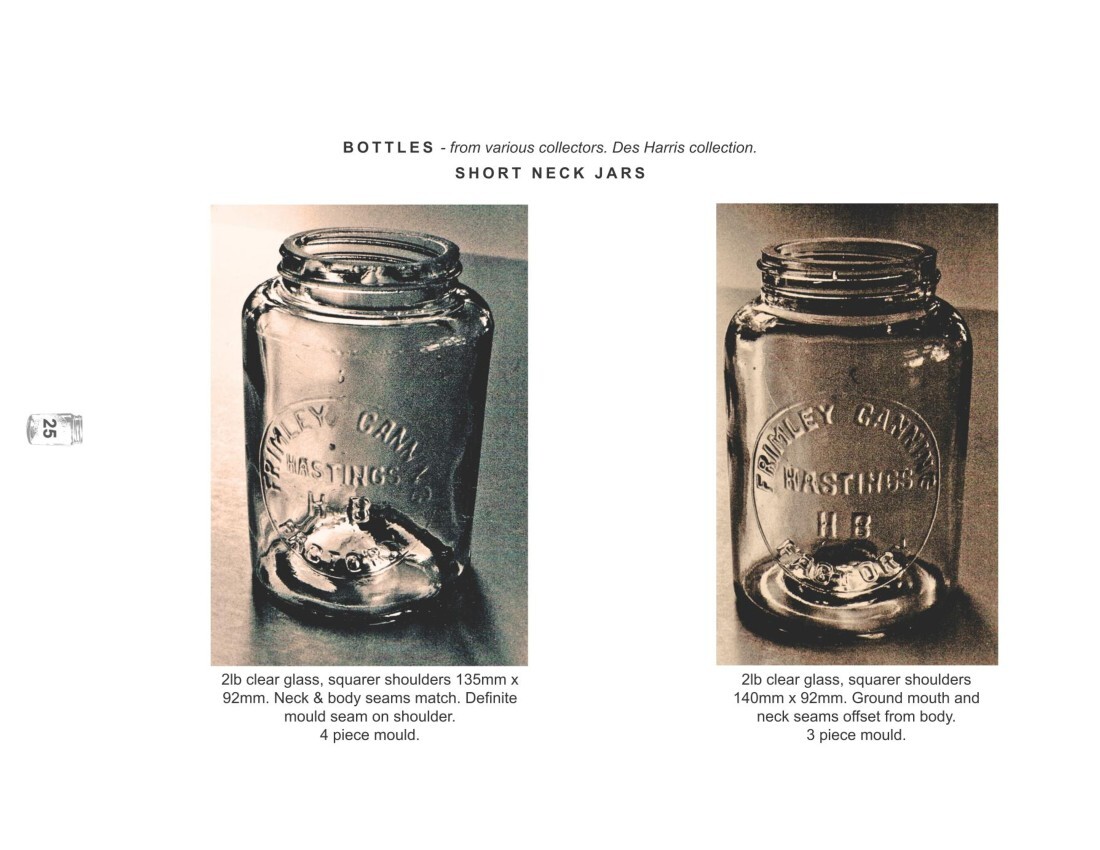

BOTTLES – from various collectors. Des Harris collection.

SHORT NECK JARS

2lb clear glass, squarer shoulders 135mm x 92mm. Neck & body seams match. Definite mould seam on shoulder. 4 piece mould

2lb clear glass, squarer shoulders 140mm x 92mm. Ground mouth and neck seams offset from body. 3 piece mould.

Page 29

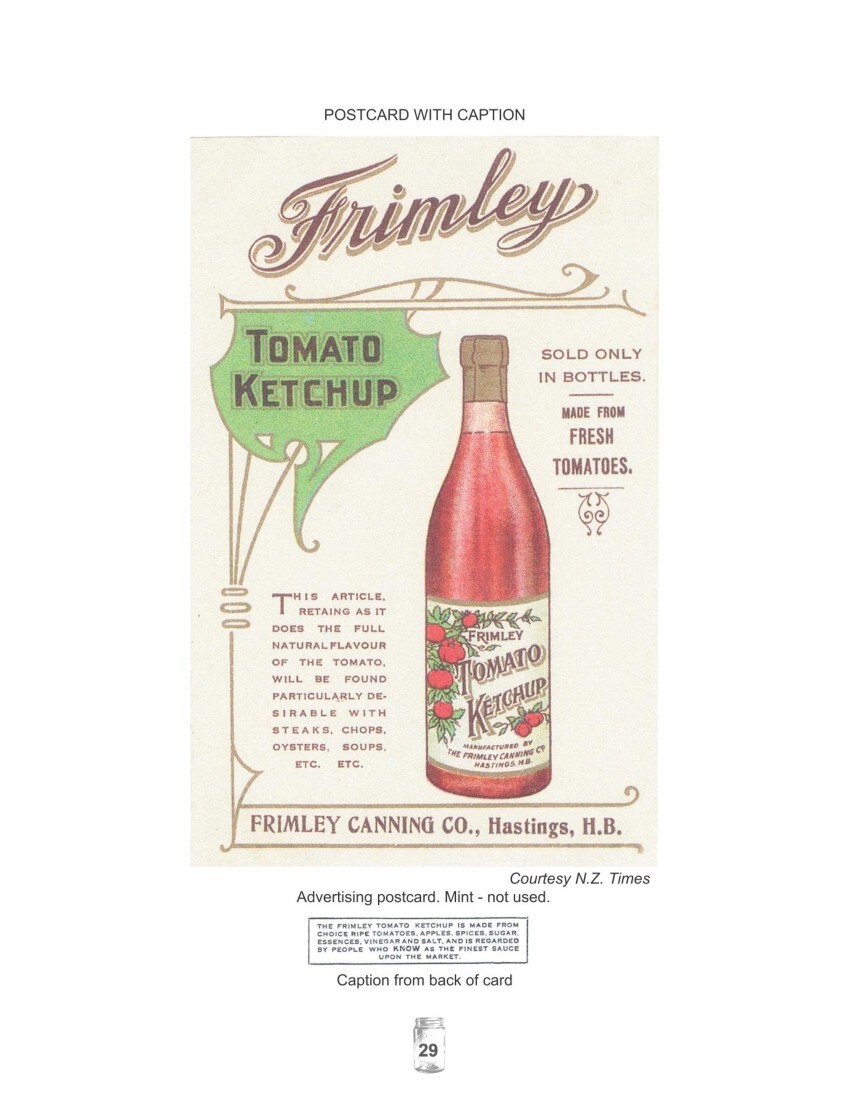

POSTCARD WITH CAPTION

Frimley

TOMATO

KETCHUP

SOLD ONLY IN BOTTLES.

MADE FROM FRESH TOMATOES.

THIS ARTICLE, RETAINING AS IT DOES THE FULL FLAVOUR OF THE TOMATO, WILL BE FOUND PARTICULARLY DESIRABLE WITH STEAKS, CHOPS, OYSTERS, SOUPS, ETC. ETC.

FRIMLEY CANNING CO., Hastings, H.B.

Courtesy N.Z. Times

Advertising postcard. Mint – not used.

THE FRIMLEY TOMATO KETCHUP IS MADE FROM CHOICE RIPE TOMATOES, APPLES, SPICES, SUGAR, ESSENCES, VINEGAR AND SALT, AND IS REGARDED BY PEOPLE WHO KNOW AS THE FINEST SAUCE UPON THE MARKET.

Caption from back of card

Page 30

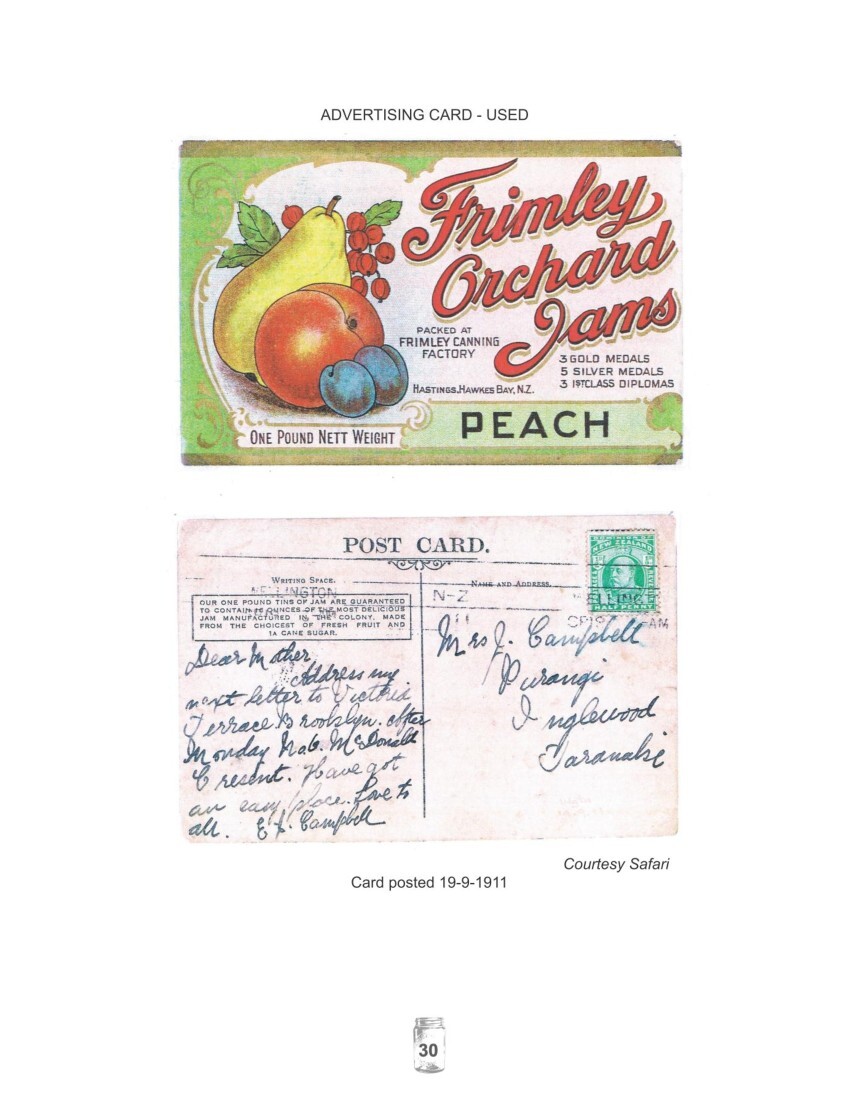

ADVERTISING CARD – USED

Frimley

Orchard

Jams

PACKED AT FRIMLEY CANNING FACTORY

HASTINGS, HAWKES BAY, N.Z.

3 GOLD MEDALS

5 SILVER MEDALS

3 1ST CLASS DIPLOMAS

ONE POUND NETT WEIGHT

PEACH

POST CARD.

OUR ONE POUND TINS OF JAM ARE GUARANTEED TO CONTAIN 16 OUNCES OF THE MOST DELICIOUS JAM MANUFACTURED IN THE COLONY, MADE FROM THE CHOICEST OF FRESH FRUIT AND 1A CANE SUGAR.

[Postcard text]

Courtesy Safari

Card posted 19-9-1911

Page 31

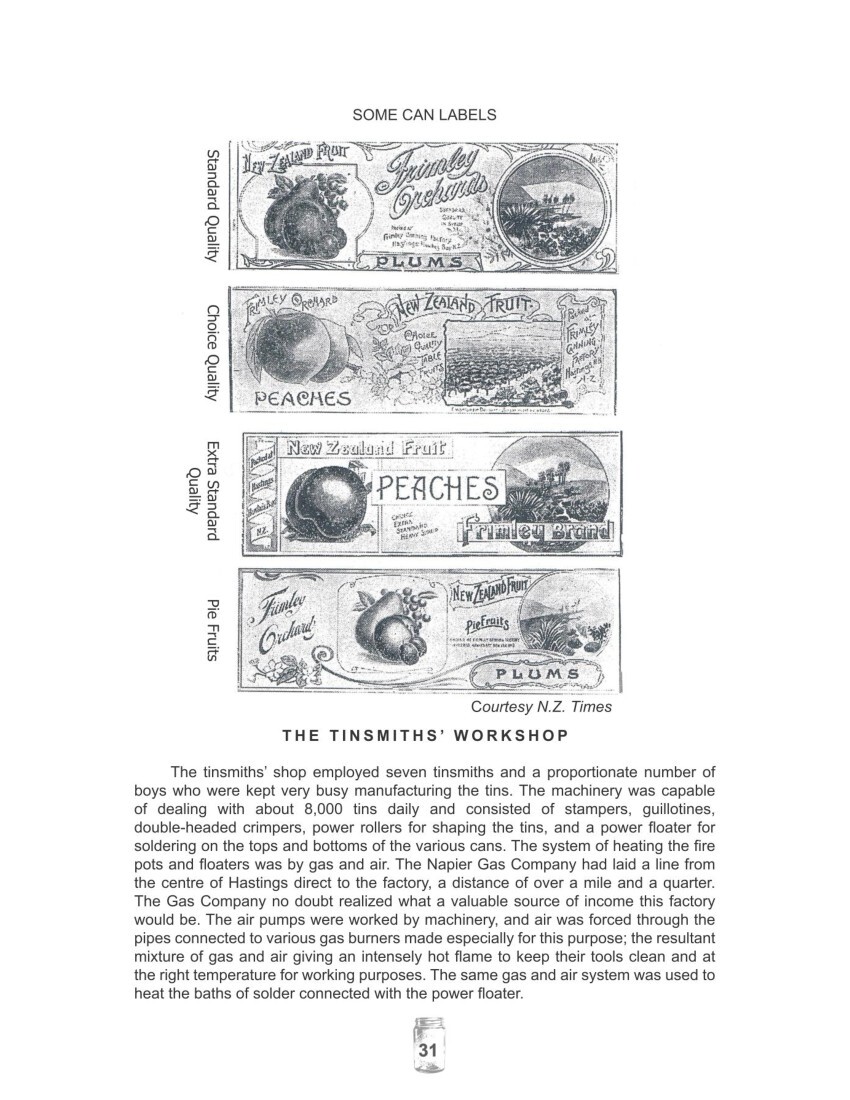

SOME CAN LABELS

Standard Quality

NEW ZEALAND FRUIT

Frimley Orchards

[…] QUALITY IN SYRUP

PACKED BY

Frimley Canning Factory

Hastings Hawkes Bay N.Z.

PLUMS

Choice Quality

FRIMLEY ORCHARD

PEACHES

NEW ZEALAND FRUIT

Packed at FRIMLEY CANNING FACTORY Hastings, H.B. N.Z

Extra Standard Quality

Packed at Hastings Hawkes Bay N.Z.

New Zealand Fruit

PEACHES

CHOICE

EXTRA

STANDARD

[…]

Frimley Brand

Pie Fruits

Frimley Orchard

NEW ZEALAND FRUIT

Pie Fruits

[…]

PLUMS

Courtesy N.Z. Times

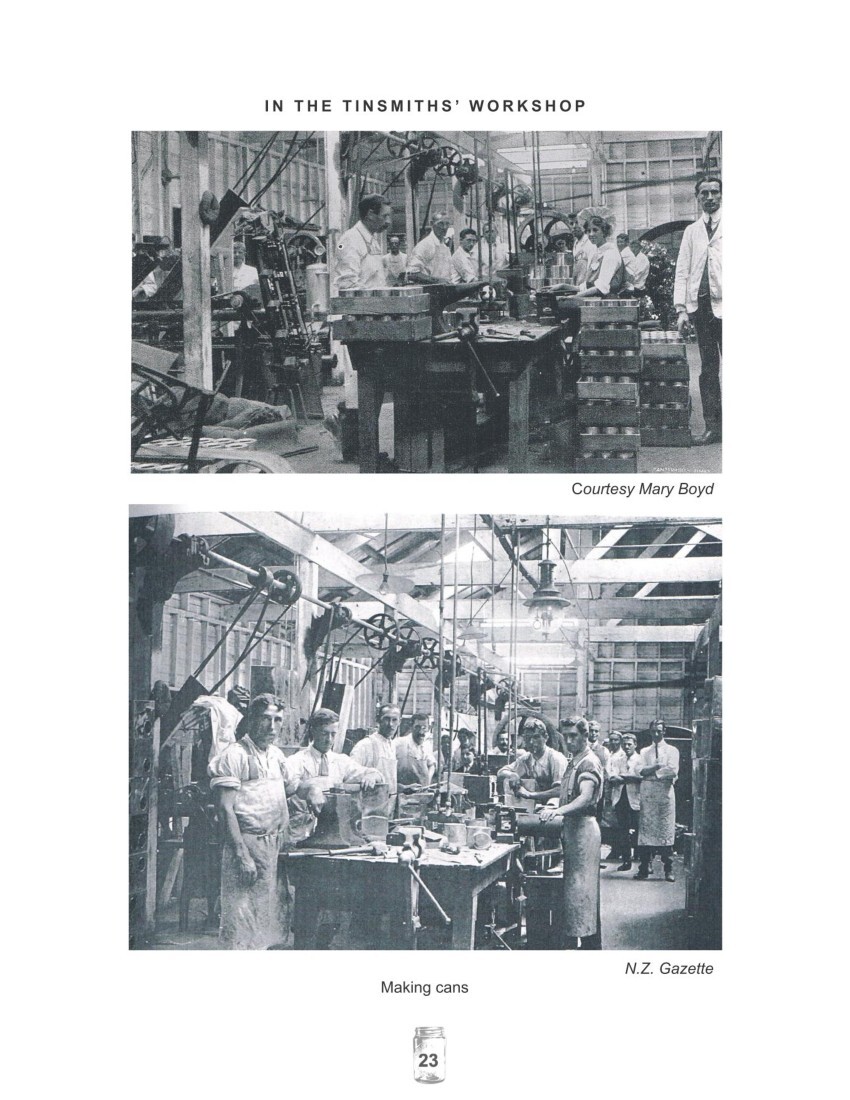

THE TINSMITHS’ WORKSHOP

The tinsmiths’ shop employed seven tinsmiths and a proportionate number of boys who were kept very busy manufacturing the tins. The machinery was capable of dealing with about 8,000 tins daily and consisted of stampers, guillotines, double-headed crimpers, power rollers for shaping the tins, and a power floater for soldering on the tops and bottoms of the various cans. The system of heating the fire pots and floaters was by gas and air. The Napier Gas Company had laid a line from the centre of Hastings direct to the factory, a distance of over a mile and a quarter. The Gas Company no doubt realized what a valuable source of income this factory would be. The air pumps were worked by machinery, and air was forced through the pipes connected to various gas burners made especially for this purpose; the resultant mixture of gas and air giving an intensely hot flame to keep their tools clean and at the right temperature for working purposes. The same gas and air system was used to heat the baths of solder connected with the power floater.

Page 35

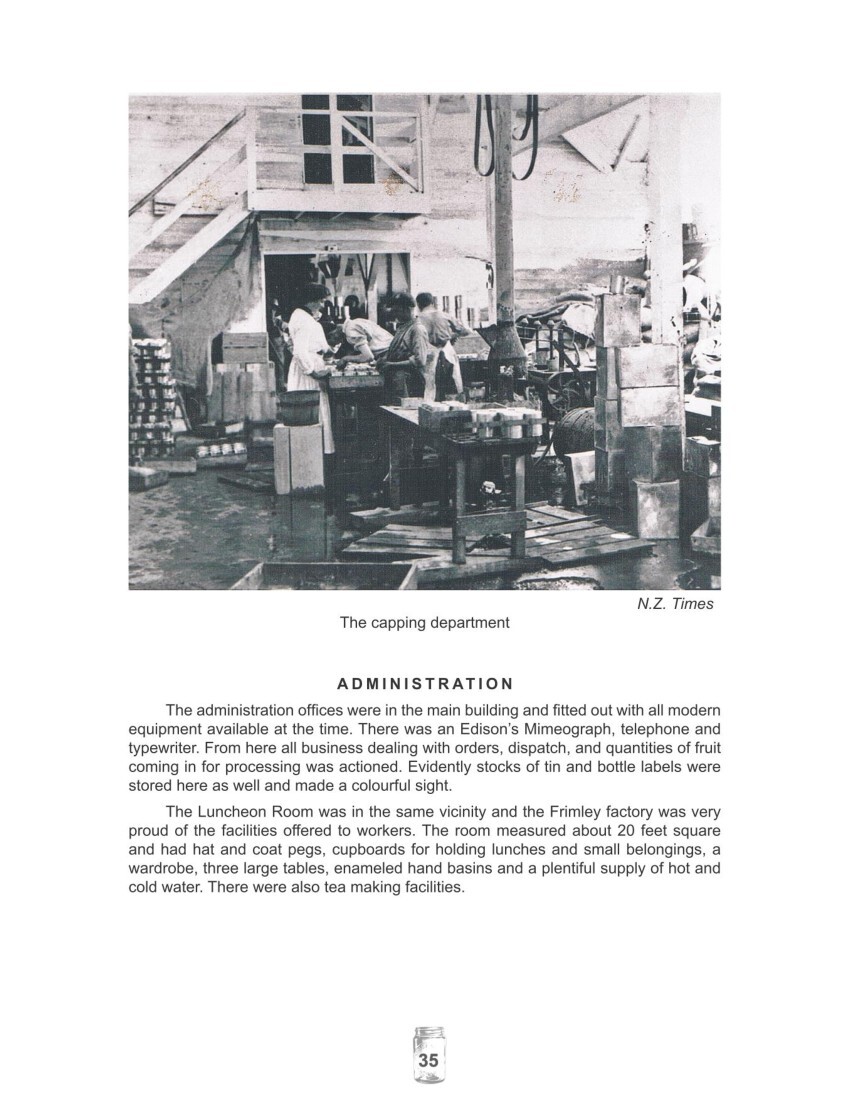

The capping department

N.Z. Times

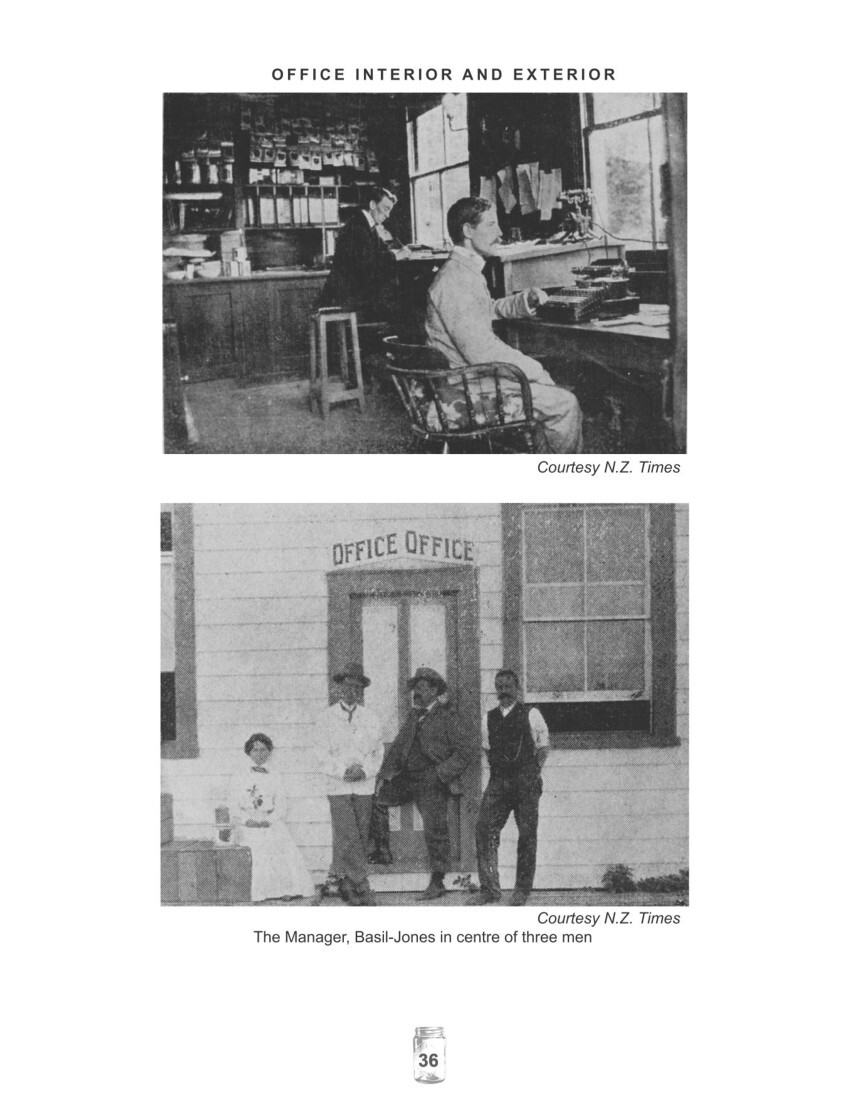

ADMINISTRATION

The administration offices were in the main building and fitted out with all modern equipment available at the time. There was an Edison’s Mimeograph, telephone and typewriter. From here all business dealing with orders, dispatch, and quantities of fruit coming in for processing was actioned. Evidently stocks of tin and bottle labels were stored here as well and made a colourful sight.

The Luncheon Room was in the same vicinity and the Frimley factory was very proud of the facilities offered to workers. The room measured about 20 feet square and had hat and coat pegs, cupboards for holding lunches and small belongings, a wardrobe, three large tables, enameled hand basins and a plentiful supply of hot and cold water. There were also tea making facilities.

Page 37

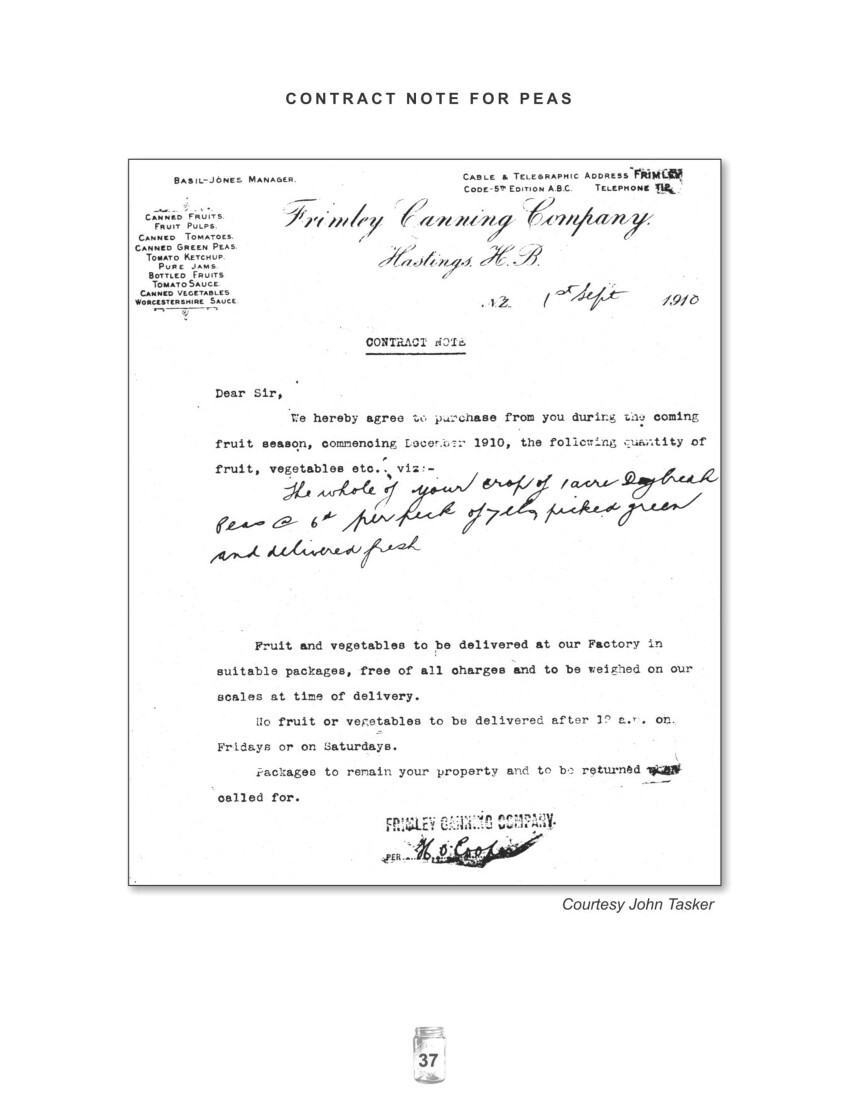

CONTRACT NOTE FOR PEAS

BASIL-JONES MANAGER.

CABLE & TELEGRAPHIC ADDRESS “FRIMLEY”

CODE – 2TH EDITION A.B.C TELEPHONE 412.

CANNED FRUITS.

FRUIT PULPS.

CANNED TOMATOES.

CANNED GREEN PEAS.

TOMATO KETCHUP.

PURE JAMS.

BOTTLED FRUITS

TOMATO SAUCE.

CANNED VEGETABLES.

WORCESTERSHIRE SAUCE.

Frimley Canning Company.

Hastings. H.B.

N.Z.

1st Sept 1910

CONTRACT NOTE

Dear Sir,

We hereby agree to purchase from you during the coming fruit season, commencing December 1910, the following quantity of fruit, vegetables etc., viz: –

The whole of your crop of 1 acre Daybreak Peas @ 6d per peck of 7lbs, picked green and delivered fresh

Fruit and vegetables to be delivered at our Factory in suitable packages, free of all charges and to be weighed on our scales at time of delivery.

No fruit of vegetables to be delivered after 12 a.m. on Fridays or on Saturdays.

Packages to remain your property and to be returned when called for.

FRIMLEY CANNING COMPANY.

PER H O Cooper

Courtesy John Tasker

Page 38

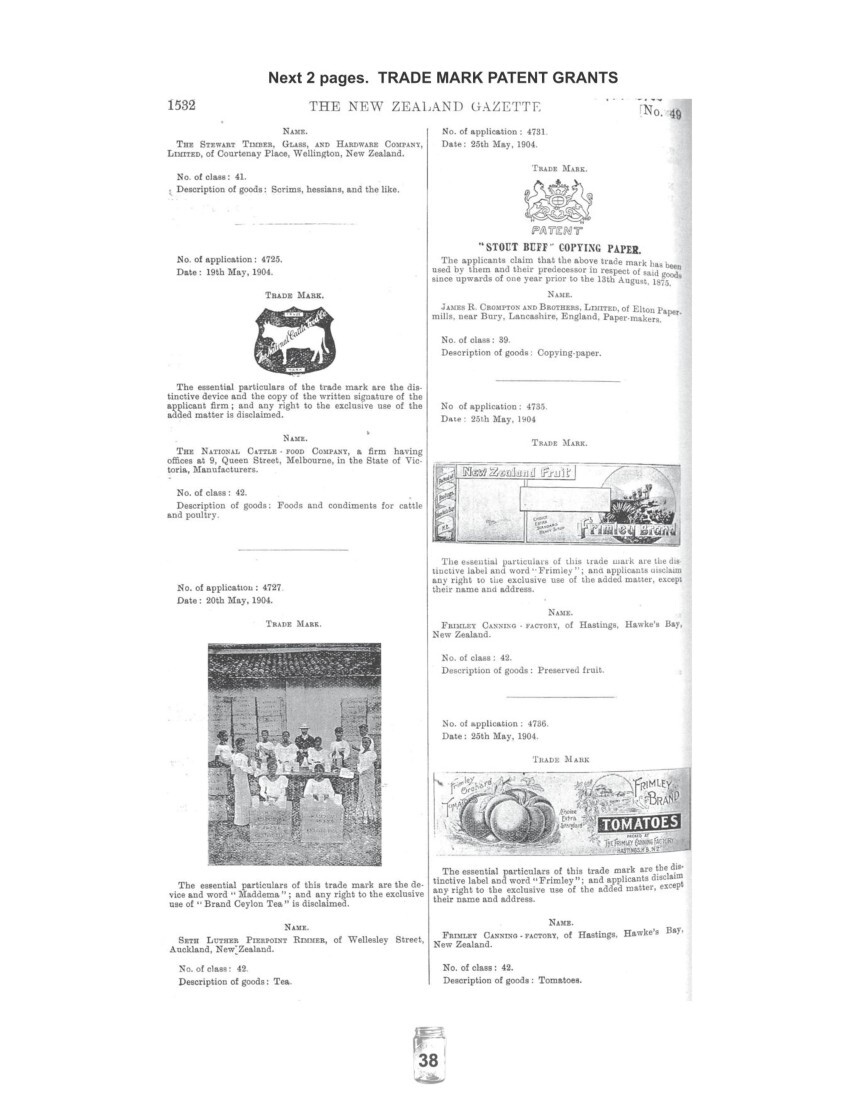

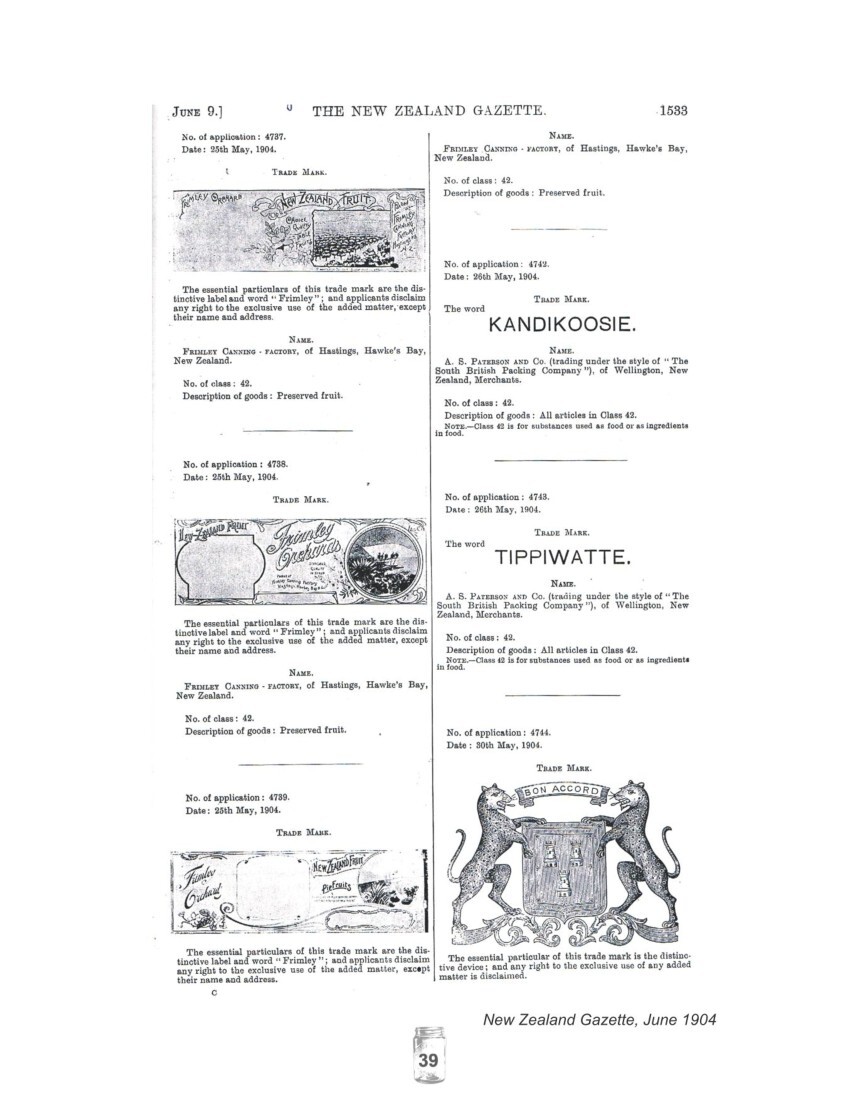

Next 2 pages. TRADE MARK PATENT GRANTS

1532 NEW ZEALAND GAZETTE No. 49

[…]

No. of application: 4735.

Date: 25th May, 1904

TRADE MARK.

The essential particulars of this trade mark are the distinctive label and word “Frimley”, and applicants disclaim any right to the exclusive use of the added matter, except their name and address.

NAME.

FRIMLEY CANNING – FACTORY, of Hastings, Hawke’s Bay, New Zealand.

No. of class: 42.

Description of goods: Preserved fruit.

No. of application: 4736.

Date: 25th May, 1904.

TRADE MARK

The essential particulars of this trade mark are the distinctive label and word “Frimley”, and applicants disclaim any right to the exclusive use of the added matter, except their name and address.

NAME.

FRIMLEY CANNING – FACTORY, of Hastings, Hawke’s Bay, New Zealand.

No. of class: 42.

Description of goods: Tomatoes.

Page 39

JUNE 9.] THE NEW ZEALAND GAZETTE. 1533

No. of application: 4737.

Date: 25th May, 1904

TRADE MARK.

The essential particulars of this trade mark are the distinctive label and word “Frimley”, and applicants disclaim any right to the exclusive use of the added matter, except their name and address.

NAME.

FRIMLEY CANNING – FACTORY, of Hastings, Hawke’s Bay, New Zealand.

No. of class: 42.

Description of goods: Preserved fruit.

No. of application: 4738.

Date: 25th May, 1904

TRADE MARK.

The essential particulars of this trade mark are the distinctive label and word “Frimley”, and applicants disclaim any right to the exclusive use of the added matter, except their name and address.

NAME.

FRIMLEY CANNING – FACTORY, of Hastings, Hawke’s Bay, New Zealand.

No. of class: 42.

Description of goods: Preserved fruit.

No. of application: 4739.

Date: 25th May, 1904

TRADE MARK.

The essential particulars of this trade mark are the distinctive label and word “Frimley”, and applicants disclaim any right to the exclusive use of the added matter, except their name and address.

NAME.

FRIMLEY CANNING – FACTORY, of Hastings, Hawke’s Bay, New Zealand.

No. of class: 42.

Description of goods: Preserved fruit.

[…]

New Zealand Gazette, June 1904

Page 40

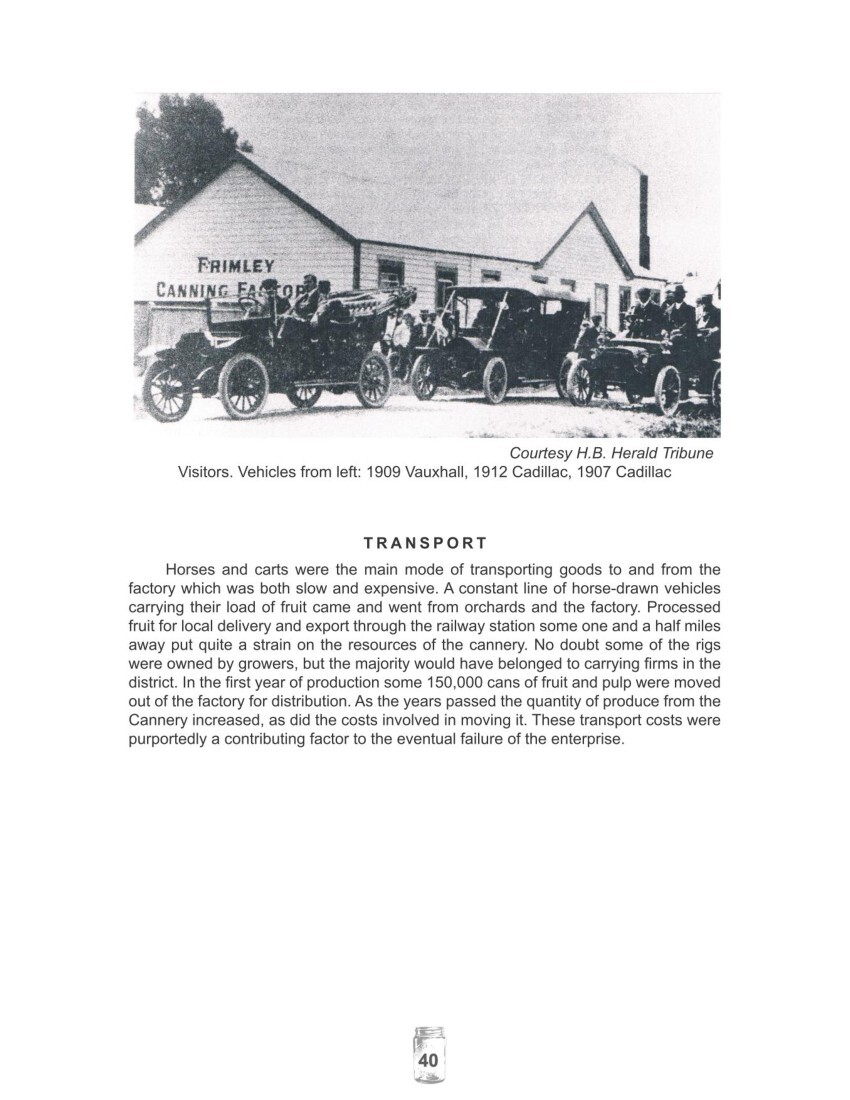

Visitors. Vehicles from left: 1909 Vauxhall, 1912 Cadillac, 1907 Cadillac

Courtesy H.B. Herald Tribune

TRANSPORT

Horses and carts were the main mode of transporting goods to and from the factory which was both slow and expensive. A constant line of horse-drawn vehicles carrying their load of fruit came and went from orchards and the factory. Processed fruit for local delivery and export through the railway station some one and a half miles away put quite a strain on the resources of the cannery. No doubt some of the rigs were owned by growers, but the majority would have belonged to carrying firms in the district. In the first year of production some 150,000 cans of fruit and pulp were moved out of the factory for distribution. As the years passed the quantity of produce from the Cannery increased, as did the costs involved in moving it. These transport costs were purportedly a contributing factor to the eventual failure of the enterprise.

Page 41

Part IV

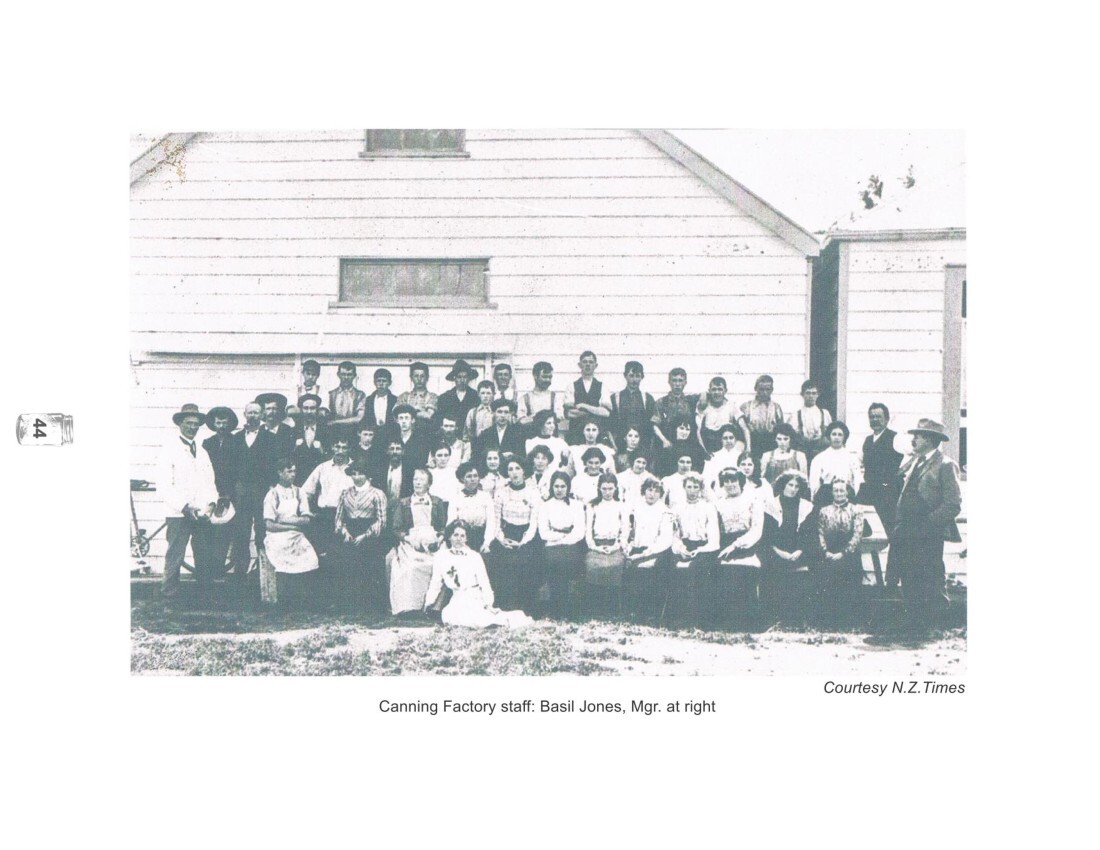

EMPLOYMENT

By their very nature fruit growing and the canning of fruit and vegetables is a very labour intensive industry, and was even more so in the early 1900’s. Mechanisation was only in its infancy and both the picking and preparing of fruit and vegetables for canning required a very substantial labour force, especially during the harvest season as most tasks were done by hand.

Different sources for research give varied information on the number of people actually employed at Frimley, but range from 60 to 80 women, men and children. During the official opening speeches on 16 January 1904 Mr Dennett, Mayor of Hastings, stated that the factory would employ 80 men, women, boys and girls. The creation of many jobs was a real boon to the district and there was a promise of increasing employment as the factory increased its output in the coming years. This was in fact the case, and in the 1907-08 season 200 workers were required to service the factory and farms.

The increasing number of workers required put a severe strain on the local labour force as Hastings had only a relatively small population from which to draw, and was in fact not able to supply the number of people required. To help solve this labour problem Williams erected two boarding houses on the Frimley property to accommodate workers from outside the district when they came for seasonal work. As an added incentive to bring the workers in, cheap subsidised board was offered in these two houses. One of the houses was on part of what is now the Frimley School grounds, and the other was at the rear of where Memorial Hospital now stands. A manager’s house was also constructed at the same time. A recreation building was erected for the workers’ use, and the men, women and girls had their own clubs which put on socials and various entertainments.

J N Williams really cared about his workforce and was always prepared to help them if he could. He even talked about staff incentive schemes, as well as the possibility of sharing the fruits of their labours by holding shares in the company, which was quite a revolutionary idea for the times. Before these ideas could be instituted the factory closed. At the close of one season Williams provided tickets for those staff interested to attend a travelling London Company’s conjuring and juggling show at the Princess Theatre.

Shortage of labour continued to plague and hinder the company’s operations making it difficult to increase production which was essential to the Company’s profit and viability.

Various schemes were tried to attract labour and make it easier to access the factory which was one and a half miles from town. Napier workers came by train and were picked up at 7.30am from the Hastings station in a bus provided by the Company.

The rail ticket was also subsidized by the Company. Basil-Jones, in conjunction with the Chamber of Commerce, attempted to get the railways to provide cheap workers’ tickets instead of the normal suburban tickets, but this action failed.

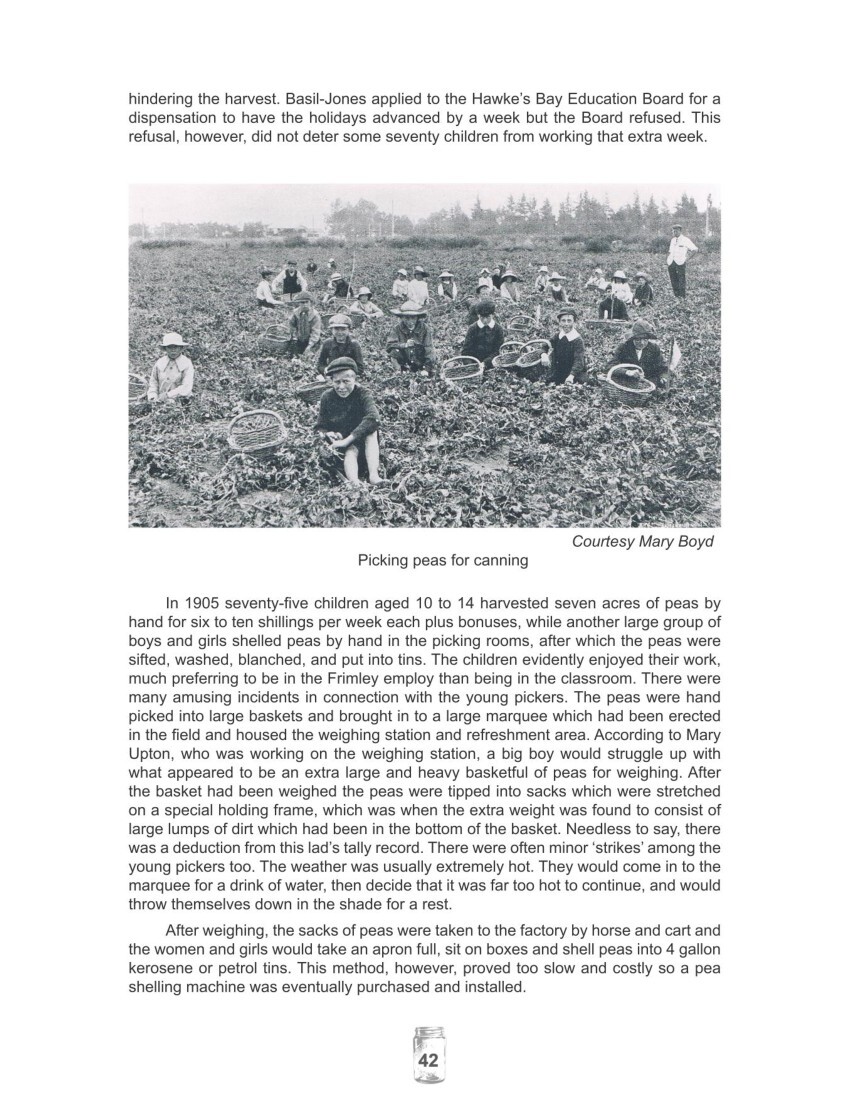

Children, mainly aged from 10 to 14, made up a great proportion of the field workforce, essential to the cannery’s operations. The first school term dates meant that these children should have been in their classrooms at the height of the season thus

Page 42

hindering the harvest. Basil-Jones applied to the Hawke’s Bay Education Board for a dispensation to have the holidays advanced by a week but the Board refused. This refusal, however, did not deter some seventy children from working that extra week.

In 1905 seventy-five children aged 10 to 14 harvested seven acres of peas by hand for six to ten shillings per week each plus bonuses, while another large group of boys and girls shelled peas by hand in the picking rooms, after which the peas were sifted, washed, blanched, and put into tins. The children evidently enjoyed their work, much preferring to be in the Frimley employ than being in the classroom. There were many amusing incidents in connection with the young pickers. The peas were hand picked into large baskets and brought in to a large marquee which had been erected in the field and housed the weighing station and refreshment area. According to Mary Upton, who was working on the weighing station, a big boy would struggle up with what appeared to be an extra large and heavy basketful of peas for weighing. After the basket had been weighed the peas were tipped into sacks which were stretched on a special holding frame, which was when the extra weight was found to consist of large lumps of dirt which had been in the bottom of the basket. Needless to say, there was a deduction from this lad’s tally record. There were often minor ‘strikes’ among the young pickers too. The weather was usually extremely hot. They would come in to the marquee for a drink of water, then decide that it was far too hot to continue, and would throw themselves down in the shade for a rest.

After weighing, the sacks of peas were taken to the factory by horse and cart and the women and girls would take an apron full, sit on boxes and shell peas into 4 gallon kerosene or petrol tins. This method, however, proved too slow and costly so a pea shelling machine was eventually purchased and installed.

Photo caption – Picking peas for canning

Courtesy Mary Boyd

Page 43

Workers in the modern orchard and canning industries would be horrified to know about the wages and conditions which applied in the Frimley days. Girls started at 16/6d weekly, their wages rising by yearly increments to 17/6d. One pound per week was considered to be a very good wage. Overtime was worked regularly, mainly because of the continual labour shortage, and this was paid at 9d per hour extra. Many of the girls came from Napier for the season of about 6 weeks, walking each day from their homes to catch the Napier-Hastings suburban train which left Napier at 7 am. Some even walked from the Taradale bridge to catch the train. They set out for home on a train which left Hastings at 9.30 pm, often not getting a hot meal at night until well after 10 pm. The Company had arranged for Graham Brothers to meet these trains at Hastings with up to four breaks (wagons) and to return the workers to the station again at night. The cost of the rail ticket for the week was 5/3d for over 21 year olds and 2/9d for under. With such meagre wages it was just as well that a subsidy from the company was introduced.

According to a person who worked in the cannery they were a happy lot and sang all day as they worked. On the way home to town and to the railway station in the big horse-drawn breaks they sang the popular songs of the time -a favourite being a parody on ‘Down at the Old Bull and Bush’, which became ‘Down at the Old Stortford Lodge’.

The Cannery had a small permanent workforce who worked throughout the year maintaining plant and machinery and making jam from fruits pulped during the busy four month season. In 1909 there were 40 staff on the permanent list. There was also another permanent group of workers who maintained the vineyards and orchards.

Frimley Canning Factory could have employed at least 300 workers during the season, but they just were not available. This constant shortage of labour would be one of the main reasons for the eventual demise of the Cannery.

The Hastings Standard

February 25, 1909 H.B. Today 25.2.09A visit to Hastings is incomplete if, when here, visitors do not see the Frimley Canning Factory and Kapoi [Kaiapo] orchards. Today about 500 people visited the factory, each of whom will spread far and wide the fame of the extensive works. The manager has made arrangements for a big day tomorrow. At 10.15 the Wanganui Garrison Band will embark in brakes at the Grand Hotel, and on arrival at the works will play selections.

Work at the factory will cease for half an hour, so that the employees may enjoy the music. The band will then be shown over the works and afterwards be entertained by Mrs Basil-Jones. Mr Jones extends a hearty welcome to all visitors and bandsmen to be at the works in the morning to listen to the music and see the fruit being prepared for the market.

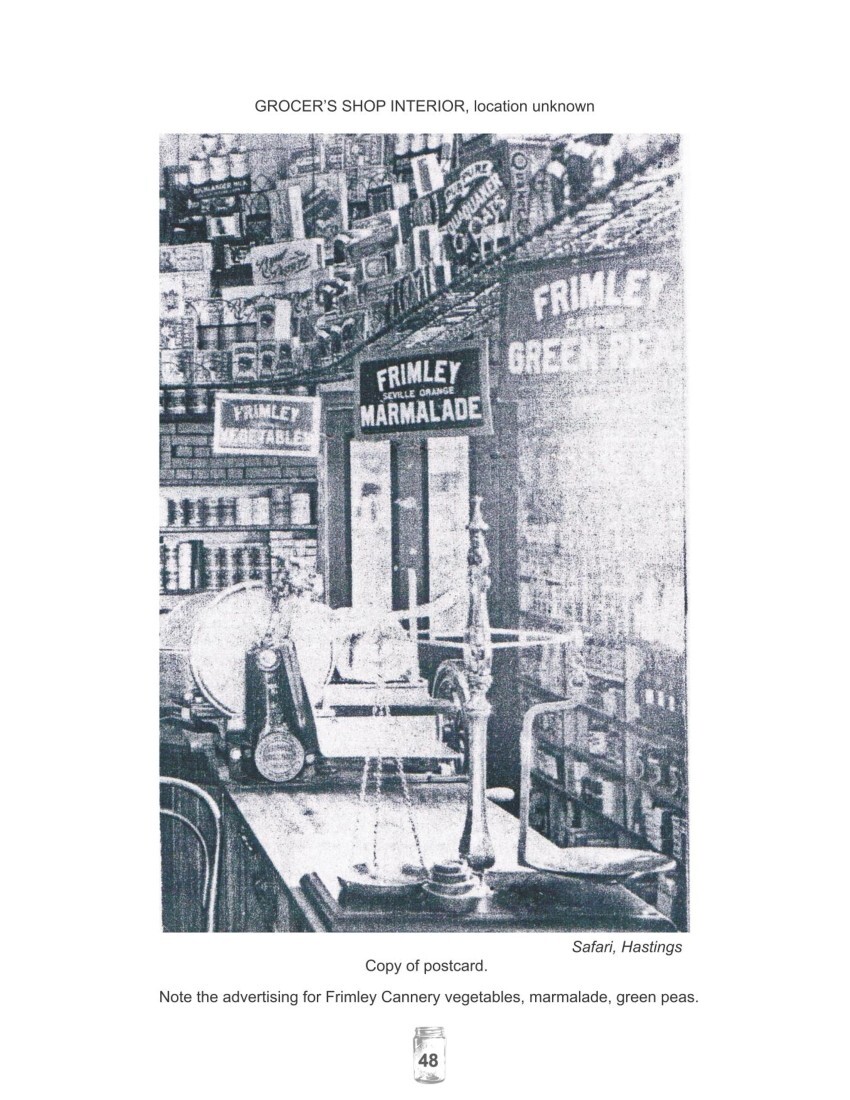

Safari, Hastings

Page 45

Part V

FRIMLEY PRODUCTS

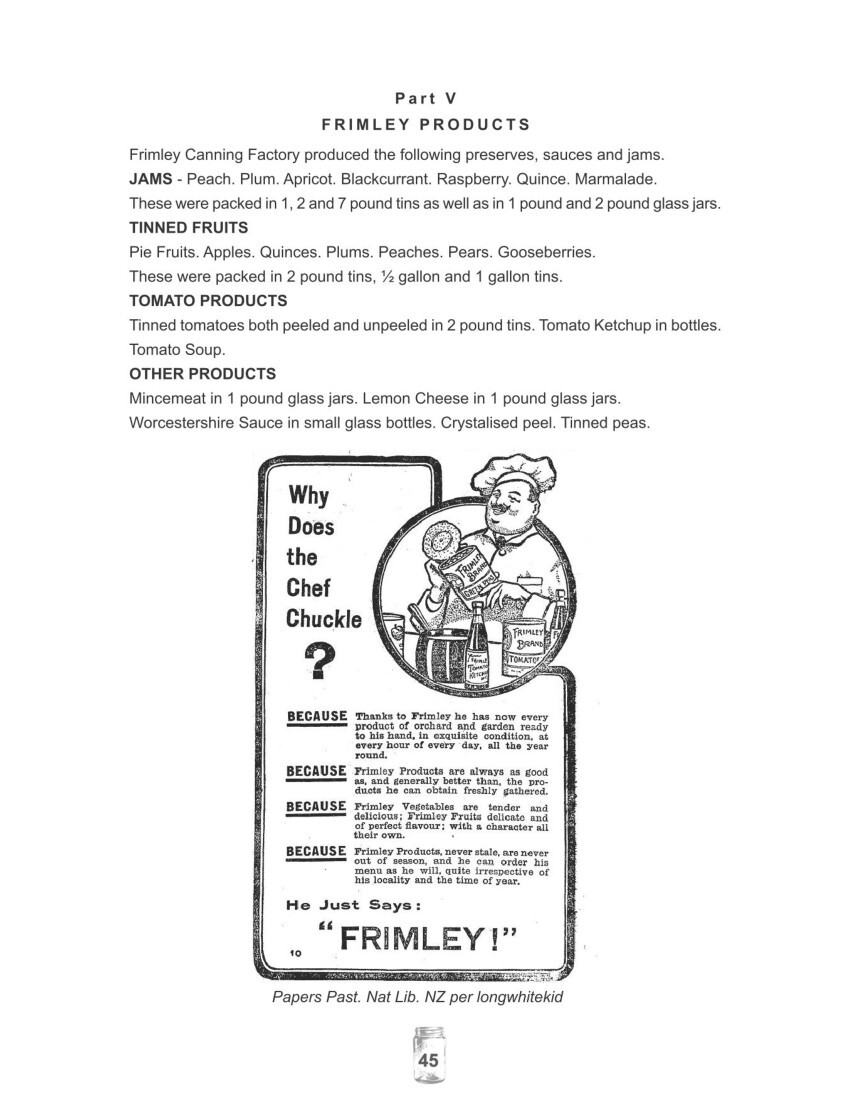

Frimley Canning Factory produced the following preserves, sauces and jams.

JAMS – Peach. Plum. Apricot. Blackcurrant. Raspberry. Quince. Marmalade.

These were packed in 1, 2 and 7 pound tins as well as in 1 pound and 2 pound glass jars.

TINNED FRUITS

Pie Fruits. Apples. Quinces. Plums. Peaches. Pears. Gooseberries.

These were packed in 2 pound tins, ½ gallon and 1 gallon tins.

TOMATO PRODUCTS

Tinned tomatoes both peeled and unpeeled in 2 pound tins. Tomato Ketchup in bottles.

Tomato Soup.

OTHER PRODUCTS

Mincemeat in 1 pound glass jars. Lemon Cheese in 1 pound glass jars.

Worcestershire Sauce in small glass bottles. Crystalised peel. Tinned peas.

Why Does the Chef Chuckle?

BECAUSE Thanks to Frimley he has now every product of orchard and garden ready to his hand. in exquisite condition, at every hour of every day, all the year round.

BECAUSE Frimley Products are always as good as, and generally better than, the products he can obtain freshly gathered.

BECAUSE Frimley Vegetables are tender and delicious; Frimley Fruits delicate and of perfect flavour; with a character all their own. BECAUSE Frimley Products, never stale, are never out of season, and he can order his menu as he will, quite irrespective of his locality and the time of year. He Just Says :

FRIMLEY!”

Papers Past. Nat Lib. NZ per longwhitekid

Page 47

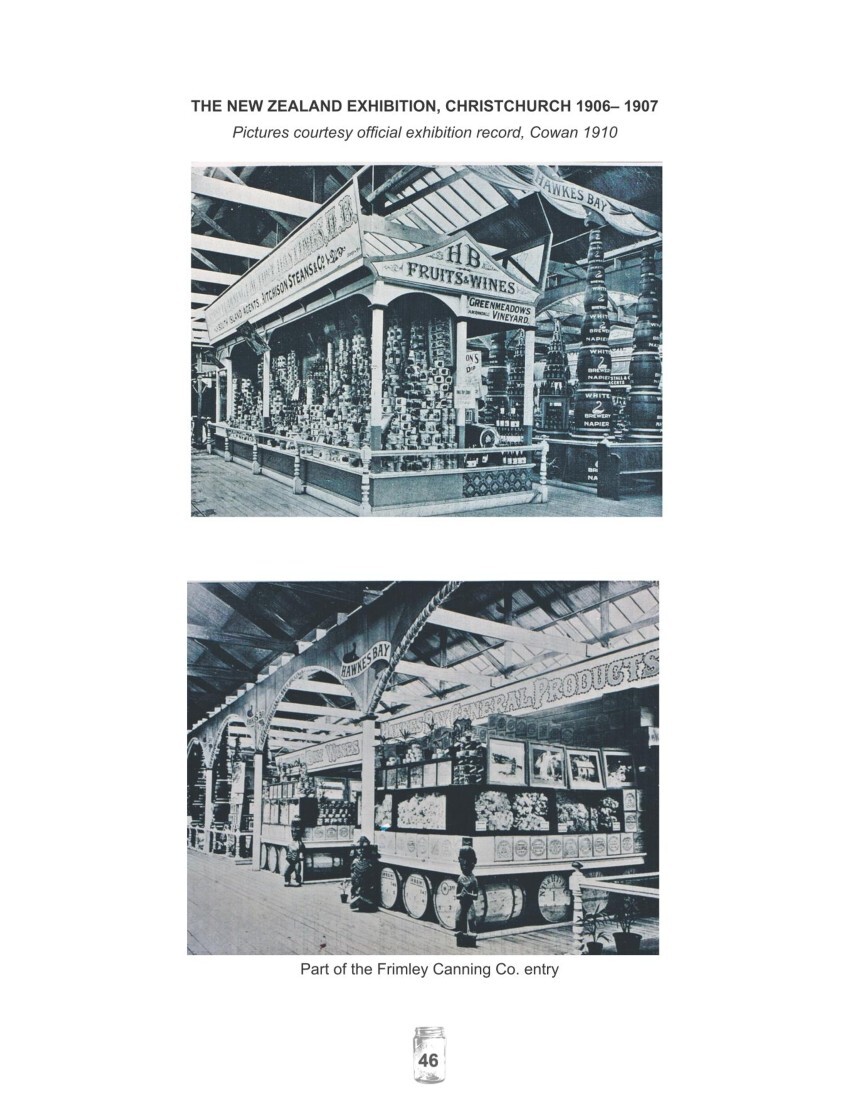

EXHIBITIONS AND AWARDS

Promotion of their products through participating in International, New Zealand and Provincial Shows and Exhibitions brought rapid local and international recognition of the excellence of their product. At the autumn show in 1905 the company displayed a stand of 10 pyramids of 7lb tins of jam, tomato sauce and ketchup in bottles, whole tomatoes, dessert fruit and pie fruit. Through these exhibitions the company was awarded three gold and five silver medals as well as seven diplomas over a period of five years.

The following extract is taken from the official record published in a book on the New Zealand Exhibition held at Christchurch, 1906-07.

HAWKE’S BAY

‘The Hawke’s Bay Exhibit consisted very largely of an excellent display of the great fruit growing and wine producing capabilities of this well favoured district. In the construction of this court no elaborate decorative scheme was followed, but the exhibit won many praises for its skilful and eye-pleasing arrangement. The wine and fruit section occupied a long frontage; a great deal of this was devoted to a display of fruits of all kinds produced in the celebrated Frimley Orchards near Hastings which, among other fruit areas, contains 150 acres of peach trees alone. There were canned fruits of every kind arranged in tiers, and the general attractiveness of the display and well known excellent qualities of the contents of the tins, made one wonder why New Zealanders ever buy imported American canned fruits. Various kinds of pure fruit-jams were shown besides fruit-pulps, tomato sauce, canned tomatoes and green peas, all from Frimley.’

AWARDS

Class 25 WINES, SPIRITS, BEERS, CORDIALS, AERATED WATERS Subdivision 1. Natural Wines, The Product of the Grape.

Frimley Vineyards, Hastings Claret (blended) GOLD

Claret (light dinner) GOLD

Class 26A ALIMENTARY FOOD PRODUCTS

Subdivision 4. Jams, and Preserved Fruits, Peels

Frimley Canning Company Display of canned fruits, pie fruits Vegetables, Jams GOLD

Sauces and Pickles

Frimley Canning Company Tomato Ketchup SILVER

Page 49

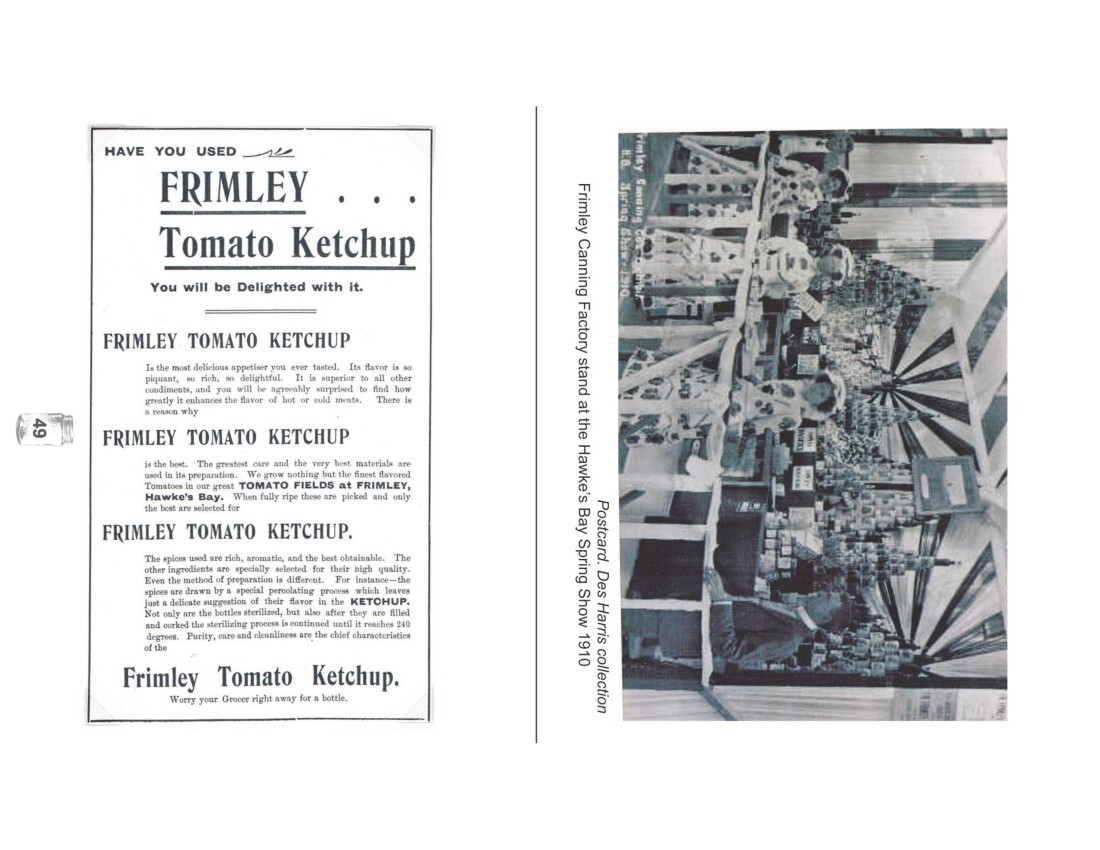

Frimley Canning Factory stand at the Hawke’s Bay Spring Show 1910

Postcard. Des Harris collection

HAVE YOU USED FRIMLEY Tomato Ketchup You will be Delighted with it.

FRIMLEY TOMATO KETCHUP Is the most delicious appetiser you ever tasted. Its flavor is so piquant, so rich, so delightful. It is superior to all other condiments, and you will be agreeably surprised to find how greatly it enhances the flavor of hot or cold meats. There is a reason why

FRIMLEY TOMATO KETCHUP is the best. The greatest care and the very best materials are used in its preparation. We grow nothing but the finest flavored Tomatoes in our great TOMATO FIELDS at FRIMLEY, Hawke’s Bay. When fully ripe these are picked and only the best are selected for

FRIMLEY TOMATO KETCHUP. The spices used are rich, aromatic, and the best obtainable. The other ingredients are specially selected for their high quality. Even the method of preparation is different. For instance – the spices are drawn by a special percolating process which leaves just a delicate suggestion of their flavor in the KETCHUP. Not only are the bottles sterilized, but also after they are filled and corked the sterilizing process is continued until it reaches 240 degrees. Purity, care and cleanliness are the chief characteristics of the

Frimley Tomato Ketchup.

Worry your Grocer right away for a bottle.

Page 50

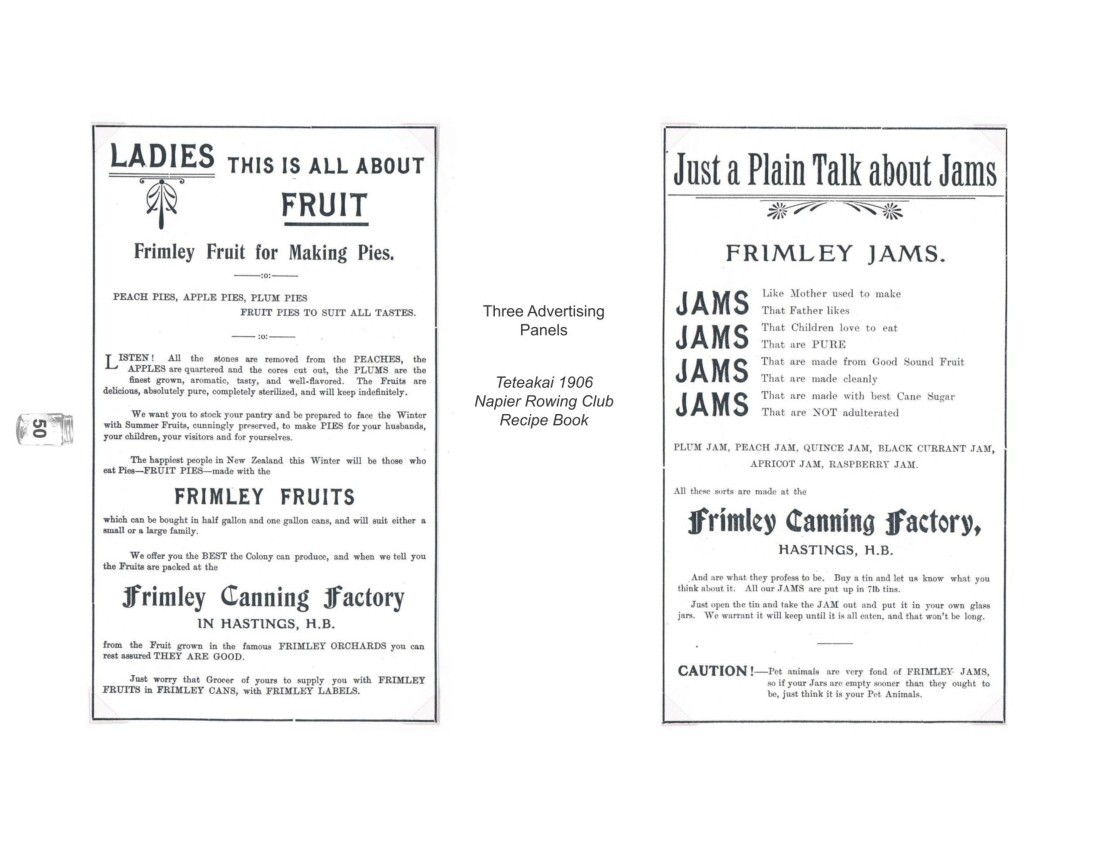

Three Advertising Panels

Teteakai 1906

Napier Rowing Club

Recipe Book

LADIES

THIS IS ALL ABOUT

FRUIT

Frimley Fruit for Making Pies. PEACH PIES, APPLE PIES, PLUM PIES FRUIT PIES TO SUIT ALL TASTES.

LISTEN! All the stones are removed from the PEACHES, the APPLES are quartered and the cores cut out, the PLUMS are the finest grown, aromatic, tasty, and well-flavored. The Fruits are delicious, absolutely pure, completely sterilized, and will keep indefinitely.

We want you to stock your pantry and be prepared to face the Winter with Summer Fruits, cunningly preserved, to make PIES for your husbands, your children, your visitors and for yourselves.

The happiest people in New Zealand this Winter will be those who eat Pies – FRUIT PIES – made with the

FRIMLEY FRUITS

which can be bought in half gallon and one gallon cans, and will suit either a small or a large family.

We offer you the BEST the Colony can produce, and when we tell you the Fruits are packed at the

Frimley Canning factory

IN HASTINGS, H.B.

from the Fruit grown in the famous FRIMLEY ORCHARDS you can rest assured THEY ARE GOOD.

Just worry that Grocer of yours to supply you with FRIMLEY FRUITS in FRIMLEY CANS, with FRIMLEY LABELS.

Just a Plain Talk about Jams

FRIMLEY JAMS.

JAMS Like Mother used to make

That Father likes

JAMS That Children love to eat

That are PURE

JAMS That are made from Good Sound Fruit

That are made cleanly

JAMS That are made with best Cane Sugar

That are NOT adulterated

PLUM JAM, PEACH JAM, QUINCE JAM, BLACK CURRANT JAM, APRICOT JAM, RASPBERRY JAM.

All these sorts are made at the

Frimley Canning Factory,

HASTINGS, H.B.

And are what they profess to be. Buy a tin and let us know what you think about it. All our JAMS are put up in 71b tins.

Just open the tin and take the JAM out and put it in your own glass jars. We warrant it will keep until it is eaten, and that won’t be long.

CAUTION! – Pet animals are very fond of FRIMLEY JAMS, so if your Jars are empty sooner than they ought to be, just think it is your Pet Animals.

Page 51

Part VI

Closure and Legacy

Frimley Canning Factory ceased operations on 5 September 1913 with the plant being sold to the rival Nelson firm of Kirkpatrick & Co. Ltd. The complete cause of the failure of this once thriving Hastings industry has vanished into oblivion, but the reason given at the time was insufficient labour. Basil-Jones blames the inadequate immigration system of the time, as well as the intransigent New Zealand education system which would not allow a local variation in school terms – the industry relying as it did on child labour.

There were hints of mismanagement. Williams was unwell by this time and may not have had his finger on the pulse of the business as firmly as he should have. Certainly the high costs of transporting fruit and canned produce to the railhead were a contributing factor.

Competition from other canneries both at home and in Australia was another major issue. A M Robertson of the Fruit Growers’ Association of Hawke’s Bay said that the markets which had been built up by Frimley throughout New Zealand and Australia were seriously eroded with the expansion of other canneries in both countries. These rival canneries were able to put a cheaper product on the market. This resulted in terminal damage to Frimley. Serious late frost in 1911 hit the orchards and no fruit was picked: only vegetables were canned and jam made.

Whatever the cause, probably a combination of those mentioned above, it was a terrible blow to the Province and the economy of Hastings and the Heretaunga Plains. Credit must, however, go to J N Williams for his vision and foresight in establishing the first viable commercial orchard and canning venture in Hawke’s Bay. He was a leader in an industry which, despite this early failure, was to rise again some years later with outstanding success.

Page 52

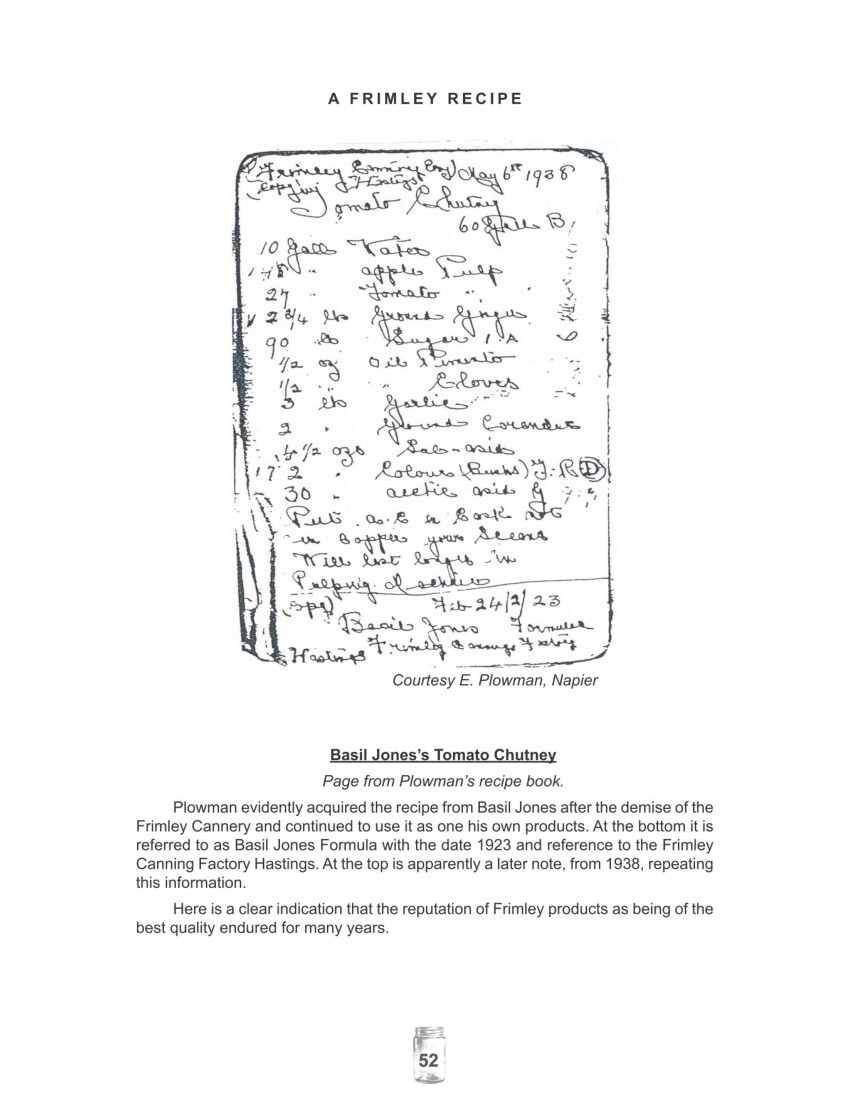

A FRIMLEY RECIPE

[Recipe]

Courtesy E. Plowman, Napier

Basil Jones’s Tomato Chutney

Page from Plowman’s recipe book.

Plowman evidently acquired the recipe from Basil Jones after the demise of the Frimley Cannery and continued to use it as one his own products. At the bottom it is referred to as Basil Jones Formula with the date 1923 and reference to the Frimley Canning Factory Hastings. At the top is apparently a later note, from 1938, repeating this information.

Here is a clear indication that the reputation of Frimley products as being of the best quality endured for many years.

Page 53

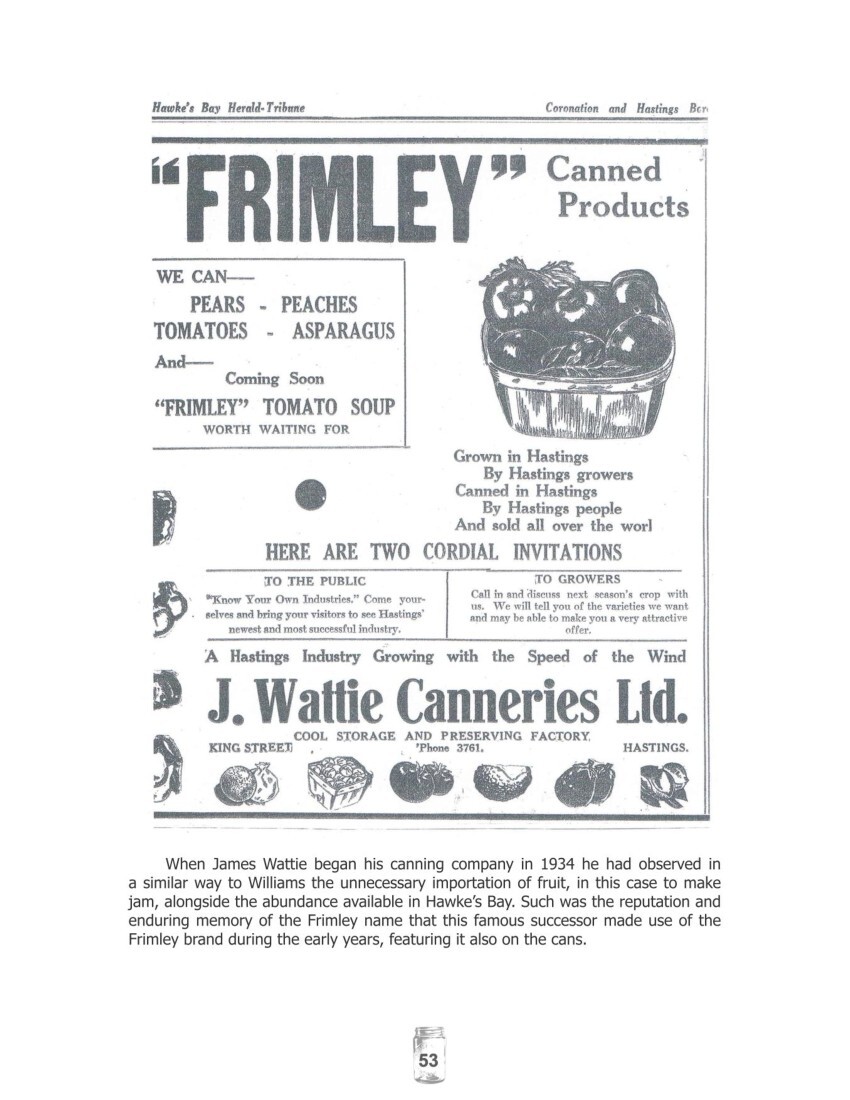

Hawke’s Bay Herald-Tribune Coronation and Hastings Ben[…]

“FRIMLEY“ Canned Products

WE CAN –

PEARS – PEACHES

TOMATOES – ASPARAGUS

And –

Coming Soon

“FRIMLEY” TOMATO SOUP

WORTH WAITING FOR

Grown in Hastings

By Hastings growers

Canned in Hastings

By Hastings people

And sold all over the world

HERE ARE Two CORDIAL INVITATIONS

TO THE PUBLIC

Know Your Own Industries.” Come yourselves and bring your visitors to see Hastings’ newest and most successful industry.

TO GROWERS

Call in and discuss next season’s crop with us. We will tell you of the varieties we want and may be able to make you a very attractive offer.

A Hastings Industry Growing with the Speed of the Wind

J. Wattie Canneries Ltd.

COOL STORAGE AND PRESERVING FACTORY.

KING STREET ‘Phone 3761. HASTINGS.

When James Wattie began his canning company in 1934 he had observed in a similar way to Williams the unnecessary importation of fruit, in this case to make jam, alongside the abundance available in Hawke’s Bay. Such was the reputation and enduring memory of the Frimley name that this famous successor made use of the Frimley brand during the early years, featuring it also on the cans.

Page 54

ACKNOWLEDGEMENTS

I would like to record my grateful thanks to the people and organizations listed below. Their assistance helped me locate information, photographs and bottles and has made this record of The Frimley Canning Company possible.

Joy Axford, Napier Museum Archivist

Maurice Bartlett, LINZ Staff, Napier

Don Baty

May Blair

Mary Boyd, Photographs

Tony Dodd

Mr and Mrs John Elms

Mrs O Francis

Hawke’s Bay Herald Tribune Archives

Hastings Library and Staff

Ivan Hughes, Photography

Geoff Johnson

David Lowe

Joe McCardell

Don Millar, Photography

Napier Museum Library

Napier Public Library Staff

E Plowman

John Tasker

Don Wilkie, Photographs

Jon Williams

Mick Wordsworth

Page 55

SOURCES OF INFORMATION

Boyd, Mary Hastings City of The Plains

Conly, Geoff Watties First 50 years

Cowan J. 1910 Official record of NZ Exhibition Christchurch 1906-07

Cyclopaedia Company Cyclopaedia of New Zealand 1908 Vol. 6

Hastings Standard various years

Hawke’s Bay Herald various years 1903-11

Herald Tribune Industrialist and Farmer, J N Williams

Herald Tribune Frimley Park

Hill, Elizabeth Between the Rivers

Hodgson, Terence Fire and Decay

King, Olwyn New Zealand Food Containers

MacGregor, Miriam Early Stations of Hawke’s Bay

Napier Rowing Club Tetakai 1906 Napier Rowing Club Recipe Book

New Zealand’s Famous Peach District of Hawke’s Bay NZ Times Wellington

Pupils R.22, Heretaunga Intermediate From Swamp to City. History of Hastings

Rochfort. Survey Maps and Field Notebooks Napier Museum Library/LINZ Napier

Upton, Mary Radio Talk Fruit Canning in Hawke’s Bay, 50 Years’ Progress. Manuscript HB Museum

Williams Family Compiled Rex and Adrienne Evans Faith and Farming. The Legacy of Henry and William Williams

Non-commercial use

This work is licensed under a Attribution-NonCommercial 3.0 New Zealand (CC BY-NC 3.0 NZ).

Commercial Use

Please contact us for information about using this material commercially.Can you help?

The Hawke's Bay Knowledge Bank relies on donations to make this material available. Please consider making a donation towards preserving our local history.

Visit our donations page for more information.

Description

Surnames in this book –

Axford, Bartlett, Basil-Jones, Baty, Blair, Boyd, Brathwaite, Close, Conly, Cooper, Cowan, Dennett, Dill, Dodd, Douglas, Elms, Evans, Fitzroy, Francis, Fraser, Gallien, Hansard, Hartgill, Heath, Hennessy, Hill, Hodgson, Horton, Hughes, Johnson, Karaitiana, King, Loudon, Lowe, MacGregor, Mackersey, MacNamara, McCardell, McLean, McLeod, McVay, Millar, Neal, Newbigin, Ormond, Platford, Plowman, Porter, Purvis, Rochfort, Russell, Russell, Russell, Sage, Seddon, Sheppard, Smith, Swan, Tanner, Tasker, Tiffen, Tomoana, Upton, Watt, Wattie, White, Wilkie, Williams, Williams, Williams, Williams, Williams, Williams, Williams, Wordsworth

Do you know something about this record?

Please note we cannot verify the accuracy of any information posted by the community.